4-in-1 EV / HEV Auxiliary Inverter

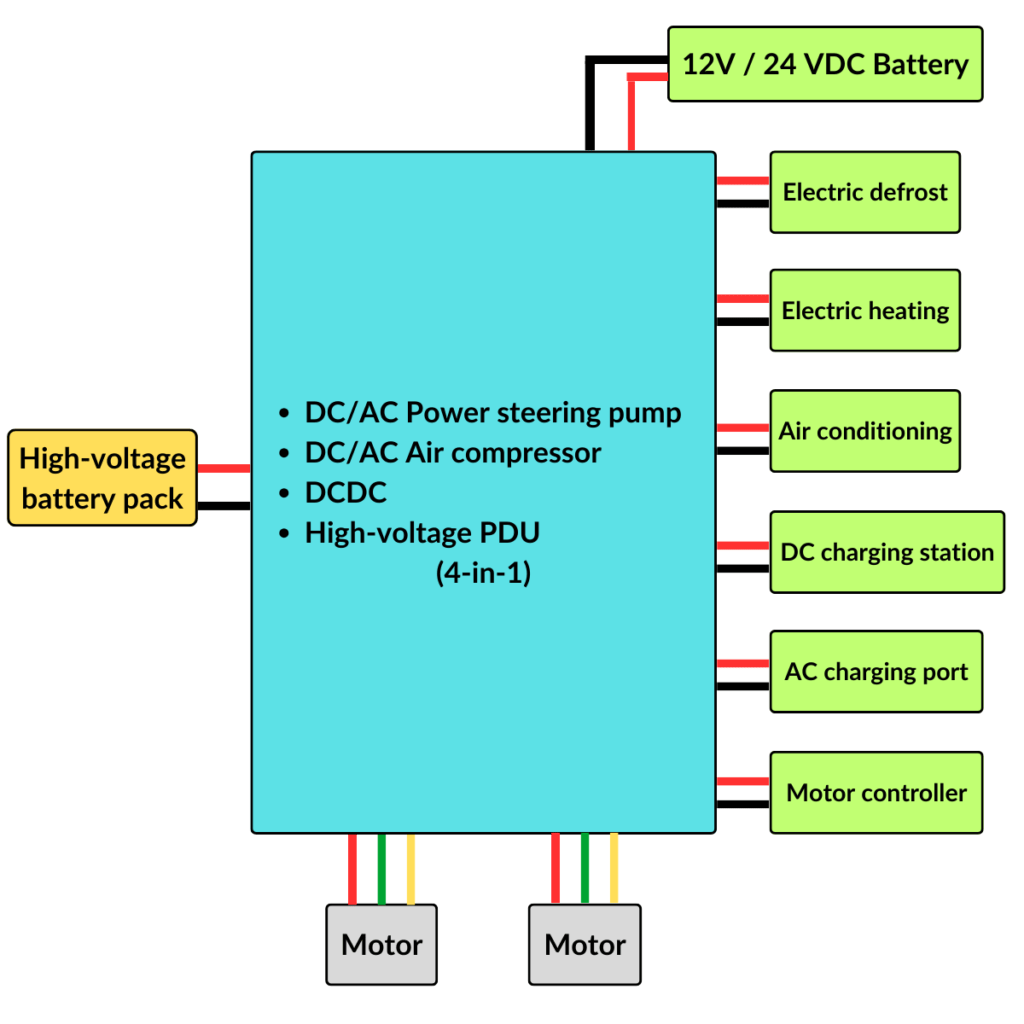

Our 4-in-1 Auxiliary Inverter comprises a DC/DC converter, two DC/AC inverters, and a high-voltage power distribution unit (PDU). Each component serves a critical function in managing the power dynamics of electric vehicles.

Applicable models: bus, light duty truck, heavy duty truck, street sweeper, etc.

Email: contact@brogenevsolution.com

Solution Details

- The DC/DC converter is responsible for transforming the high voltage from the battery into low voltage. This facilitates the charging of the onboard battery while supplying a steady DC power source to low-voltage components.

- The DC/AC inverters convert the high-voltage battery’s direct current into three-phase alternating current. This conversion is essential for controlling vital vehicle systems such as the electric air compressor and power steering pump, ensuring the operation of air pressure and power steering functionalities.

- The PDU serves as a control hub for the vehicle’s power supply system. It manages tasks such as power distribution, current measurement, short circuit protection, charge and discharge control, pre-charging, manual emergency stop, and insulation detection.

Solution Features

- Integrated and lightweight design: this Auxiliary Inverter boasts a 4-in-1 integrated design, significantly reducing system weight and size. This approach not only offers a lightweight solution but also delivers substantial space, wiring, and cost savings for electric commercial vehicles.

- Versatile application: designed to excel across diverse work conditions, the Auxiliary Inverter operates flawlessly within a temperature range of -40°C to 60°C. With an IP67 rating, it proves suitable for electric commercial vehicles across various challenging environments.

- Quiet operation: engineered for minimal disruption, our Auxiliary Inverter operates at less than 42 dB, ensuring a tranquil driving experience for both drivers and passengers.

- Enhanced safety: rigorously tested for safety and reliability, our product has undergone a series of assessments including low temperature, high temperature, humidity, salt spray, vibration, mechanical strength, noise, insulation performance, and voltage withstand tests.

Technical Specifications for the 4-in-1 Auxiliary Inverter

| Working temperature | -40°C – +60°C |

| Noise | < 42 dB |

| Cooling method | Aluminum base plate heat; Water cooling |

| Input control voltage | 9 – 36 V |

| IP rate | IP67 |

| System weight | 22.5 kg (plug not included) |

| Input voltage | 200 – 750 VDC |

| Input current | ≤ 350 A |

| Input voltage (low voltage) | 12 VDC | 24 VDC |

| (9 – 18 VDC) | (15 – 36 VDC) | |

| Input voltage (high voltage) | 380 VDC (220 – 500 VDC) | 380 VDC (220 – 500 VDC) |

| 540 VDC (400 – 750 VDC) | 540 VDC (400 – 750 VDC) | |

| Output voltage | 14 VDC | 27.5 / 27 VDC |

| Power | 1.5 kW | 3 kW |

| Rated current | 107 A | 110 A |

| Peak current 60s | 128 A | 125 A |

| Input voltage (low voltage) | 12 VDC / 24 VDC (9 – 36 VDC) | ||||||||

| Input voltage (high temperature) | 380 VDC (220 – 500 VDC) | 540 VDC (400 – 750 VDC) | |||||||

| Output voltage. Frequency | Three-phase 220 VAC. 50 Hz | Three-phase 220 VAC. 50 Hz | Three-phase 380 VAC. 50 Hz | ||||||

| Power | 2.2 kW | 3.7 kW | 5.5 kW | 2.2 kW | 3.7 kW | 5.5 kW | 2.2 kW | 3.7 kW | 5.5 kW |

| Rated current | 9 A | 13 A | 25 A | 9 A | 13 A | 25 A | 5.5 A | 9 A | 13 A |

| Peak current 60s | 18 A | 26 A | 50 A | 18 A | 26 A | 50 A | 11 A | 18 A | 26 A |

| Control voltage | 12 VDC / 24 VDC | ||||||||

| Control method | Enable control | High level is active by default (high and low levels can be configured) | |||||||

| Output voltage. Frequency | CAN control | DCDC, DCAC*2, high-voltage control panel accepts CAN control | |||||||

Auxiliary Inverter System Advantages

Tailored for Commercial Vehicles

Our integrated 4-in-1 Auxiliary Inverter is built to cater to the demanding requirements of commercial vehicle applications. Crafted with automotive-qualified components and EMC compliance, it adheres to pertinent national standards.

Robust Design for Commerical Environments

Designed to withstand the rigors of commercial use, our Auxiliary Inverter is engineered to endure shock and vibration, ensuring reliability and longevity in diverse operating conditions.

Versatile Applications

Our Auxiliary Inverter finds application in a variety of commercial vehicles, including electric buses, light-duty trucks, heavy-duty trucks, street sweepers, delivery vans, and more.

Scalable and Modular Design

Engineered as a scalable and modular system solution, our Auxiliary Inverter offers flexibility to accommodate various vehicle types and configurations. This design approach allows for seamless integration and customization to meet specific needs.

Cost-Effective Solution

By consolidating multiple functions into a single unit, our Auxiliary Inverter eliminates the need for individual inverters for each auxiliary. This scalable design significantly reduces redundant components such as DC cables, DC fuses, low voltage wiring harnesses, and coolant plumbing, resulting in cost savings and operational efficiency.

Hybrid Electric Semi-Truck Project in Canada

Edison Motors is a Canadian clean technology company that manufactures hybrid electric semi-trucks. For this project, we supplied our compact auxiliary inverter system. This integrated solution combines a DC/DC converter, DC/AC inverter, and high-voltage PDU, offering versatility across various vehicle types, including HEVs, BEVs, and FCEVs. Ideal for applications in passenger cars, logistics vehicles, buses, municipal vehicles, and semi-trucks, our system enhances efficiency and performance, meeting the diverse needs of modern electric transportation.

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >