Electric Motors for Light Commercial Vehicles

We supply electric motors for light commercial vehicles, including pickup trucks, light trucks, vans, and minibuses. Our portfolio covers both standalone electric motors and integrated motor-gearbox e-powertrain assemblies, enabling OEM engineering teams to choose the most appropriate solution based on vehicle performance targets, packaging constraints, and duty cycle profiles.

For light commercial vehicles, central drive architectures remain a mature and widely adopted solution. By pairing with our PMSM-based motors with centralized drivetrain layouts, OEMs can limit chassis modifications, reduce integration complexity, and accelerate platform development using proven engineering practices.

Email: contact@brogenevsolution.com

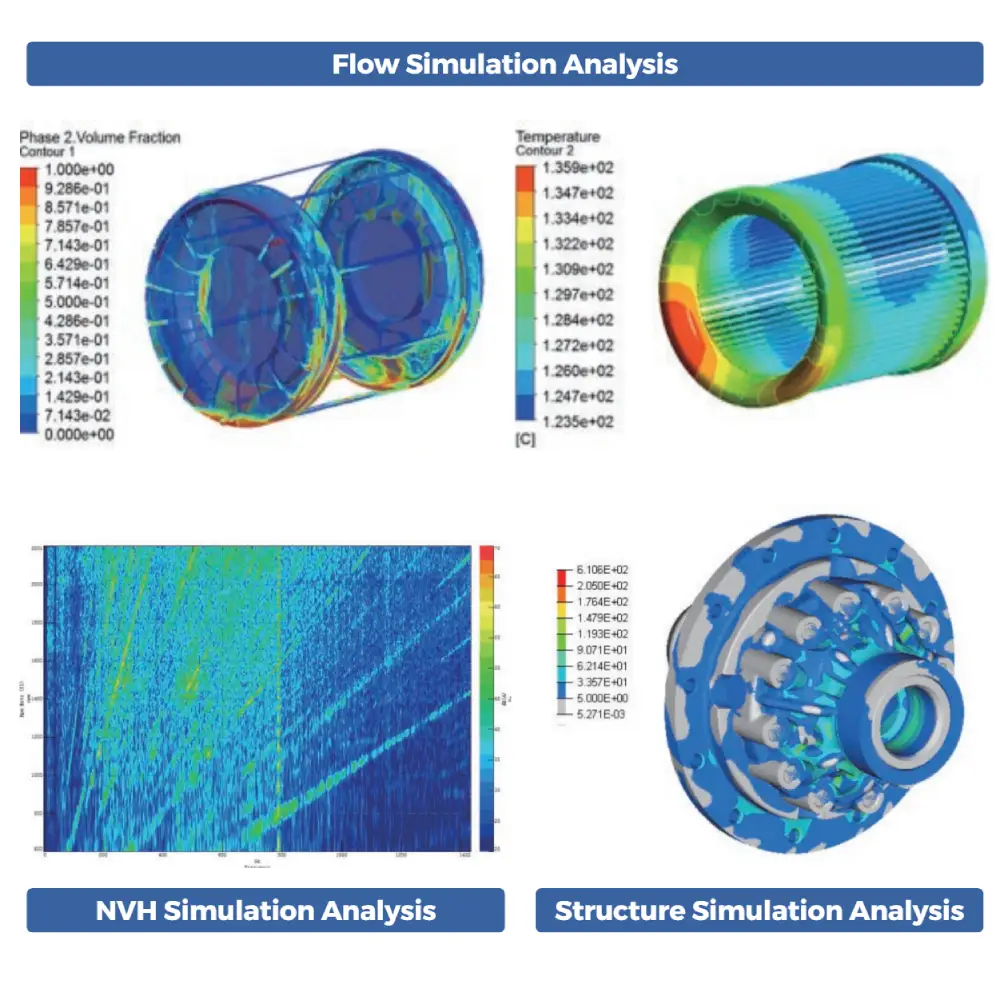

Strong R&D and Validation Capabilities

Our team has full-cycle validation capabilities for electric powertrain development. Systems undergo a rigorous testing process, including bench tests and vehicle trials, to ensure predictable performance under defined duty cycles.

We leverage advanced testing equipment and a fleet of 20+ test vehicles to perform structured experiments covering key conditions such as immersion, temperature extremes, salt spray, vibration, durability, noise, and on-road operation. This comprehensive validation ensures that our electric powertrain systems meet defined performance targets for power, weight, and integration suitability in light commercial vehicle platforms.

Benefits of Brogen Electric Motors for Light Commercial Vehicles

Enhanced Motor Efficiency

The motors use thin silicon steel laminations, high magnetic permeability materials, and sinusoidal air-gap flux density optimization to reduce core losses. Peak motor efficiency exceeds 97%, with system efficiency ≥85% across most of the operating range.

Low-Noise Operation

Rotor design includes segmented skewing and optimized auxiliary slot parameters at the rotor periphery, minimizing torque ripple and reducing acoustic noise under typical duty cycles.

Optimized Cooling System

A dual-helical water channel design provides uniform heat dissipation and maintains thermal stability while preserving water resistance and pressure characteristics sutiable for LCV operation.

Environmental Protection

Flange-mounted dustproof structure prevents ingress of mud, sand, and water, supporting long-term operational reliability in off-road or urban delivery conditions.

Our Offerings of Electric Motors for Light Commercial Vehicles

1. Central Direct-Drive Motor

The central direct-drive configuration replaces the original internal combustion engine with an electric motor while retaining the existing driveshaft and overall drivetrain layout. By leveraging the original vehicle architecture, this solution enables integration into existing platforms with minimal modifications to the chassis or axles.

As a mature and widely adopted approach for light commercial vehicles, central direct drive offers low integration complexity, predictable system behavior, and reduced development risk.

Value for Clients

- Easy conversion: ideal for retrofitting traditional fuel vehicles with minimal modifications and low risk.

- Cost-effective & fast development: short development cycle with manufacturing costs similar to conventional vehicles.

- Superior NVH performance: ensures a quieter and smoother ride.

- High efficiency: over 95% peak efficiency with a broad high-efficiency range for optimal performance.

- Wide applicability: suitable for sanitation trucks, short-haul cargo vans, range-extended models, and more.

Our Offerings

- Please note that the parameters listed are for reference only. Final specifications may vary depending on application requirements. For detailed technical data, available configurations, and controller options, please contact us at Email: contact@BrogenEVSolution.com

- Most of the motor models listed below have completed calibration and have progressed to the SOP stage, with selected models applied in commercial vehicle projects.

| Model | Target Vehicle Segment | Motor Power (Rated/Peak) | Motor Torque (Rated/Peak) | Peak Speed |

| LCV-motor-1 | 2.5 t van | 30 / 60 kW | 90 / 223 N.m | 9000 rpm |

| LCV-motor-2 | Light truck; van | 50 / 110 kW | 120 / 342 N.m | 12000 rpm |

| LCV-motor-3 | 6.5 m city bus; school bus | 60 / 120 kW | 477 / 1200 N.m | 3000 rpm |

| LCV-motor-4 | 4.5-6 t truck | 60 / 120 kW | 358 / 1000 N.m | 4500 rpm |

| LCV-motor-5 | 3.5 t truck; airport tractor | 60 / 120 kW | 300 / 500 N.m | 5000 rpm |

| LCV-motor-6 | Light truck; van | 75 / 120 kW | 350 / 850 N.m | 5000 rpm |

| LCV-motor-7 | 6 m bus; 4.5 t truck | 60 / 130 kW | 400 / 1000 N.m | 4000 rpm |

| LCV-motor-8 | 6 m bus; port AGV | 90 / 190 kW | 550 / 1300 N.m | 4000 rpm |

Can’t find a configuration that meets your requirements? Contact us to discuss project-specific solutions and customization options.

2. Central Drive - Integrated Electric Motor + Gearbox

The integrated central drive e-powertrain system combines the motor and gearbox into a single unit, available in 2-in-1 (motor + gearbox) or 3-in-1 (motor + gearbox + controller) configurations.

By incorporating a reduction gearbox, the system supports higher motor operating speeds and improved torque matching, contributing to reduced motor size and optimized drivetrain packaging compared with direct-drive solutions.

Value for Clients

- Optimized vehickle layout: the integrated motor+gearbox design enhances overall vehicle structure.

- Cost-effective performance: the transmission enables a smaller motor to match the power of a larger direct-drive motor, reducing size and cost.

- High efficiency: over 95% peak efficiency with a broad high-efficiency range for optimal performance.

- Easy conversion: ideal for retrofitting traditional fuel vehicles with minimal modifications and low risk.

- Cost-effective & fast development: short development cycle with manufacturing costs similar to conventional vehicles.

- Superior NVH performance: ensures a quieter and smoother ride.

- Optimized vehickle layout: the integrated motor+gearbox design enhances overall vehicle structure.

Our Offerings

- Please note that the parameters listed are for reference only. Final specifications may vary depending on application requirements. For detailed technical data, available configurations, and controller options, please contact us at Email: contact@BrogenEVSolution.com

- Most of the motor models listed below have completed calibration and have progressed to the SOP stage, with selected models applied in commercial vehicle projects.

| Model | Target Vehicle Segment | Motor Power (Rated/Peak) | Motor Torque (Rated/Peak) | Peak Speed | Speed Ratio | Integration |

| LCV-motor-11 | Light truck; van | 60 / 115 kW | 115 / 332 N.m | 11600 rpm | 3.037 | Motor+gearbox |

| LCV-motor-12 | Light truck; van | 60 / 100 kW | 120 / 280 N.m | 12000 rpm | 3.04 | Motor+gearbox+controller |

Can’t find a solution that fits your needs? Reach out to us to explore customized options for your project.

How We Work

Navigating Our Process

Demand Analysis & Project Evaluation

Once we receive your inquiry, our experts will connect with you within two business days to understand your specific requirements for the EV solution and conduct an initial feasibility evaluation of your project.

Project & Technical Coordination

If the project is deemed feasible, our engineering team will collaborate closely with your team on both hardware and software aspects to develop a viable solution. We will also provide a detailed quotation based on the technical requirements.

Development, Manufacturing & Testing

For customized or modified systems, we proceed with product development, including hardware and software adaptations. Our EV systems undergo rigorous testing to ensure quality, reliability, and full functionality before deployment.

In-Time Global Shipping & Delivery

We have established strong partnerships with international shipping providers, ensuring safe and timely delivery of products to your specified location. This guarantees a smooth and efficient deployment of your EV project.

Full-Stage Remote/Onsite Technical Support

We provide technical support throughout the entire project lifecycle, including consultancy, hardware and software development, calibration, and both onsite and remote debugging, ensuring optimal performance and long-term success.

Case Studies

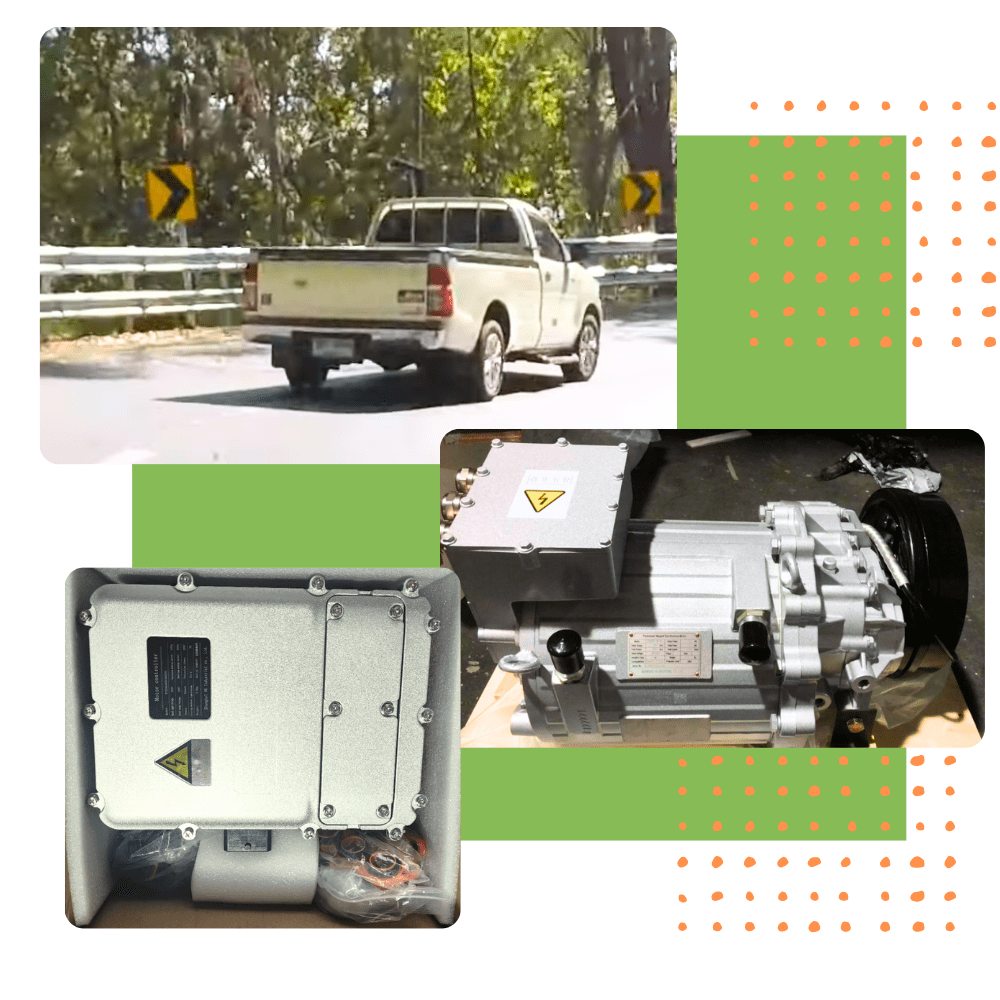

3-ton Electric Pickup Truck in Thailand

In 2022, we provided an electric powertrain solution to our client in Thailand for their electric pickup truck project. The e-powertrain solution includes the 2-in-1 system integrating the electric drive motor and the reducer, and a motor control unit.

Once our e-powertrain system was integrated into the client’s electric pickup truck, they conducted rigorous testing, including water wading, high-speed performance, and other essential assessments. Our system successfully passed all tests, making the client highly satisfied.

Due to the successful outcome of this project, the client expanded their collaboration with us, requesting e-powertrain solutions for other models, including their 6-ton medium-duty trucks and 25-ton heavy-duty trucks. Throughout this collaboration, we also supplied other systems such as onboard chargers and battery thermal management systems.

Electric Light Truck in South Korea

In 2021, we provided the electric powertrain solution to one client in South Korea for their light-duty truck project. The solution includes the 120 kW electric motor, integrated with the gearbox and controller, and the water pump, EHPS, DC/DC converter, and air conditioning compressors. This combination ensured that our solution perfectly aligned with the unique demands of their EV projects.

Additionally, we provided professional technical support to ensure their electric light-duty trucks were operational quickly and efficiently. In just ten days, our electric powertrain solution had the customer’s vehicles up and running. The success made local news. The customer thanked us for a transformative journey that successfully converted the electric light-duty truck into their fleet and laid a solid foundation for their electric future. We’re currently in active discussions with the customer about electrification options for other models in their fleet.

Gallery

Our electric motors for light commercial vehicles have been extensively adopted in electric vehicle applications worldwide, demonstrating proven performance in large-scale deployments. These solutions have been successfully exported to numerous markets, including the United States, Canada, Australia, Malaysia, Indonesia, the Philippines, Mexico, Thailand, and beyond.

Today, the majority of our electric motor systems are in full-scale mass production, ensuring exceptional reliability, scalability, and readiness to support large fleet electrification initiatives.

60 kW electric motor

60 kW electric motor

Vans with our motor

Vans with our motor

Brogen electric motor shipment

Brogen electric motor

Brogen 3-in-1 electric powertrain

Brogen 2-in-1 electric powertrain

Brogen electric motors shipment

Brogen electric motors shipment

Brogen electric motors shipment

Brogen electric motors shipment

Frequently Asked Questions

Our electric motors for LCVs are designed for light commercial vehicle applications, including pickup trucks, light trucks, vans, and minibuses. Typical use cases cover urban logistics, last-mile delivery, and light-duty utility vehicles.

We offer both standalone electric motors and integrated motor-gearbox drive units. The selection depends on vehicle architecture, performance targets, and integration strategy defined by the customer’s engineering team.

Yes. Our motors and central drive solutions are commonly applied to existing LCV paltforms, where minimizing chassis modifications and integration complexity is a key requirement.

We are responsible for the embedded software and control functions of the systems we supply, including motor control and inverter-related software.

Vehicle-level electrical system design, mechanical packaging, and overall vehicle control unit (VCU) integration – including control strategies and calibration – remain the responsibility of the customer or the vehicle integrator.

We support interface definition and communication requirements related to the supplied system. However, full vehicle-level VCU integration, control logic development, and functional safety validation are handled by the customer.

Customers are expected to provide vehicle electrical architecture, mechanical layout constraints, and system-level control requirements to enable proper integration of the supplied motor or drive unit.

Most of our motor models have completed calibration and entered the SOP phase, with selected models applied in commercial vehicle projects. Availability may vary by configuration and application.

Motor specifications and configurations can be adjusted based on project requirements. Final parameters are defined through technical discussion and validation.

We focus on supplying EV systems. Full vehicle electrification, including VCU development, is typically managed by the customer or a designated system integrator.

Yes. We support small-batch orders for prototype development, with flexible MOQ and lead time.

- Our electric motors for light commercial vehicles are designed and tested in compliance with Chinese national standards, which, in many aspects, are more stringent than international equivalents.

- For some models, we do not preapply certain certificates, but we can provide the necessary technical documents and support to assist you in completing local certifications in your country.

We support flexible shipping terms such as FOB, CFR, and CIF. Lead times vary based on system type and customization.

- We provide tailored EV solutions, but not ready-to-install retrofit kits.

- To ensure optimal system performance and safety, we require that our clients have a professional EV engineering team with hardware and software capabilities.

- During the early stage of the project, we also expect the client’s technical team to participate in solution discussions to ensure the best fit between our solution and your vehicle architecture.

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >