Coaxial eAxle for Light Trucks: Technology Overview and Performance Analysis

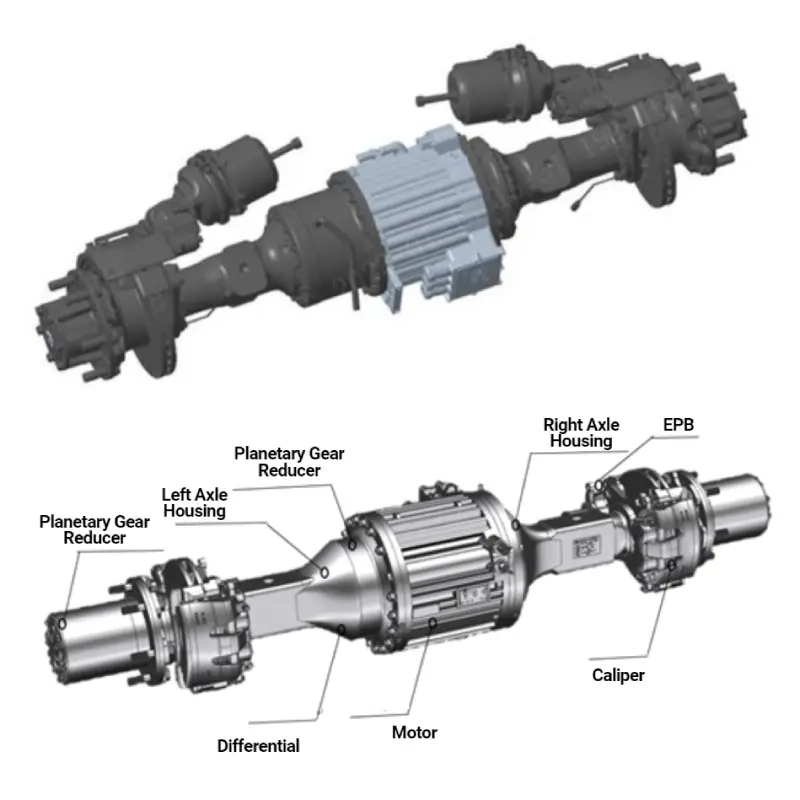

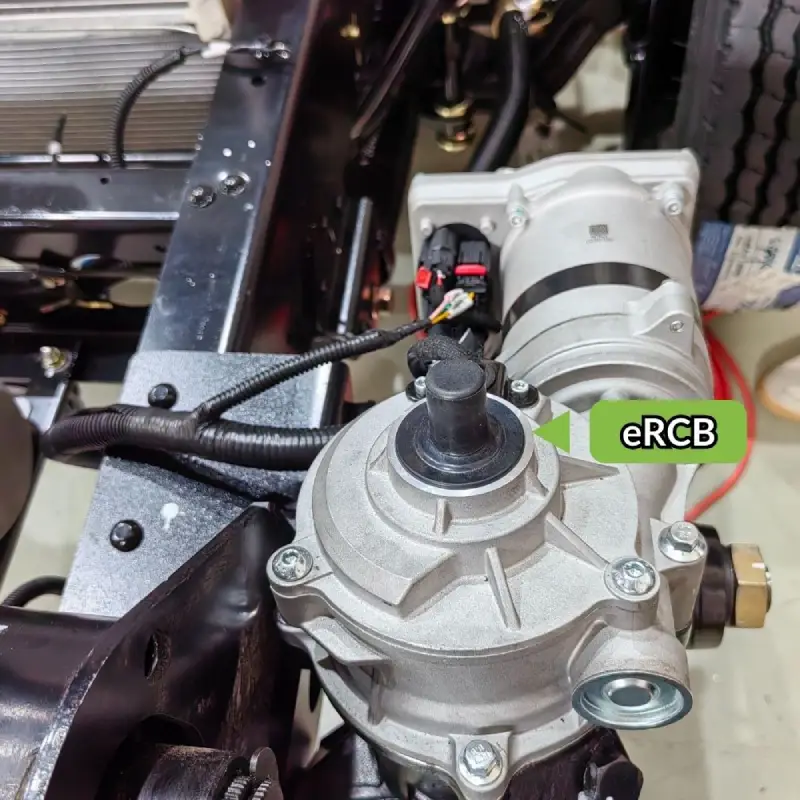

Coaxial eAxle for Light Trucks: Technology Overview and Performance Analysis Traditional fuel-powered trucks reply on a complex drivetrain consisting of an engine, clutch, transmission, driveshaft, and axle. This setup is not only heavy but also has low transmission efficiency. Early electric trucks often adopted a “retrofit” approach, replacing the engine and transmission with a motor and reducer. However, this direct-drive solution was both costly and inefficient. With the growing understanding of electric truck design and the need to lower costs, reduce energy consumption, and lighten vehicle weight, the industry is shifting toward integrated electric drivetrains. Today, many small and light-duty electric trucks are equipped with a coaxial eAxle. A coaxial eAxle integrates the motor, planetary reducer, differential, and axle housing into a single, compact unit, significantly shortening the drivetrain, reducing parts, and simplifying structure. This system offers traction, braking, and efficient energy conversion while ensuring higher transmission efficiency than direct-drive systems. It also features automatic transmission and regenerative braking, which help extend driving range by recovering energy. Advantages of Brogen Coaxial Drive eAxle Over Central Motor Direct-Drive At Brogen, we provide coaxial drive eAxles, suitable for electric light duty trucks. They have the following advantages: Structural Efficiency:The coaxial drive eAxle combines the motor, planetary reducer, differential, and axle housing in one integrated unit, creating a short drivetrain with fewer parts and a simpler structure. In contrast, the direct-drive approach requires separate motor, reducer, driveshaft, and axle assemblies, resulting in a longer, more complex drivetrain. Space Efficiency: The coaxial design is highly integrated, freeing up valuable chassis space and simplifying the assembly process. Direct-drive systems, on the other hand, require space for multiple components, complicating the overall vehicle layout. Energy Efficiency: With a direct-drive and planetary reduction transmission, the coaxial eAxle achieves an overall transmission efficiency of ≥94%, while traditional direct-drive systems fall below 90% due to a longer drivetrain and additional components. Transmission Process: In the coaxial system, power from the battery drives the motor shaft, which in turn powers the differential and planetary reducer to move the wheels. Direct-drive systems use the motor torque to drive a longer sequence of parts, resulting in lower efficiency. Weight Advantage: Coaxial drive axles are 10-25% lighter than direct-drive systems, reducing energy consumption, increasing motor speed capacity, and offering a higher power density, which extends range. Direct-drive systems are bulkier and lower in power density. Technical Superiority: Coaxial eAxles support a high level of regenerative braking and align with future trends in drivetrain integration. Direct-drive systems, by contrast, offer lower levels of integration and energy recovery. Maintenance Benefits: Coaxial drive eAxles have fewer components, which simplifies maintenance and reduces lifecycle costs. Direct-drive systems, with more parts, tend to have more complex maintenance requirements. In sum, the coaxial electric drive axle offers a highly integrated, efficient, and cost-effective solution for electric light trucks, aligning well with the industry’s movement towards compact, high-performance e-powertrains that maximize both range and durability. Discover our e-axle solutions here: https://brogenevsolution.com/electric-axle-system/ Contact Us Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days. Email: contact@brogenevsolution.com Respond within 1 business day Whatsapp: +8619352173376 Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri. LinkedIn channel Follow us for regular updates > YouTube channel Ev systems introduction & industry insights > ContactFill in the form and we will get in touch with you within 2 business days.Please enable JavaScript in your browser to complete this form.Please enable JavaScript in your browser to complete this form. Name * FirstLast Work Email *Company Name *Your Project Type *– Please select –Car, SUV, MPVBus, coach, trainLCV (pickup truck, light-duty truck, etc.)HCV (heavy-duty truck, tractor, trailer, concrete mixer, etc.)Construction machinery (excavator, forklift, crane, bulldozer, loader, etc.)Vessel, boat, ship, yacht, etc.Others (please write it in the note)Your Interested Solutions *– Please select –Motore-AxleBatteryChassisAuxiliary inverterOBC / DCDC / PDUAir brake compressorEPS / EHPS / SbW / eRCBBTMSOthers (please write it in the note)Do you have other contact info? (Whatsapp, Wechat, Skype, etc.)Please introduce your project and your request here. * Checkbox * I consent to receive updates on products and events from Brogen, and give consent based on Brogen’s Privacy Policy. Submit