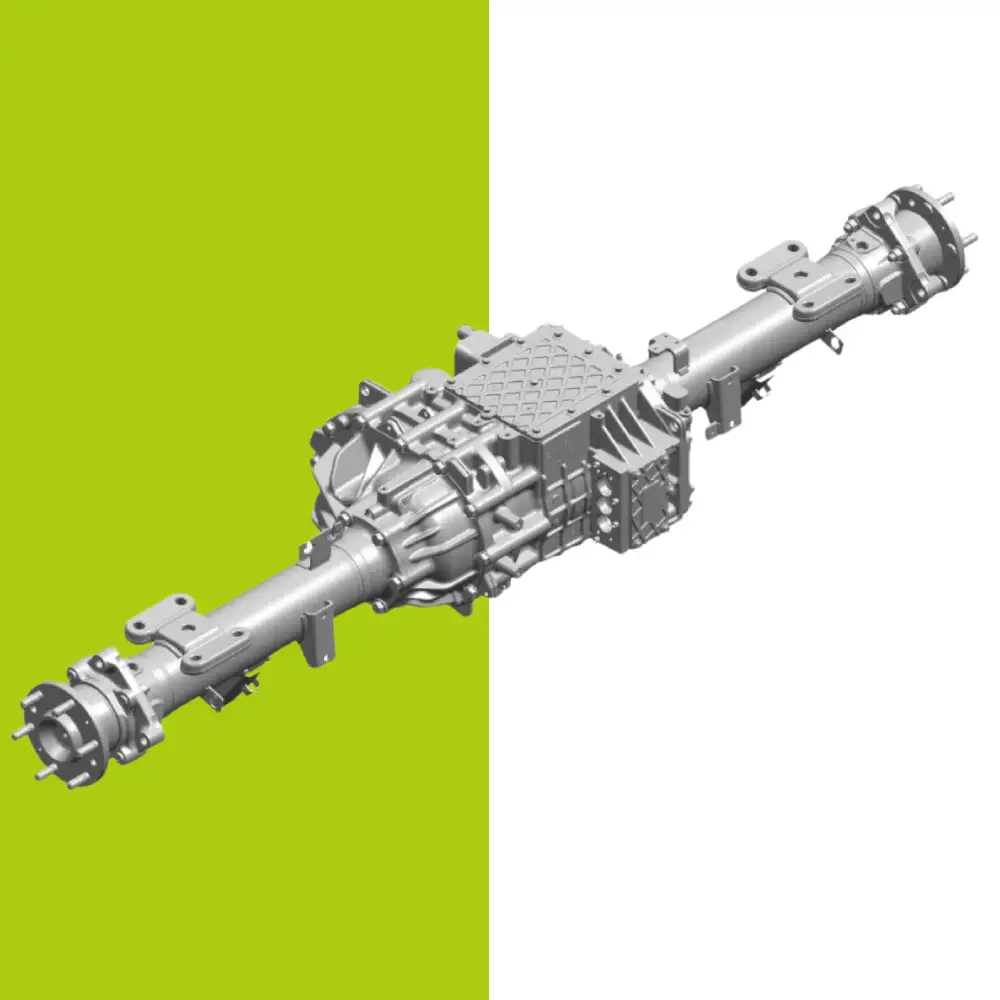

e-Beam Axle Solution

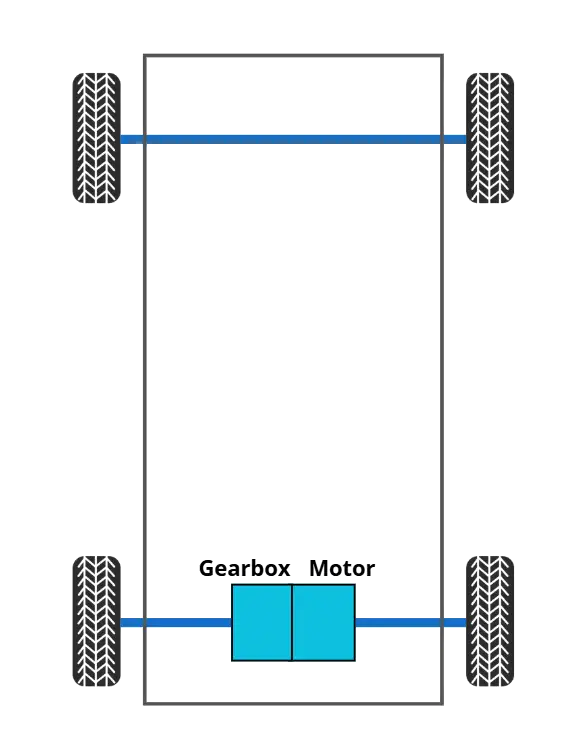

For light commercial vehicles, we have introduced an e-Beam axle solution, which is applicable to MPVs, pickups, light-duty vans, and large SUVs based on pickup truck chassis.

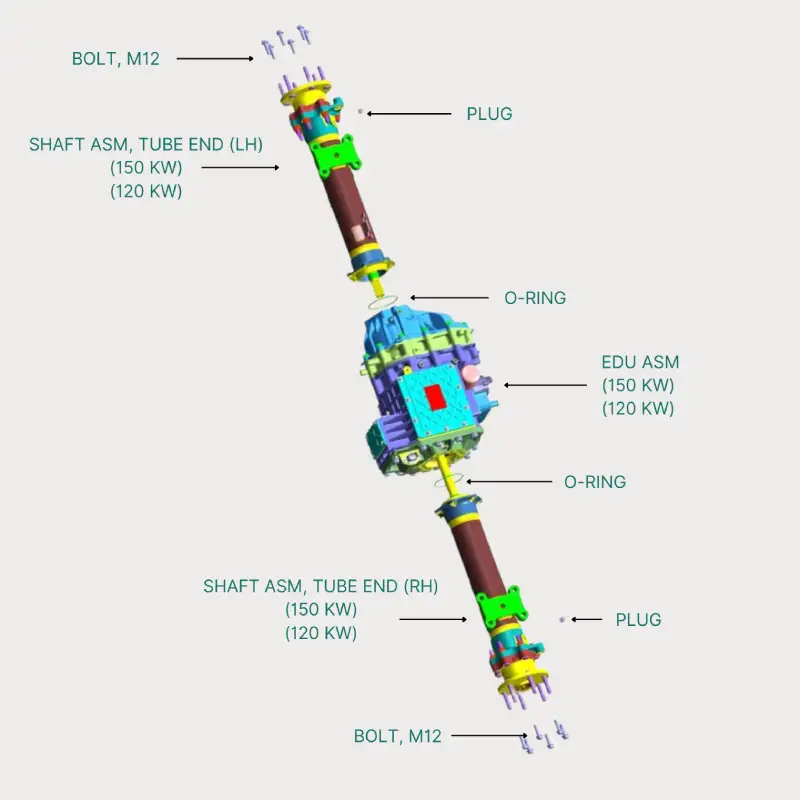

The system incorporates a welded lightweight differential, die-cast aluminum housing, offset coaxial gearbox, and welded insert tube technology. These design optimizations reduce axle mass, minimize the size of the center drive unit, and improve overall vehicle dynamics compared to conventional designs.

Importantly, the e-Beam axle retains the torque capacity and load-bearing performance of traditional axles, ensuring mechanical robustness while enabling reliable electrification across pickup trucks, light vans, SUVs, MPVs, and light logistics vehicles.

Email: contact@brogenevsolution.com

e-Beam Axle Solution Details

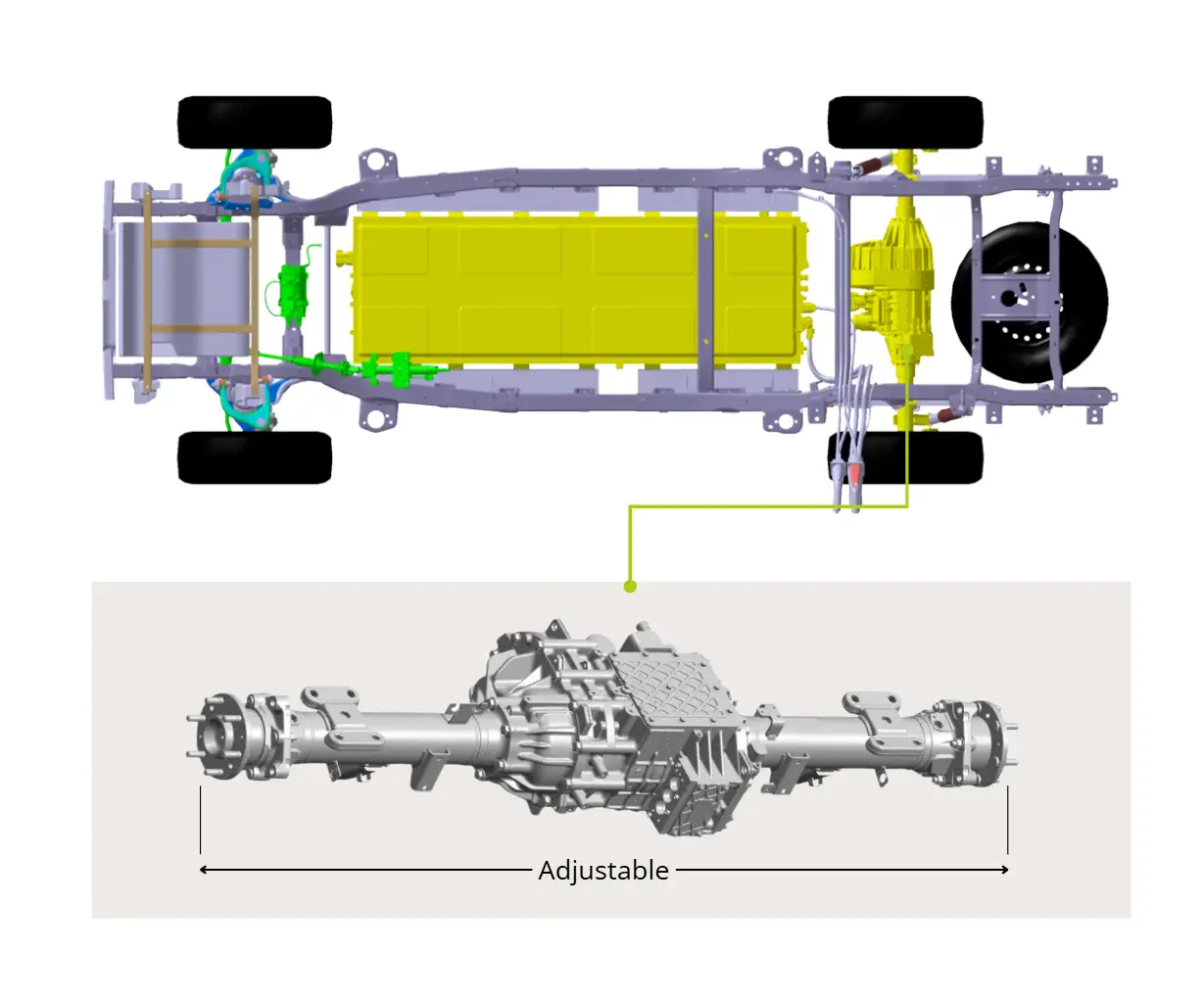

The e-beam axle is a modular and scalable system that integrates the traction motor, gearbox, and axle assembly into a compact unit. This integration minimizes overall system volume, optimizing chassis packaging and providing increased space for battery installation – enabling either extended driving range or reduced battery capacity depending on application requirements.

Developed with a platform-based architecture, the e-beam axle supports multiple axle load ratings, ensuring adaptability across a broad spectrum of light commercial vehicle platforms. The drivetrain module and axle housing are engineered as relatively independent subassemblies, which enhances design flexibility, allows rapid customization for different vehicle architectures, and reduces both development complexity and overall vehicle integration costs.

Reduce Integration Complexity

Our modular e-Beam axle simplifies vehicle integration, shortening development cycles and lowering engineering costs.

Maximize Payload Capacity

Optimized structural design ensures superior strength-to-weight ratio, enabling higher payloads without compromising vehicle range or performance.

Improve Cost Efficiency

Streamlined manufacturing processes and reduced component count drive down system cost, enhancing your project's ROI.

Accelerate Time-to-Market

With proven compatibility and adaptable design, the e-Beam axle minimizes validation time and supports scalable production.

Technical Parameters

The parameters may vary depending on the configuration. For more parameter information, please contact us at contact@BrogenEVSolution.com

| System Series | TSeries |

| Axle Load | 2200 kg / 3100 kg / 3500 kg |

| Voltage Platform | 380 VDC / 540 VDC |

| Motor Power | Design Value (Rated/Peak): 80 kW / 160 kW |

| Measured Value (Rated/Peak): 100 kW / 175 kW | |

| Motor Torque | Design Value (Rated/Peak): 220 N.m / 380 N.m |

| Measured Value (Rated/Peak): 200 N.m / 400 N.m | |

| Wheel End Torque (Peak) | 4500 N.m (4800 N.m) |

| Gear Ratio | 11.9 |

| Center Distance | 112.5 mm |

| Motor Speed (Peak) | 13,700 rpm |

| Motor Type | Oil-cooled flat-wire motor |

Leading the Way in Innovative Electric Powertrain Technology

Strengthen Your Electric Pickup Truck Design With Our e-Beam Axle

Our e-Beam axle system is a transformative solution designed to accelerate and optimize your electric pickup truck development. By reimagining traditional architecture through structural innovation and precision engineering, we deliver critical advantages in cost, efficiency, and payload – helping you bring competitive electric pickups to market faster.

1. Direct Drive vs. Parallel-Axis E-Axle vs. e-Beam Axle

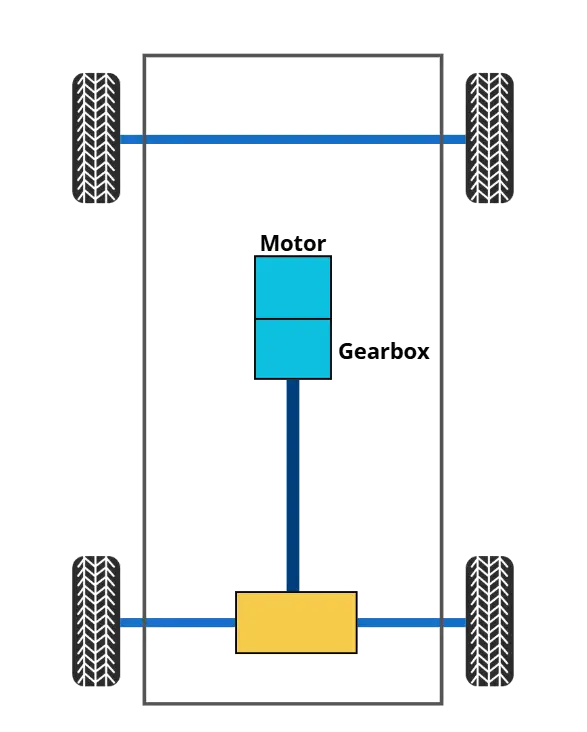

Direct Drive Solution

- Minimal modification to the traditional chassis

- Retains drive shaft → limits battery packaging space → smaller battery capacity

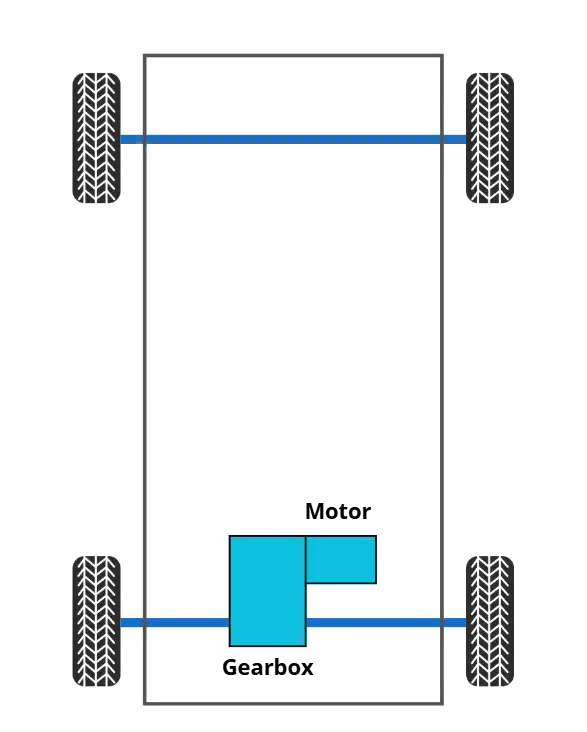

Parallel-Axis E-Axle

- Eliminates driveshaft → more battery space → extended driving range

- Cantilevered centroid design → vibration during start/acceleration, harsh response under heavy load

Coaxial E-Axle (e-Beam Axle)

- Coaxial layout → optimized centroid position → reduced impact and vibration

- Higher energy conversion efficiency, best NVH performance, resolves low-frequency vibration issues

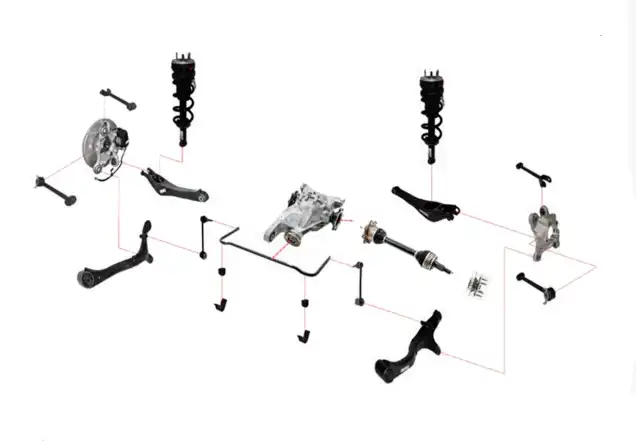

2. Independent Electric Drive Unit (EDU) vs. e-Beam Axle

Independent Electric Drive Unit (EDU) Architecture

- EDU with independent suspension

- Axle is sprung mass, does not move with the wheels

- Axle is mounted to the frame

- Knuckles, wheel hubs, and half-shafts required

- Suspension options

- Double wishbone

- Multi-link / trailing arm

- MacPherson strut

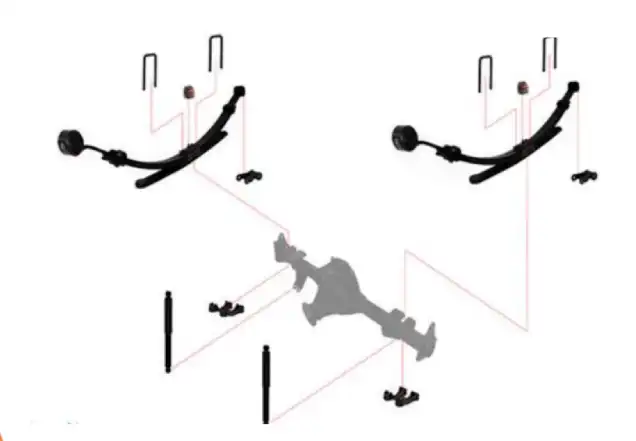

e-Beam Axle Architecture

- e-Beam axle with rigid suspension

- Axle is unsprung mass, moves with the wheels

- Axle is mounted to the suspension

- Axle shafts and wheel flanges are part of the axle

- Suspension options

- Leaf spring

- Multi-link

Weight Optimization: Over 25 kg Reduction and Higher Payload

Benchmark testing demonstrates that when both systems are designed to their minimum feasible mass (EDU with trailing-arm independent suspension vs. e-Beam with leaf-spring rigid suspension), the e-Beam achieves a 5-10% weight reduction, cutting over 25 kg from the vehicle.

Efficiency Optimization: Up to 1.7% Longer Range

Backed by real-world test data, at gross vehicle weight (GVW, 5000 lb / 2268 kg), the e-Beam reduced energy consumption by 0.67 kWh per 100 miles, delivering an efficiency gain of 1.0%-1.7%. A 1.7% efficiency improvement may seem small on paper, but for electric LCVs with 300-400 km of typical range, it translates to an extra 5-7 km of real-world driving range for urban logistics, last-mile delivery, and frequent stop-and-go usage.

Cost Optimization: 10%-20% BOM Reduction

Under equivalent system configurations, the e-Beam can reduce BOM costs by 10–20%, primarily due to fewer components and higher manufacturing efficiency. In addition, its lower weight and higher drivetrain efficiency enable OEMs to reduce battery capacity while maintaining the same driving range. For example, a 1.7% efficiency improvement can eliminate 1–2 kWh of battery capacity. As the battery is the most expensive EV component, this secondary effect further amplifies the e-Beam’s overall cost advantage.

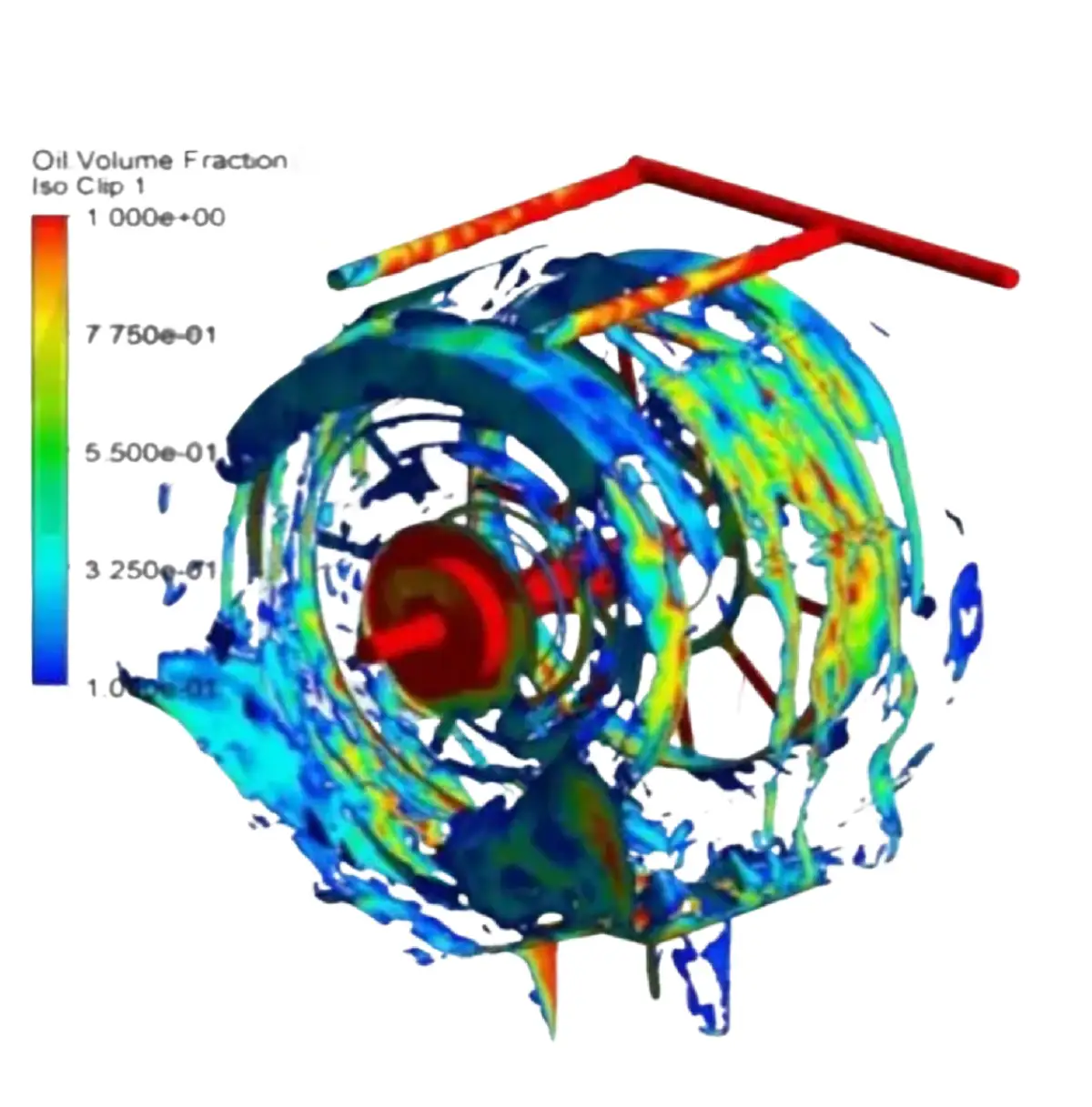

Oil-Cooled Flat-Wire Hairpin Electric Motor Technology

High Power Density

Combines flat-wire (hairpin) motor technology with advanced oil cooling. With oil cooling, power density is further increased, enabling over 20% higher continuous power density and approximately 10% improvement in space utilization.

Extended Service Life

Oil cooling addresses lubrication challenges for bearings and seals while enhancing the protective effect of lubricating oil on the insulation system. Compared with water-cooled designs, this significantly improves the motor's design lifespan.

System Integration Benefits

Oil cooling eliminates the need for the dual-layer cooling housing required by water-cooled motors and removes the oil seal structure between the gearbox and motor. This allows greater flexibility in the assembly of the motor stator and housing, simplifying system integration.

Lightweighting Design

Die-Cast Aluminum Housing

Maximizes weight reduction

Oil-Cooled Flat-Wire Motor

Improves efficiency with integrated oil cooling and shared-cavity design

Reduced Gear Center Distance

Descreases overall assembly size, simplifies vehicle packaging, and lowers material costs

Laser-Welded Differential

Eliminates threaded holes, reduces machining steps, lowers cost, decreases weight, provides a more compact structure, and ensures high assembly accuracy

Frequently Asked Questions

Our e-beam axles are designed for light commercial vehicles, including MPVs, vans, and pickup trucks.

At present, our solutions are available exclusively to B2B clients, such as OEMs, engineering companies, retrofit workshops, and system integrators. They are not intended for individual or personal projects. For diesel-electric conversion projects, customized R&D and tooling may be required for certain models. For single-vehicle projects, these development costs cannot be amortized, which makes them impactical.

No. We specialize in supplying electric powertrain systems for commercial vehicles, but we do not carry out retrofit or vehicle conversion services directly. For individual conversion needs, we recommend reaching out to a local engineering or retrofit service provider.

No. Our solutions are not plug-and-play. Successful integration requires technical expertise in both hardware and software from the client side.

Pricing depends on factors such as order quantity and the level of customization required. While we do support customization, additional development fees may apply. For bulk orders, these costs can be distributed across larger volumes, significantly reducing the average unit price.

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >