Electric Motor Solutions for Commercial Vehicles

We provide electric motor solutions for commercial and industrial applications, including buses, trucks, marine vessels, and specialty vehicles. Our portfolio is built on standardized and mass-produced motor platforms, covering centralized direct-drive motors, integrated e-powertrains (motor+transmission+controller), and high-power dual-motor solutions for heavy commercial vehicles.

Most of our EV motors are already in mass production and widely deployed by OEMs worldwide, offering proven reliability, durability, and consistent performance under real-world commercial operating conditions. By focusing on platform-based solutions with practical engineering adaptability, we enable customers to accelerate electrification while minimizing development risk, cost, and time-to-market.

Email: contact@brogenevsolution.com

Why Choose Brogen Electric Motor Solutions for Commercial Vehicles?

Pickup Truck

LCV

Heavy Truck

Car

Tractor

Shuttle Bus

City Bus

Vessel

Mature and Stable Motor Control

Our electric motors adopt validated motor control strategies that deliver precise and stable speed, torque, and position control. These control algorithms have been proven across multiple commercial applications, ensuring predictable behavior and smooth operation under real-world working conditions.

Consistent Quality and Long-Term Reliability

Supported by an MES-based manufacturing and quality management system, our motors benefit from standardized production processes, traceability, and strict quality control. This ensures consistent product performance and long-term operational stability across production batches.

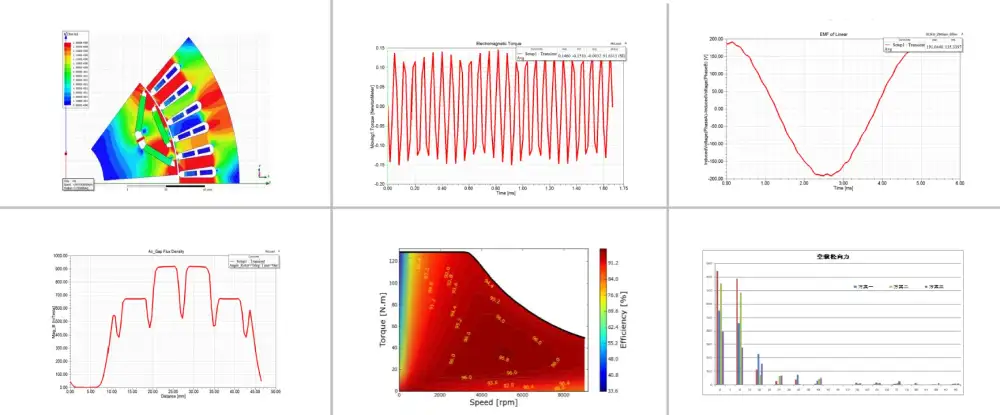

Efficiency Optimized for Commercial Duty Cycles

Rather than focusing on peak laboratory efficiency, our motors are designed to maintain high efficiency across typical commercial operating ranges. With system efficiency exceeding 90% in real-world use, they help reduce energy consumption and operating costs throughout the vehicle lifecycle.

Compact and Practical Lightweight Design

By leveraging permanent magnet motor architectures and optimized structural design, our EV motors achieve high power density while maintaining robustness. This allows efficient packaging and flexible integration without compromising durability for heavy-duty applications.

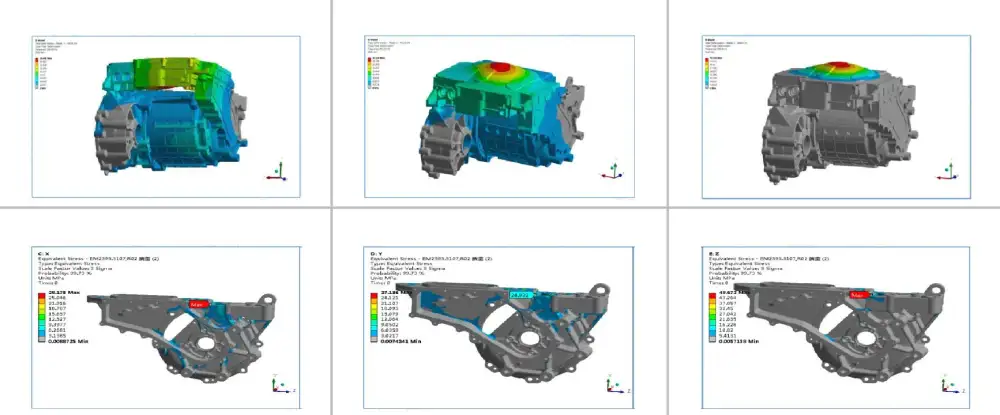

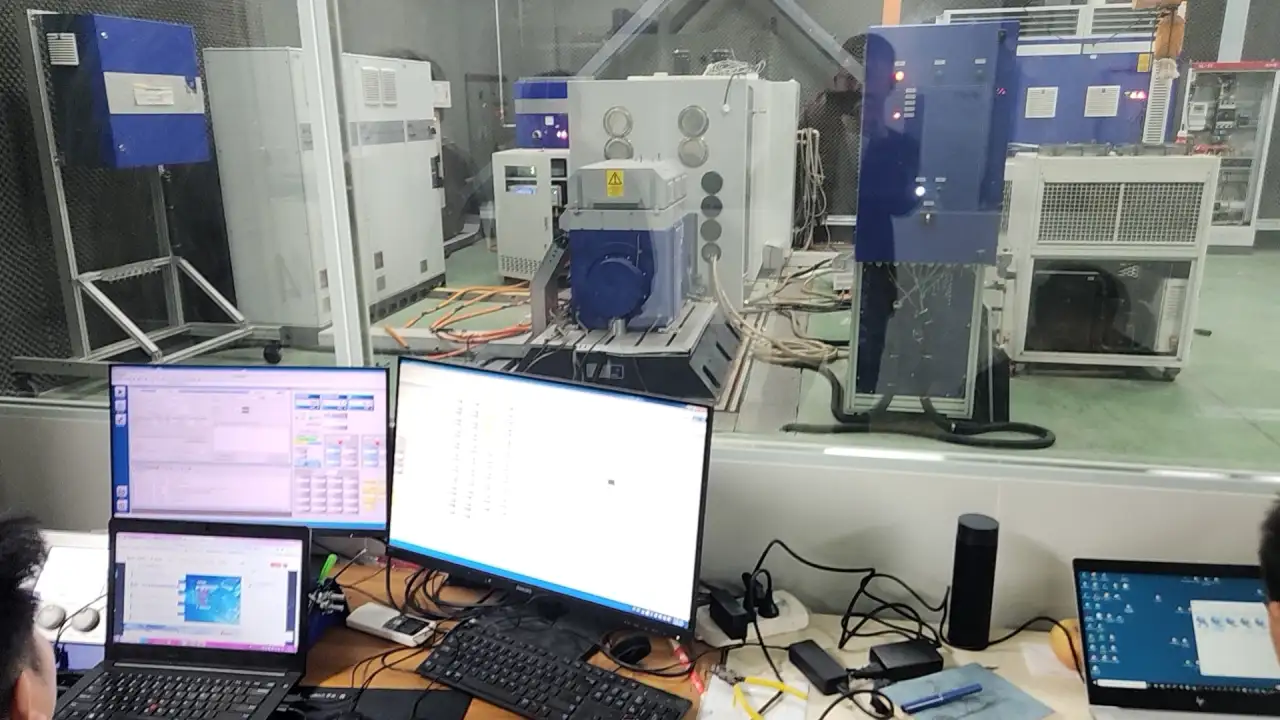

Proven Technologies and Engineering Validation for EV Motors

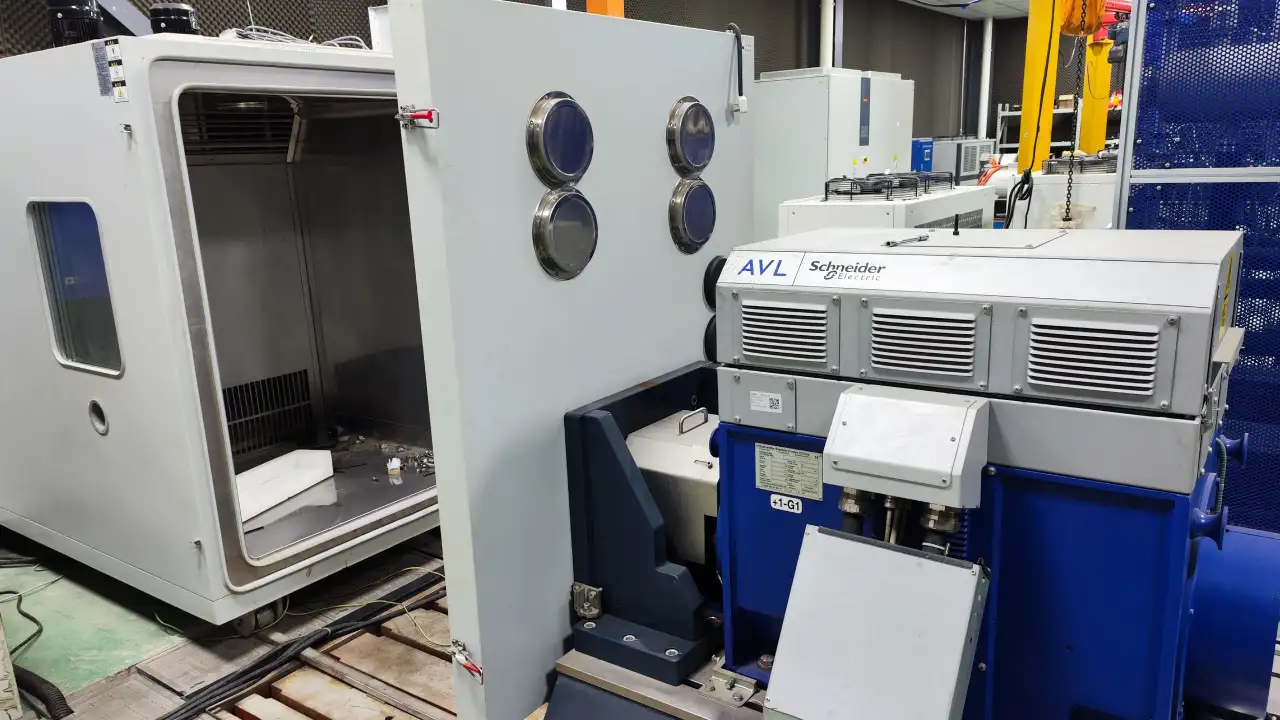

Our R&D team has full-cycle validation capabilities for electric motor development, from individual components to complete assemblies. Our rigorous testing process, including bench tests and vehicle trials, ensures continuous improvement and reliable performance. With over 100 advanced testing devices, 20+ test vehicles, and a robust experimental process, we validate products through a range of tests, including immersion, temperature extremes, salt spray, vibration, durability, noise, and road tests. This ensures excellent reliability, cost-efficiency, power, and lightweight design of our systems.

System Integration Development

Develop a range of products including TED, CED, and parallel hybrid systems.

Motor & Controller Development

Develop and mass-produce multiple electric motor models and controller platforms.

Software Development

Develop software for direct-drive systems, and parallel hybrid configurations.

Transmission Development

Develop and mass-produce a variety of transmission systems.

Engineering Process Aligned with Automotive Standards

Our engineering and validation processes follow a structured V-model development framework aligned with automotive industry standards. Verification covers functional performance, environmental endurance, EMC, NVH, vibration, and reliability at both component and system levels, ensuring that each motor platform meets the expectations of commercial and industrial vehicle applications.

Applications

Urban Delivery

For pickup trucks, box trucks, cargo trucks, light trucks, municipal vehicles, and more.

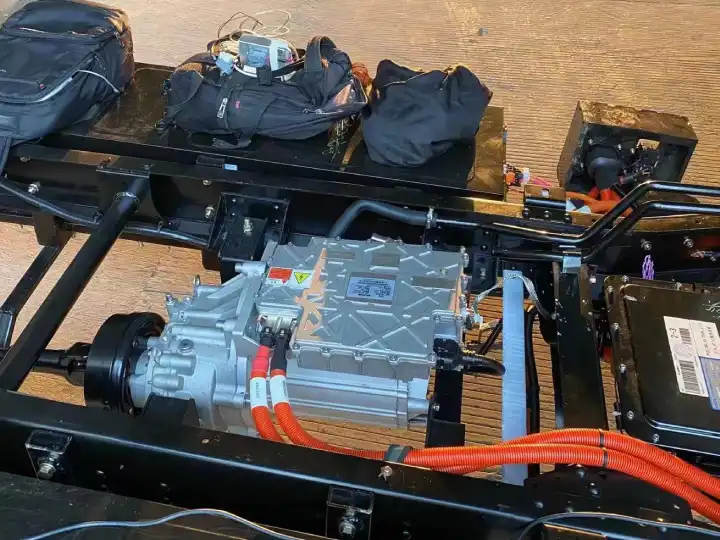

Our EV electric motors for LCVs offer high efficiency and a compact design, optimizing vehicle layout while reducing weight and space requirements. This mature, streamlined solution requires mininal chassis modifications, enabling OEMs to accelerate the transition to electrified mobility with ease.

Public Transport

For city buses, highway coaches, double-decker buses, articulated buses, trolleybuses, and more.

The electric bus motor solutions are designed to accelerate the shift toward clean, reliable, and efficient public transportation. We offer proven direct-drive motors as well as integrated e-powertrains that combine the motor, controller, and gearbox into a single, optimized unit. These solutions help bus manfuacturers and fleet operators reduce costs, shorten time-to-market, and deliver sustainable, high-performance electric mobility with confidence.

Heavy Haulage

For semi-trucks, trailers, tippers, dump trucks, mining trucks, concrete mixers, water trucks, garbage trucks, and more.

Brogen electric truck motors deliver high efficiency and proven reliability, engineered to perform under diverse environmental conditions. Our solutions are designed to help fleets reduce operational costs and energy consumption while promoting sustainability through lower carbon emissions. For truck manufacturers, these scalable e-powertrain soltuions help simplify manufacturing, improve vehicle reliability, and strengthen brand positioning in the competitive EV market.

Marine Application

For boats, ships, yachts, jet ski, and more.

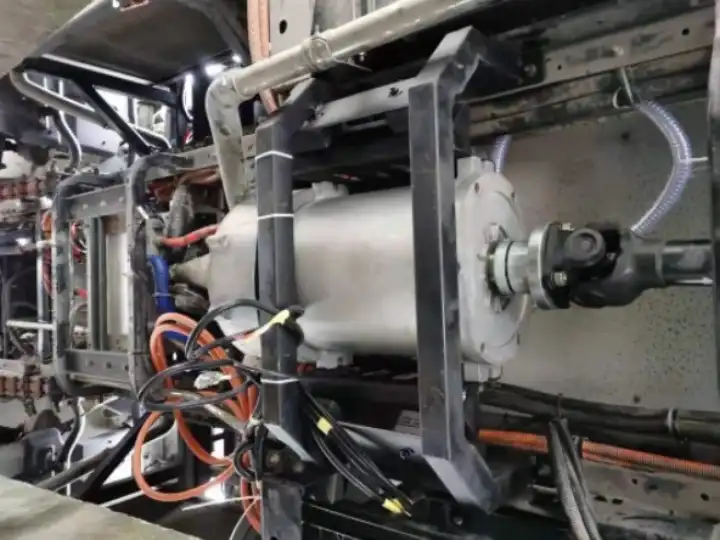

We provide advanced electric propulsion systems to support the electrification of modern vessels. Our electric boat motor solutions are engineered for compactness, ensuring easy installation and optimal use of space. They are ideally suited for both main propulsion and auxiliary thruster applications.

Brogen Application Examples

Concrete mixer upfit

Hybrid bulldozer drive system

Electric boat propulsion system

Client installing the motor to the train

Client installing the motor to the LCV

EV motor for the light duty truck

Electric heavy duty truck

Electric heavy duty truck

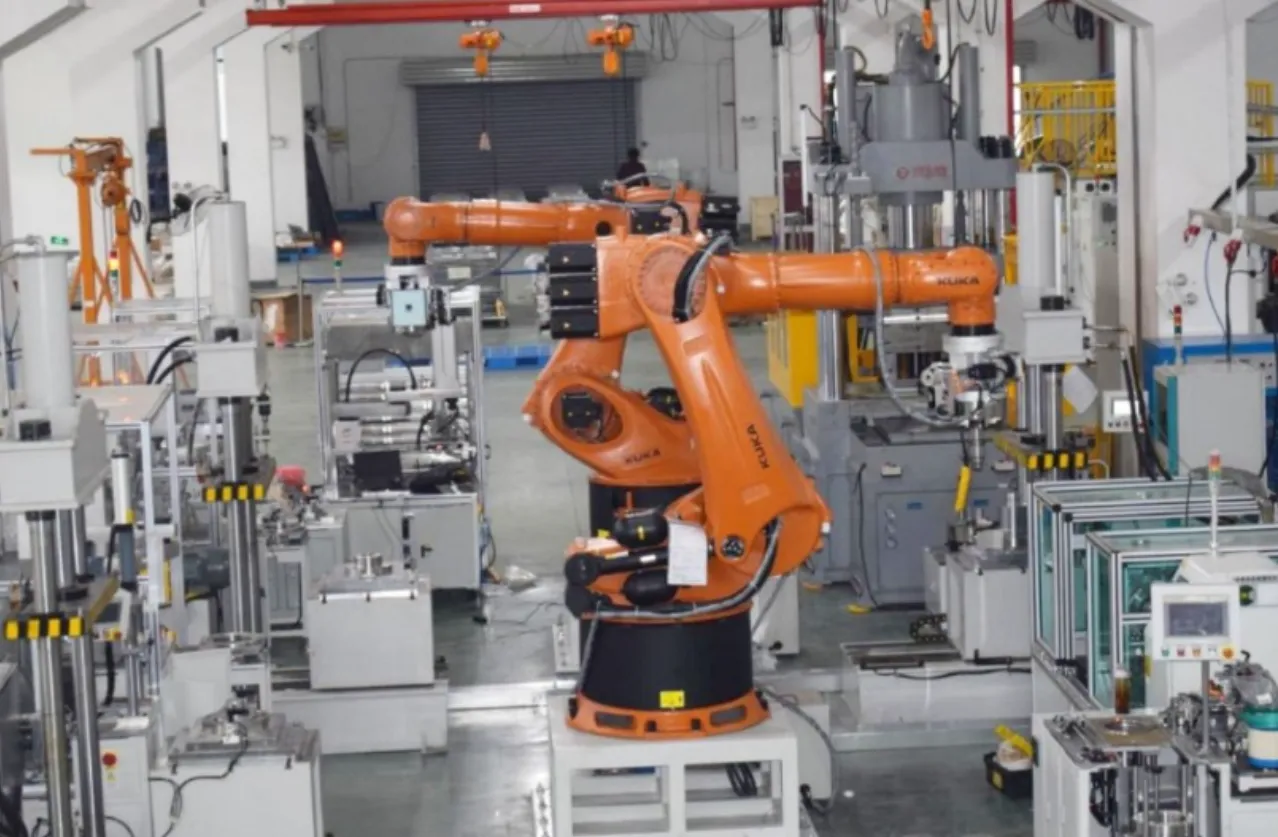

Intelligent Manufacturing Plant for Brogen EV Motors

Motor Stator Automatic Production Line

Capable of automated processes such as wire embedding, shaping, wire tiring, and terminal pressing, with a high level of automation.

Motor Rotor Automatic Production Line

Features automated material handling, magnet insertion with full position recognition, press-fitting with pressure and stroke monitoring, and automatic dynamic balancing.

Transmission Housing and Gear Shaft Automatic Production Line

Supports automated marking, scanning, machining, cleaning, pressure testing, and on-line measurement. Pre-heating shaft and gear machining lines employ robots for material handling, replacing manual operations. The entire production process is transparent, efficient, controlled, and traceable in real-time.

Comprehensive Gear Grinding With Modifications

Transmissions for (hybrid) electric vehicles require higher speeds, greater efficiency, improved NVH performance, and the ability to withstand greater reverse torque. Our advanced gear modification and full grinding processes meet these demanding requirements.

Connected Equipment

CNC equipment is interconnected, enabling real-time monitoring of equipment status, production orders, and operator information. This enhances product traceability, supports automated statistical analysis, and provides production anomaly alerts, improving both quality and efficiency.

How We Work

Navigating Our Process

Demand Analysis & Project Evaluation

Once we receive your inquiry, our experts will connect with you within two business days to understand your specific requirements for the EV solution and conduct an initial feasibility evaluation of your project.

Project & Technical Coordination

If the project is deemed feasible, our engineering team will collaborate closely with your team on both hardware and software aspects to develop a viable solution. We will also provide a detailed quotation based on the technical requirements.

Development, Manufacturing & Testing

For customized or modified systems, we proceed with product development, including hardware and software adaptations. Our EV systems undergo rigorous testing to ensure quality, reliability, and full functionality before deployment.

In-Time Global Shipping & Delivery

We have established strong partnerships with international shipping providers, ensuring safe and timely delivery of products to your specified location. This guarantees a smooth and efficient deployment of your EV project.

Full-Stage Remote/Onsite Technical Support

We provide technical support throughout the entire project lifecycle, including consultancy, hardware and software development, calibration, and both onsite and remote debugging, ensuring optimal performance and long-term success.

Frequently Asked Questions

Our EV motors are designed for commercial vehicle applications, including pickup trucks, light trucks, vans, minibuses, heavy trucks, construction equipment, vessels, and more. Typical use cases cover urban logistics, last-mile delivery, light-duty utility vehicles, public transport, and heavy-haul transport, etc.

Motor controllers are typically supplied together with the motor as part of an integrated solution. We do not offer a standalone MCU supply. Controller availability depends on the selected motor model and project requirements.

Yes. Our motors are commonly applied to existing platforms, where minimizing chassis modifications and integration complexity is a key requirement.

We are responsible for the embedded software and control functions of the systems we supply, including motor control and inverter-related software.

Vehicle-level electrical system design, mechanical packaging, and overall vehicle control unit (VCU) integration – including control strategies and calibration – remain the responsibility of the customer or the vehicle integrator.

We support interface definition and communication requirements related to the supplied system. However, full vehicle-level VCU integration, control logic development, and functional safety validation are handled by the customer.

Customers are expected to provide vehicle electrical architecture, mechanical layout constraints, and system-level control requirements to enable proper integration of the supplied motor or drive unit.

Most of our motor models have completed calibration and entered the SOP phase, with selected models applied in commercial vehicle projects. Availability may vary by configuration and application.

Motor specifications and configurations can be adjusted based on project requirements. Final parameters are defined through technical discussion and validation.

We focus on supplying EV systems. Full vehicle electrification, including VCU development, is typically managed by the customer or a designated system integrator.

Yes. We support small-batch orders for prototype development, with flexible MOQ and lead time.

- Our electric motors for commercial vehicles are designed and tested in compliance with Chinese national standards, which, in many aspects, are more stringent than international equivalents.

- For some models, we do not preapply certain certificates, but we can provide the necessary technical documents and support to assist you in completing local certifications in your country.

We support flexible shipping terms such as FOB, CFR, and CIF. Lead times vary based on system type and customization.

- We provide tailored EV solutions, but not ready-to-install retrofit kits.

- To ensure optimal system performance and safety, we require that our clients have a professional EV engineering team with hardware and software capabilities.

- During the early stage of the project, we also expect the client’s technical team to participate in solution discussions to ensure the best fit between our solution and your vehicle architecture.

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >