Compact Wheel Loader Electrification Solutions

At Brogen, we offer compact wheel loader electrification solutions, designed to strike a balance between performance, efficiency, and sustainability.

- Cable-electric loader solution: Best suited for operations with long working hours and fixed work sites, ensuring continuous power supply without downtime.

- Fully electric loader solution: Ideal for mobile operations across varied job sites, offering high mobility, zero local emissions, and lower noise levels.

Whether for urban construction, logistics yards, or industrial plants, our electrified systems deliver reliable power, optimized efficiency, and a cleaner working environment – helping clients move toward a more sustainable future in heavy equipment.

Email: contact@brogenevsolution.com

Why Drive Compact Wheel Loader Electrification?

1. Reduce fuel costs

Industry data shows that the energy efficiency ratio between diesel and electric loaders is roughly 1:3 - meaing the same workload that requires 1 liter of diesel consumes about 3 kWh of electricity. For example, a 5-ton loader typically burns around 12 liters of diesel per hour, while an electric model performing the same work consumes about 36 kWh. Under normal operating conditions, converting a 5-ton loader from diesel to electric can save operators up to ~ $USD 40,000 in annual fuel costs - depending on local fuel prices.

2. Lower maintenance and service costs

After electrification, the loader eliminates the engine and traditional drivetrain components, significantly reducing maintenance demands. Routine servicing and part replacements drop by over 60%. Moreover, diesel engines operating long hours at idle or in dusty environments tend to lose stability after around five years. Electrification greatly improves long-term reliability, simplifies maintenance, and reduces lifecycle costs.

3. Save time and increase uptime

Traditional diesel loaders require frequent refueling during continuous operation, often interrupting workflow. In contrast, electric loaders enable fast charging and high efficiency. Take a 5-ton loader equipped with a 282 kWh LFP battery - it can operate for about 5 hours per charge. With a 240 kW charger, a full charge takes just 1 hour; with a 320 kW charger, charging time drops to under 40 minutes.

Brogen Compact Wheel Loader Electrification Solutions

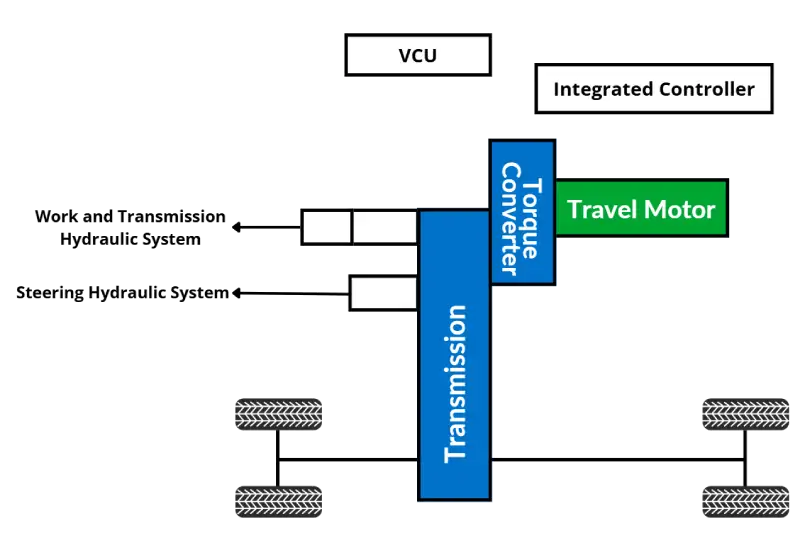

1. Fully Electric Wheel Loader – Single-Motor Solution Overview

In this solution, the engine is replaced by an electric motor, while the hydraulic torque converter is retained. Other auxiliary components originally mounted on the engine are reselected and reconfigured accordingly.

- Engine

- Engine intake and exhaust system

- Air-conditioning compressor

- Generator

- Air pump

- Fan

→

- Motor, motor controller, and battery

- PTC heater

- Air-conditioning compressor

- Generator

- Air pump

- LV electric fan

- Brackets, cooling system, and other auxiliary components

The system uses a dual-shaft motor – one side connects to the torque converter and transmission, while the other side drives the air-conditioning compressor, generator, and air pump via a belt pulley. This configuration minimizes system changes and achieves the lowest overall cost, making it an efficient and practical approach to compact wheel loader electrification.

2. Fully Electric Wheel Loader – Single-Motor Solution Details

* Note: Solutions shown are for reference only. Final design depends on the model and working conditions.

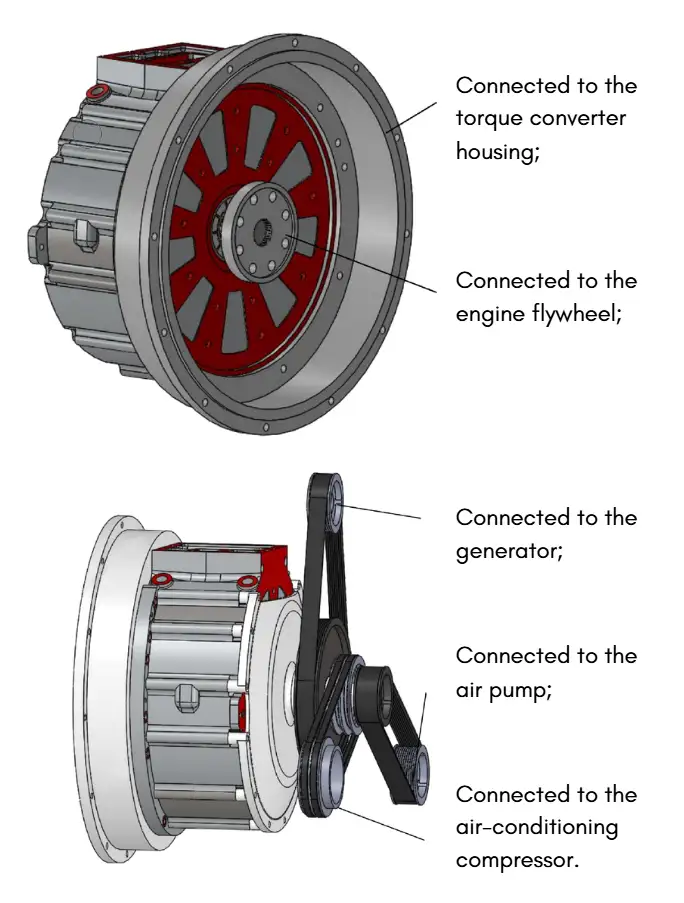

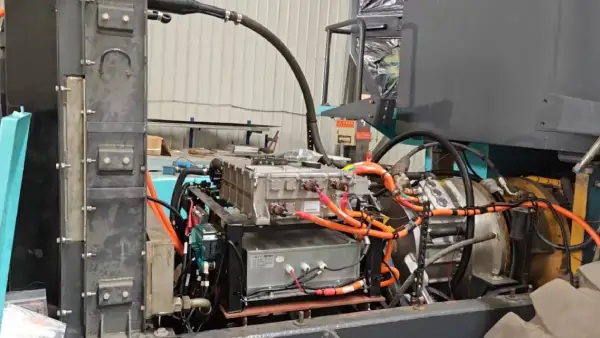

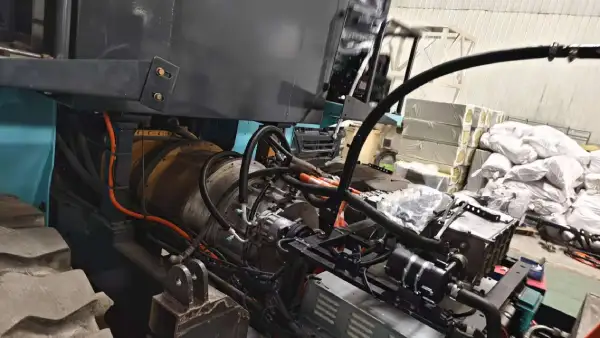

- The motor’s outer transition flange directly connects to the torque converter housing, making it compatible with most 5-ton loader models.

- The motor output shaft connects to the original vehicle flywheel via an adapter shaft, which is then linked to the torque converter’s flex plate – maintaining the same interface as the original engine.

- The rear output of the motor drives the generator, air-conditioning compressor, and air pump via belt transmission, ensuring normal operation of the vehicle’s low-voltage electrical, air-conditioning, and braking systems.

| Motor Type | PMSM |

| Rated Voltage | 600 VDC |

| Rated/Peak Power | 150/215 kW |

| Rated/Peak Torque | 650/1300 N.m |

| Rated/Peak Speed | 2200/5500 rpm |

| Cooling Method | Liquid cooling |

| IP Rate | IP68 |

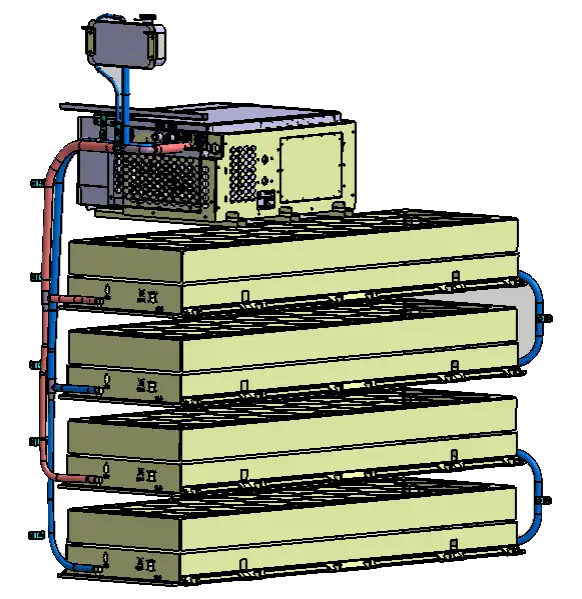

Adopting an integrated control design, the system integrates the main drive motor controller, PDU, and other functional modules into a single unit. This high level of integration saves installation space and simplifies system layout.

| Controller Input Voltage Range | DC 400 V – 750 V |

| Main Drive Module | 800 A |

| Rated AC Output Current | 245 A |

| Peak AC Output Current | 570 A |

| PDU | PTC heating |

The battery system has a capacity of 282 kWh, allowing approximately 5 hours of continuous operation under full-charge conditions. It can be fully recharged in 1 hour. Additionally, the battery capacity can be customized according to customer requirements.

| Battery Cell Type | LFP |

| Nominal Voltage | 614.4 V |

| Operating Voltage Range | 480 – 700.8 V |

| Nominal Capacity | 460 Ah |

| Total Energy | 282 kWh |

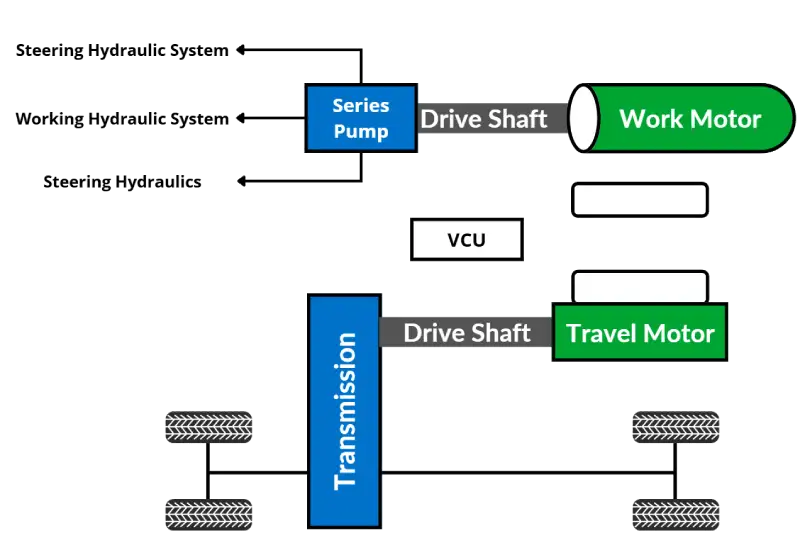

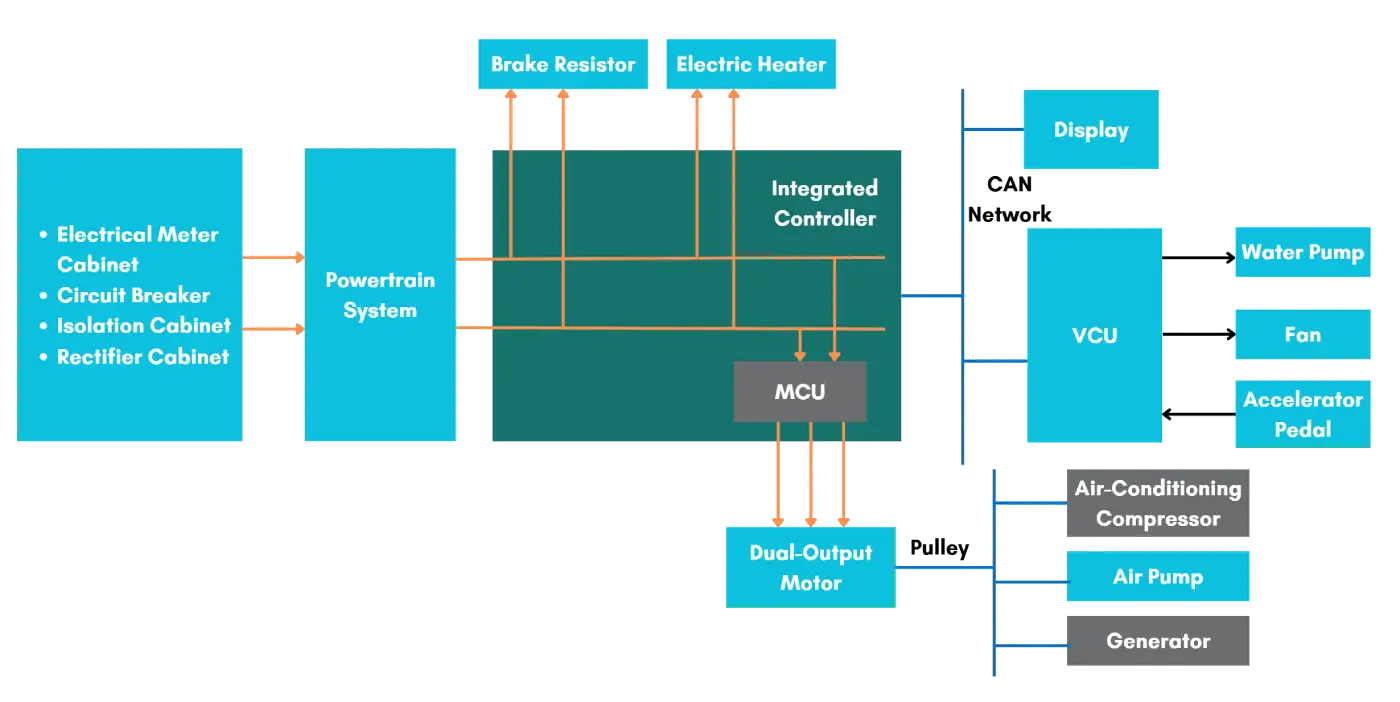

3. Cable-Electric Loader Solution - System Architecture

Navigating Our Process

Demand Analysis & Project Evaluation

Once we receive your inquiry, our experts will connect with you within two business days to understand your specific requirements for the EV solution and conduct an initial feasibility evaluation of your project.

Project & Technical Coordination

If the project is deemed feasible, our engineering team will collaborate closely with your team on both hardware and software aspects to develop a viable solution. We will also provide a detailed quotation based on the technical requirements.

Development, Manufacturing & Testing

For customized or modified systems, we proceed with product development, including hardware and software adaptations. Our EV systems undergo rigorous testing to ensure quality, reliability, and full functionality before deployment.

In-Time Global Shipping & Delivery

We have established strong partnerships with international shipping providers, ensuring safe and timely delivery of products to your specified location. This guarantees a smooth and efficient deployment of your EV project.

Full-Stage Remote/Onsite Technical Support

We provide technical support throughout the entire project lifecycle, including consultancy, hardware and software development, calibration, and both onsite and remote debugging, ensuring optimal performance and long-term success.

Gallery

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >