Electric Chassis for LCV

This electric chassis for LCV caters to a diverse range of vehicles, including buses, as well as Class 1 to Class 5 light- and medium-duty trucks, accommodating weights from 1.5 tons to 8 tons, and lengths spanning from 3770 mm to 5995 mm. Customization is integral to our service, allowing us to tailor the dimensions preciously to our customers’ requirements.

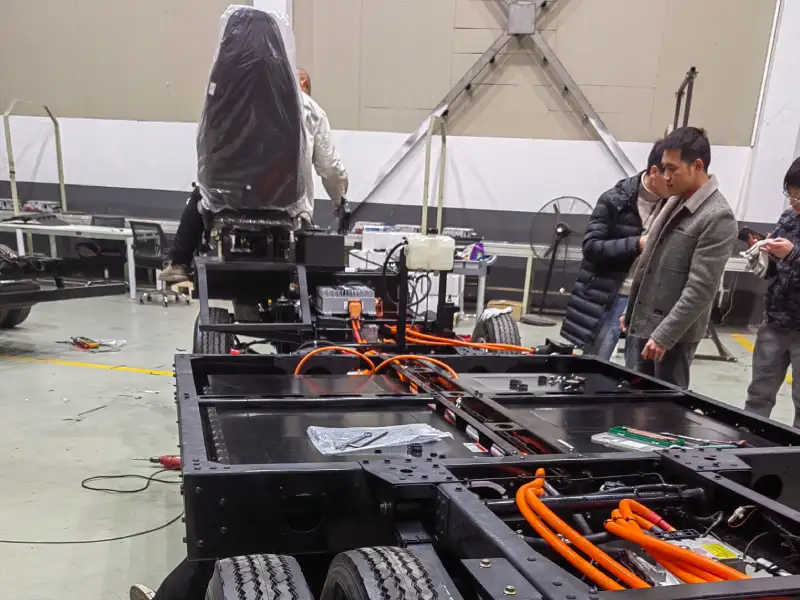

The comprehensive solution integrates essential EV components, including motors, batteries, e-axles, steering systems, braking systems, tires, and more onto a rugged EV platform. By doing so, we streamline the development and production processes of electric vehicles, significantly reducing both time and cost for EV builders. This efficiency allows our clients to expedite their production timelines, enabling them to bring their electric vehicles to market swiftly and gain a competitive advantage.

Applicable models: bus, truck (Class 1 to Class 5)

Email: contact@brogenevsolution.com

Benefits of Our Electric Chassis for LCV

Compact Design

This electric chassis for LCV boasts a compact design, integrating electric motors, e-axles, EV batteries, and all essential components onto a single platform. This space-saving design maximizes efficiency and improves the overall vehicle layout.

Scalability

The electric chassis system offers scalability, allowing for adaptation to various vehicle types and payloads. Whether it's a bus or a light-duty commercial truck, our platform can be tailored to meet diverse transportation needs.

Flexibility

Our EV truck chassis platform embodies the principle of flexibility. Virtually every aspect of the chassis is customizable to suit the specific requirements of your fleet, including the length, height of the frame, the energy of the battery, the power of the motor, etc.

Cost-saving Benefits

With the EV truck chassis solutions, we aim to provide substantial cost benefits for EV companies. Our solution eliminates the need for expensive connecting cables and redundant components, resulting in significant cost savings throughout the production process.

Electric Chassis for LCV Benefits

- Improved Performance: Our EV chassis system optimizes vehicle performance, delivering smooth acceleration, responsive handling, and enhanced driving dynamics.

- Enhanced Safety: The integration of key EV components on the chassis enhances overall vehicle stability and safety.

- Reduced Operating Costs: Electric vehicles built on our chassis platform benefit from lower operating costs, including reduced fuel expenses, maintenance costs, and emissions, translating to long-term savings for drivers.

- Eco-Friendly Transportation: Electric vehicles powered by our chassis solution contribute to reduced greenhouse gas emissions and environmental impact, supporting sustainable transportation initiatives and cleaner air quality.

- Increased Efficiency: Battery electric vehicles built on our chassis platform offer fleet operators improved efficiency, with reduced downtime, lower maintenance requirements, and longer vehicle lifespans.

- Cost Savings: Fleet operators can benefit from lower operating costs associated with electric vehicles, including reduced fuel expenses, maintenance costs, and compliance with environmental regulations.

- Enhanced Reliability: Our EV chassis solution is engineered for durability and reliability, minimizing the risk of breakdowns and ensuring consistent performance across the fleet.

- Sustainability Initiatives: Adopting electric vehicles built on our chassis supports fleet operators' sustainability initiatives, reducing carbon footprint and contributing to corporate social responsibility goals.

- Simplified Development: Our integrated electric truck chassis solution streamlines the vehicle development process, reducing design complexities and engineering challenges for EV builders.

- Cost Efficiency: By consolidating key EV components onto the chassis, EV manufacturers can achieve cost savings through reduced components, production site space, and assembly time.

- Enhanced Customization: Our modular electric chassis design allows for flexible customization options, enabling EV companies to tailor electric vehicles to meet specific customer needs and market demands.

- Accelerated Time-to-Market: With a ready-to-use EV chassis platform, EV manufacturers can expedite the production timeline, bringing electric vehicles to market faster and gaining a competitive edge.

- Quality Assurance: We uphold stringent quality standards, ensuring that our chassis solution delivers reliable performance and durability, minimizing post-production issues and warranty claims.

System Features

Scalable & Customizable Platform

We offer a variety of options for electric chassis for LCVs. The length and height of the vehicle can be customized to meet the specific requirements. Additionally, we provide refrigerated vehicle options and offer both pure electric chassis and methanol-hydrogen fuel cell electric vehicle chassis. These solutions are suitable for logistics vehicles, refrigerated trucks, and emergency power generation vehicles, among others.

Electric Drive Axle

The electric axle serves as the traction power source for this electric chassis for LCV. It features a highly efficient PMSM motor integrated into the rear axle, offering a compact and lightweight design. This integration eliminates the need for a traditional drive shaft, optimizes the overall vehicle layout, and creates additional space for battery placement.

LFP Battery System

Our traction battery system utilizes high-energy density LFP cells from industry-leading manufacturers to optimize vehicle efficiency and safety. To meet diverse customer needs, we offer customizable battery capacities. For enhanced stability and protection, the entire battery system is integrated into the chassis frame, lowering the vehicle’s center of gravity.

Electric Chassis for LCV - Design Details

The wiring on the chassis is neatly organized, minimizing the number of harnesses customers need to handle upon receipt. This simplifies installation and customization processes.

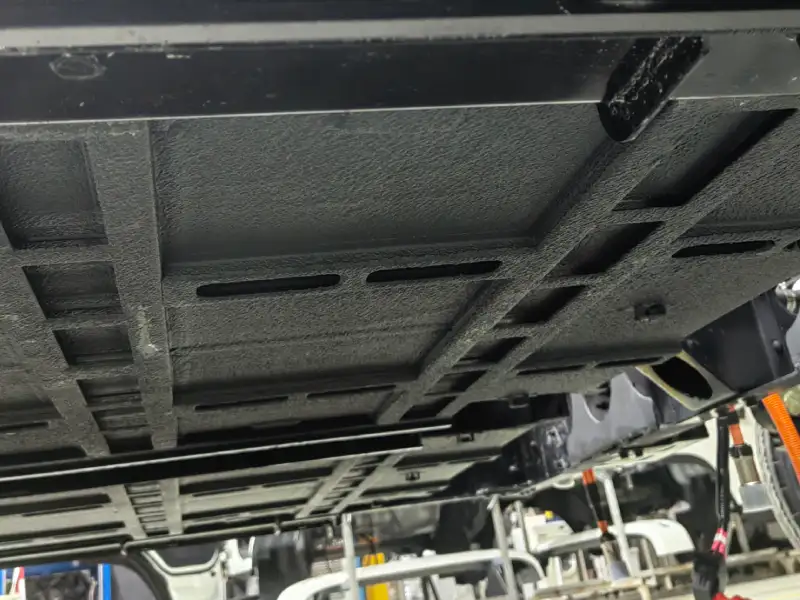

The bottom of our electric chassis is fortified with a specialized coating to safeguard the battery, enhancing the vehicles’s resilience against road debris and potential punctures from stones.

The seats or driver’s cab are designed for removal. By detaching the seats or cabin, a single container can accommodate more chassis units, optimizing shipping efficiency and reducing transportation costs.

Our range extender electric chassis options boost vehicle range across diverse applications.

Frequently Asked Questions

While the existing chassis is not designed for autonumous vehicles, we can develop a drive-by-wire chassis according to your specific needs.

We need to assess the suitability of the existing chassis for your fleet before providing you with the detailed price range.

Yes, it is possible. We can accommodate redundant systems upon request.

Currently, we can produce 300 units per month for the existing chassis. For drive-by-wire chassis, our production capacity is 50 units per month.

Currently, we can produce 300 units per month for the existing chassis. For drive-by-wire chassis, our production capacity is 50 units per month.

A standard 40HQ container can accommodate 2 chassis. However, if the seats are removed from the chassis, 4 chassis can be put together in the container.

- You may fill in the form below to get in touch with us first. Remember to describe your project info and product requirements as detailed as possible.

- Then we will arrange an expert to get back to you shortly and provide a customized solution for you.

- If necessary, our engineering team will discuss with your engineering team to check if our system can work well on your platform and if we need further modification, etc.

- Then we will provide the quotation to you.

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >