Electric Truck Powertrain: Central Drive Motor vs. Rear Electric Drive Axle

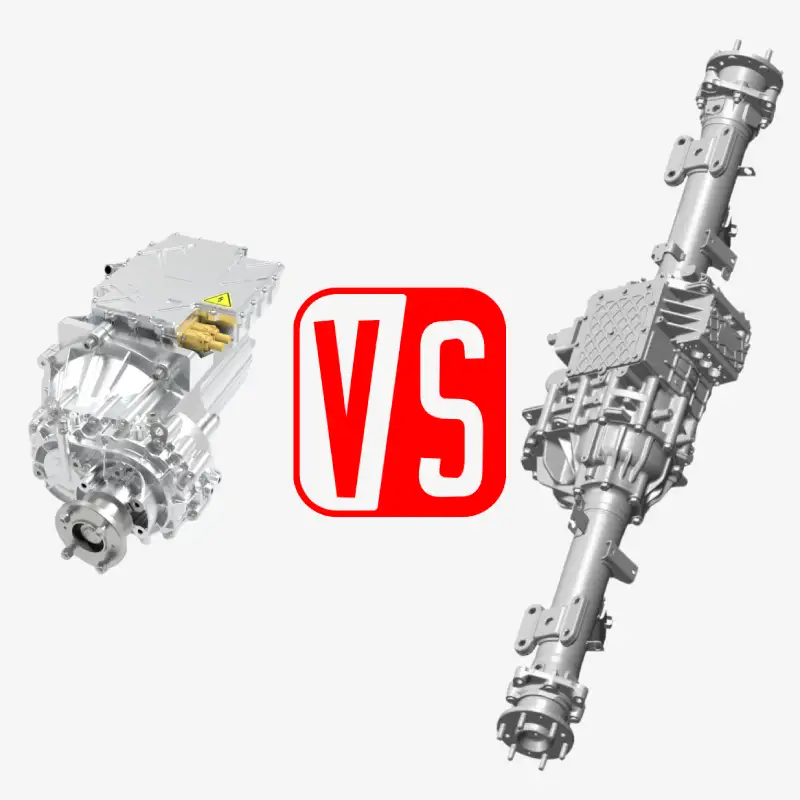

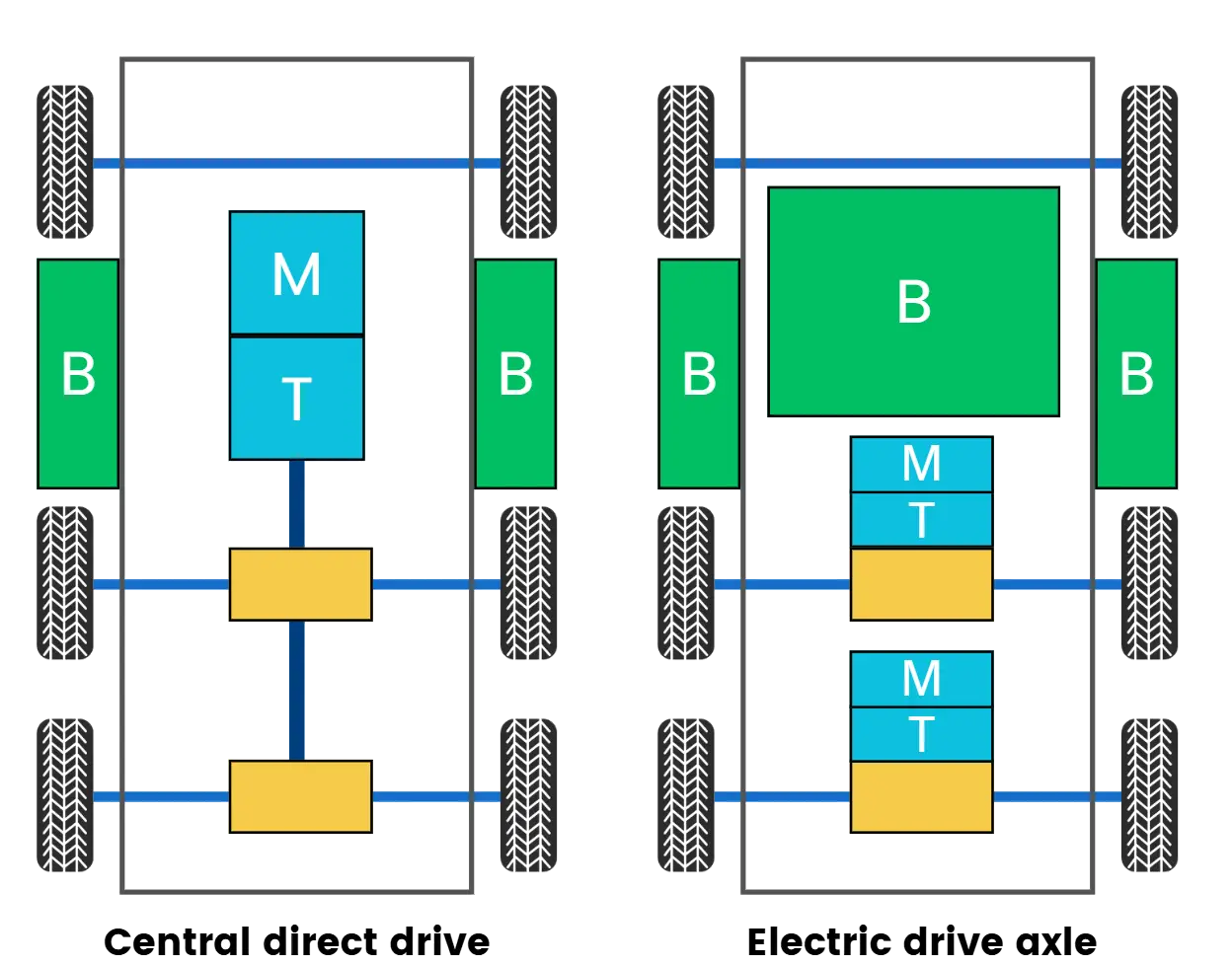

For modern battery-electric trucks, selecting the right electric truck powertrain is critical for balancing efficiency, payload, and reliability. Two main approaches dominate today’s EV truck market: traditional central drive systems and integrated rear electric drive axles (e-axles).

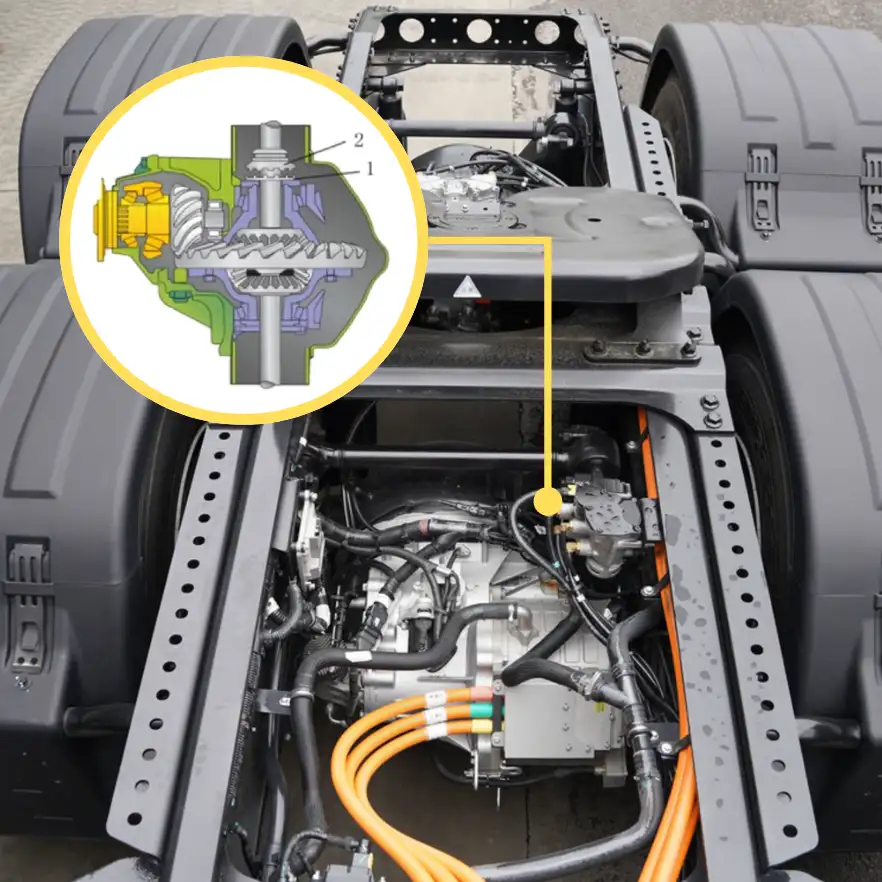

Traditional Truck Powertrain Structure - Central Drive System

A central drive system typically features an EV motor coupled with a reducer (gearbox) that amplifies torque before transmitting power through a driveshaft to the rear axle. This setup resembles conventional truck powertrains and is well-suited for heavy-duty applications requiring high torque and flexible gearing.

How It Works:

- Motor output: The EV motor generates high-speed, low-torque power.

- Torque amplification: The reducer increases torque for heavy-duty operations.

- Power transmission: Torque travels through a driveshaft to the rear axle.

- Final drive: The rear axle delivers power to the wheels.

While reliable and mature, central drive systems add weight and occupy chassis space, which can reduce available room for batteries or other vehicle components.

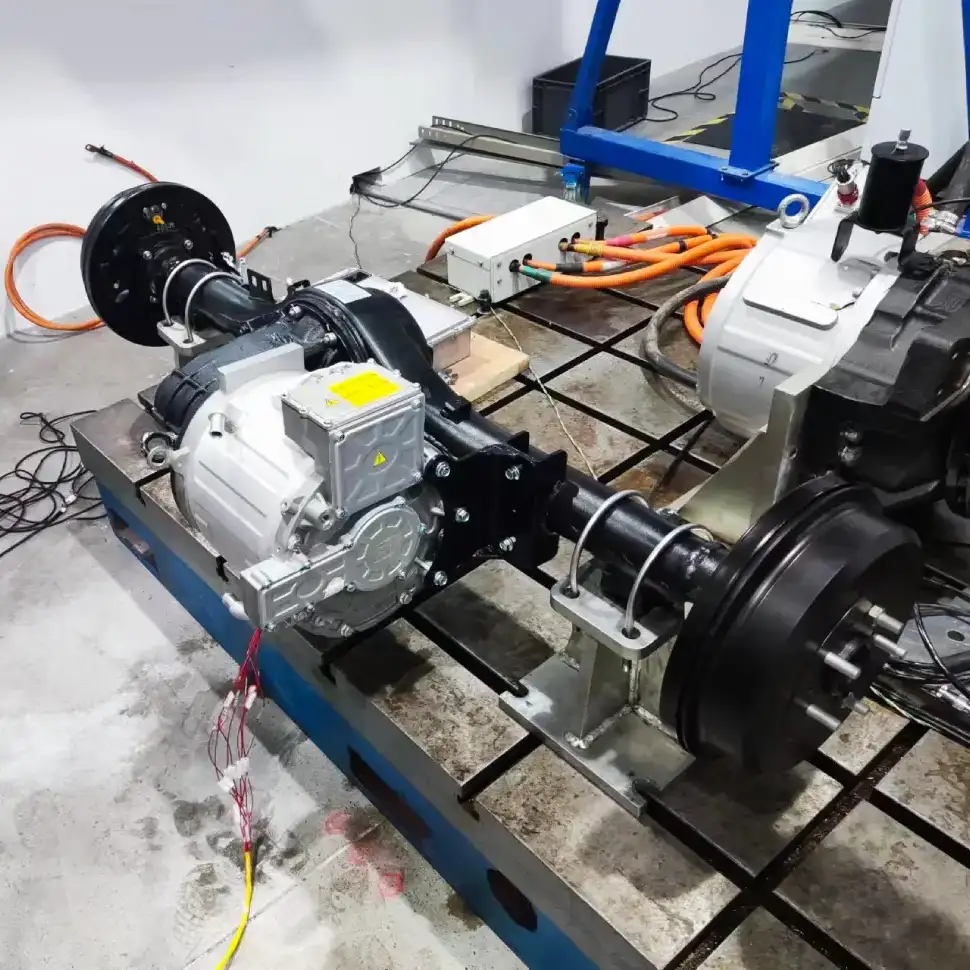

Electric Drive Axle (E-Axle)

The e-axle integrates the EV motor, rear axle, transmission, and differential into a single compact unit, representing a modern electric truck powertrain solution.

Key Advantages:

- Weight reduction: Eliminates the driveshaft and separate reducer, allowing higher payloads.

- Improved efficiency: Direct power delivery to the axle reduces energy loss and extends vehicle range.

- Space optimization: Frees chassis space for additional batteries or systems.

- Simplified design: Fewer mechanical components reduce maintenance needs and improve reliability.

Considerations:

E-axles are optimized for efficiency and simplicity but may have lower peak torque compared to central drive systems with large reducers. High-power e-axles require careful design and thermal management.

Choosing the Right Electric Truck Powertrain

Fleet operators and OEMs should select the appropriate electric truck powertrain based on operational needs:

- Central drive systems excel in heavy-duty applications requiring high torque and multi-speed gearing.

- E-axles are ideal for medium-duty and logistics trucks where weight savings, efficiency, and packaging flexibility are critical.

Understanding these trade-offs ensures that electric trucks achieve optimal peformance, range, and uptime.

Brogen Electric Truck Powertrain Solutions

At Brogen, we offer a comprehensive range of electric truck powertrain solutions, tailored for various vehicle models and applications.

- Explore our central drive solutions here: https://brogenevsolution.com/electric-motors-for-truck/

- Explore our electric truck axle solutions here: https://brogenevsolution.com/electric-axle-for-truck/

- Business inquiry: contact@BrogenEVSolution.com

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >