Tailored EV Traction Battery Solutions

We provide tailored EV traction battery solutions for a wide range of applications, including passenger cars, trucks, buses, municipal vehicles, marine vessels, construction equipment, and more.

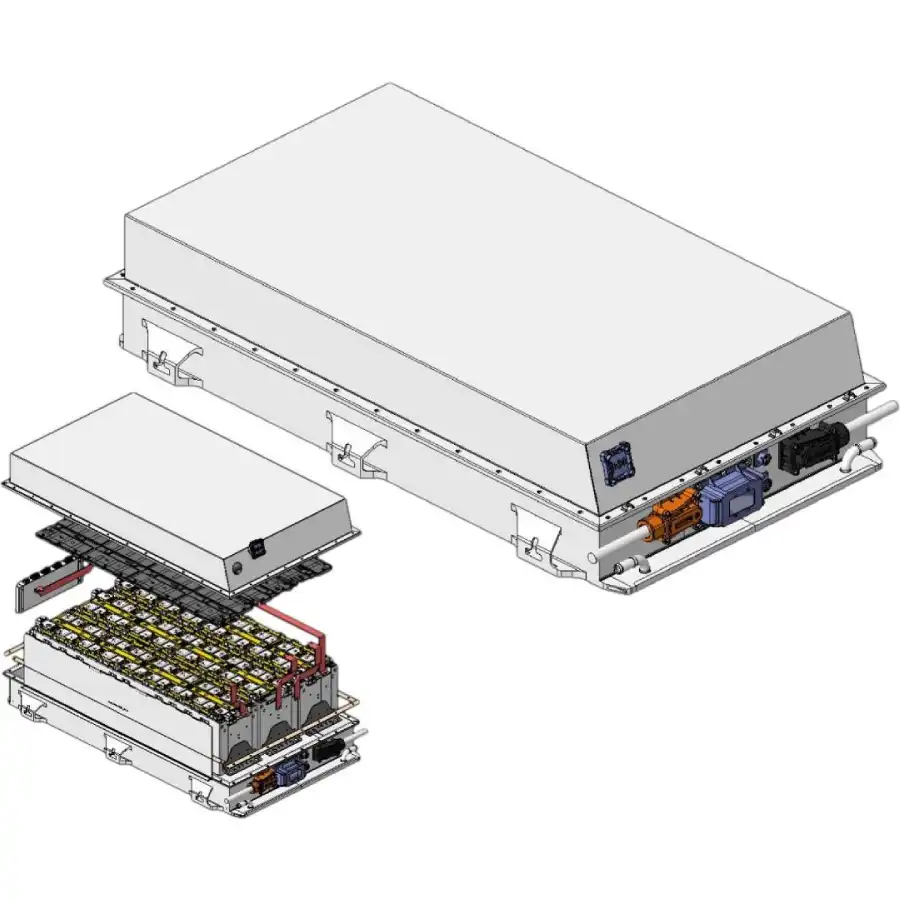

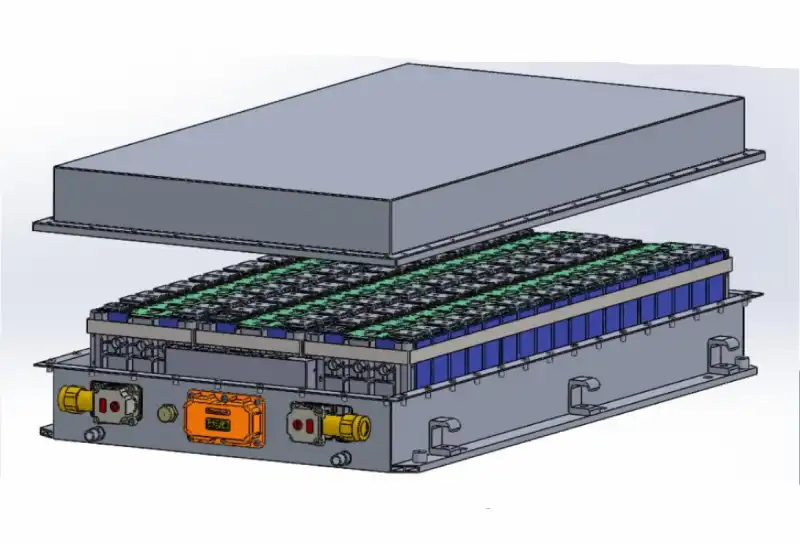

Our solutions include full system integration— traction battery packs, BMS, BTMS, PDU, and more—designed to meet your specific performance requirements and working conditions. With a strong focus on safety, reliability, and efficiency, we ensure each system is built to the highest standards.

To date, we’ve supported EV builders in Australia, Canada, Turkey, Spain, Chile, and other regions, powering vehicles across transport, logistics, and marine sectors.

Email: contact@brogenevsolution.com

Why Brogen

Our robust capabilities go beyond numbers.

14+

years of EV industry experience

30+

countries of system presence

350+

global clients

200%

expected revenue growth rate 2024-2025

Your Reliable EV Traction Battery Solution Provider

At Brogen, we specialize in providing tailored, vehicle-specific EV traction battery systems for OEMs and EV technology providers worldwide. Whether you’re building electric buses, trucks, or light commercial vehicles, we deliver battery solutions that fit your design, performance goals, and production needs — not the other way around.

- Tailor-made for your electric vehicle project

- Full system integration: Pack + BMS + BTMS + PDU

- Proven deployment in 30+ countries

- Professional support from design to delivery

- Premium battery cells from top battery cell suppliers

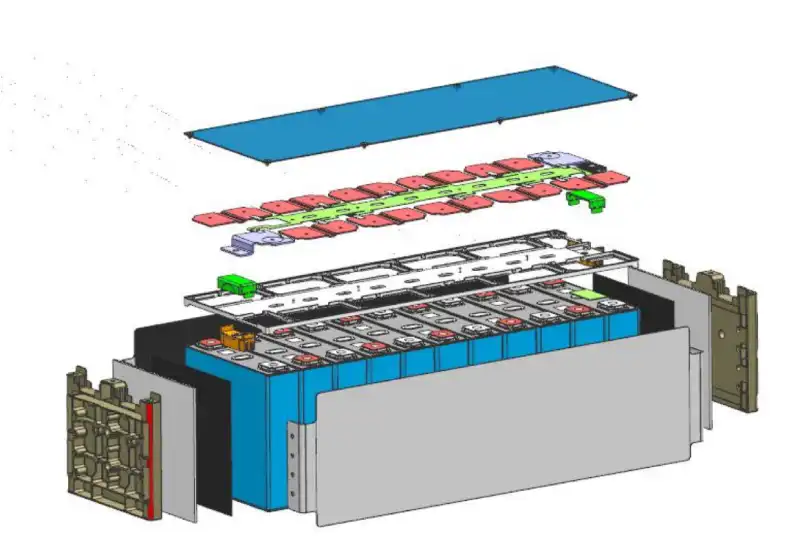

- Excellent thermal management strategy for enhanced reliability

- Lightweight design with aluminum alloy composites for battery box

Tailored to Fit Your Platform

From compact LCVs to heavy trucks, we adapt everything — from battery pack layout to communication protocols — to your platform. Our engineering team works closely with yours to ensure optimal packaging, voltage compatibility, cooling integration, and CAN communication.

Light Truck

Pickup Truck

Heavy Truck

Tractor

Bus

Van

E-trailer

Ship

Our Comprehensive EV Traction Battery Solutions

Our EV traction battery solutions are designed for a wide spectrum of applications, including LCVs, buses, HCVs, and specialized platforms such as airport ground support equipment (GSE), heavy-duty machinery, and marine vessels. To meet diverse project requirements, the systems can be configured with liquid cooling or integrated heating and are equipped with an advanced battery thermal management system to ensure stable performance, safety, and efficiency across a broad range of operating environments and duty cycles.

Case Studies

Electric Car Project

We supplied customized EV battery systems for an OEM's small electric car projects and carried out integration testing with the OBC, DC/DC, and auxiliary battery.

Electric Truck Project

We delivered a tailored blade battery solution for a client's electric truck project and conducted integration testing with the PDU and BTMS.

Electric Boat Project

We designed a complete traction battery solution for our client's electric boat project and supplied battery systems that deliver high quality and reliable performance.

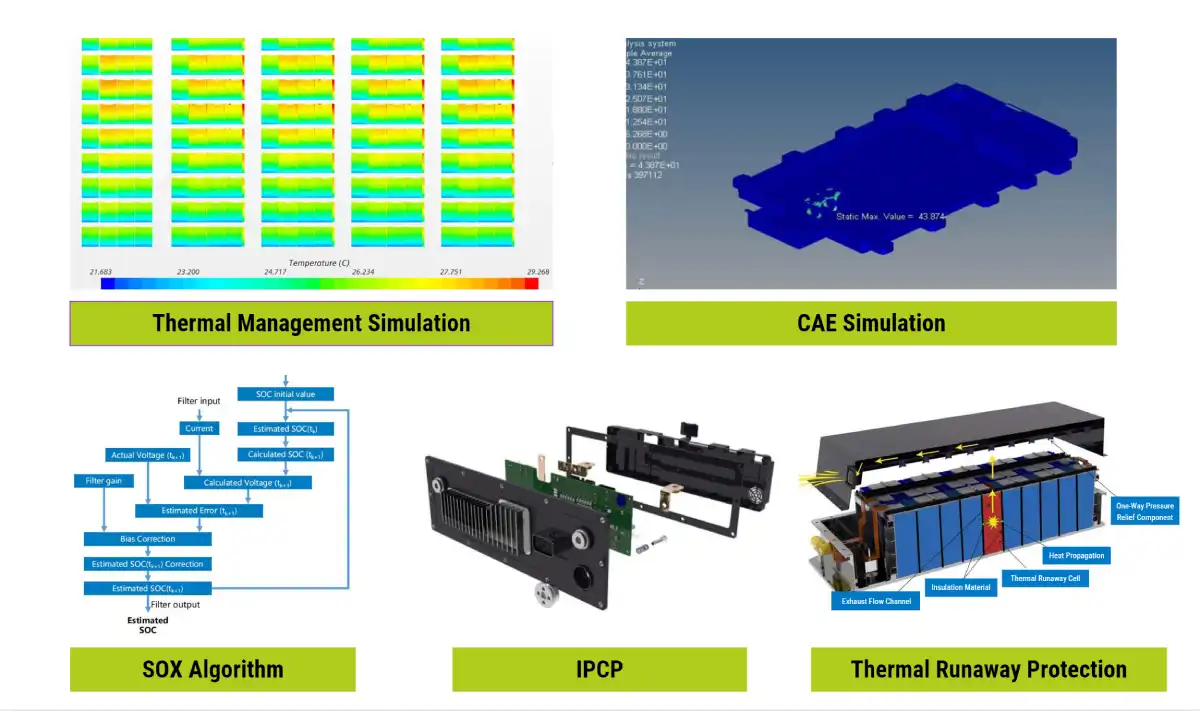

Leading the Way in Innovative EV Traction Battery Technology

Exceptional R&D Expertise

1. Battery Engineering Research Institute

The Battery Engineering Research Institute boasts a team of experienced R&D professionals, with more than 30% holding master’s or doctoral degrees. Equipped with state-of-the-art infrastructure, advanced testing equipment, highly skilled technical personnel, and a stringent quality management system, we ensure excellence at every stage of development.

| Battery Research Institute | Product Research Institute | Materials Research Institute | R&D Laboratory | Technology Management |

|

|

|

|

|

BMS Design & Development

Independently develop BMS software; design control strategies and diagnostic analysis algorithms in-house; design the controller main board, control circuits, monitoring circuits, and communication circuits

Pack Structural & Electricial Design & Development

Independently design integrated battery pack structures to accommodate various battery cell types and capacity needs; independently design electrical circuits and select components, with electrical testing and verification environments to ensure compliance with standards

Battery System Integration Design & Development

Independently design electrical systems and structures; capable of integrating third-party systems, equipment, and components

2. Battery Validation & Testing Center

The Battery Validation & Testing Center spans 6,000 m², fully equipped to cover every stage of battery verification – from cells to modules and packs. The facility is built strictly in accordance with CNAS laboratory standards, ensuring internationally recognized quality and credibility. Capabilities include:

- Normal temperature cycle testing

- High/low temperature and thermal cycling tests

- Rate charge/discharge performance testing

- HPPC

- EOL assessments

- Comprehensive environmental adaptability, safety, and reliability tests

Cell Testing Channel

5V10A: 1000 5V300A: 50

System Testing Channel

1000V300A: 20 1500V300A: 5

Energy Storage System Testing

1500V 2.5MW

Module Testing Channel

100V150A: 100 100V300A: 50

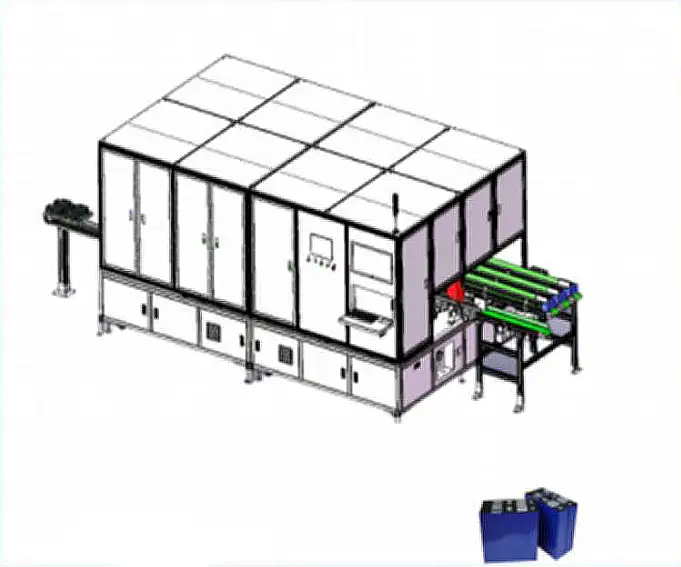

3. Battery Pack Production Line Testing Equipment

Battery Cell Test

- High-precision measurement

- Modular design

- Rapid model change

- Grade sorting configurable via software

Low-Voltage Insulation Test

- High-precision measurement

- Modular design

- Rapid model change

- Key circuit switching modules independently developed

- Probes can be quickly adjusted according to the spacing between cells in the module.

Battery Module EOL Test

- High-precision measurement

- Modular design

- Rapid model change

- Key circuit switching modules independently developed

- Probes can be quickly adjusted according to the spacing between cells in the module.

Module Harness Continuity Test

- High-precision measurement

- Modular design

- Rapid model change

- Key circuit switching modules independently developed

Battery Pack EOL Test

- High-precision measurement

- Modular design

- Rapid model change

- Key circuit switching modules independently developed

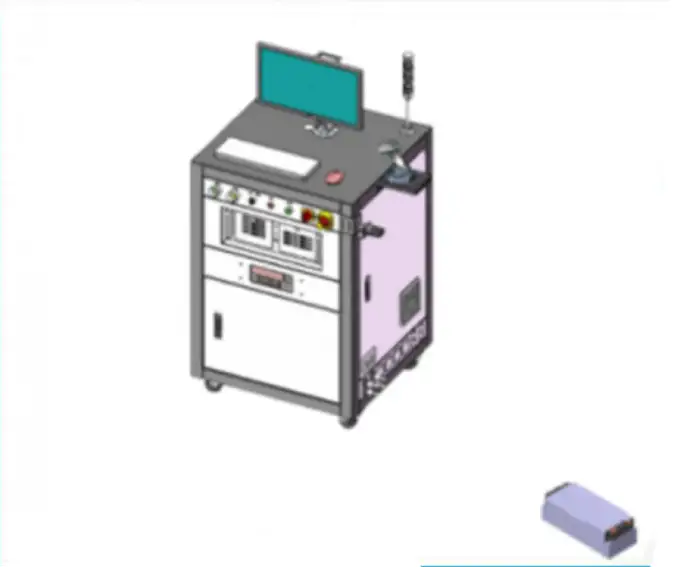

Battery Pack Charge/Discharge Test

- High-precision measurement and output

- Automatic multi-range current switching

- 5 ms fast current response

- Flexible channel paralleling

- Direct DCIR testing

- Integrated multi-function inspection, water cooling system, BMS, etc., customizable linked modules for automated data reporting

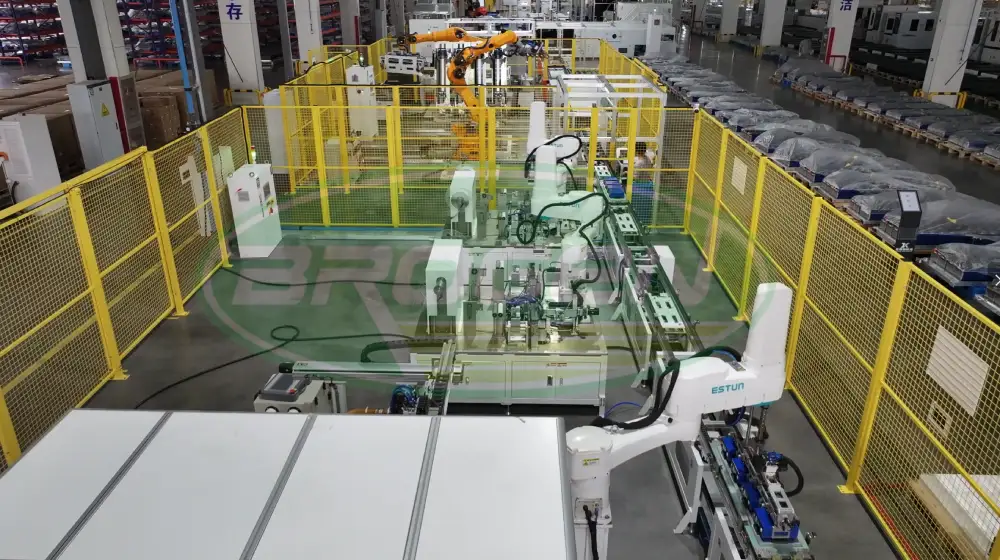

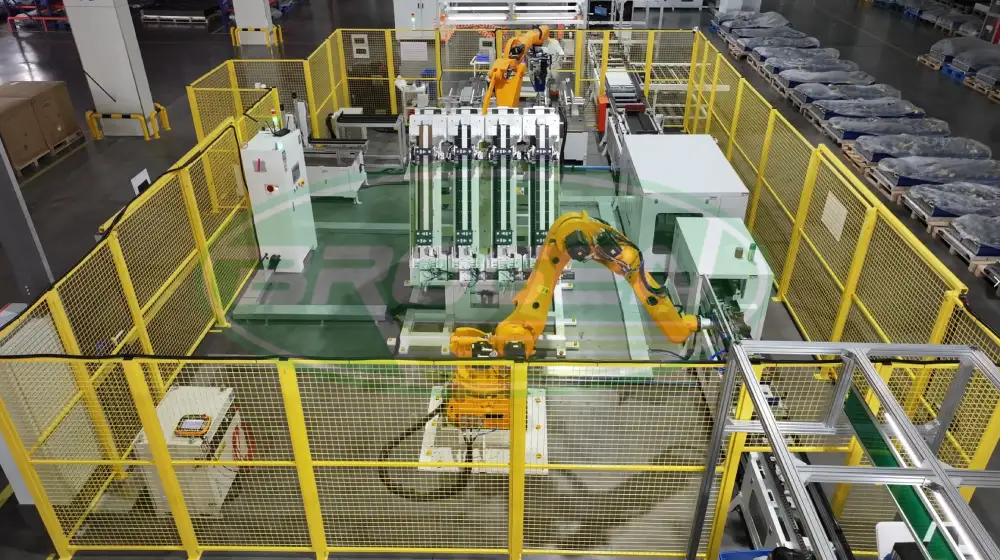

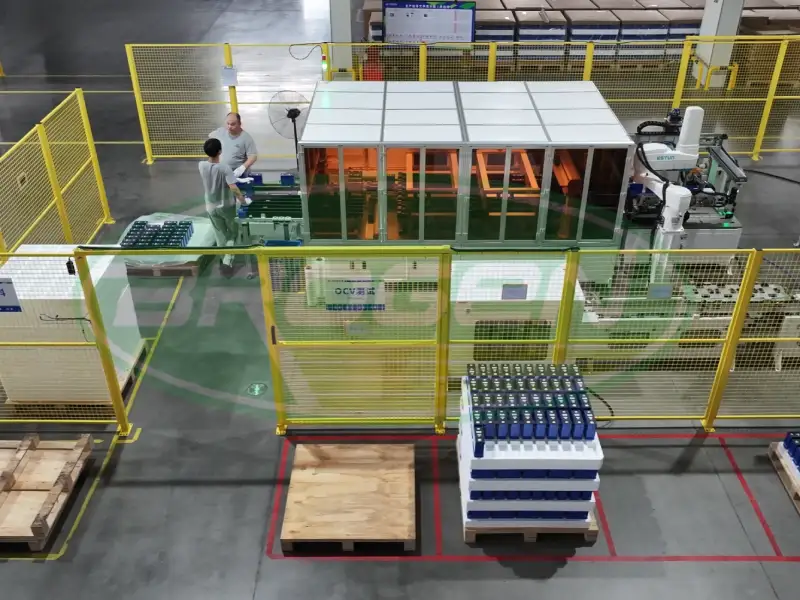

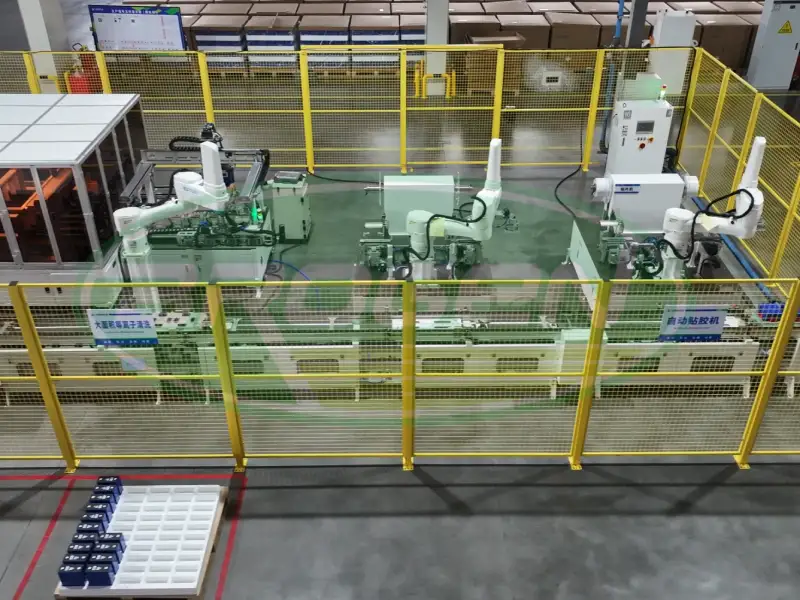

Scalable Battery Manufacturing Capability

New Production Base for EV Traction Battery Manufacturing

Our new production base covers 200,000 m² of land with a 150,000 m² building area, equipped with a 5 GWh automated battery pack production line and a 10 GWh traction battery pack production line. With advanced battery manufacturing capabilities, the site is managed through a centralized MES control system, combining remote monitoring and automation to enable intelligent production. The system also provides end-to-end material traceability and quality control data, ensuring consistency, reliability, and efficiency across the entire process.

- OCV Testing

- Large-Scale Plasma Cleaning

- Structural Adhesive Bonding

- Large Module side Plate Riveting

- Large Module Laser Welding

- Large Module EOL Testing

- Full-Process Quality Control

Extensive Global Project Experience

We have extensive experience in exporting EV traction battery cells, modules, and packs worldwide, serving markets in Australia, Spain, South Korea, Turkey, Germany, Chile, Canada, and beyond.

How We Work

Navigating Our Process

Demand Analysis & Project Evaluation

Once we receive your inquiry, our experts will connect with you within two business days to understand your specific requirements for the EV solution and conduct an initial feasibility evaluation of your project.

Project & Technical Coordination

If the project is deemed feasible, our engineering team will collaborate closely with your team on both hardware and software aspects to develop a viable solution. We will also provide a detailed quotation based on the technical requirements.

Development, Manufacturing & Testing

For customized or modified systems, we proceed with product development, including hardware and software adaptations. Our EV systems undergo rigorous testing to ensure quality, reliability, and full functionality before deployment.

In-Time Global Shipping & Delivery

We have established strong partnerships with international shipping providers, ensuring safe and timely delivery of products to your specified location. This guarantees a smooth and efficient deployment of your EV project.

Full-Stage Remote/Onsite Technical Support

We provide technical support throughout the entire project lifecycle, including consultancy, hardware and software development, calibration, and both onsite and remote debugging, ensuring optimal performance and long-term success.

FAQ

Absolutely. We offer comprehensive software services tailored to your needs:

Customized Software Services:

If you provide your own CAN communication protocol, our engineers can develop and program it into our controllers accordingly.

We can also modify our base software to meet your system requirements and flash it to the control unit before shipment.

Standard Software Availability:

For clients without existing protocol experience, we can offer a standard communication protocol that’s ready to use.

Technical Support After Delivery:

We provide online software support for any technical issues that may arise during integration or use.

Vehicle-Level Debugging:

Our team can assist with full-vehicle debugging to fine-tune the software and ensure your EV system performs optimally under your specific conditions.

For our standard battery packs, we do not enforce strict MOQ requirements. We aim to help EV builders accelerate development and reduce sourcing time — whether you’re building a prototype or preparing for mass production.

At this time, our battery systems are developed for OEMs and commercial EV projects only. We do not sell battery packs for retrofit or personal use on existing passenger cars.

Yes, we specialize in custom battery system development.

Our process includes:

Requirement analysis

Technical feasibility evaluation

Engineering coordination

Proposal & quotation

Project development and delivery

We work closely with your engineering team to ensure the system meets your technical and application needs.

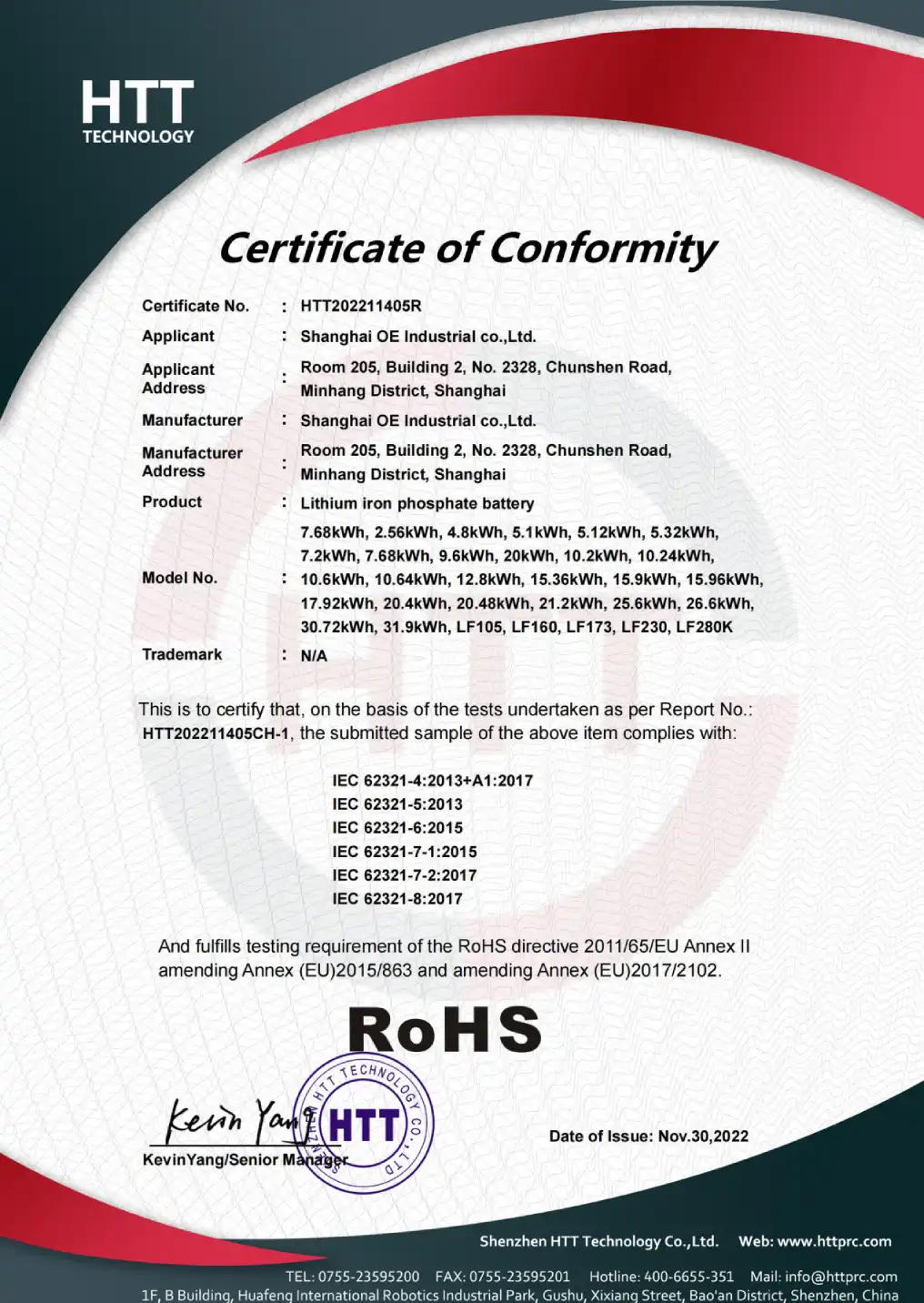

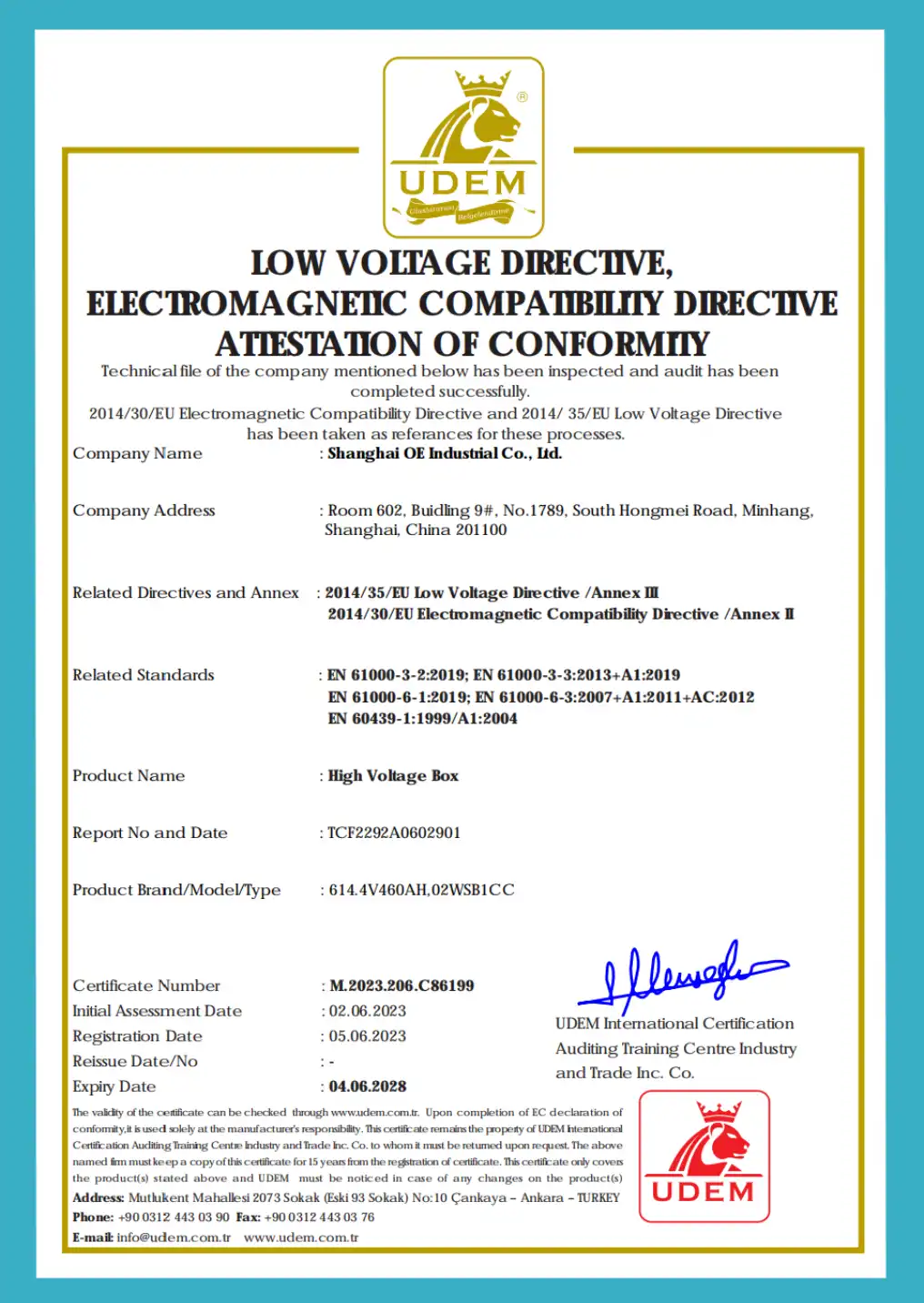

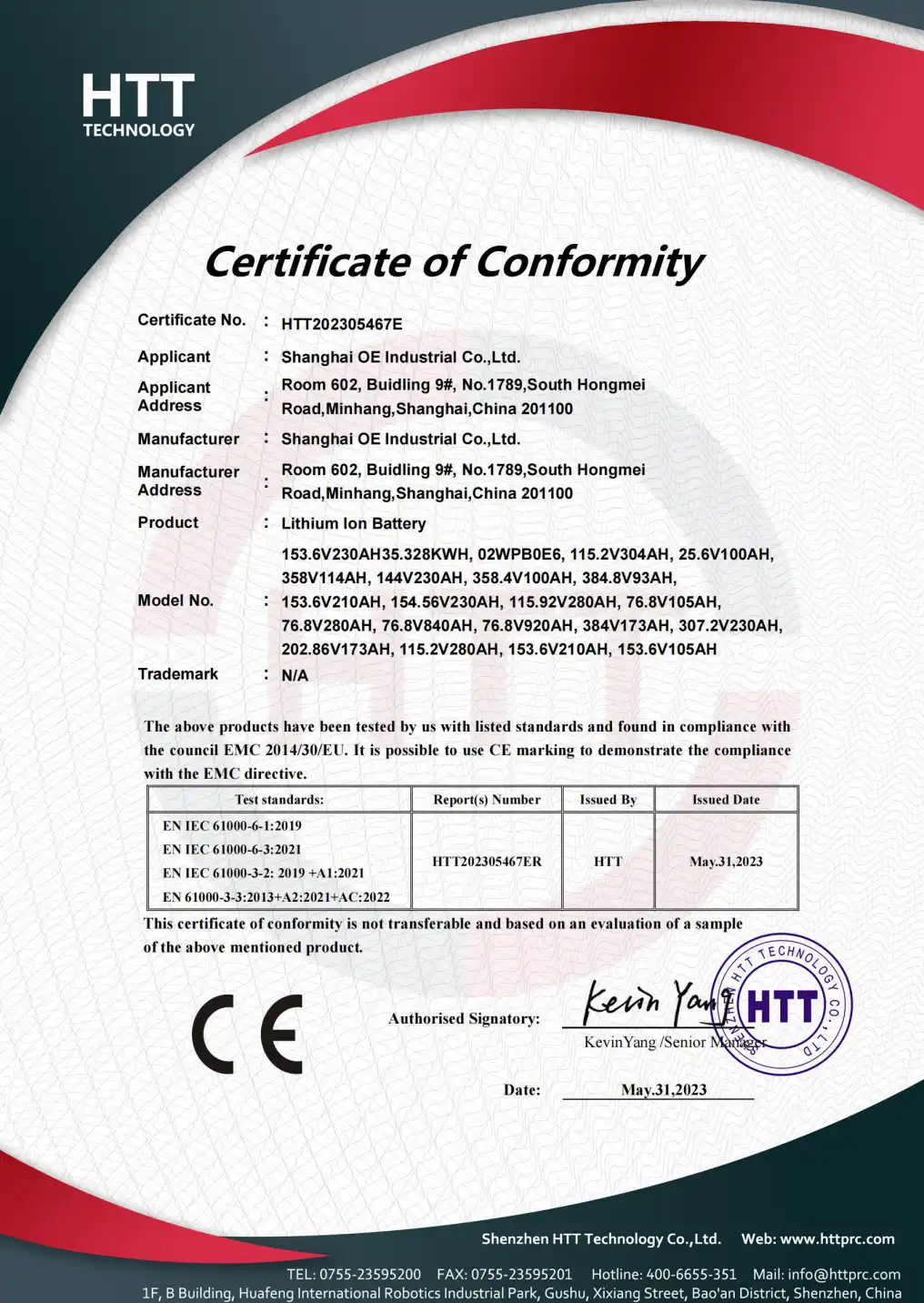

Yes, some of our battery products have already obtained certifications.

If certification is required for your specific project or market, we can provide supporting documents to help you obtain the necessary approvals.

Yes, some of our battery products have already obtained certifications.

Typically, our PDU is integrated within the full battery system and not sold separately. However, depending on the project, we can offer certain components individually — including battery cells, modules, battery packs, or BTMS — based on availability and project evaluation.

Our battery systems have been delivered to EV builders globally, such as: Australia, the United States, Turkey, Chile, India, Germany, South Korea, and more.

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >