Integrated Electric Axles for Light Truck, Van, Minibus, Pickup

For EV builders developing electric light trucks, vans, minibuses, and pickup platforms, e-powertrain packaging, system efficiency, and cost control are core platform-level considerations. Electric axle architectures provide a practical approach to balancing these requirements within the limited space and weight constraints of light commercial vehicles.

Our electric axles for LCV applications integrate the traction motor, reduction gearbox, and drive axle into a compact, lightweight unit optimized for commercial vehicle duty cycles. By eliminating the traditional driveshaft and simplifying the drivetrain layout, this architecture frees chassis space for battery integratijon, improves drivetrain efficiency, and supports more straightfoward vehicle-level integration by customer engineering teams.

Email: contact@brogenevsolution.com

Electric Axle Architecture Optimized for LCV Platforms

Reduced Vehicle Integration Cost

By eliminating traditional drivetrain components such as the driveshaft and associated mounting structures, the eAxle architecture simplifies vehicle installation compared with centralized motor layouts used in LCVs. This simplified drivetrain layout reduces installation effort and associated integration costs at the vehicle level.

Parallel-Axis eAxle Structure

In a parallel-axis eAxle configuration, torque is transmitted along a straight power path without redirection. This allows the drivetrain to rely on cylindrical gear stages rather than bevel gears. The resulting reduction in gear mesh losses and improved torque continuity support higher utilization of regenerative braking.

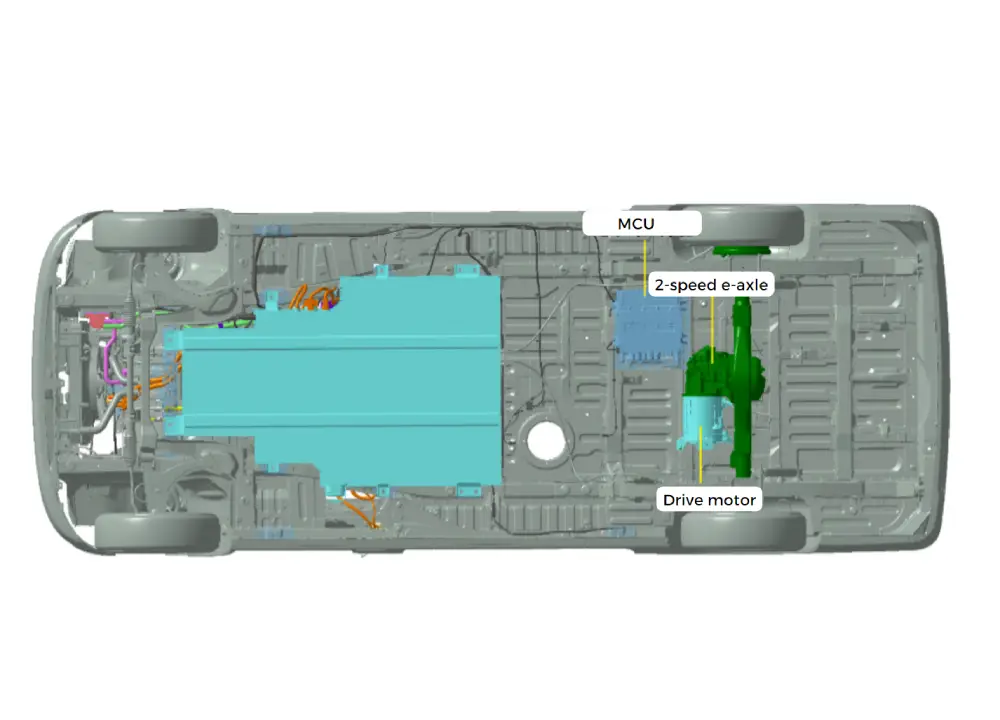

Compact Rear-Drive ePowertrain Layout

The compact eAxle design supports rear-mounted, rear-wheel-drive configurations for light trucks, as well as short rear-overhang layouts for buses. By consolidating drivetrain components at the axle, this architecture frees chassis space for battery pack placement and can reduce overall system weight compared with conventional configurations.

Applicable Models

Pickup Truck

Mini Truck

Van

Mini Bus

Brogen LCV Electric Axle Specifications & Platform Compatibility

Designed for light commercial vehicle platforms, our parallel-axis electric axles integrate the traction motor and reduction gearbox directly into the axle housing. By using a high-ratio cylindrical gear transmission and eliminating unnecessary drivetrain components, the architecture achieves a compact layout, improved mechanical efficiency, and simplified vehicle-level integration for customers with in-house engineering capability.

- The configurations shown are representative reference designs. Specifications may vary depending on vehicle architecture and performance requirements. Customization is available. Please contact us for detailed technical information: contact@BrogenEVSolution.com

| Reference Configuration | Target Vehicle Segment | Axle Load Rating | Motor Rated / Peak Power | Motor Rated / Peak Torque | Max. Wheel Output Torque |

| LCV eAxle-A | 1.8-3.5 t truck; 1.8-3.5 t van | 2000 kg | 30/70 kW | 90/230 N.m | 2415 N.m |

| LCV eAxle-B | van, mini bus, pickup truck, mini truck | 2500 kg | 30/70 kW | 80/230 N.m | 2415 N.m |

| LCV eAxle-C | 4.5-6 t truck; 5-6 m bus | 2700 kg | 60/115 kW | 135/350 N.m | 5400 N.m |

| LCV eAxle-D | MPV, pickup, mini truck, van, large SUV | 2200/3100/3500 kg | 100/175 kW | 200/400 N.m | 4500 N.m |

| LCV eAxle-E | 4 t truck; 6 m bus | 3000-3500 kg | 80/180 kW | 170/355 N.m | 4496 N.m |

| LCV eAxle-F | 4.5-6 t truck; 6 m bus | 3500 kg | 60/120 kW | 145/335 N.m | 5300 N.m |

| LCV eAxle-G | 3.5-4.5 t truck; 5-6 m bus | 3500 kg | 60/120 kW | 150/360 N.m | 5774 N.m |

| LCV eAxle-H | 4.5-6 t truck; 5-6 m bus | 4000 kg | 65/130 kW | 135/288 N.m | 5740 N.m |

| LCV eAxle-I | 4.5-6 t truck; 6 m bus | 4500 kg | 80/160 kW | 175/400 N.m | 6640 N.m |

| LCV eAxle-J | 8 t truck | 4000-5500 kg | 65/120 kW | 170/355 N.m | 5775 N.m |

| LCV eAxle-K | 4.5-8 t truck; 6-8 m bus | 5000 kg | 65/130 kW | 135/288 N.m | 5748 N.m |

| LCV eAxle-L | Light truck; 7-8 m coach | 5000 kg | 2×60/2×120 kW | 2×145/2×400 N.m | 2×4272 N.m |

Integrated One-Piece Formed Axle Housing (Expansion-Formed)

High load-bearing capacity, lightweight design, and reduced risk of oil leakage.

Optimized Housing & Lubrication Design

A single-piece housing minimizes oil leakage risks, while a smooth, curved inner cavity reduces oil churning losses.

High-Precision Two-Stage Helical Gear Transmission

Features dual-surface precision grinding for improved efficiency, lower noise, and extended lifespan.

Compact Motor - Axle Integration

Minimizes offset distance between the motor and axle housing, further reducing the risk of oil leakage at the reducer interface.

Platform-Based Development Process

- Vehicle duty cycle & road profile data analysis

- Requirement definition & system architecture design

- Simulation, bench testing & vehicle validation

- Small-batch pilot & final verification

Key Engineering Focus Areas

- Power & efficiency optimization

- Reliability, NVH & comfort

- Functional safety & protection

- Sealing, lubrication & thermal management

- Compact e-axle layout enabling flexible chassis integration

- Lightweight architecture improving energy efficiency and payload potential

- Low-noise, precision-ground gears enhancing driving comfort

- High transmission efficiency reducing energy consumption

- Extending maintenance intervals (100,000 km oil change)

- Real-time monitoring of key components for enhanced operational safety

Controller Architecture Options

- Standalone MCU

- High-voltage integrated controller (MCU+PDU+DC/DC+steering & braking interfaces)

Note: Controllers are usually supplied as part of the electric powertrain system and are not sold separately.

Key Control & Safety Capabilities

- IS26262 compliant (ASIL C)

- Dual-inverter control (up to 98.5% peak efficiency)

- Modular & scalable architecture

- Digital simulation & optimization

- Advanced EMC design (Class 5 under no-load conditions)

Why An Electric Axle Solution for Your LCV Platform?

Central Direct Drive Layout

Motor (or+ Reducer) → Universal Driveshaft → Traditional Drive Axle Assembly (Main Reducer + Differential + Half Shafts) → Wheels

Same structure as the drivetrain of fuel-powered vehicles: use the drive motor to replace the engine. To increase the installation space for the battery pack, the size of the driveshaft is usually reduced and power is transmitted through the original vehicle’s drive axle.

- Short development time but high manufacturing cost.

- Takes up a lot of space in the X-direction, making battery placement difficult.

- Placing the battery up front creates an axle load imbalance, making the front heavier.

- The drive system isn't very light.

Electric Axle Solution Layout

Motor → Drive Axle Assembly (Cylindrical Gear Main Reducer + Differential + Half Shafts) → Wheels

Take the 2.34 T logistic van as an example, the motor and the gearbox are integrated onto the rear axle, allowing for easy installation. This integration reduces the number of components required by 11 types and slashing the overall weight by about 33 kilograms.

- High integration: compact structure, efficient transmission.

- Fully release the X-direction space under the floor, conducive to battery layout.

- Due to the small space occupied, it's convenient to adjust the axle load of the whole vehicle.

- The overall performance is superior.

- For most light commercial vehicle platforms requiring high payload, cost control, and scalability, the electric axle solution provides the best balance between performance and system simplicity.

Our LCV Electric Axle Gallery

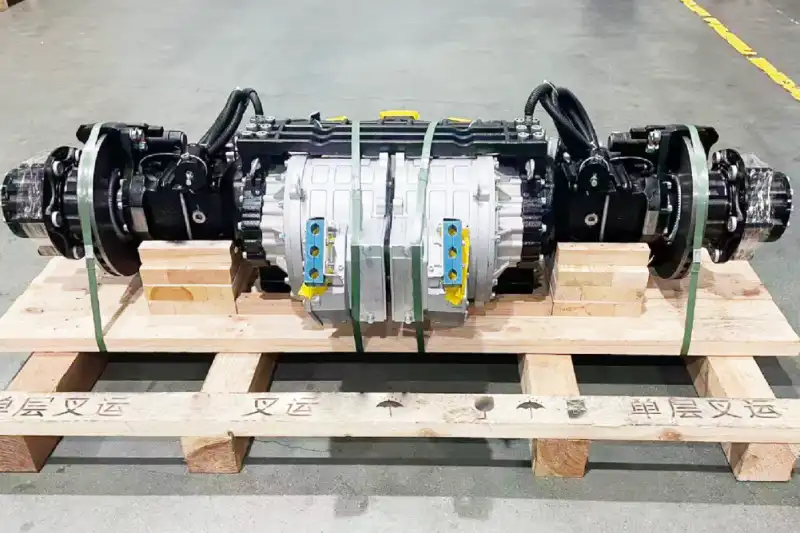

Our electric axles for light trucks have been validated through large-scale deployment in light commercial vehicle fleets across global markets. Currently in mass production, these systems are widely applied in light trucks, cargo vans, pickup trucks, and municipal vehicles, delivering proven reliability and performance in real-world use and supporting rapid scale-up for OEM programs.

120 kW, 3500 kg eAxle

2x120 kW, 5000 kg eAxle

LCV e-Axle - Sample Delivery

LCV e-Axle - Sample Delivery

LCV eAxle - Finished Products Delivery

LCV e-Axle - Large Scale Supply

115 kW, 3500 kg eAxle

115 kW, 3500 kg eAxle

How We Work

Navigating Our Process

Demand Analysis & Project Evaluation

Once we receive your inquiry, our experts will connect with you within two business days to understand your specific requirements for the EV solution and conduct an initial feasibility evaluation of your project.

Project & Technical Coordination

If the project is deemed feasible, our engineering team will collaborate closely with your team on both hardware and software aspects to develop a viable solution. We will also provide a detailed quotation based on the technical requirements.

Development, Manufacturing & Testing

For customized or modified systems, we proceed with product development, including hardware and software adaptations. Our EV systems undergo rigorous testing to ensure quality, reliability, and full functionality before deployment.

In-Time Global Shipping & Delivery

We have established strong partnerships with international shipping providers, ensuring safe and timely delivery of products to your specified location. This guarantees a smooth and efficient deployment of your EV project.

Full-Stage Remote/Onsite Technical Support

We provide technical support throughout the entire project lifecycle, including consultancy, hardware and software development, calibration, and both onsite and remote debugging, ensuring optimal performance and long-term success.

Frequently Asked Questions (FAQs)

Our LCV e-axle solutions are designed for a wide range of light commercial vehicles, including light trucks, cargo vans, pickup trucks, minibuses, and light logistics vehicles. Performance parameters can be tailored to meet specific vehicle platform requirements.

Our LCV e-Axle platform typically supports axle load ratings from approximately 2.0 to 5.5 tons for light commercial vehicle applications. Final axle load capability can be configured based on vehicle architecture, duty cycle, and performance targets.

Compared to EDU-based independent drivetrains, our e-Axle solution features a simpler mechanical architecture with fewer components and interfaces. This results in reduced system mass, lower vehicle integration complexity, and improved drivetrain efficiency under higher vehicle loads, making it particularly well-suited for commercial vehicle applications.

Our LCV e-Axles integrate a high-efficiency PMSM traction motor with a parallel-axis reduction gearbox utilizing high-precision helical gears. Motor power, torque output, voltage level, and gear ratios can be configured to match specific application requirements.

Yes. Key parameters such as motor power, torque, voltage, gear ratio can be customized within the existing e-Axle platform. For requirements beyond current platform boundaries, additional engineering development may be required.

The integrated design of the e-Axle simplifies vehicle integration by reducing the number of mechanical interfaces. This helps OEMs and other EV builders shorten development timelines, lower integration risk, and reduce overall vehicle integration costs.

Yes. Our LCV e-Axle platforms have been validated through simulation, bench testing, and vehicle-level evaluation. Similar configurations have been adopted by OEMs and deployed in real-world light commercial vehicle applications.

To evaluate platform suitability, we typically require information such as target axle load, vehicle mass, performance requirements, duty cycle, suspension layout, and packaging constraints. Based on these inputs, a tailored e-Axle solution can be proposed.

Development and delivery timelines depend on project maturity and the level of customization required. Platform-based configurations can significantly shorten development cycles compared to clean-sheet designs.

We offer standard or extended warranty options depending on the product and project requirements. For bulk orders, spare parts support can be arranged in advance to minimize downtime and ensure efficient handling of warranty cases.

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >