Electric Semi-Truck

As heavy-duty trucks accelerate toward electrification, drivetrain architecture has become a key determinant of performance, efficiency, and platform scalability. Electric axles for trucks integrate the traction motor, transmission, and drive axle into a compact, high-efficiency system—replacing traditional motor, driveshaft, and axle layouts.

We offer a comprehensive range of electric axle solutions for trucks, covering both centralized drive e-axle and distributed drive e-axle architectures. Designed for diverse truck platforms and duty cycles, our eAxle systems deliver high torque density, strong efficiency, and flexible integration. Most solutions are already in mass production and globally deployed, providing OEMs with a proven, production-ready foundation for electric heavy-duty vehicles.

Electric axles enable a fundamental shift from diesel-based or retrofit electric truck architectures to purpose-built electric platforms. By eliminating the central driveshaft and consolidating the drivetrain into the axle, electric axle systems unlock new possibilities for chassis layout optimization.

Electric axle solutions supporting truck platforms from Class 1 to Class 8, including tractor-trailers and electrified trailers.

Modular designs compatible with high-voltage platforms, enabling customization for power, axle load, and duty cycle requirements.

Advanced monitoring, diagnostics, and protection strategies ensure safe and stable operation under demanding commercial vehicle conditions.

Both centralized and distributed drive eAxle architectures are available, allowing OEMs to select the optimal solutions.

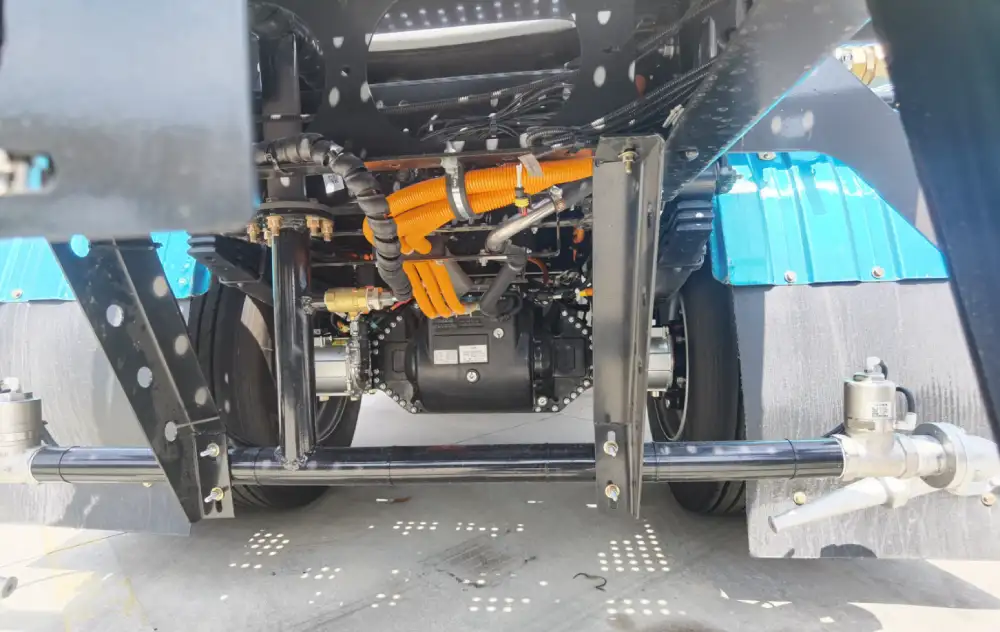

The centralized electric axles for trucks feature one or two high-speed motors, high-ratio reducers, and an integrated axle in a compact X-in-1 design, replacing traditional direct-drive systems (motor+driveshaft+axle). This integration improves transmission efficiency and optimizes chassis space, addressing key challenges in electric heavy truck design.

*Parameters may differ depending on the configuration and vehicle model. Certain specifications can be customized. For more information, please contact us at contact@BrogenEVSolution.com

| Reference Configuration | Truck eAxle-A | Truck eAxle-B | Truck eAxle-C | Truck eAxle-D | Truck eAxle-E-1.5 | Truck eAxle-E-1.6 | Truck eAxle-F-1 | Truck eAxle-F-2 |

|  |  |  |  |  |  |  | |

| Rated axle load capacity | 6000 kg | 8500 kg | 9500 kg | 10000 kg | 13000 kg | 13000 kg | 13000 kg | 13000 kg |

| Speed ratio | 16.473 | 20.475 | 19.22 | 55.2/17.24 | 13.2/4.4 | 13.2/4.4 | 1st: main transmission 71.0+auxiliary transmission 46.8 2nd: main transmission 36.3+auxiliary transmission 46.8 3rd: main transmission 20.0+auxiliary transmission 13.2 4th: main transmission 10.2+auxiliary transmission 13.2 | |

| Motor rated/peak power | 100/200 kW | 80/160 kW | 200/320 kW | 200/320 kW | 121/250 kW | 135/290 kW | 150/252 kW*2 | 190/310 kW*2 |

| Motor rated/peak torque | 220/426 N.m | 200/450 N.m | 350/750 N.m | 350/750 N.m | 320/850 N.m | 326/860 N.m | 285/550 N.m | 280/590 N.m |

| Brake type | Pneumatic disc type | Pneumatic disc type | Pneumatic disc type | Pneumatic disc type | Drum brake | Drum brake | Drum brake φ410*220; disc brake 22.5″ | Drum brake φ410*220; disc brake 22.5″ |

High load-bearing capacity, lightweight design, and reduced risk of oil leakage.

A single-piece housing minimizes oil leakage risks, while a smooth, curved inner cavity reduces oil churning losses.

Features dual-surface precision grinding for improved efficiency, lower noise, and extended lifespan.

Minimizes offset distance between the motor and axle housing, further reducing the risk of oil leakage at the reducer interface.

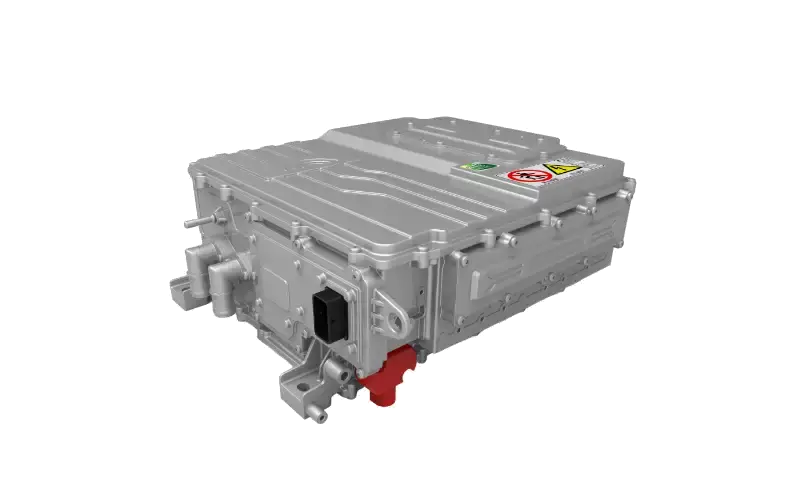

According to clients’ different requirements, we can provide standalone MCUs or high-voltage integrated controller systems, integrating MCU, PDU, DC-DC, and steering and braking DC/AC.

Note: Controllers are usually supplied as part of the electric powertrain system and are not sold separately.

Functional safety requirements and software/hardware development meet ASIL C standards.

Combines functional and physical integration to significantly reduce size, weight, and manufacturing costs.

Minimizes losses and achieves a maximum efficiency of 98.5%.

Designed for flexibility and easy expansion.

Uses digital modeling for simulation analysis, enabling more efficient and cost-effective component selection.

Multi-stage filtering, optimized wiring layout, enhanced shielding, and structural improvements ensure Class 5 compliance under no-load conditions.

Designed for high-load and high-performance applications, distributed drive electric axles integrate dual motors directly with the axle, enabling independent torque control on each side.

*Parameters may differ depending on the configuration and vehicle model. Certain specifications can be customized. For more information, please contact us at contact@BrogenEVSolution.com

| Model | Truck eAxle-G-1 | Truck eAxle-G-1 |

|  | |

| Cooling Method | Liquid-Cooled | Oil-Cooled |

| Rated axle load capacity | 11500/13000/16000 kg | |

| Maximum output torque | 2×27262 N.m | 2×22397~25740 N.m |

| Motor rated/peak power | 2×80/180 kW | 2×200/300 kW |

| Maximum wheel speed | 615 rpm | |

| Brake type | Air disc/drum brakes | |

| Gear ratio | 61.955/19.18 | |

| Weight | 856~950 kg (depending on the configuration) | |

| Rated voltage | 600 VDC | 600/800 VDC |

| Suspension type | Air suspension / Leaf spring | |

| PTO | Optional integrated PTO | |

Our electric axle solutions are designed for a wide range of applications, including 4×2 electric semi-trucks, 6×4 tractors, various heavy-duty trucks, electric trailers, mining trucks, and battery electric municipal vehicles such as electric street sweepers, water tankers, and garbage trucks.

These systems have been exported to markets such as the UAE, Brazil, Canada, and more, where they operate reliably in real-world conditions, including logistics, port terminals, and industrial transport.

All major electric axle solutions are already in mass production and ready for large-scale global deployment.

Electric Semi-Truck

Electric Trailer

Electric Truck

Electric Trailer

Battery Electric Truck

18T Electric Municipal Vehicle

4x2 Electric Truck

4x2 Battery Swapping Truck

Finished E-Axles Mass Delivery

Finished E-Axles Mass Delivery

eAxle Delivery

eAxle Delivery

How We Work

Once we receive your inquiry, our experts will connect with you within two business days to understand your specific requirements for the EV solution and conduct an initial feasibility evaluation of your project.

If the project is deemed feasible, our engineering team will collaborate closely with your team on both hardware and software aspects to develop a viable solution. We will also provide a detailed quotation based on the technical requirements.

For customized or modified systems, we proceed with product development, including hardware and software adaptations. Our EV systems undergo rigorous testing to ensure quality, reliability, and full functionality before deployment.

We have established strong partnerships with international shipping providers, ensuring safe and timely delivery of products to your specified location. This guarantees a smooth and efficient deployment of your EV project.

We provide technical support throughout the entire project lifecycle, including consultancy, hardware and software development, calibration, and both onsite and remote debugging, ensuring optimal performance and long-term success.

Electric axles are best suited for truck platforms where chassis packaging, drivetrain efficiency, and system simplification are key design objectives. They can be applied in electric semi-trucks, tractors, tippers, municipal vehicles, and electric trailers, especially when flat battery layout, lower center of gravity, or reduced mechanical complexity is required.

Yes. Our electric axle solutions are platform-based but configurable, allowing customization of key parameters such as motor power, voltage level, and control strategy.

For projects aligned with our existing platforms, customization can be achieved with limited development effort, reducing project risk and timeline.

Compared to traditional central-drive layouts, electric axles significantly reduce vehicle integration complexity by eliminating the driveshaft and consolidating powertrain interfaces. OEM involvement typically focuses on suspension integration, mounting interface definition, cooling routing, adn vehicle-level calibration.

Most of our electric axle solutions are already in mass production and deployed globally. The architectures, key components, and control strategies have been validated through bench testing, vehicle testing, and long-term real-world operation, making them suitable for series-production projects rather than prototype-only projects.

Our electric axles for trucks are engineered for high axle loads, frequent start-stop cycles, and demanding environments such as ports, construction sites, and mining operations. Architecture selection (centralized vs. distributed drive) allows optimization for torque delivery, redundancy, and thermal robustness under heavy-duty duty cycles.

Compared with conventional motor + driveshaft + axle layouts, electric axles enable better packaging, lower system complexity, and improved efficiency, particularly on purpose-built electric truck platforms. The benefits become more pronounced as vehicle electrification levels increase and platform integration deepens.

To evaluate suitability, we typically require information on axle load rating, target torque and power, duty cycle, vehicle mass, voltage platform, and packaging constraints. Based on this, we can propose an appropriate electric axle architecture and configuration.

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Respond within 1 business day

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

Follow us for regular updates >

Ev systems introduction & industry insights >