Centralized Electric Drive Axle Solution for Trucks

As truck electrification moves beyond pilot projects and into large-scale production, OEMs and EV builders are increasingly focused on production-proven electric drive axle solutions that offer reliable performance, predictable costs, and long-term durability. Our electric drive axle solution for trucks is built on platforms that have already entered SOP and mass deployment, supporting 4.5-ton to 49-ton light-, medium-, and heavy-duty truck applications.

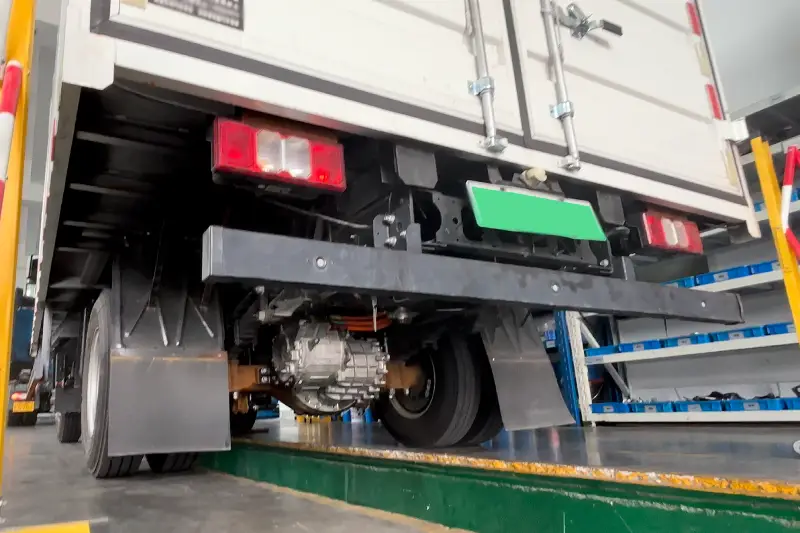

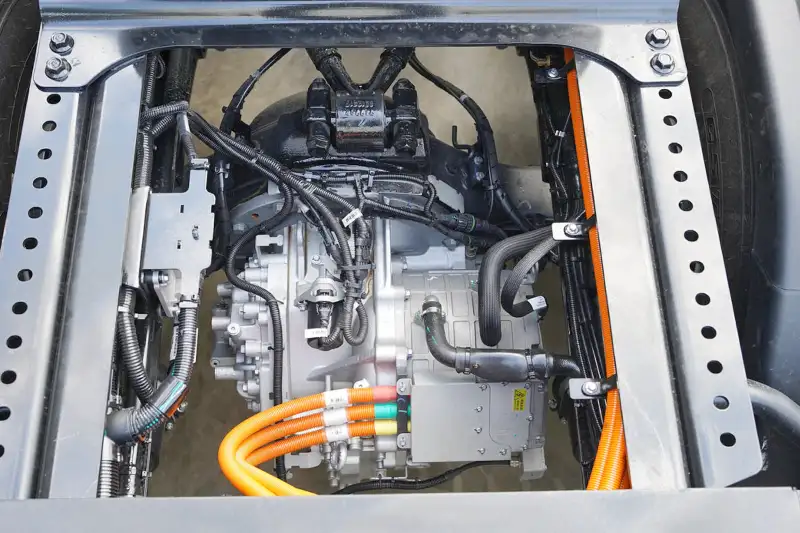

Based on a centralized, highly integrated e-axle architecture, this solution delivers high reliability and stability under demanding operating conditions. Designed with an emphasis on system integration and lightweight optimization, it improves overall drivetrain efficiency while giving OEMs the flexibility to adapt the system across different truck platforms and use cases.

Email: contact@brogenevsolution.com

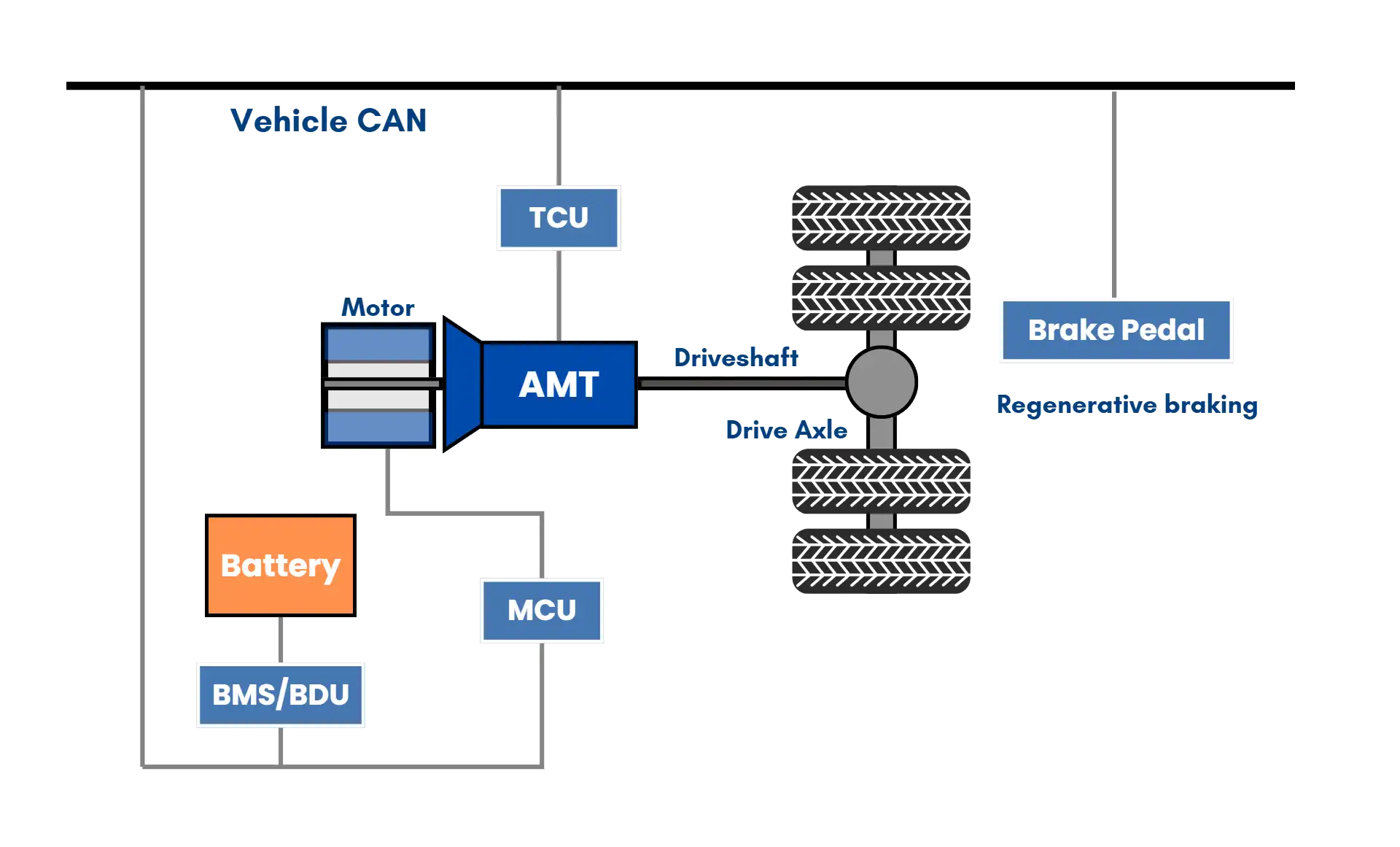

Electric Truck Powertrain Architecture Considerations

Conventional Motor + Transmission + Axle

Typically considered when:

- Proven mechanical layouts and long-term durability are prioritized

- Existing chassis and driveline architecture are retained

- Fast deployment with minimal system redesign is required

Key characteristics:

- Mature and easy to implement

- Lower integration, limited regenerative braking efficiency

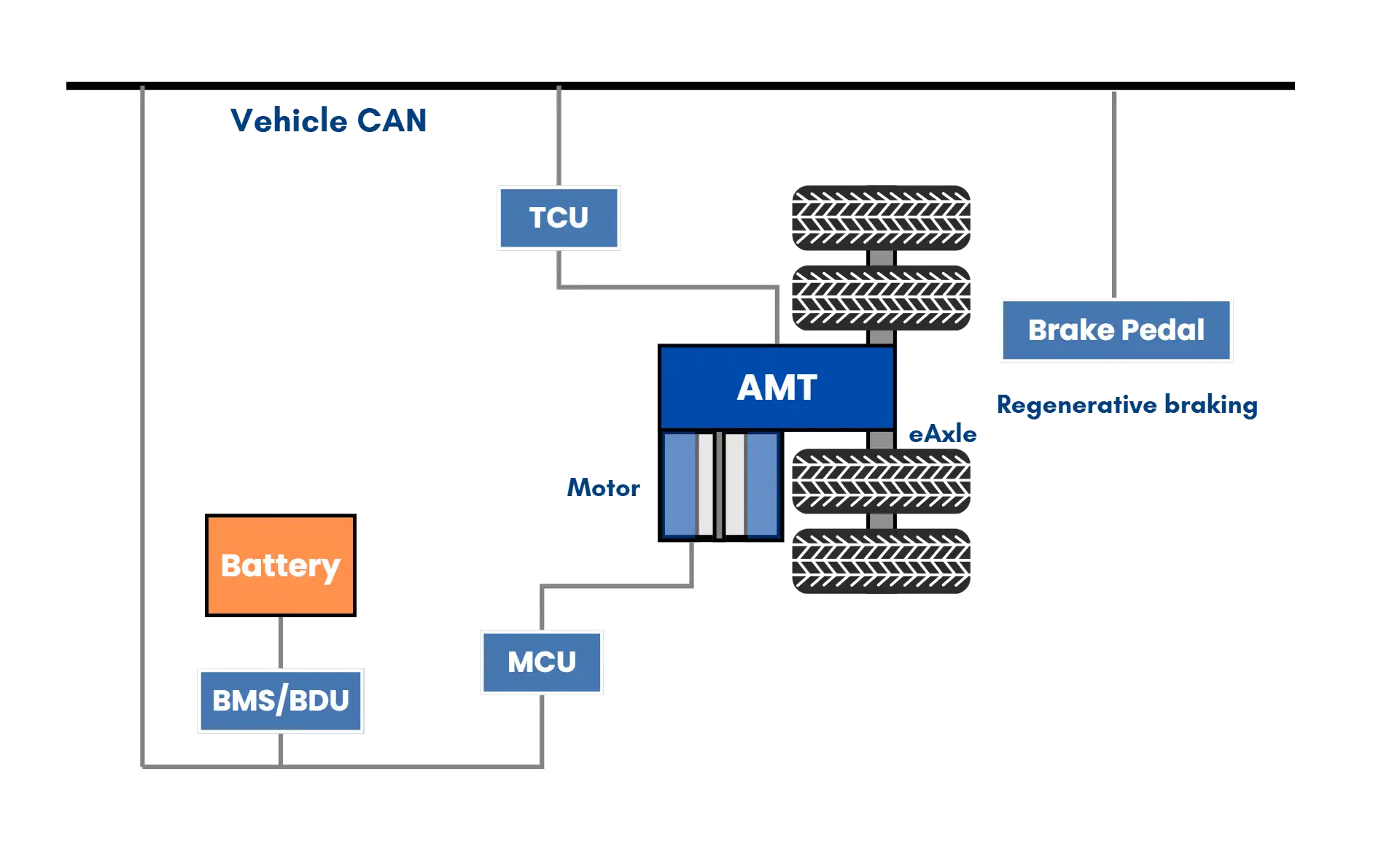

Integrated Centralized Electric Drive Axle

Typically considered when:

- System-level integration and efficiency are prioritized

- Packaging simplicity and battery space optimization are critical

- OEMs target scalable electric platforms for series production

Key characteristics:

- High integration of motor, transmission, and axle

- Simplified drivetrain layout with improved energy efficiency

When to Choose a Centralized Electric Drive Axle Solution

Centralized electric truck axles are a strong choice when the operating profile and platform objectives align with the following conditions. If your project matches most of the criteria below, this architecture is typically a rational and low-risk option.

Resource Transportation (Aggregates, Coal, Ore)

A centralized electric drive axle is a good fit when:

- Operating routes are predictable and combine loading yards with regional roads, highways, or expressways

- Uneven road conditions are localized, without sustained deep ruts or extreme ground clearance risks

- The project targets a balanced trade-off between acquisition cost, efficiency, and durability

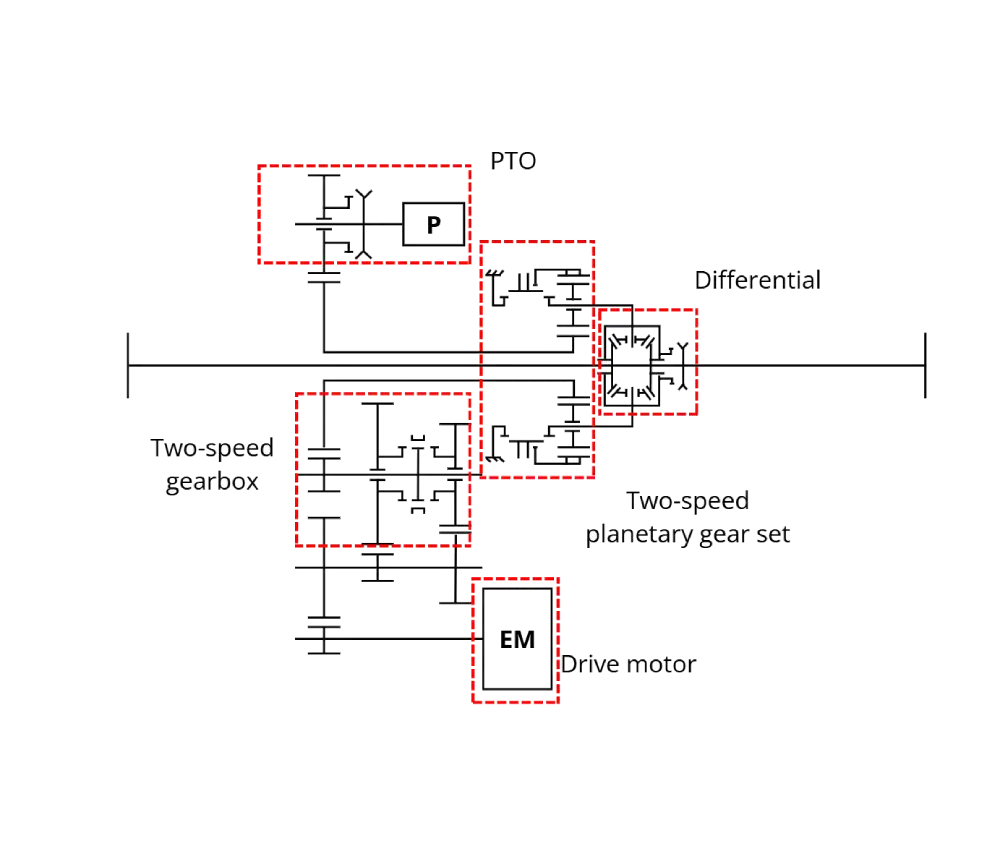

Key decision signals:

- Ground clearance should be >260 mm at axle level

- PTO integration is needed for tipping or hydraulic systems

- Multi-speed gearbox (3-4 speeds) is required to cover start-up, gradients, and cruising

Express & Line-Haul Logistics

A centralized electric drive axle is a good fit when:

- Vehicles operate primarily on highways with stable road conditions and limited surface variability

- Annual mileage is high, making energy efficiency a primary cost driver

- Duty cycles are consistent, with limited extreme-grade requirements

Key decision signals:

- Energy consumption per kilometer is a critical KPI

- 2-speed transmission is sufficient due to limited steep climbing

- Lightweight drivetrain design supports efficiency-focused operation

Engineering Advantages of Our Centralized Electric Drive Axle Solution for Trucks

Broad Platform Coverage

Electric axle solutions supporting truck platforms from Class 1 to Class 8, including tractor-trailers and electrified trailers.

Scalable Architecture

Modular designs compatible with high-voltage platforms, enabling customization for power, axle load, and duty cycle requirements.

Proven Reliability

Advanced monitoring, diagnostics, and protection strategies ensure safe and stable operation under demanding commercial vehicle conditions.

Cost Efficiency

Shared components with existing centralized drive platforms reduce part complexity and achieve lower amortized system cost.

Applicable Models

- Applicable to light- and heavy-duty trucks ranging from 4.5 t to 49 t

Brogen Centralized Electric Axle Specifications & Platform Compatibility

- The configurations shown are representative reference designs. Customization is available depending on vehicle architecture and performance requirements. Please contact us for detailed technical information: contact@BrogenEVSolution.com

| Reference Configuration | Target Vehicle Segment | Axle Load Rating | Motor Rated/Peak Power | Motor Rated/Peak Torque | Max. Wheel Output Torque |

| LCV eAxle-F | 4.5-6 t truck | 3500 kg | 60 kW / 120 kW | 145 N.m / 335 N.m | 5300 N.m |

| LCV eAxle-I | 4.5-6 t truck | 4500 kg | 80 kW / 160 kW | 175 N.m / 400 N.m | 6640 N.m |

| Truck eAxle-E-1.5 | 6×4 / 4×2 truck | 13000 kg | 121 kW / 250 kW | 320 N.m / 850 N.m | 40000 N.m |

| Truck eAxle-E-1.6 | 6×4 / 4×2 truck | 13000 kg | 136 kW / 290 kW | 326 N.m / 860 N.m | 40000 N.m |

| Truck eAxle-H | 6×4 / 4×2 truck | 13000 kg | 150 kW / 252 kW | 285 N.m / 550 N.m | 39089 N.m |

| Truck eAxle-F-1 | 6×4 / 4×2 truck | 13000 kg | 150 kW / 250 kW*2 | 285 N.m / 550 N.m | 45000 N.m |

| Truck eAxle-F-2 | 6×4 / 4×2 truck | 13000 kg | 190 kW / 310 kW*2 | 280 N.m / 590 N.m | 45000 N.m |

Technical Highlights of Brogen Centralized Electric Drive Axle Solutions

Efficiency

- Fewer drivetrain stages with no hub reduction

- Eliminates spiral bevel main reduction gears for higher transmission efficiency

- Supports up to 100% regenerative braking capability

- Planetary shifting architecture reduces oil churning speed, resulting in lower lubrication losses

Reliability

- One-piece rigid axle housing provides high structural strength and load-bearing capability

- Proven lubrication concept using mechanical pump + splash lubrication, ensuring reliability under heavy-duty operating conditions

Integration & Flexibility

- Supports PTO and hydraulic pump integration

- Multiple gearing options available, including single-motor 4-speed and dual-motor combined 6-speed configurations

- Standardized axle housing platform enables dual-, triple-, and quad-motor vehicle layouts

- Compatible with disc brakes, drum brakes, and low-friction hub units, depending on vehicle requirements

Cost Optimization

- Wide gear ratio coverage reduces motor torque demand at low speeds and motor speed at cruise

- Enables the use of lower-current (450 A) inverters, lowering overall system cost

- Modular architecture improves serviceability and lowers lifecycle maintenance cost

Validation & Application Status

- SOP-ready platform, already in series production and supplied to domestic OEMs, with vehicles in real-world operation

- Component & system-level DV testing completed, including fatigue durability, lubrication performance, temperature rise, high-speed operation, efficiency, no-load losses, axle housing batch validation, and full-axle water immersion testing

- Vehicle-level validation completed, including 12,000 km enhanced durability testing on proving grounds, 1,000 m rough-road testing, over 5,000 test cycles, and loaded vehicle field operation

Frequently Asked Questions

This solution is applicable to light- to heavy-duty trucks from 4.5 t to 49 t, covering a wide range of use cases including resource transport, regional haul, and highway logistics applications.

Yes. The axle is designed as a modular and standardized platform, supporting dual-, triple-, and quad-motor configurations, multiple gear options, and various braking options for the vehicle.

Yes. The solution supports PTO and hydraulic pump integration, making it suitable for applications such as dump trucks and other vocational vehicles that require auxiliary hydraulic functions.

The wide gear ratio spread reduces motor torque demand at low speeds and motor speed at cruise, enabling the use of low-current (e.g. 450 A) inverters. Combined with high component commonality and modular design, this helps OEMs achieve lower drivetrain and lifecycle costs.

Yes. For trucks operating primarily on highways with stable road conditions, the centralized electric drive axle delivers strong efficiency, durability, and cost advantages, making it well-suited for high annual mileage logistics operations.

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >