Electric Truck Project in Portugal with Brogen Electric Truck Motor

This project marks an important milestone as we partnered with a new energy company in Portugal to deliver their first next-generation electric heavy truck. The vehicle is powered by our e-powertrain system, integrating the electric motor and the gearbox, supporting the client’s transition toward cleaner and more sustainable transport solutions.

Project Overview

- Project timeline: 2021

- Offered solutions: e-powertrain, power steering system, braking system, integrated auxiliary converter

- Application model: 40-ton pure electric heavy duty truck

- Provided services: pre-sales consultation, solution planning, technical coordination, product testing, post-sales technical support, remote debugging

Challenges in the Client's First Battery Electric Truck Project

Because this was the client’s first battery electric truck development, both sides faced several challenges:

1. Limited EV Technical Background: Although the parent company had experience in construction and energy storage, the EV division lacked the engineering expertise needed to develop a fully electric powertrain, high-voltage system, and vehicle integration plan.

2. High Development Costs & Long Timelines: Building an in-house solution would require significant R&D investment, potentially prolonging development and delaying vehicle launch.

3. Need for Clear Technical Alignment: Our first priority was to establish efficient communication and fully understand the client’s performance targets, vehicle architecture, and expectations – so we could provide a tailored EV solution that met all operational requirements.

Our Approach

To support the project from concept to delivery, we followed a structured and collaborative process:

- Requirement Analysis: We worked closely with the client to review propulsion needs, electrical architecture, voltage standards, thermal management, and packaging constraints.

- Customized Engineering: Our engineering team designed a complete e-powertrain solution, assisted the client with system integration, and provided engineering guidance during development and testing.

- Long-Term Support: We continued to provide remote technical support, software updates, and troubleshooting after delivery, ensuring stable long-term operation of the vehicle.

Solutions We Provided

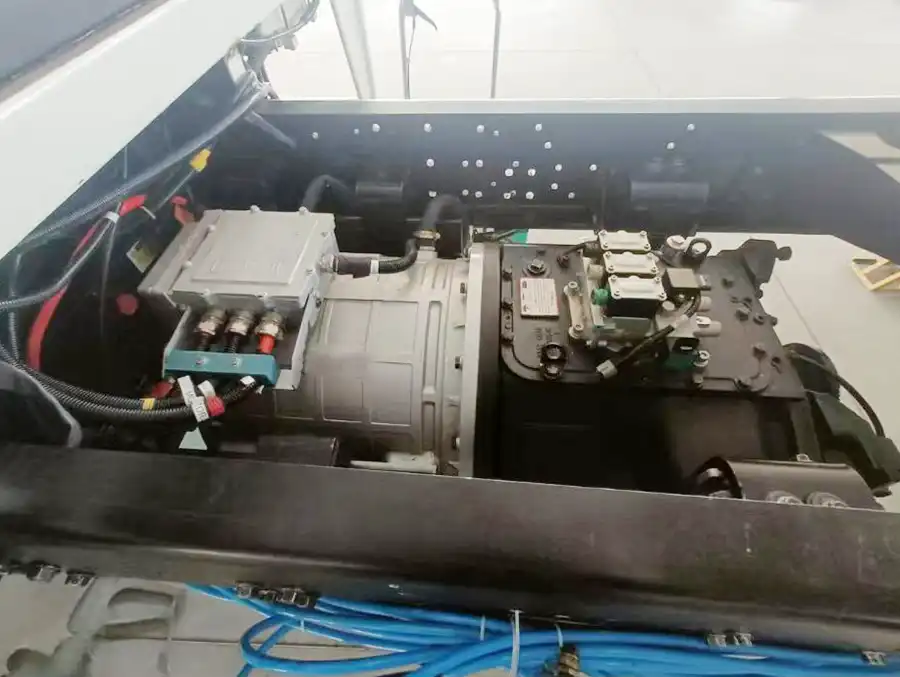

A. 350 kW Integrated E-Powertrain System

System Features

- Integrated motor: a streamlined design for convenient vehicle layout, eliminating phase harness EMC radiation while minimizing energy loss.

- Real-time weight measurement: ensures precision within 10%, while dynamic slope measurement boasts an accuracy of ±0.2° and static accuracy of ±0.1°.

- Adaptive shift timing: responds to factors like vehicle weight, slope, and driver input, including throttle system, pedal depth, and acceleration, adjusting shift points dynamically. Shift time clocks in at under 0.7s.

- Digital intelligent shifting: employs an electronically controlled shifting system for precise gear changes, enhancing overall performance.

Technical Parameters

- Rated / peak power: 220 / 350 kW

- Rated voltage: 618 V

- Rated / peak speed: 1400 / 3000 rpm

- Rated / peak torque: 1500 / 2500 N.m

- Rated / peak current: 340 / 610 A

- Protection level: IP67/H

- Cooling method: liquid cooling

- Applicable models: heavy truck

Explore our other electric truck motor solutions here: https://brogenevsolution.com/electric-motors-for-truck/

B. 4 kW Electro-Hydraulic Power Steering (EHPS)

We have supplied the 4 kW electro-hydraulic power steering system (EHPS) on the truck. The integrated design combines a motor, steering pump, ECU, DC power processing, and oil tank into a single unit, which maximizes space utilization, simplifies system integration, and offers compact size and light weight.

System Parameters

- Rated power: 4 kW

- Rated voltage: AC 380 V

- Rated current: 7.4 A

- Rated torque: 34.2 N.m

- Rated speed: 1200 rpm

- Peak power: 10.75 kW

- Back EMF (rated speed): 140 V/krpm

- Peak current: 19.2 A

- Peak torque: 85.6 N.m

- Peak speed: 1281 rpm

- Controlled flow: 18±2 L/min

- Insulation class: H

- Rated efficiency: 92%

- Line resistance (20°C): 1.88Ω

- Phase resistance (20°C): 0.9Ω

- Working frequency: 80 Hz

- Protection class: IP67

- Pole pairs: 4

- Q-axis inductance: 9.3 mH

- D-axis inductance: 12.5 mH

Explore our other EHPS solutions here: https://brogenevsolution.com/electro-hydraulic-power-steering-system-ehps/

C. 4 kW Air Brake Compressor

We have supplied the 4 kW oil-free air brake compressor for the electric heavy truck. With the latest technology, our air compressor delivers air that’s entirely oil and water-free, eliminating concerns of oil emulsification, leaks, and fire hazards. Its innovative structural design minimizes energy waste during compression, optimizing efficiency.

System Parameters

- Rated exhaust: 380 L/min

- Rated exhaust pressure: 1 Mpa

- Exhaust pressure: 1.2 Mpa

- Dimensions: 560*335*370 mm

- Motor power: 4 kW

- Weight: 65 kg

- Operating temperature: -40°C ~ + 60°C

- Protection class: IP67

Explore our other electric air brake compressor solutions here: https://brogenevsolution.com/air-compressors-for-commercial-vehicles/

D. Integrated Auxiliary Inverter

We have used the 3-in-1 auxiliary inverter for the project, which consists of a DC/DC converter, a DC/AC oil pump, and a DC/AC air compressor. This integrated and lightweight design significantly reduces system weight and size. It not only offers a lightweight solution but also delivers substantial space, wiring, and cost savings for electric commercial vehicles.

Explore our other integrated auxiliary inverter solutions here: https://brogenevsolution.com/auxiliary-inverters-for-hev/

Project Results

Our systems performed exceptionally well on the client’s 40-ton electric heavy trucks, earning high satisfaction from the client.

Due to the strong results, the client promptly initiated another project involving a 26-ton logistics truck (AGV) for port operations, utilizing our systems to efficiently transport goods between sites.

Our Customizable Solution for Heavy-Duty Trucks

At Brogen, we provide a wide portfolio of EV systems for electric trucks, including:

- Electric truck motors or integrated e-powertrain

- Traction battery systems

- Steering and braking systems

- Auxiliary power electronics

- High-voltage distribution and wiring harnesses

Our modular and customizable solutions help OEMs accelerate the development of reliable electric commercial vehicles while reducing engineering complexity and cost.

- Looking for an EV solution for your project? Reach out to us at contact@BrogenEVSolution.com

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >