Range Extender Systems

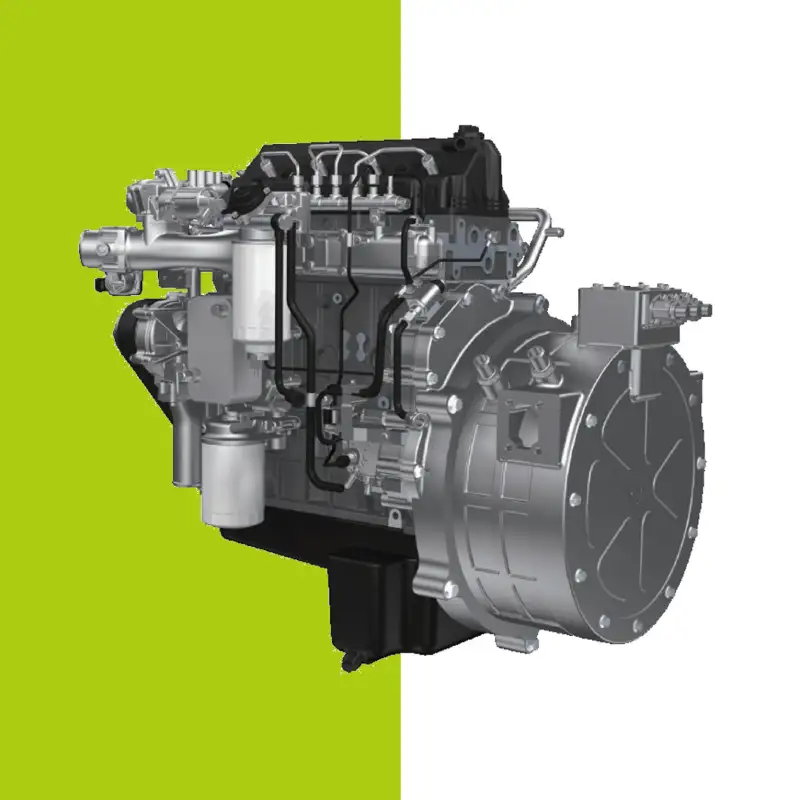

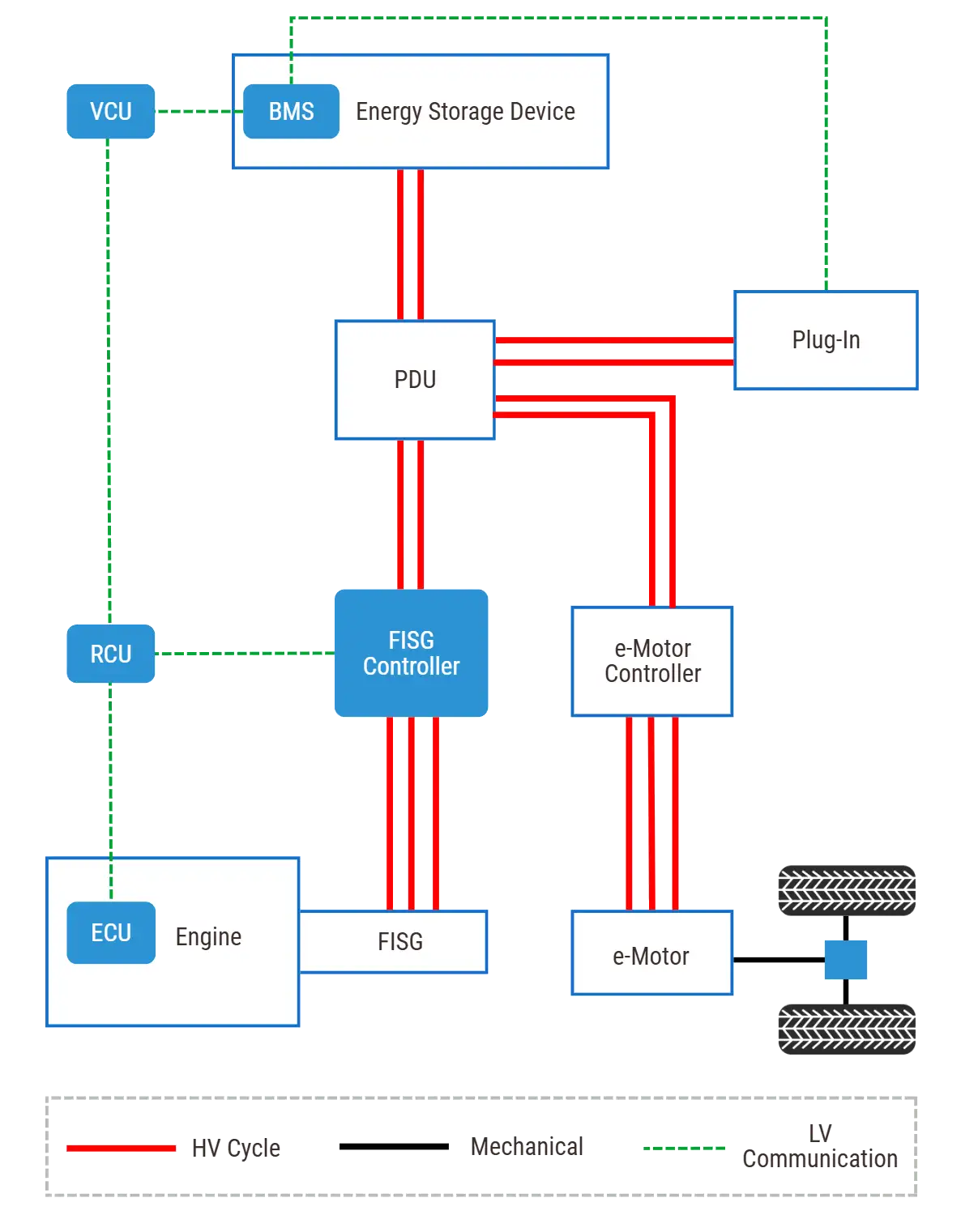

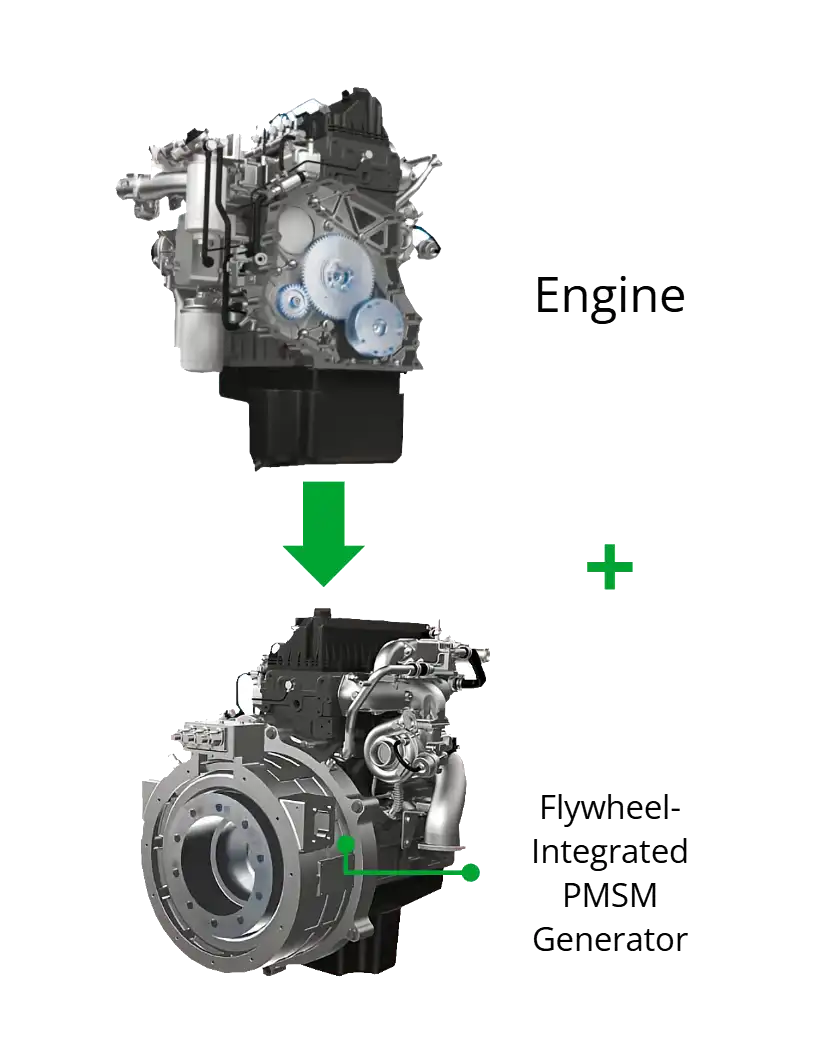

To support the electrification of commercial vehicles and off-highway machinery, we provide range extender systems engineered as tightly integrated electromechanical powertrain units. The system features a Flywheel-Integrated PMSM Generator, enabling high-efficiency electromechanical coupling and precise, coordinated hybrid control.

Compared with pure battery-electric vehicle architectures, our range extender systems effectively address range anxiety, charging-infrastructure limitations, and energy availability challenges in real-world operations. And relative to traditional ICE powertrains, vehicles equipped with our range extender systems offer significantly lower operating costs, while maintaining the durability and performance required for demanding duty cycles.

Email: contact@brogenevsolution.com

Why Range Extender Systems?

Range extender systems provide a practical solution for commercial and off-highway electric vehicles, combining the advantages of pure electric propulsion with the efficiency and flexibility of an onboard engine-generator unit. By mechanically decoupling the engine from the driveline, these systems enable high-efficiency operation, reduce battery requirements, and maintain BEV-like driving performance. The following key benefits highlight why range extenders are increasingly adopted in demanding commercial applications.

Mechanical Decoupling for Efficiency

The engine operates independently of wheel speed, running in its optimal efficiency zone to convert fuel to electricity effectively.

BEV Driving Experience

Pure electric propulsion ensures smooth, responsive driving, while the range extender system compensates for battery limitations in range, charging convenience, and energy density.

Smaller Battery, Lower Costs

Range-extended electric vehicles (REEVs) require smaller battery packs, reducing system cost, vehicle weight, and improving energy efficiency.

Ideal for Urban and Stop-and-Go Operations

Perfect for buses, sanitation trucks, and city distribution trucks, where frequent starts and stops benefit from electric drive efficiency.

Benefits for Off-Highway Applications

In construction, agriculture, mining, and port vehicles, regenerative braking recovers energy in heavy-duty cycles, while the range extender ensures operational continuity where charging infrastructure is limited.

Brogen EV Range Extender Systems Features

Flywheel-Integrated Motor Design

A high-efficiency, bearingless PM integrated directly with the flywheel eliminates maintenance requirements and enables a highly compact range extender system architecture. This design increases fuel-to-electric conversion efficiency by 20% and boost volumetric power density by 14%, reaching a leading international level.

Active Vibration Reduction

Through integrated structural and control optimization, the system achieves more than a 40% reduction in torque ripple, significantly improving smoothness and overall drivability.

Adaptive Multi-Objective Coordinated Control

With tightly integrated mechanical and control design, the system continuously learns external operating conditions and delivers coordinated optimization of fuel consumption, emissions, and NVH performance.

Applicable Models

Light Truck

Heavy Truck

Municipal Vehicle

Tractor

Shuttle Bus

City Bus

Ship

Our Range Extender Systems

*Parameters may differ depending on the configuration and vehicle model. Certain specifications can be customized. For more information, please contact us at contact@BrogenEVSolution.com

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Image |  |  |  |  |  |  |  |

| Dimension (L*W*H) | 813*670*791 mm | 1110*640*910 mm | 952*678*907 mm | 1140*820*1063 mm | 1384*793*1023 mm | 1675*1032*1213 mm | 1571*968*1277 mm |

| System Weight | 270 kg | 410 kg | 470 kg | 667 kg | 929 kg | 1100 kg | 1154 kg |

| Motor Rated/Peak Power | 65/80 kW | 75/95 kW | 100/125 kW | 150/170 kW | 200/240 kW | 250/290 kW | 300/320 kW |

| Peak System Efficiency | 4.06 kWh/L | 4.12 kWh/L | 4.09 kWh/L | 4.21 kWh/L | 4.11 kWh/L | 4.27 kWh/L | 4.41 kWh/L |

| Voltage Platform | 576 V | 576 V | 576 V | 600 V | 600 V | 600 V | 620 V |

| Output Voltage | 400-720 V | 400-720 V | 400-720 V | 400-720 V | 400-720 V | 400-720 V | 480-720 V |

| Cooling | Liquid cooling | Liquid cooling | Liquid cooling | Liquid cooling | Liquid cooling | Liquid cooling | Liquid cooling |

| Emission Level | China VI | T4 | China VI | China VI | T4 | T4 | T4 |

| Application | 4.5-8 ton trucks, 6-8 meter buses, coaches | Off-highway machinery, such as forklifts, loaders, and terminal tractors | 12-36 ton trucks, 8-12 meter buses, coaches | Cement mixers, municipal vehicles such as street sweepers, dump trucks | Mining trucks and other off-highway machinery | Mining trucks and other off-highway machinery | Mining trucks and other off-highway machinery |

Value for Clients

EV Platform Compatibility

- Range-extended electric vehicles (REEVs) can be developed directly on pure EV platforms, enabling highly efficient system integration.

- Share the battery and electric drive system with BEV models, and can be produced on the same manufacturing line, reducing production costs.

- A single platform can support both BEV and REEV configurations, allowing OEMs to serve different market requirements with mininal additional investment.

Intelligent Technologies Compatibility

- The range extender system integrates with intelligent energy-management algorithms, optimizing cooperation between the electric drive and the extender to maximize range and ensure the vehicle never runs out of usable power.

- OTA updates can continuously refine energy-distribution strategies, improving efficiency and enhancing the intelligent driving experience.

- Compatible with advanced autonomous-driving systems, enabling optimized extender engagement timing for smoother driving and improved ride comfort.

Case Studies

100 kW Range Extender System Application on 10.5 m Electric City Buses

Our 100 kW range extender system has been deployed on 10.5-meter city buses, generating up to 4.20kW·h/L of electricity per liter of fuel. This delivers up to 50% fuel savings and up to a 50% reduction in annual CO₂ emissions versus conventional diesel buses.

Compact, Efficient Engine

Features a small-displacement power unit that is lightweight, space-saving, and cost-effective, reducing both system mass and upfront expenses.

Lower TCO and Extended Range Confidence

Effectively mitigates the high cost, limited range, insufficient charging infrastructure, and battery degradation of pure BEVs - especially valuable in urban environments where land constraints make installing additional chargers challenging.

Smooth, Uninterrupted Operation

Eliminates torque interruptions from gear shifts, ensuring excellent drivability, strong regenerative braking, and a simpler system architecture, outperforming parallel or series-parallel hybrids in fuel efficiency under stop-and-go urban conditions.

Regulatory Compliance and Cost Efficiency

Supports operators in meeting road-access regulations and fuel-consumption limits while reducing overall operating costs.

| Historical operational data of conventional buses | |||||||

| Year | 2017 | 2018 | 2019 | 2020 | 2021 | 2022 | |

| Route | Model | Fuel Consumption per 100 km | |||||

| A | Small bus Euro III | 30.92 | 31.37 | 33.32 | 26.14 | 31.76 | 30.38 |

| B | Large bus Euro III | – | – | – | – | 41.92 | 42.30 |

| B | Large bus Euro IV | – | – | – | – | 35.69 | 36.55 |

| C | Small bus Euro V | 22.20 | – | – | – | – | – |

| C | Small bus Euro III | – | – | – | – | – | 40.99 |

| C | Small bus Euro III | 30.42 | 26.31 | 30.03 | 29.37 | 32.76 | – |

| Operational data of range-extended buses | ||||

| Route | Electricity generated per liter of fuel | Customer fuel-consumption data | Fuel consumption of conventional buses | Fuel-saving rate |

| C | 4.06 kWh/L | 15.2 L/100 km | 32.76 L/100 km | 53.6% |

| A | 4.17 kWh/L | 16.5 L/100 km | 30.38 L/100 km | 45.6% |

| B | 4.12 kWh/L | 20.9 L/100 km | 36.55 L/100 km | 42.8% |

- Actual fuel-saving rate of range-extended buses in operation: 42.8%–53.6%.

150 kW Range Extender System Application on 12 m³ Range-Extended Electric Concrete Mixer Trucks

From TCO (Total Cost of Ownership) to TOE (Total Operating Economy), our approach focuses on helping OEMs deliver superior operating efficiency to end customers through an optimally matched motor, battery, and engine system.

In concrete mixer trucks and muck trucks equipped with our range extender systems, operators achieve 30% to 40% or more in fuel savings, enabling a 1.5-year to 2-year payback period. This demonstrable economic advantage stands out, particularly in a challenging transport market, and provides OEMs with a highly competitive value proposition for their customers.

| Operating conditions | CHTC-D Loaded+unloaded | C-WTVC Loaded+unloaded | Mixing duty cycle Loaded+unloaded |

| Mileage | 16.95 km | 12.27 km | 27.45 km |

| Idling time ratio | 17.25% | 5.51% | 69.8% |

| Average driving speed | 28.56 km/h | 47.15 km/h | 15.60 km/h |

| Maximum driving speed | 73 km/h | 78 km/h | 42.34 km/h |

| Fuel consumption of the conventional chassis | 36.99 L/100 km | 37.57 L/100 km | 53.09 L/100 km |

| Fuel consumption of range-extended chassis | 30.24 L/ 100 km | 31.99 L/100 km | 38.58 L/100 km |

| Chassis fuel-saving rate | 18.2% | 14.9% | 27.3% |

| Electric mixer body fuel-saving rate | 15% | 15% | 15% |

| Total vehicle fuel-saving rate (range-extended) | 33.2% | 29.9% | 42.3% |

Actual fuel-saving performance of the range-extended concrete mixer truck in bench tests: 30%–42%.

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >