Electro-Hydraulic Power Recirculating Ball Steering (RCB) Gear for Commercial Vehicles

We provide electro-hydraulic power recirculating ball steering systems designed for heavy commercial vehicles, including large buses and medium-to-heavy trucks. Based on conventional hydraulic power steering (HPS) architecture, the electro-hydraulic power recirculating ball steering system integrates electronic control units (ECU) and actuators – most importantly, a servo motor to enhance steering performance.

The key advantage of the EHPS lies in its ability to communicate with the vehicle’s control system. The servo motor enables variable steering assist that automatically adjusts according to vehicle speed and road conditions, ensuring optimal steering performance and a more comfortable driving experience.

Email: contact@brogenevsolution.com

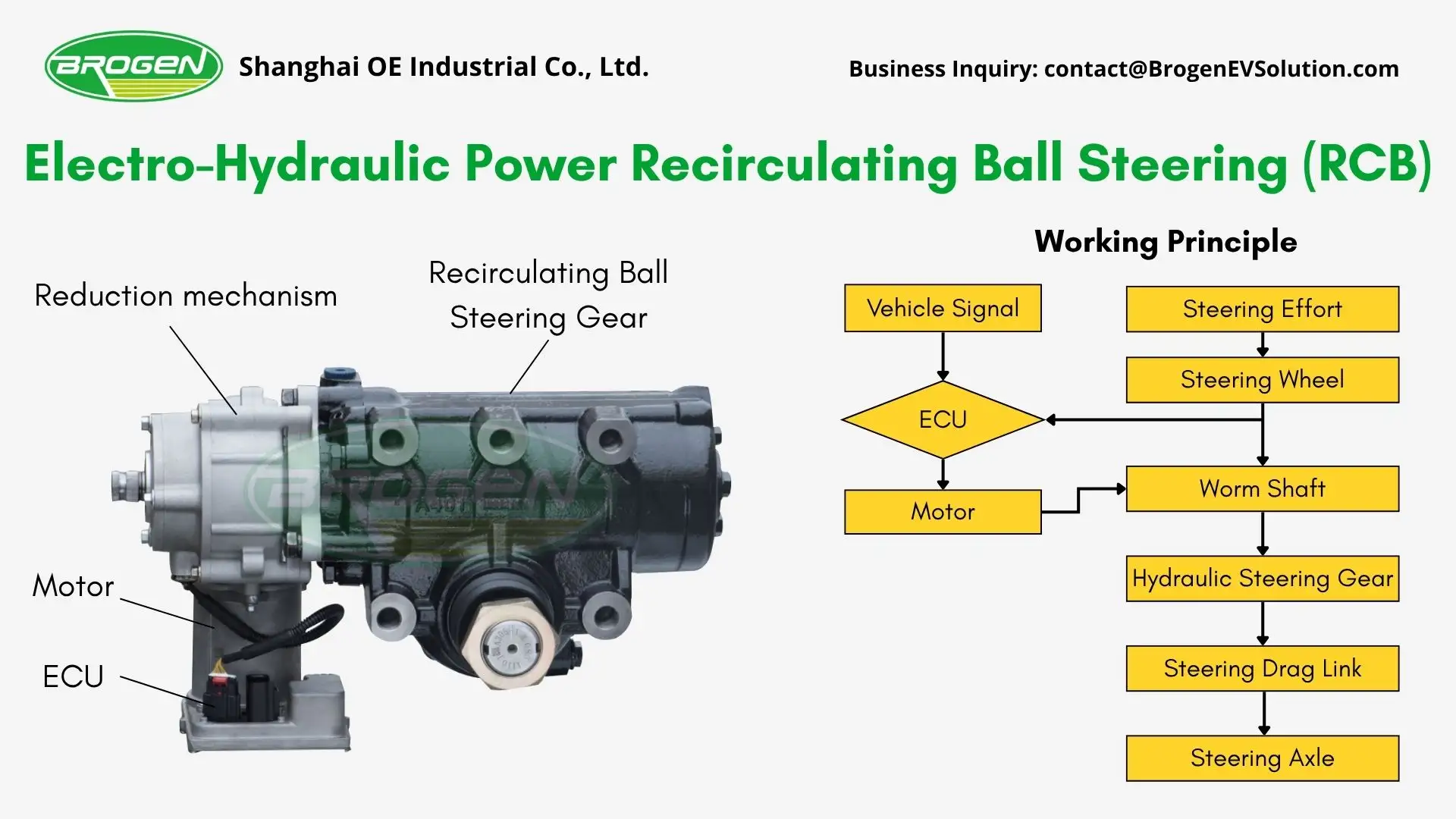

How Does the Electro-Hydraulic Power Recirculating Ball Steering System Work?

The electro-hydraulic power recirculating ball steering system mainly consists of an ECU control unit, motor, reduction mechanism, and recirculating ball steering gear. When the driver turns the steering wheel, the angle and torque sensors detect the steering angle and torque in real time and send the signals instantly to the ECU controller. At the same time, the ECU receives real-time vehicle speed data via the CAN network and, based on the EHPS assist curve, calculates the required steering assist torque. The ECU then commands the motor to deliver the corresponding torque output, which is applied to the worm shaft to provide additional steering assist. This coordination effectively reduces the driver’s steering effort and ensures smooth, real-time steering response for the vehicle.

Features of Brogen Electro-Hydraulic Power Recirculating Ball Steering

- Compact structure with high reliability, stability, safety, and energy efficiency.

- The rack-and-pinion engagement adopts an auxiliary radial displacement design, ensuring smooth and stable meshing without jamming. The meshing point is precisely controlled at the center position, effectively eliminating steering clearance and improving self-centering performance.

- With newly developed oil seal materials, the product withstands temperatures up to 135°C continuously and 150°C instantaneously, while maintaining reliable performance at -40°C.

- Incorporates variable transmission ratio technology: at high speeds, only small steering angles are required for precise and stable control; at low speeds, steering remains light and effortless even at large angles.

- The output shaft uses a high-pressure skeleton oil seal with a specialized design. The pitman shaft support employs closely spaced roller bearings, enhancing load capacity. A retaining ring prevents bearing dislocation, while a dust seal protects against water and mud ingress.

- The valve structure features grooved oil channels and a composite port design, effectively reducing noise and abnormal sounds.

- Speed-sensitive power assist: The controller adjusts motor assist according to vehicle speed and steering torque signals, providing light steering at low speeds and stability at high speeds.

- Active return-to-center control: The controller detects steering wheel angle and uses the motor to actively restore the wheel to center – a function not achievable by traditional hydraulic systems.

- Performance and fault monitoring: The controller includes a self-diagnostic function. In case of malfunction, it sends alerts to the instrument panel and communicates error data via CAN to the main controller.

- Emergency steering: If hydraulic assist fails during driving, the motor can provide 100% steering assist temporarily, allowing the vehicle to safely pull over.

| Item | Technical Parameters | Item | Technical Parameters |

| Cylinder diameter | Ø117 | Working temperature | -40℃ ~105℃ |

| Transmission force | (21.64-24.67):1 | Operating voltage range | DC24V±20% |

| Maximum working pressure | 17 MPa | Static current | ≤0.1A |

| Output angle | ±47° | Dark current | ≤0.001A |

| Total steering turns | 6.15 | Angle & torque sensors | VALEO TAS(±1224°) |

| Structure type | Non-through type | Communication method | CAN Bus |

| Worm gear ratio | 20.5:1 | Motor rated speed | 1800 rpm / 1000 rpm |

| Center distance | 92 | Motor rated torque | 4 N.m / 7.98 N.m |

| Applicable front axle load | 9T | IP rating | IP6K9K |

| Applicable temperature range | -40℃ -105℃ | Protection functions | Under-voltage, over-voltage, overload, phase loss, short circuit, over-temperature, over-current, reverse connection, sensor failure, and other fault protections. |

| Applicable vehicle type | large bus, medium truck, heavy truck |

- The configuration shown is for reference only. For project-specific specifications and detailed parameters, please reach out to our team.

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >