Electric Bus Motor Solutions

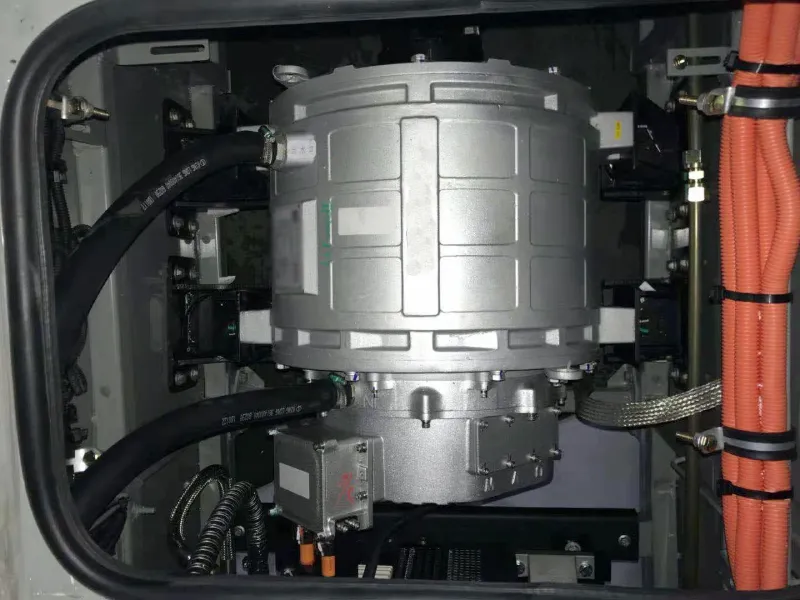

Our electric bus motor solutions are developed for electric bus platforms, with a focus on system maturity, integration feasibility, and long-term operational reliability. We offer both central direct-drive motor solutions and integrated e-powertrain configurations, enabling OEM engineering teams to select architectures aligned with vehicle performance targets and platform constraints.

Selected motor platforms have been applied in public transportation projects across multiple regions, including Europe, Southeast Asia, Australia, and South America, with proven field operation in mass-deployment scenarios. By leveraging validated motor platforms and established drivetrain architectures, bus manufacturers can reduce integration complexity, manage development risk, and shorten vehicle project timelines.

Email: contact@brogenevsolution.com

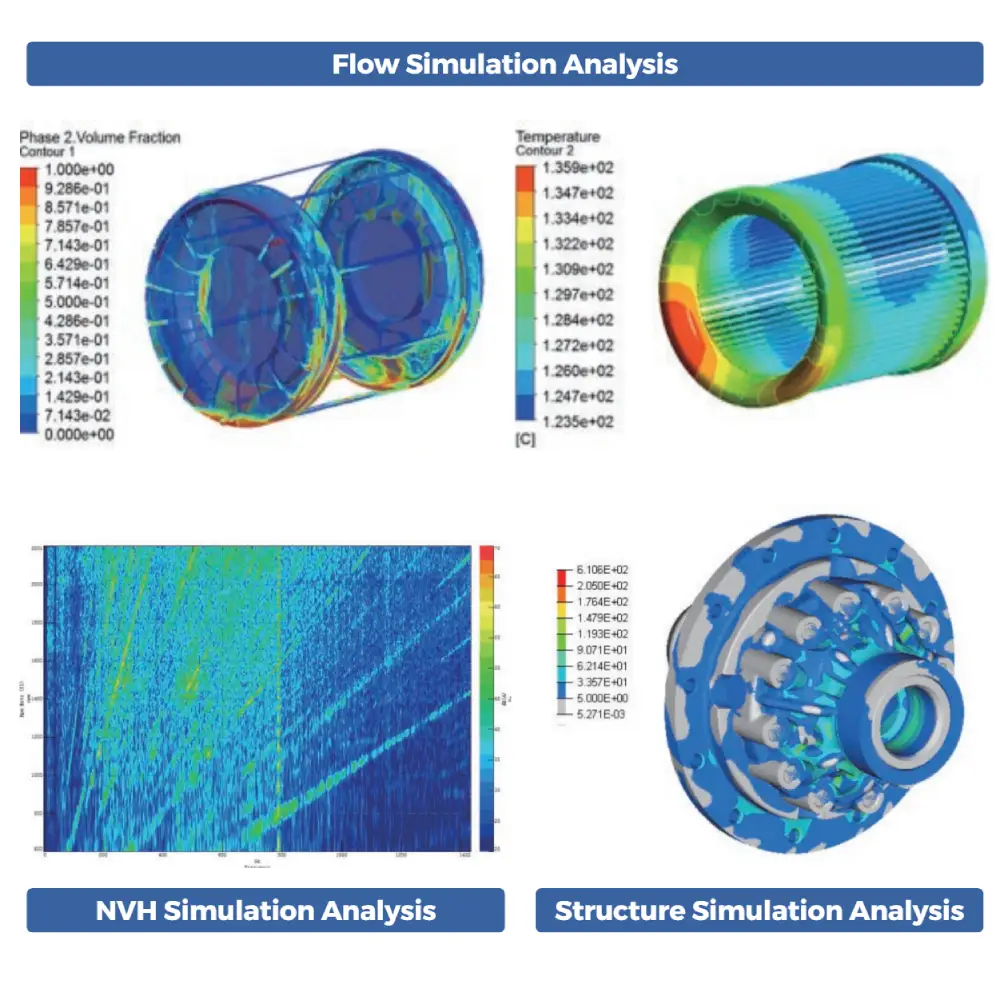

Strong R&D Capabilities

We have full-cycle validation capabilities for electric bus powertrain development. Our rigorous testing process, including bench tests and vehicle trials, ensures continuous improvement and reliable performance. With advanced testing devices, 20+ test vehicles, and a robust experimental process, we validate products through a range of tests, including immersion, temperature extremes, salt spray, vibration, durability, noise, and road tests. This ensures excellent reliability, cost-efficiency, power, and lightweight design of our systems.

- System Integration Development

- Software Development

- Motor & Controller Development

- Transmission Development

Brogen Electric Bus Motor Solution Features

- Precision Control

Relevant duty cycle scenarios:

- Frequent stop-and-go operation in urban routes

- Low-speed driving in congested traffic and bus depots

- Operation under varying passenger loads

Engineering value:

Precise torque and speed control support smooth vehicle launch and consistent low-speed behavior, reducing driveline shock and improving controllability during frequent acceleration and deceleration cycles typical of city bus operation.

- Lightweight and Compact Design

Relevant duty cycle scenarios:

- High passenger load operation during peak hours

- Limited installation space due to low-floor layouts

- Repeated acceleration under full or near-full load

Engineering value:

Reduced system mass and compact packaging improve axle load distribution and integration flexibility, supporting vehicle layout optimization without compromising structural or performance requirements.

- High Energy Efficiency

Relevant duty cycle scenarios:

- Long daily operating hours with multiple charging cycles

- Routes with frequent acceleration and deceleration

- Energy consumption-sensitive public transport operations

Engineering value:

High drivetrain efficiency reduces energy consumption per operating cycle, supporting extended driving range and improved overall energy utilization in high-duty, high-cycle bus applications.

Brogen Offerings of Electric Bus Motor Solutions

1. Central Direct-Drive Electric Bus Motor

Our central direct-drive motors are based on PMSM technology, delivering high efficiency and high power density within a compact package. With power ratings ranging from 60 to 400 kW and torque outputs from 500 to 5,000 N.m, these motors support a broad range of vehicle classes and operating profiles.

Designed for commercial vehicle applications, the motors provide stable and predictable performance, supporting reliable and durable vehicle operation across diverse duty cycles.

- Power range: 60 - 400 kW

- Torque range: 500 - 5000 N.m

- Applications: buses, coaches

Technical Parameters

- Please note that the parameters listed are for reference only. Final specifications may vary depending on application requirements. For detailed technical data, available configurations, and controller options, please contact us at Email: contact@BrogenEVSolution.com

- Most of the motor models listed below have completed calibration and have progressed to the SOP stage, with selected models applied in commercial vehicle projects.

| Model | Target Vehicle Segment | Motor Power (Rated/Peak) | Motor Torque (Rated/Peak) | Peak Motor Speed |

| LCV-motor-7 | 6 m bus; 4.5 t truck | 60 / 130 kW | 400 / 1000 N.m | 4000 rpm |

| LCV-motor-8 | 6 m bus; port AGV | 90 / 190 kW | 550 / 1300 N.m | 4000 rpm |

| Bus-motor-1 | 8 m bus | 80 / 150 kW | 750 / 1700 N.m | 3000 rpm |

| Bus-motor-2 | 8 m coach | 100 / 220 kW | 750 / 1700 N.m | 4000 rpm |

| Bus-motor-3 | 8.5 m bus | 80 / 185 kW | 900 / 2100 N.m | 2800 rpm |

| Bus-motor-4 | 8.5 m coach | 90 / 195 kW | 900 / 2100 N.m | 3500 rpm |

| Bus-motor-5 | 10 m bus | 100 / 200 kW | 1000 / 2500 N.m | 2800 rpm |

| Bus-motor-6 | 12 m bus | 115 / 200 kW | 1200 / 2800 N.m | 2600 rpm |

| Bus-motor-7 | 12 m coach; terminal tractor | 135 / 275 kW | 1200 / 2800 N.m | 3500 rpm |

| Bus-motor-8 | 12 m coach; terminal tractor | 180 / 290 kW | 1600 / 3400 N.m | 3000 rpm |

| Bus-motor-9 | 8-10 m bus; coach | 120 / 240 kW | 1200 / 2400 N.m | 3000 rpm |

| Bus-motor-10 | 11-18 m bus | 220 / 350 kW | 1200 / 3200 N.m -20s | 3000 rpm |

| Bus-motor-11 | 9-12 m coach | 215 / 350 kW | 1260 / 2800 N.m (3100 N.m -20s) | 3500 rpm |

| Bus-motor-12 | 8-9 m bus; 6-7 m coach | 80 / 160 kW | 800 / 1600 N.m | 3000 rpm |

| Bus-motor-13 | 10-12 m bus; 8-10 m coach | 120 / 240 kW | 1200 / 2400 N.m | 3000 rpm |

| Bus-motor-14 | 10-12 m bus; 8-10 m coach | 120 / 240 kW | 1400 / 2800 N.m | 2500 rpm |

High Efficiency

Designed with thin silicon steel sheets, high-permeability magnetic materials, and sinusoidal air-gap magnetic density optimization, our motors achieve peak efficiency exceeding 97%. More than 90% of the system operates within an efficiency range of ≥85%, significantly enhancing energy utilization.

Noise Reduction

By incorporating advanced rotor segmentation and optimized auxiliary slot parameters, our motors effectively minimize operational noise. The no-load noise level across the full speed range remains below 72dB(A), providing a distinct competitive advantage in the industry.

Enhanced Thermal Management

The dual-helix water-cooling design maximizes heat dissipation and system stability while maintaining optimal hydraulic resistance and pressure balance, ensuring long-term reliability under demanding conditions.

Advanced Environmental Protection

The motor features a flange-mounted sealing structure that effectively prevents the ingress of mud, sand, and water. This enhances operational reliability, particularly in challenging environments.

Optimized Manufacturing and Insulation

The junction box utilizes a stamped sheet-metal and vulcanized rubber construction process, improving production efficiency and reducing material costs. Additionally, the vulcanized rubber layer minimizes internal temperature fluctuations, enhancing resistance to condensation and extending service life.

According to clients’ different requirements, we can provide standalone MCUs or high-voltage integrated controller systems, integrating MCU, PDU, DC-DC, and steering and braking DC/AC.

Note: Controllers are usually supplied as part of the electric powertrain system and are not sold separately.

*The specific features vary depending on the configuration. For more parameter information, please contact us at contact@BrogenEVSolution.com

ISO 26262 Compliance

Functional safety requirements and software/hardware development meet ASIL C standards.

Dual-Integration Design

Combines functional and physical integration to significantly reduce size, weight, and manufacturing costs.

Dual-Inverter Control Technology

Minimizes losses and achieves a maximum efficiency of 98.5%.

Modular & Scalable Architecture

Designed for flexibility and easy expansion.

Digital Simulation & Optimization

Uses digital modeling for simulation analysis, enabling more efficient and cost-effective component selection.

Advanced EMC Design

Multi-stage filtering, optimized wiring layout, enhanced shielding, and structural improvements ensure Class 5 compliance under no-load conditions.

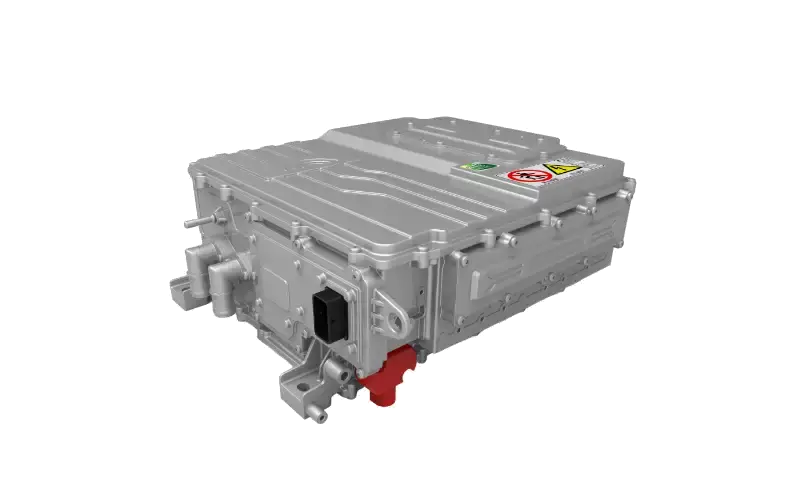

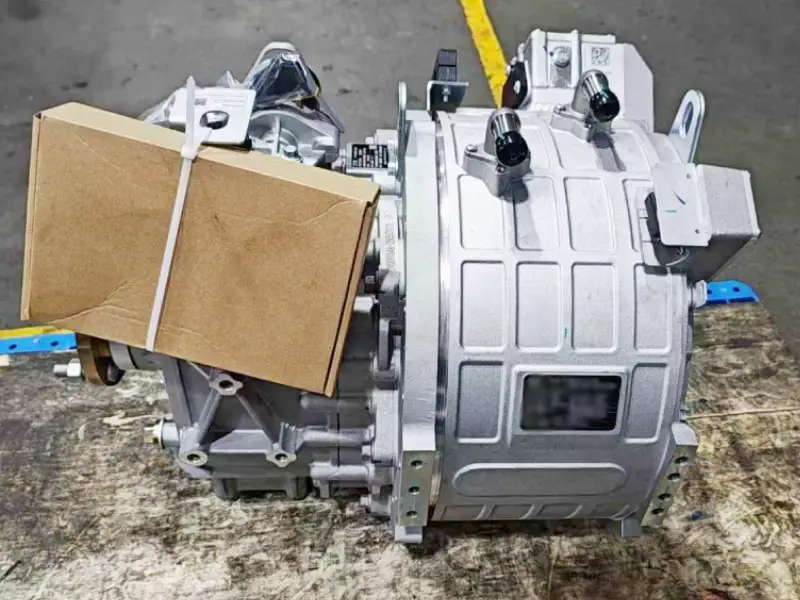

2. Integrated Electric Bus Powertrain (Motor+MCU)

We offer an integrated electric powertrain solution for electric buses and coaches in the 8–12 meter class, designed with a focus on efficiency, reliability, and production readiness. The 2-in-1 e-powertrain integrates the motor and controller into a single unit, supporting simplified system integration and platform-level deployment.

This solution has been in mass production since 2018, with more than 30,000 units deployed across commercial bus applications. Designed to meet the operational and regulatory requirements of modern electric buses, the powertrain supports zero tailpipe emissions and low-noise operation suitable for urban and intercity public transport.

- Increased Driving Range

- Smaller Size and Lightweight Design

- Enhanced Vehicle Layout

Technical Parameters

- Please note that the parameters listed are for reference only. Final specifications may vary depending on application requirements. For detailed technical data, available configurations, and controller options, please contact us at Email: contact@BrogenEVSolution.com

- Most of the motor models listed below have completed calibration and have progressed to the SOP stage, with selected models applied in commercial vehicle projects.

| Motor Model | Bus-motor-15 | Bus-motor-16 | Bus-motor-17 | Bus-motor-18 |

| Rated Power | 120 kW | 100 kW | 90 kW | 90 kW |

| Peak Power | 200 kW | 200 kW | 180 kW | 150 kW |

| Rated Torque | 1300 N.m | 1000 N.m | 860 N.m | 636 N.m |

| Peak Torque | 2800 N.m | 2500 N.m | 2150 N.m | 1700 N.m |

| Rated Speed | 881 rpm | 955 rpm | 1000 rpm | 1350 rpm |

| Peak Speed | 2500 rpm | 2700 rpm | 2700 rpm | 3000 rpm |

| Battery Voltage | 540 VDC | 540 VDC | 540 VDC | 540 VDC |

| Peak Current | 540 A | 451 A | 451 A | 420 A |

| Cooling Method | Liquid cooling | Liquid cooling | Liquid cooling | Liquid cooling |

| IP Rate | IP67 | IP67 | IP67 | IP67 |

| Applicable Vehicles | 12-meter bus | 10.5-meter bus | 8.5~10-meter bus | 8-meter bus |

Compact Integrated Design

Optimized for minimal space usage, making vehicle integration more efficient.

Enhanced EMC Performance

Eliminates three-phase wiring harness radiation, reducing electromagnetic interference while improving overall system stability.

Lower Energy and Procurement Costs

Reduces power loss in wiring, improving efficiency and lowering component costs.

High Motor Efficiency

Achieves the "Dual 90" efficiency standard, ensuring exceptional performance and energy savings.

Applications

Our electric bus motor systems have been applied in public transportation projects across multiple regions, with validated operation in large-scale fleet deployments. Selected systems have been exported to and deployed in countries including the UAE, Australia, Malaysia, Indonesia, the Philippines, Canada, and Mexico.

Today, most of these electric bus motor systems are in mass production, supporting consistent quality, scalable supply, and readiness for fleet-level electrification programs.

How We Work

Navigating Our Process

Demand Analysis & Project Evaluation

Once we receive your inquiry, our experts will connect with you within two business days to understand your specific requirements for the EV solution and conduct an initial feasibility evaluation of your project.

Project & Technical Coordination

If the project is deemed feasible, our engineering team will collaborate closely with your team on both hardware and software aspects to develop a viable solution. We will also provide a detailed quotation based on the technical requirements.

Development, Manufacturing & Testing

For customized or modified systems, we proceed with product development, including hardware and software adaptations. Our EV systems undergo rigorous testing to ensure quality, reliability, and full functionality before deployment.

In-Time Global Shipping & Delivery

We have established strong partnerships with international shipping providers, ensuring safe and timely delivery of products to your specified location. This guarantees a smooth and efficient deployment of your EV project.

Full-Stage Remote/Onsite Technical Support

We provide technical support throughout the entire project lifecycle, including consultancy, hardware and software development, calibration, and both onsite and remote debugging, ensuring optimal performance and long-term success.

Frequently Asked Questions

These motors are designed for electric bus applications, including city buses and intercity coaches, typicall in the 6-12 meter vehicle class.

Motor controllers are typically supplied together with the motor as part of an integrated solution. Standalone controller supply is not offered.

Most of our electric bus motor solutions have entered SOP and are currently in mass production. Selected models have been deployed in bus fleets.

We are responsible for the embedded software and control functions of the systems we supply, including motor control and inverter-related software.

Vehicle-level electrical system design, mechanical packaging, and overall vehicle control unit (VCU) integration – including control strategies and calibration – remain the responsibility of the customer or the vehicle integrator.

We support interface definition and communication requirements related to the supplied system. However, full vehicle-level VCU integration, control logic development, and functional safety validation are handled by the customer.

Customers are expected to provide vehicle electrical architecture, mechanical layout constraints, and system-level control requirements to enable proper integration of the supplied motor or drive unit.

Most of our motor models have completed calibration and entered the SOP phase, with selected models applied in commercial vehicle projects. Availability may vary by configuration and application.

Motor specifications and configurations can be adjusted based on project requirements. Final parameters are defined through technical discussion and validation.

We focus on supplying EV systems. Full vehicle electrification, including VCU development, is typically managed by the customer or a designated system integrator.

Yes. We support small-batch orders for prototype development, with flexible MOQ and lead time.

- Our electric bus motors are designed and tested in compliance with Chinese national standards, which, in many aspects, are more stringent than international equivalents.

- For some models, we do not preapply certain certificates, but we can provide the necessary technical documents and support to assist you in completing local certifications in your country.

We support flexible shipping terms such as FOB, CFR, and CIF. Lead times vary based on system type and customization.

- We provide tailored EV solutions, but not ready-to-install retrofit kits.

- To ensure optimal system performance and safety, we require that our clients have a professional EV engineering team with hardware and software capabilities.

- During the early stage of the project, we also expect the client’s technical team to participate in solution discussions to ensure the best fit between our solution and your vehicle architecture.

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >