Electric Truck Motor Solutions

Electric truck motor solutions for urban delivery and heavy-duty transport must support a wide range of load profiles, road conditions, and operating patterns. This solution portfolio is developed to address these application requirements at the system level, rather than as a standalone motor component.

Our electric truck motor solutions support three electrification architectures — battery electric (BEV), fuel cell electric (FCEV), and hybrid electric (HEV) — enabling alignment with different vehicle platform designs and energy strategies.

Currently, they have been validated through integration into multiple commercial vehicle platforms and real-world operating environments.

Email: contact@brogenevsolution.com

Our Electric Truck Motor Solution Features

Precision Motor Control

Advanced motor control strategies enable accurate torque and speed regulation under varying load and road conditions, supporting smooth vehicle operation during frequent start-stop and transient driving scenarios.

High Power Density

Incorporates permanent magnet materials and integration technology to reduce system weight while increasing power density, helping optimize axle load distribution, available payload, and packaging space.

High Energy Efficiency

Optimized electromagnetic and control design enables motor efficiency exceeding 90% across typical operating ranges, reducing energy consumption and thermal stress in continuous-duty commercial vehicle applications.

Value for EV Projects and Operations

For OEMs and System Integrators

Enable faster platform development through modular motor solutions compatible with BEV, FCEV, and HEV architectures. Reduced system integration effort and calibrated performance across defined duty cycles help improve platform reliability and shorten development timelines.

Improved energy efficiency and thermal stability contribute to lower operating energy consumption and reduced maintenance frequency under real-world duty cycles, supporting lower total cost of ownership (TCO) over the vehicle lifecycle.

For Vehicle Operation and Drivers

Stable torque delivery and smooth control under frequent start-stop conditions improve drivability and reduce mechanical and thermal stress, supporting consistent vehicle performance in daily operation.

Applicable Models

- 20 T / 4x2

- 26 T / 6x2

- 42 T / 4x2

- 49 T / 6x4 & 8x4

- 65 T / 6x4 & 8x4

Brogen Offerings of Electric Truck Motor Solutions

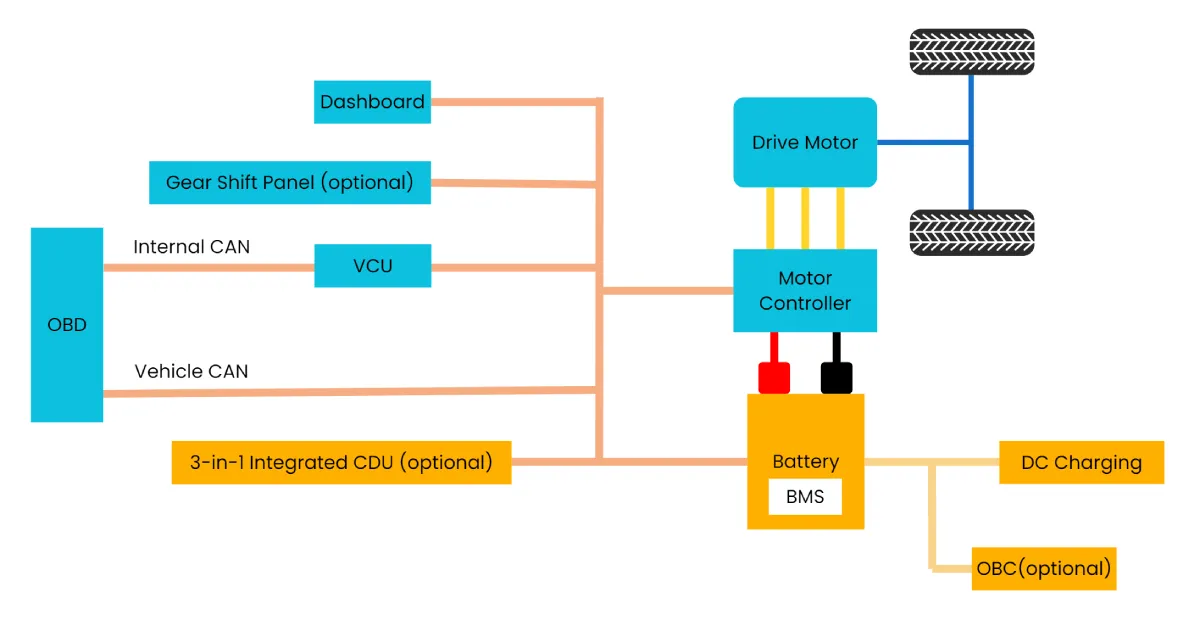

1. Centralized Direct Drive Electric Truck Motor

Centralized direct-drive motors are best suited for light- and medium-duty trucks operating in urban or semi-urban duty cycles, where frequent start-stop operation is required; vehicle speeds are moderate, with limited high-speed cruising; high launch torque and smooth low-speed control are critical; and drivetrain simplicity and reliability are prioritized over multi-speed optimization.

Without intermediate gearing, direct-drive motors provide immediate torque response and reduced mechanical complexity, making them suitable for applications such as urban delivery trucks, light-duty distribution vehicles, airport tractors, and specialized industrial trucks.

- Please note that the parameters listed are for reference only. Final specifications may vary depending on application requirements. For detailed technical data, available configurations, and controller options, please contact us at Email: contact@BrogenEVSolution.com

- Most of the motor models listed below have completed calibration and have progressed to the SOP stage, with selected models applied in commercial vehicle projects.

| Model | Target Vehicle Segment | Motor Power (Rated/Peak) | Motor Torque (Rated/Peak) | Peak Speed | Typical Use |

| LCV-motor-5 | 3.5 t truck; airport tractor | 60 / 120 kW | 300 / 500 N.m | 5000 rpm | Last-mile delivery trucks; airport ground service vehicles |

| LCV-motor-6 | Light truck; van | 75 / 120 kW | 350 / 850 N.m | 5000 rpm | Urban logistics vans; light-duty box trucks |

| LCV-motor-7 | 6 m bus; 4.5 t truck | 60 / 130 kW | 400 / 1000 N.m | 4000 rpm | Urban shuttle buses, heavier light-duty trucks |

| LCV-motor-8 | 6 m bus; port AGV | 90 / 190 kW | 550 / 1300 N.m | 4000 rpm | Port AGVs, heavier urban service vehicles |

Simplified Vehicle Integration

The centralized direct-drive architecture enables straightforward integration into existing vehicle platforms, making it suitable for drivetrain conversion or electrification projects with limited structural modification and controlled engineering risk.

Reduced Development Complexity

Our direct-drive motor solution shortens development cycles and reduces system complexity, with manufacturing and integration costs comparable to conventional drivetrain layouts.

High Operating Efficiency

Optimized PMSM design delivers peak motor efficiency above 95%, with a broad high-efficiency operating range that supports typical low- to mid-speed truck duty cycles and reduces energy consumption under real-world operation.

Application-Specific Deployment

The solution is best suited for defined truck applications such as urban and regional distribution trucks, where moderate vehicle speeds, high launch torque, and frequent start-stop operation are required.

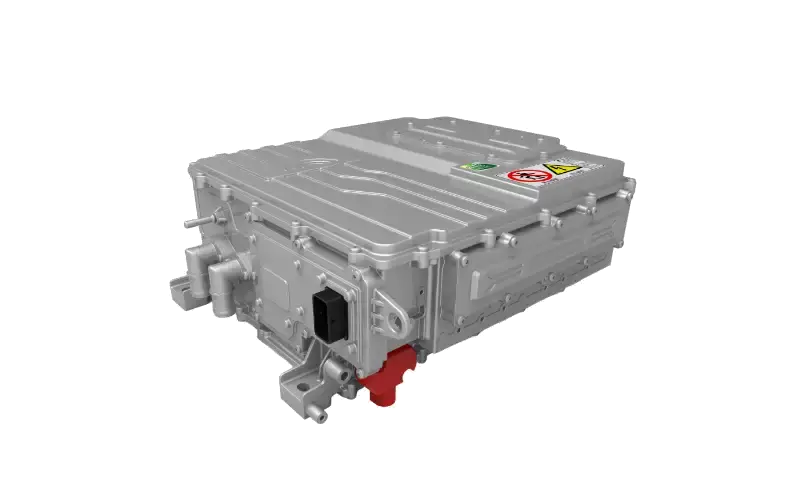

According to clients’ different requirements, we can provide standalone MCUs or high-voltage integrated controller systems, integrating MCU, PDU, DC-DC, and steering and braking DC/AC.

Note: Controllers are usually supplied as part of the electric powertrain system and are not sold separately.

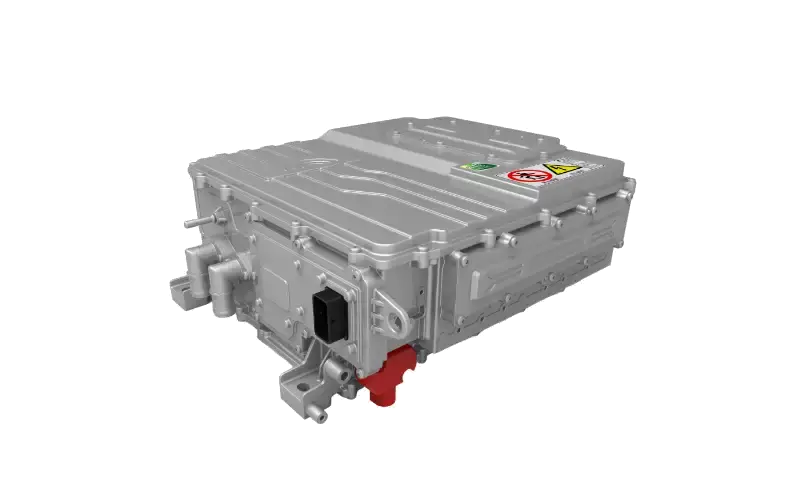

ISO 26262 Compliance

Functional safety requirements and software/hardware development meet ASIL C standards.

Dual-Integration Design

Combines functional and physical integration to significantly reduce size, weight, and manufacturing costs.

Dual-Inverter Control Technology

Minimizes losses and achieves a maximum efficiency of 98.5%.

Modular & Scalable Architecture

Designed for flexibility and easy expansion.

Digital Simulation & Optimization

Uses digital modeling for simulation analysis, enabling more efficient and cost-effective component selection.

Advanced EMC Design

Multi-stage filtering, optimized wiring layout, enhanced shielding, and structural improvements ensure Class 5 compliance under no-load conditions.

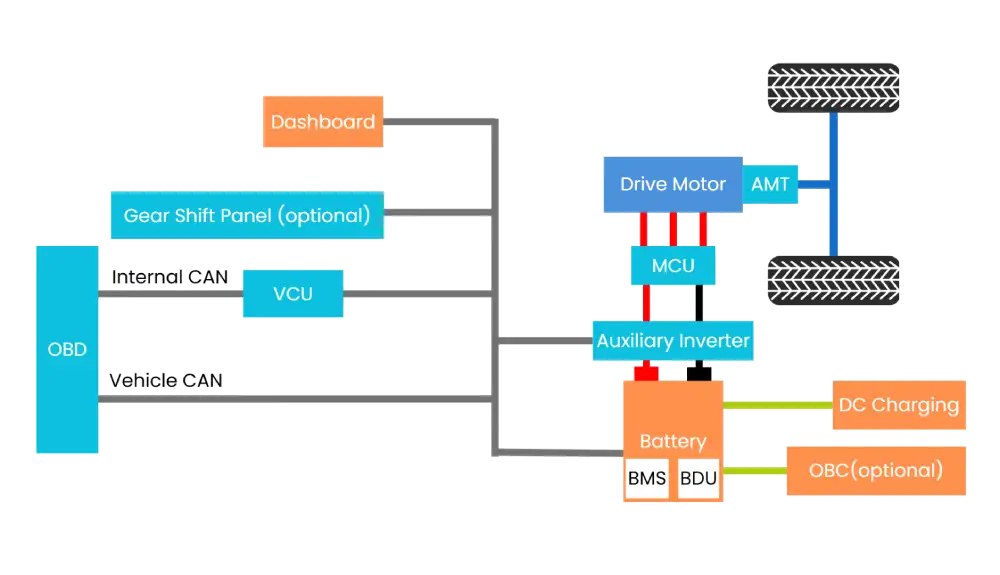

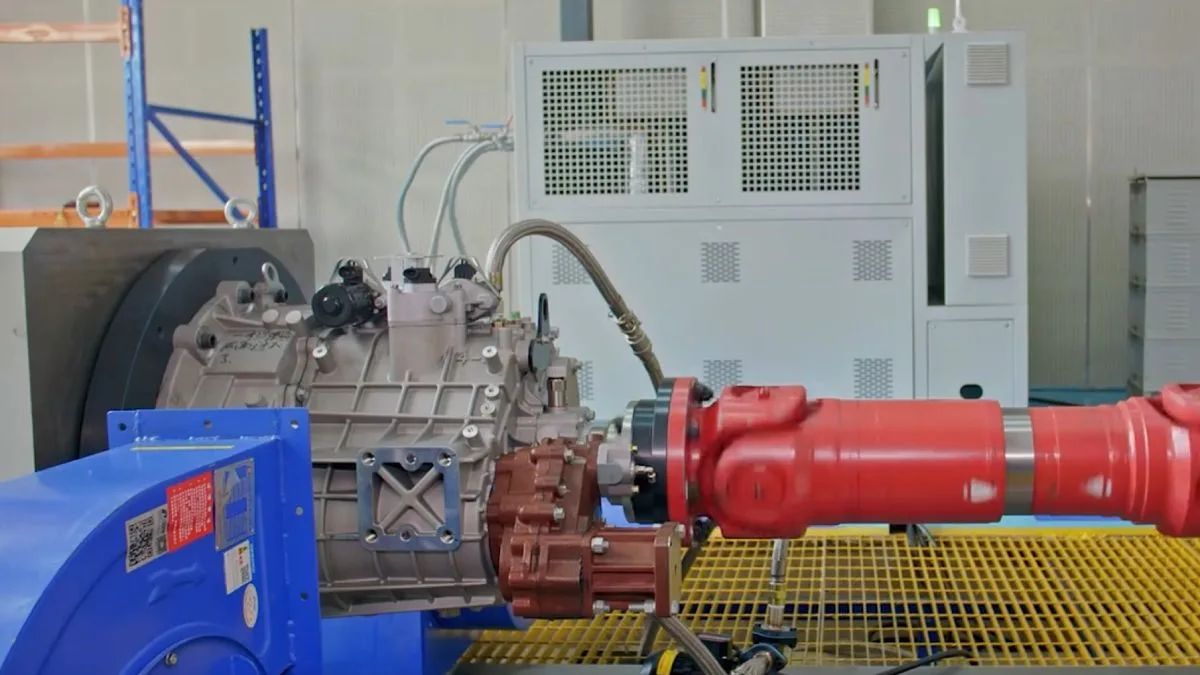

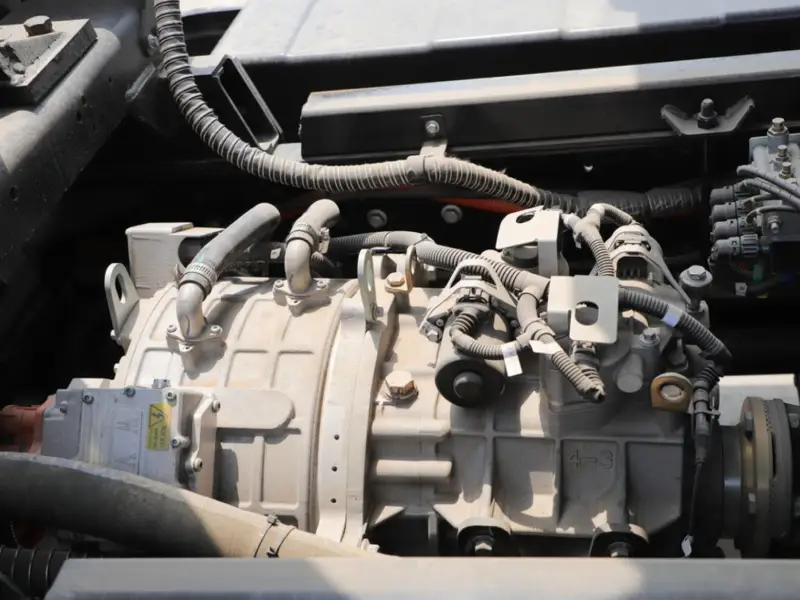

2. Integrated Electric Truck Powertrain (Electric Truck Motor + Multi-speed AMT)

We provide integrated electric powertrain solutions for medium- and heavy-duty truck platforms from 12 tons to over 40 tons, covering rigid trucks, mixer trucks, heavy-duty trucks, and semi-trailer tractors under defined operating duty cycles.

The solutions combine high-torque traction motors with a 2-speed or 4-speed AMT transmissions, enabling the required wheel-end torque for loaded startability, gradeability, low-speed maneuvering, and efficient cruising across mixed operating conditions.

For vocational truck applications, PTO functionality can be integrated to support auxiliary equipment while maintaining coordinated control within the e-powertrain system.

- Please note that the parameters listed are for reference only. Final specifications may vary depending on application requirements. For detailed technical data, available configurations, and controller options, please contact us at Email: contact@BrogenEVSolution.com

- Most of the motor models listed below have completed calibration and have progressed to the SOP stage, with selected models applied in commercial vehicle projects.

| Item | System Parameters | Motor Paramters | Transmission Parameters | PTO Parameters | |||||

| Model | Target Vehicle Segment | Maximum Output Torque | Motor Power (Rated/Peak) | Motor Torque (Rated/Peak) | Peak Speed | Gears | Gear Ratio | Speed Ratio | Peak Output Torque |

| Truck-motor-1 | 12 t truck | 3015 N.m | 80 / 160 kW | 500 / 1100 N.m | 4500 rpm | 2 | 2.741, 1 | 1.175 | 300 N.m |

| Truck-motor-2 | 12 t truck | 3380 N.m | 120 / 185 kW | 650 / 1300 N.m | 3500 rpm | 2 | 2.741, 1 | 1.175 | 300 N.m |

| Truck-motor-3 | 14-18 t truck | 6610 N.m | 100 / 200 kW | 500 / 1100 N.m | 3500 rpm | 4 | 6.61, 3.52, 1.89, 1 | 1.02 | 300 N.m |

| Truck-motor-4 | 25 t mixer truck | 16360 N.m | 200 / 300 kW | 850 / 1950 N.m | 3500 rpm | 4 | 8.39, 3.54, 1.74, 1 | 1.643 | 700 N.m |

| Truck-motor-5 | Heavy-duty truck | 20136 N.m | 250 / 400 kW | 1200 / 2400 N.m | 3500 rpm | 4 | 8.39, 3.54, 1.74, 1 | 1.643 | 700 N.m |

| Truck-motor-6 | Heavy-duty truck | 21814 N.m | 280 / 420 kW | 1500 / 2600 N.m | 3500 rpm | 4 | 8.39, 3.54, 1.74, 1 | 1.643 | 700 N.m |

| Truck-motor-7 | Heavy-duty truck | 22542 N.m | 360 / 550 kW | 1500 / 2600 N.m | 3500 rpm | 4 | 8.67, 4.57, 2.29, 1 | 1.643 | 700 N.m |

| Truck-motor-8 | Heavy-duty truck | 24276 N.m | 315 / 510 kW | 1650 / 2800 N.m | 3500 rpm | 4 | 8.67, 4.57, 2.29, 1 | 1.643 | 700 N.m |

| Truck-motor-9 | Heavy-duty truck | 24276 N.m | 360 / 550 kW | 1800 / 2800 N.m | 3500 rpm | 4 | 8.67, 4.57, 2.29, 1 | 1.643 | 700 N.m |

| Truck-motor-10 | Concrete mixer truck | 16438 N.m | 200 / 300 kW | 850 / 1950 N.m | 3500 rpm | 4 | 8.43, 3.90, 1.98, 1 | 1.353 | 700 N.m |

| Truck-motor-11 | Semi-trailer tractor | 20232 N.m | 250 / 400 kW | 1200 / 2400 N.m | 3500 rpm | 4 | 8.43, 3.90, 1.98, 1 | 1.353 | 700 N.m |

| Truck-motor-12 | Semi-trailer tractor | 21918 N.m | 280 / 420 kW | 1500 / 2600 N.m | 3500 rpm | 4 | 8.43, 3.90, 1.98, 1 | 1.353 | 700 N.m |

| Truck-motor-13 | Semi-trailer tractor | 21918 N.m | 335 / 510 kW | 1500 / 2600 N.m | 3500 rpm | 4 | 8.43, 3.90, 1.98, 1 | 1.353 | 700 N.m |

High Torque Delivery with Smooth Drivability

The multi-speed transmission enables coordinated torque delivery across different speed ranges. Optimized shift control minimizes driveline interruption during gear changes, improving gradeability, launch performance, and overall drivability under loaded conditions.

Integrated and Configurable PTO Capability

PTO functionality can be integrated into the e-powertrain architecture to support application-specific auxiliary loads. This integrated approach reduces additional mechanical interfaces and simplifies system layout compared to add-on PTO solutions.

Automated Multi-Speed AMT Transmission

The AMT transmission operates automatically based on vehicle speed, motor speed, and load conditions. Automated shifting logic removes the need for manual gear operation while maintaining consistent performance across varying duty cycles.

Validated System Durability

Our e-powertrain system has been developed and validated in collaboration with established transmission partners. Road testing under representative operating conditions has been conducted to verify durability and system stability.

According to clients’ different requirements, we can provide standalone MCUs or high-voltage integrated controller systems, integrating MCU, PDU, DC-DC, and steering and braking DC/AC.

Note: Controllers are usually supplied as part of the electric powertrain system and are not sold separately.

ISO 26262 Compliance

Functional safety requirements and software/hardware development meet ASIL C standards.

Dual-Integration Design

Combines functional and physical integration to significantly reduce size, weight, and manufacturing costs.

Dual-Inverter Control Technology

Minimizes losses and achieves a maximum efficiency of 98.5%.

Modular & Scalable Architecture

Designed for flexibility and easy expansion.

Digital Simulation & Optimization

Uses digital modeling for simulation analysis, enabling more efficient and cost-effective component selection.

Advanced EMC Design

Multi-stage filtering, optimized wiring layout, enhanced shielding, and structural improvements ensure Class 5 compliance under no-load conditions.

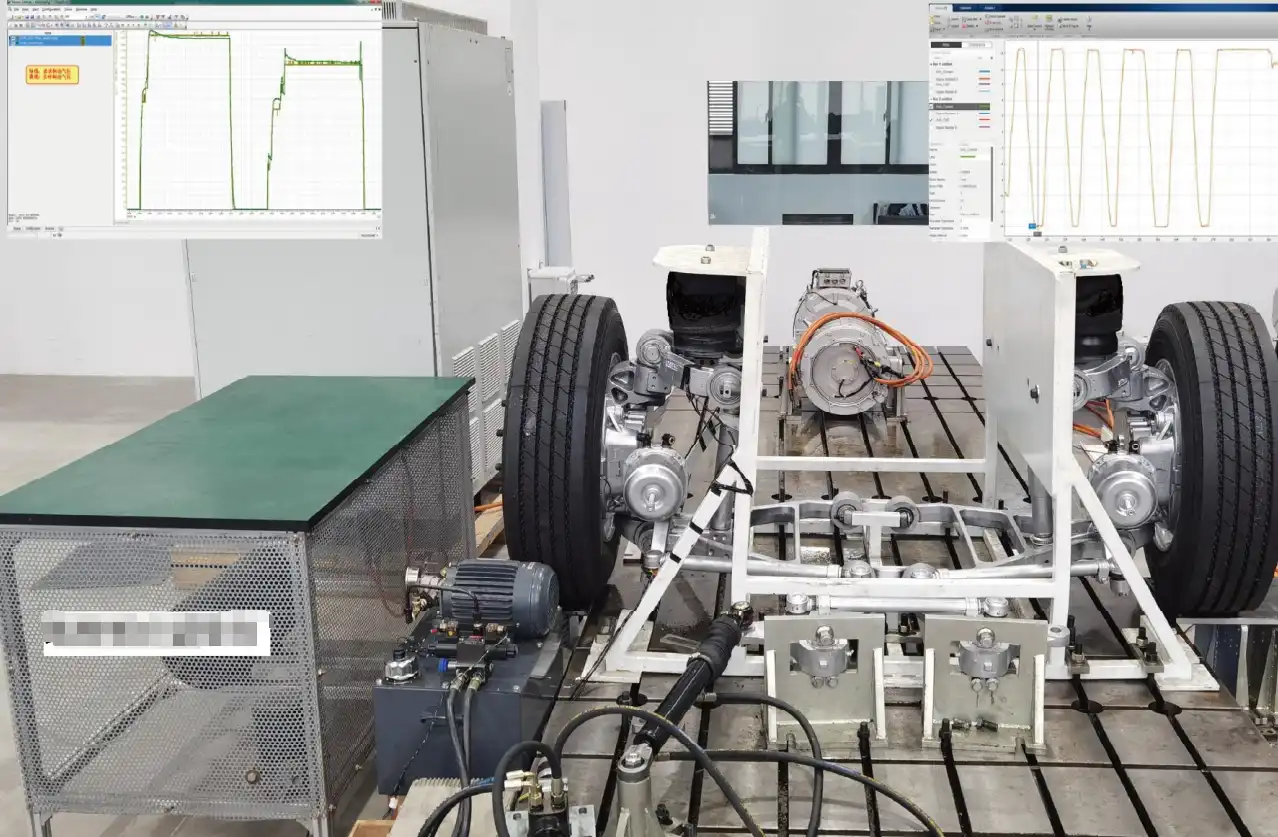

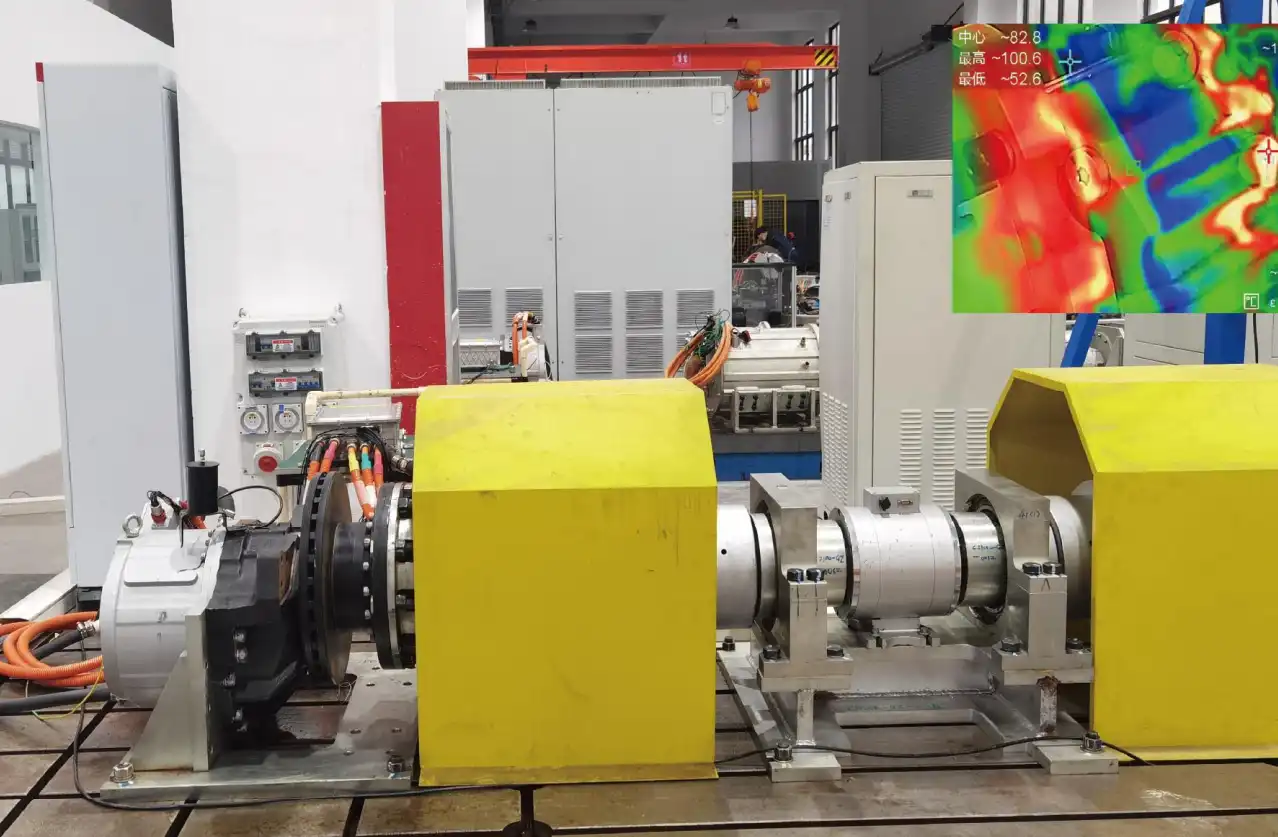

R&D and Validation Capabilities

We have full-cycle validation capabilities for electric truck powertrain development, covering both individual components and complete system assemblies. Validation activities include bench testing and vehicle-level testing to support iterative development and engineering verification.

Our testing infrastructure comprises over 100 specialized test devices and more than 20 test vehicles, enabling structured validation across multiple operating and environmental conditions. The test scope includes immersion, high- and low-temperature exposure, salt spray, vibration, durability, noise, and road testing.

Through this systematic validation process, powertrain performance, durability, and system integration are verified under representative operating conditions, supporting reliable and cost-effective deployment in commercial truck applications.

System Integration Development

Develop a range of systems including electric drive motors, e-axles, and hybrid drive systems.

Motor & Controller Development

Develop and mass-produce multiple electric truck motor models and controller platforms.

Software Development

Develop software for direct-drive systems, e-axles, and hybrid configurations.

Transmission Development

Develop and mass-produce a variety of transmission systems.

Precision Manufacturing

To ensure consistency and superior quality in mass production, our factory is equipped with advanced manufacturing systems and rigorous quality controls:

Automated Production Lines

Internationally deployed rotor and stator automation lines are used together with fully automated motor and controller assembly lines, supporting stable process control and repeated assembly quality.

High-Precision Manufacturing Equipment

Advanced gear grinding machines for gearboxes and precision machining equipment for housings.

Comprehensive Quality Testing

Every component undergoes strict inspection using fully automated measuring instruments, followed by thorough assembly verification through bench and road tests.

This manufacturing framework supports repeatable product quality and reliable performance in commercial truck powertrain applications.

How Do We Ensure the Reliability of the AMT?

To maximize transmission reliability, our multi-speed AMT, specifically designed for pure electric vehicles, undergoes a comprehensive series of environmental and durability tests. Through these interative tests and optimizations, our pure electric AMT achieves a service life exceeding 1 million kilometers, delivering reliability comparable to direct-drive systems.

- Environmental testing: waterproof, dustproof, high/low temperature, salt spray, and vibration tests.

- Torque endurance: static torque tests exceeding 3x the rated torque.

- Durability testing: rigorous comprehensive endurance tests, including over 1 million shift cycles per gear.

- Bench simulation: over 200,000 km of chassis dynamometer testing simulating real vehicle operation.

- Real-world road testing: more than 50,000 km of on-road trials.

- Consistency verification: full-vehicle consistency tests across 50 assembled units.

How We Work

Navigating Our Process

Demand Analysis & Project Evaluation

Once we receive your inquiry, our experts will connect with you within two business days to understand your specific requirements for the EV solution and conduct an initial feasibility evaluation of your project.

Project & Technical Coordination

If the project is deemed feasible, our engineering team will collaborate closely with your team on both hardware and software aspects to develop a viable solution. We will also provide a detailed quotation based on the technical requirements.

Development, Manufacturing & Testing

For customized or modified systems, we proceed with product development, including hardware and software adaptations. Our EV systems undergo rigorous testing to ensure quality, reliability, and full functionality before deployment.

In-Time Global Shipping & Delivery

We have established strong partnerships with international shipping providers, ensuring safe and timely delivery of products to your specified location. This guarantees a smooth and efficient deployment of your EV project.

Full-Stage Remote/Onsite Technical Support

We provide technical support throughout the entire project lifecycle, including consultancy, hardware and software development, calibration, and both onsite and remote debugging, ensuring optimal performance and long-term success.

Gallery

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >