Industrial Electric Motors

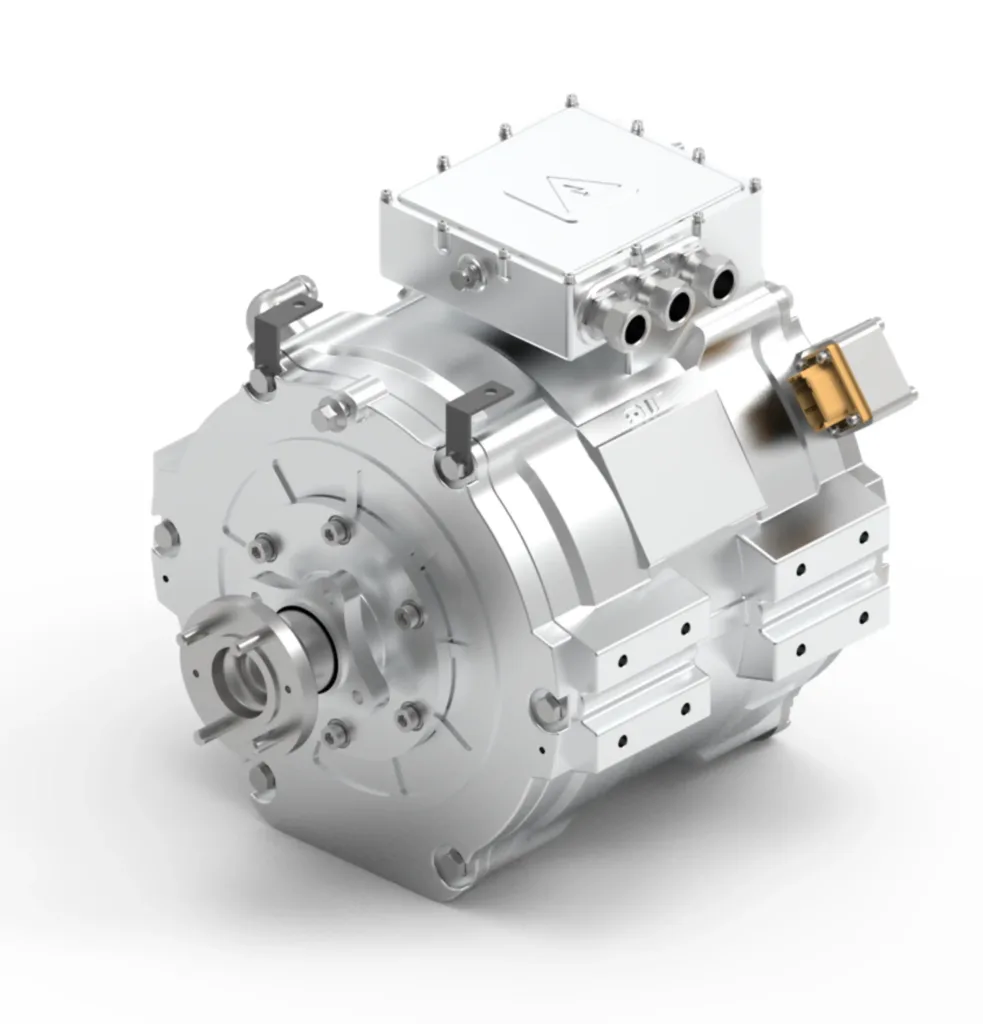

Our high-efficiency permanent magnet synchronous industrial electric motors are extensively utilized across various high-tech industries, including mining, oil field, water treatment, power generation, marine applications, etc. These industrial electric motors offer exceptional efficiency and low energy loss, ensuring reliable performance. They are the ideal choice for use in sensitive environments and under extreme conditions.

Whatsapp: +8619352173376

Email: contact@brogenevsolution.com

Why Choose Our PMSM Industrial Electric Motors

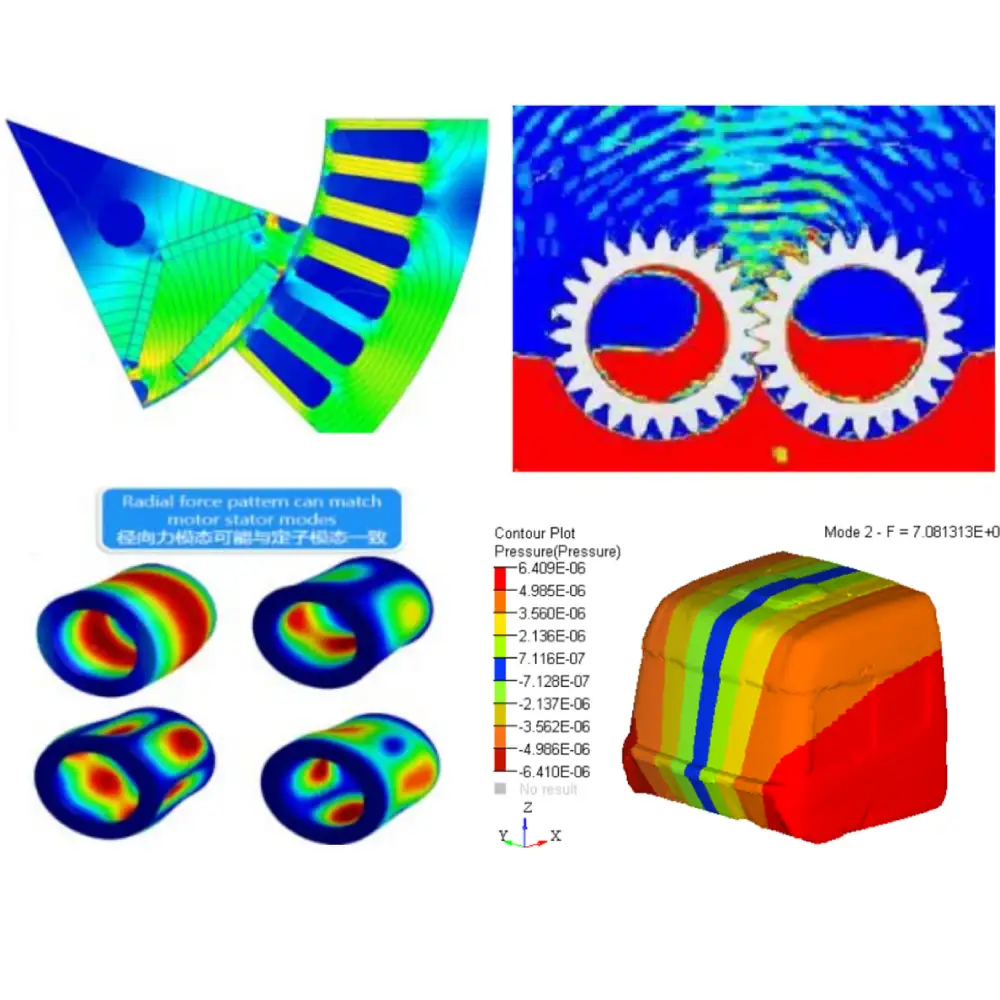

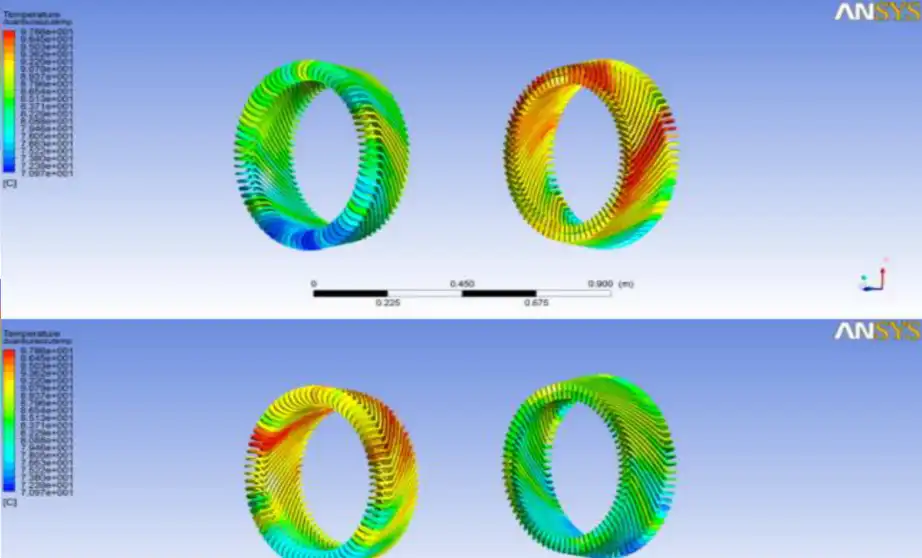

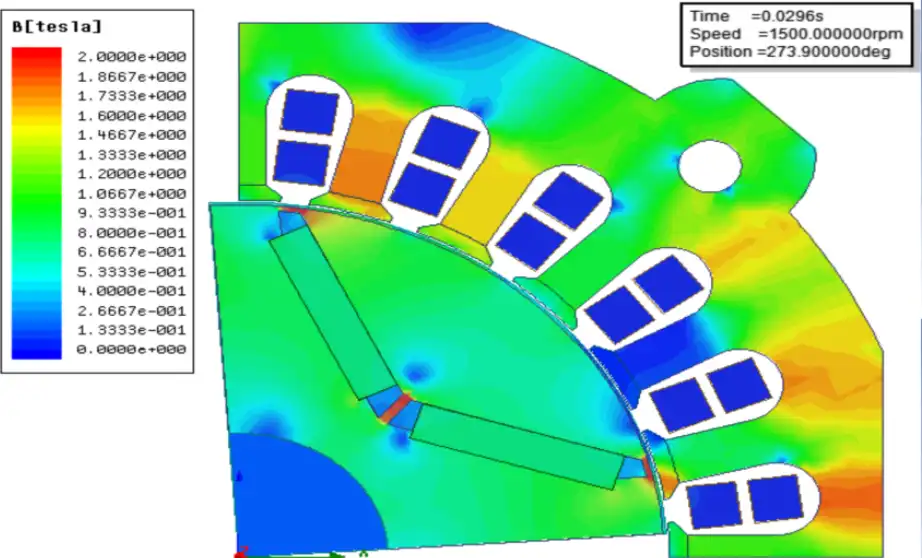

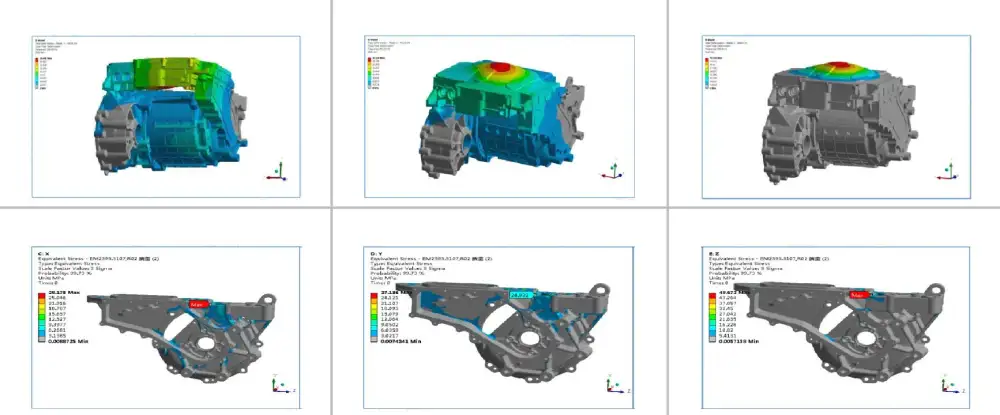

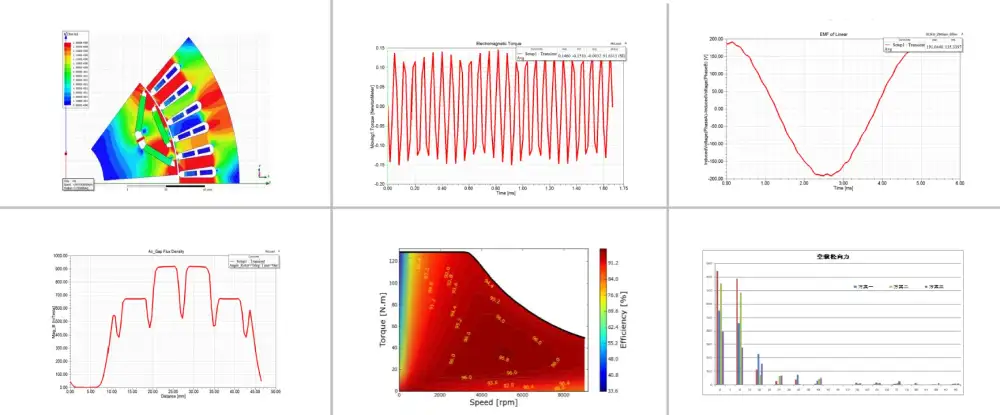

Cross-dimensional deep simulation & Full control over development quality

We Offer Best Features

Advanced Materials

Utilizes permanent magnets with high intrinsic coercivity and residual magnetism, and H-class insulated enameled copper wire.

Safe and Efficient

Features H-class insulation for enhanced protection, high power factor, high mechanical efficiency, and low losses.

Exceptional Environmental Adaptability

Engineered to meet passenger vehicle standards and processes, capable of operating at temperatures up to 180°C.

High Power Density

The application of PMSM motors ensure a compact design which help minimizes space requirements, thus increasing power density.

Comprehensive Testing and Validation

Verification includes 55 corporate testing standards covering areas such as motor, control system, performance, environment, reliability, temperature rise, efficiency, vibration, noise, sealing, and more.

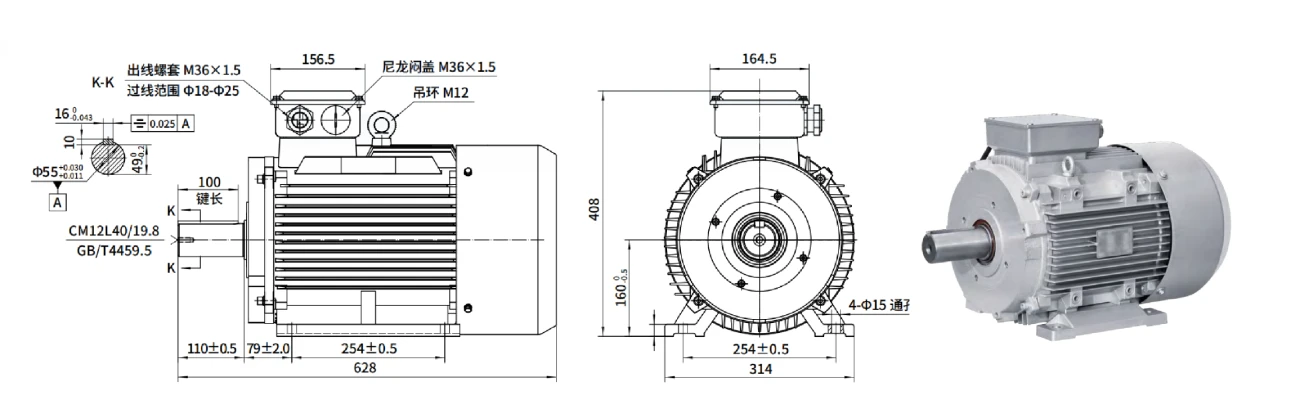

Our Industrial Electric Motors Offerings

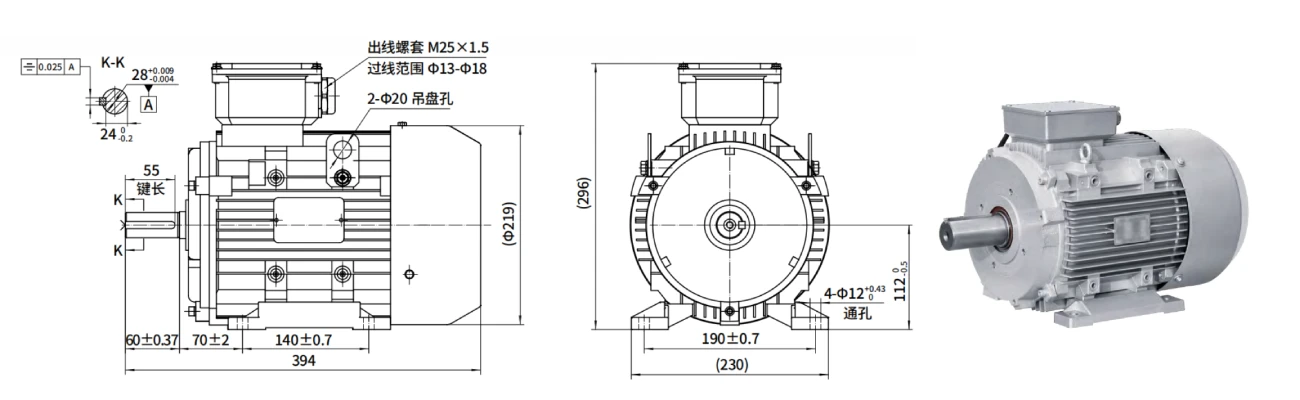

- The system operates with constant torque below the rated speed and constant power above the rated speed.

- The installation method and performance parameters can be adjusted according to the customer’s personalized requirements.

- Ambient temperature: -20°C ~ 40°C

- Altitude: not more than 1000 meters

- Working system: continuous working system (S1)

- Protection level: IP56

- Insulation level: H

- Cooling method: IC411/IC416

| Model | Rated Power (kW) | Rated Voltage (V) | Rated Current (A) | Rated Speed (rpm) | Rated Frequency (Hz) | Rated Torque (N.m) | Efficiency (%) | Power Factor | Speed Range |

| OE112M-4-1000 | 4 | 380 | 6.9 | 1000 | 100 | 38.2 | 93 | 0.95 | 0-1500 |

| OE112M-5.5-1000 | 5.5 | 380 | 9.4 | 1000 | 100 | 52.5 | 93.6 | 0.95 | 0-1500 |

| OE112M-4-1500 | 4 | 380 | 6.9 | 1500 | 150 | 25.5 | 93 | 0.95 | 0-2250 |

| OE112M-5.5-1500 | 5.5 | 380 | 9.5 | 1500 | 150 | 35 | 93 | 0.95 | 0-2250 |

| OE112M-7.5-1500 | 7.5 | 380 | 12.9 | 1500 | 150 | 47.8 | 93.1 | 0.95 | 0-2250 |

| OE112M-4-3000 | 4 | 380 | 6.8 | 3000 | 300 | 12.7 | 93.5 | 0.95 | 0-4500 |

| OE112M-5.5-3000 | 5.5 | 380 | 9.3 | 3000 | 300 | 17.5 | 94.2 | 0.95 | 0-4500 |

| OE112M-7.5-3000 | 7.5 | 380 | 12.7 | 3000 | 300 | 23.9 | 94.6 | 0.95 | 0-4500 |

| OE112M-11-3000 | 11 | 380 | 18.5 | 3000 | 300 | 35 | 95.3 | 0.95 | 0-4500 |

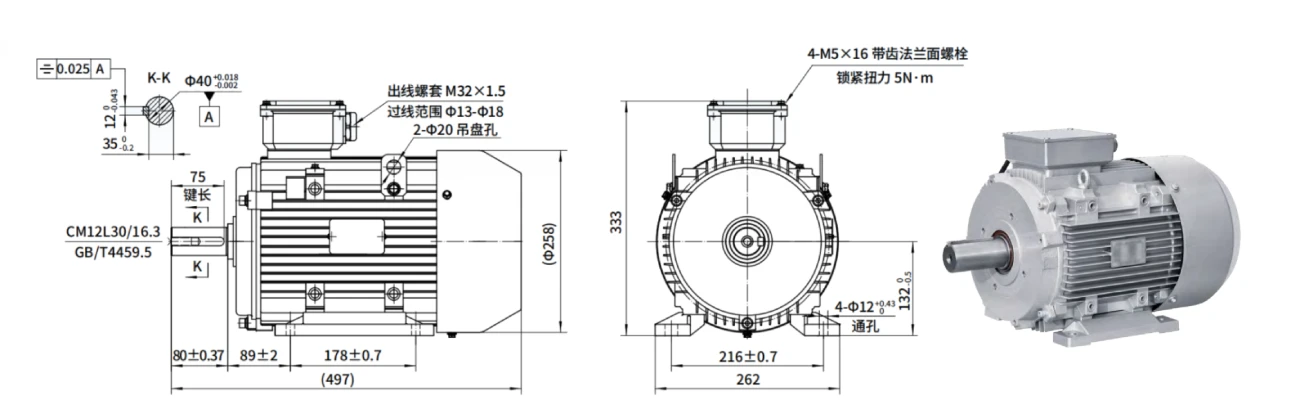

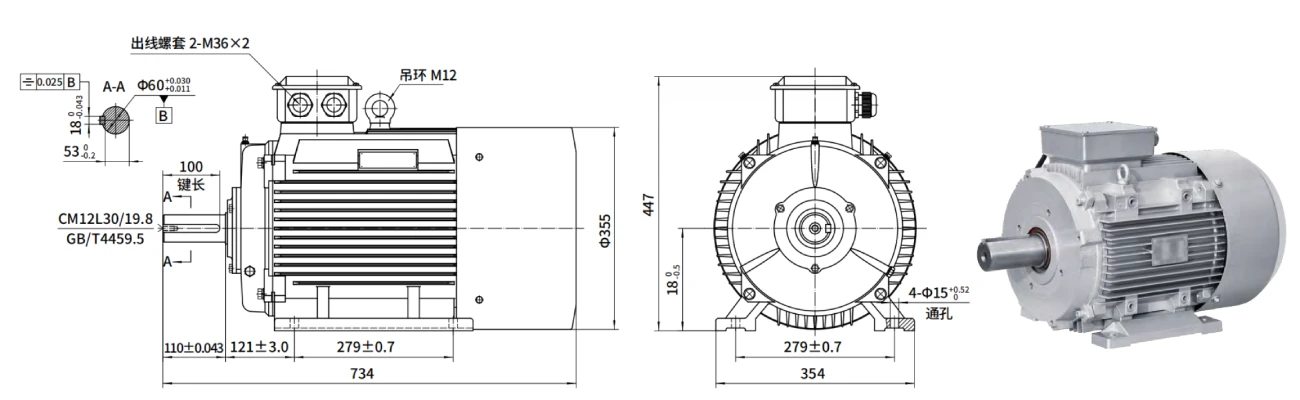

- The system operates with constant torque below the rated speed and constant power above the rated speed.

- The installation method and performance parameters can be adjusted according to the customer’s personalized requirements.

- Ambient temperature: -20°C ~ 40°C

- Altitude: not more than 1000 meters

- Working system: continuous working system (S1)

- Protection level: IP56

- Insulation level: H

- Cooling method: IC411/IC416

| Model | Rated Power (kW) | Rated Voltage (V) | Rated Current (A) | Rated Speed (rpm) | Rated Frequency (Hz) | Rated Torque (N.m) | Efficiency (%) | Power Factor | Speed Range |

| OE132M-4-750 | 4 | 380 | 6.9 | 750 | 50 | 50.9 | 93 | 0.95 | 0-1200 |

| OE132M-5.5-750 | 5.5 | 380 | 9.4 | 750 | 50 | 70 | 93.6 | 0.95 | 0-1200 |

| OE132M-7.5-750 | 7.5 | 380 | 12.7 | 750 | 50 | 95.5 | 94.2 | 0.95 | 0-1200 |

| OE132M-11-0-750 | 11 | 380 | 18.6 | 750 | 50 | 140.1 | 94.6 | 0.95 | 0-1200 |

| OE132M-7.5-1000 | 7.5 | 380 | 12.7 | 1000 | 66.7 | 71.63 | 94.5 | 0.95 | 0-1500 |

| OE132M-11-1000 | 11 | 380 | 18.5 | 1000 | 66.7 | 105.05 | 95 | 0.95 | 0-1500 |

| OE132M-15-1000 | 15 | 380 | 25.2 | 1000 | 66.7 | 143.25 | 95.2 | 0.95 | 0-1500 |

| OE132M-11-1500 | 11 | 380 | 18.7 | 1500 | 100 | 70 | 94 | 0.95 | 0-2250 |

| OE132M-15-1500 | 15 | 380 | 25.4 | 1500 | 100 | 95.5 | 94.5 | 0.95 | 0-2250 |

| OE132M-18.5-1500 | 18.5 | 380 | 31.1 | 1500 | 100 | 117.8 | 95 | 0.95 | 0-2250 |

| OE132M-22-1500 | 22 | 380 | 37 | 1500 | 100 | 140.1 | 95.1 | 0.95 | 0-2250 |

| OE132M-15-3000 | 15 | 380 | 25.1 | 3000 | 200 | 47.8 | 95.4 | 0.95 | 0-4500 |

| OE-132M-18.5-3000 | 18.5 | 380 | 30.9 | 3000 | 200 | 58.9 | 95.7 | 0.95 | 0-4500 |

| OE132M-22-3000 | 22 | 380 | 36.7 | 3000 | 200 | 70 | 95.9 | 0.95 | 0-4500 |

| OE132M-30-3000 | 30 | 380 | 49.9 | 3000 | 200 | 95.5 | 96.1 | 0.95 | 0-4500 |

| OE132M-37-3000 | 37 | 380 | 61.4 | 3000 | 200 | 117.8 | 96.3 | 0.95 | 0-4500 |

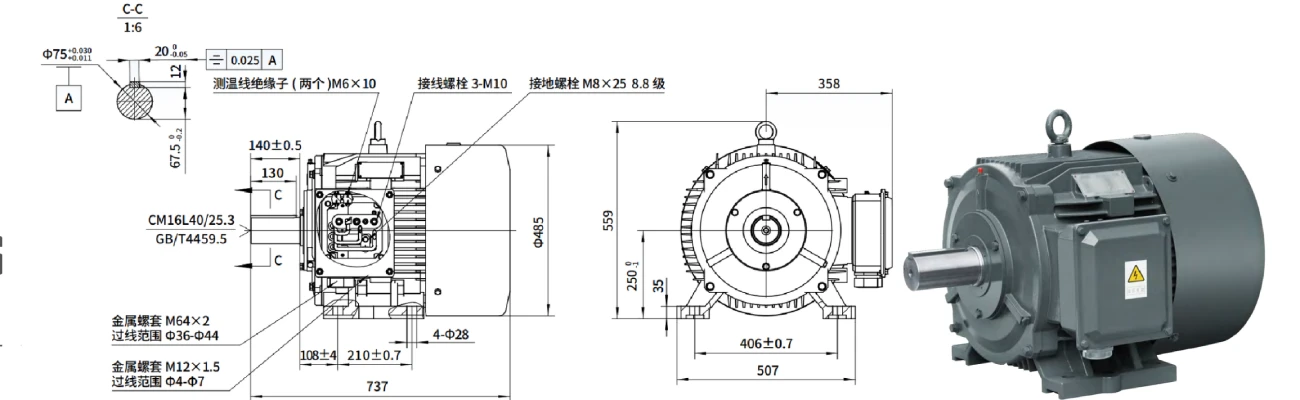

- The system operates with constant torque below the rated speed and constant power above the rated speed.

- The installation method and performance parameters can be adjusted according to the customer’s personalized requirements.

- Ambient temperature: -20°C ~ 40°C

- Altitude: not more than 1000 meters

- Working system: continuous working system (S1)

- Protection level: IP56

- Insulation level: H

- Cooling method: IC411/IC416

| Model | Rated Power (kW) | Rated Voltage (V) | Rated Current (A) | Rated Speed (rpm) | Rated Frequency (Hz) | Rated Torque (N.m) | Efficiency (%) | Power Factor | Speed Range |

| OE160L-15-750 | 15 | 380 | 25.1 | 750 | 50 | 191 | 94.5 | 0.96 | 0-1200 |

| OE160L-18.5-750 | 18.5 | 380 | 31 | 750 | 50 | 235.6 | 94.6 | 0.96 | 0-1200 |

| OE160L-22-750 | 22 | 380 | 36.7 | 750 | 50 | 280.1 | 94.9 | 0.96 | 0-1200 |

| OE160L-18.5-1000 | 18.5 | 380 | 30.7 | 1000 | 66.7 | 176.7 | 95.3 | 0.96 | 0-1500 |

| OE160L-22-1000 | 22 | 380 | 36.4 | 1000 | 66.7 | 210.1 | 95.6 | 0.96 | 0-1500 |

| OE160L-30-1000 | 30 | 380 | 49.6 | 1000 | 66.7 | 286.5 | 95.8 | 0.96 | 0-1500 |

| OE160L-30-1500 | 30 | 380 | 50 | 1500 | 100 | 191 | 95 | 0.96 | 0-2250 |

| OE160L-37-1500 | 37 | 380 | 61.4 | 1500 | 100 | 235.6 | 95.3 | 0.96 | 0-2250 |

| OE160L-45-1500 | 45 | 380 | 74.5 | 1500 | 100 | 286.5 | 95.6 | 0.96 | 0-2250 |

| OE160L-45-3000 | 45 | 380 | 74.3 | 3000 | 200 | 143.3 | 95.8 | 0.96 | 0-4500 |

| OE160L-55-3000 | 55 | 380 | 90.9 | 3000 | 200 | 175.1 | 95.8 | 0.96 | 0-4500 |

| OE160L-75-3000 | 75 | 380 | 123.4 | 3000 | 200 | 238.8 | 96.2 | 0.96 | 0-4500 |

| OE160L-90-3000 | 90 | 380 | 147.5 | 3000 | 200 | 286.5 | 96.6 | 0.96 | 0-4500 |

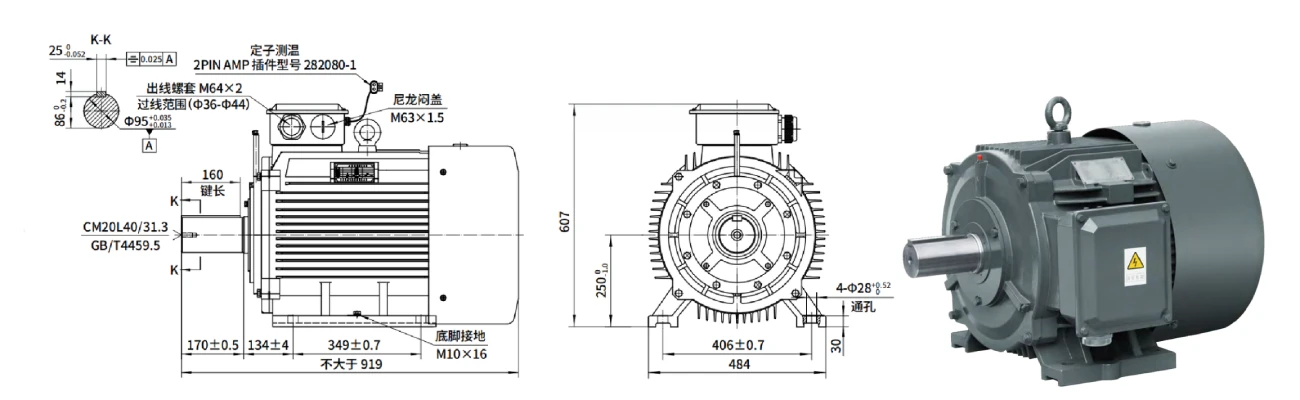

- The system operates with constant torque below the rated speed and constant power above the rated speed.

- The installation method and performance parameters can be adjusted according to the customer’s personalized requirements.

- Ambient temperature: -20°C ~ 40°C

- Altitude: not more than 1000 meters

- Working system: continuous working system (S1)

- Protection level: IP56

- Insulation level: H

- Cooling method: IC411/IC416

| Model | Rated Power (kW) | Rated Voltage (V) | Rated Current (A) | Rated Speed (rpm) | Rated Frequency (Hz) | Rated Torque (N.m) | Efficiency (%) | Power Factor | Speed Range |

| OE180L-30-750 | 30 | 380 | 50.1 | 750 | 50 | 382 | 94.8 | 0.96 | 0-1200 |

| OE180L-37-750 | 37 | 380 | 61.6 | 750 | 50 | 471.1 | 95 | 0.96 | 0-1200 |

| OE180L-37-1000 | 37 | 380 | 61.1 | 1000 | 66.7 | 353.35 | 95.8 | 0.96 | 0-1500 |

| OE180L-45-1000 | 45 | 380 | 74.2 | 1000 | 66.7 | 429.75 | 96 | 0.96 | 0-1500 |

| OE180L-55-1500 | 55 | 380 | 90.8 | 1500 | 100 | 350.2 | 95.9 | 0.96 | 0-2250 |

| OE180L-75-1500 | 75 | 380 | 123.6 | 1500 | 100 | 477.5 | 96 | 0.96 | 0-2250 |

| OE180L-110-3000 | 110 | 380 | 180.4 | 3000 | 200 | 350.2 | 96.5 | 0.96 | 0-4500 |

| OE180L-132-3000 | 132 | 380 | 216 | 3000 | 200 | 420.2 | 96.7 | 0.96 | 0-4500 |

- The system operates with constant torque below the rated speed and constant power above the rated speed.

- The installation method and performance parameters can be adjusted according to the customer’s personalized requirements.

- Ambient temperature: -20°C ~ 40°C

- Altitude: not more than 1000 meters

- Working system: continuous working system (S1)

- Protection level: IP56

- Insulation level: H

- Cooling method: IC411/IC416

| Model | Rated Power (kW) | Rated Voltage (V) | Rated Current (A) | Rated Speed (rpm) | Rated Frequency (Hz) | Rated Torque (N.m) | Efficiency (%) | Power Factor | Speed Range |

| OE250S-45-750 | 45 | 380 | 74.8 | 750 | 75 | 573 | 95.2 | 0.96 | 0-1200 |

| OE250S-55-750 | 55 | 380 | 90.9 | 750 | 75 | 700.3 | 95.8 | 0.96 | 0-1200 |

| OE250S-60-800 | 60 | 380 | 98.5 | 800 | 80 | 716 | 96.4 | 0.96 | 0-1200 |

| OE250S-55-1000 | 55 | 380 | 90.4 | 1000 | 100 | 525.25 | 96.3 | 0.96 | 0-1500 |

| OE250S-60-1000 | 60 | 380 | 98.6 | 1000 | 100 | 573 | 96.3 | 0.96 | 0-1500 |

| OE250S-72-1200 | 72 | 380 | 118.5 | 1200 | 120 | 573 | 96.2 | 0.96 | 0-1800 |

| OE250S-75-1000 | 75 | 380 | 123.1 | 1000 | 100 | 716.25 | 96.4 | 0.96 | 0-1500 |

| OE250S-90-1500 | 90 | 380 | 147.6 | 1500 | 150 | 573 | 96.5 | 0.96 | 0-2250 |

| OE250S-110-1500 | 110 | 380 | 180 | 1500 | 150 | 700.3 | 96.7 | 0.96 | 0-2250 |

| OE250S-160-3000 | 160 | 380 | 261.6 | 3000 | 300 | 509.3 | 96.8 | 0.96 | 0-4500 |

- The system operates with constant torque below the rated speed and constant power above the rated speed.

- The installation method and performance parameters can be adjusted according to the customer’s personalized requirements.

- Ambient temperature: -20°C ~ 40°C

- Altitude: not more than 1000 meters

- Working system: continuous working system (S1)

- Protection level: IP56

- Insulation level: H

- Cooling method: IC411/IC416

| Model | Rated Power (kW) | Rated Voltage (V) | Rated Current (A) | Rated Speed (rpm) | Rated Frequency (Hz) | Rated Torque (N.m) | Efficiency (%) | Power Factor | Speed Range |

| OE-250M-66-750 | 66 | 380 | 109.4 | 750 | 75 | 840.4 | 95.5 | 0.96 | 0-1200 |

| OE-250M-75-750 | 75 | 380 | 124.2 | 750 | 75 | 955 | 95.6 | 0.96 | 0-1200 |

| OE-250M-90-750 | 90 | 380 | 148.7 | 750 | 75 | 1146 | 95.8 | 0.96 | 0-1200 |

| OE-250M-90-1000 | 90 | 380 | 148.1 | 1000 | 100 | 859.5 | 96.2 | 0.96 | 0-1500 |

| OE-250M-110-1000 | 110 | 380 | 180.8 | 1000 | 100 | 1050.5 | 96.3 | 0.96 | 0-1500 |

| OE-250M-132-1000 | 132 | 380 | 216.9 | 1000 | 100 | 1260.6 | 96.3 | 0.96 | 0-1500 |

| OE-250M-132-1500 | 132 | 380 | 216.6 | 1500 | 150 | 840.4 | 96.3 | 0.96 | 0-2250 |

| OE-250M-160-1500 | 160 | 380 | 262.4 | 1500 | 150 | 1018.7 | 96.5 | 0.96 | 0-2250 |

| OE-250M-200-1500 | 200 | 380 | 327.7 | 1500 | 150 | 1273.3 | 96.6 | 0.96 | 0-2250 |

| OE-250M-200-3000 | 200 | 380 | 328.4 | 3000 | 300 | 636.7 | 96.4 | 0.96 | 0-4500 |

| OE-250M-250-3000 | 250 | 380 | 410 | 3000 | 300 | 795.8 | 96.5 | 0.96 | 0-4500 |

- The system operates with constant torque below the rated speed and constant power above the rated speed.

- The installation method and performance parameters can be adjusted according to the customer’s personalized requirements.

- Ambient temperature: -20°C ~ 40°C

- Altitude: not more than 1000 meters

- Working system: continuous working system (S1)

- Protection level: IP56

- Insulation level: H

- Cooling method: IC411/IC416

| Model | Rated Power (kW) | Rated Voltage (V) | Rated Current (A) | Rated Speed (rpm) | Rated Frequency (Hz) | Rated Torque (N.m) | Efficiency (%) | Power Factor | Speed Range |

| OE280M-110-750 | 110 | 380 | 181 | 750 | 75 | 1400.7 | 96.2 | 0.96 | 0-1200 |

| OE280M-132-750 | 132 | 380 | 216.9 | 750 | 75 | 1680.8 | 96.3 | 0.96 | 0-1200 |

| OE280M-116-1000 | 160 | 380 | 263 | 1000 | 100 | 1528 | 96.3 | 0.96 | 0-1500 |

| OE280M-200-1000 | 200 | 380 | 328 | 1000 | 100 | 1910 | 96.5 | 0.96 | 0-1500 |

| OE280M-250-1500 | 250 | 380 | 408.8 | 1500 | 150 | 1591.7 | 96.8 | 0.96 | 0-2250 |

| OE280M-280-1500 | 280 | 380 | 456.9 | 1500 | 150 | 1782.7 | 97 | 0.96 | 0-2250 |

Applications

Construction Site

Mining

Oil Field

Marine

Power Plant

Water Conservancy

Cut Your Energy Costs With Our High-Efficiency Industrial Electric Motors

Electric motors power essential equipment like pumps, fans, and compressors, accounting for over 60% of global electricity consumption. By using energy-efficient variable frequency drive (VFD) technology, we can reduce motor energy use by 20-30%, supporting energy savings. Upgrading to IE5 efficiency is crucial for carbon peak and neutrality, with permanent magnet technology being key to achieving this.

Our high-efficiency permanent magnet three-phase synchronous motors offer compact design, high power density, and low energy losses, helping businesses achieve substantial energy savings and sustainability.

AC Induction Motors v.s. PMSM Motors

High Efficiency

By using permanent magnet materials in the rotor, there is no need for reactive excitation current. The magnetic flux provided by the magnets replaces the electrical excitation, reducing stator current and stator resistance losses.

High Power Factor

The motor maintains a high power factor and efficiency across the rated load range, providing more significant energy savings at light loads. The power factor exceeds 0.95 at rated load.

High Starting Torque

Unlike typical induction motors, which have a starting torque of 1.8-2.2 times, the PMSM offers a starting torque range of 3.5-4.3 times, significantly reducing startup time.

Compact and Lightweight

Compared to traditional motors of the same power, PMSM reduces size by about 40% and weight by about 17%.

Additional Features

Long service life. Low maintenance cost. Stable magnetic field strength with minimal demagnetization.

Example Projects

Wire saw machine

- Model: OE250-60-800

- Model: OE250-66-750

- Model: OE250-83-750

- The comprehensive power-saving rate is 20%.

- Adapt to the harsh working environment of mines with dust, water mist, and unstable voltage.

Mining circular saw

- Model: OE250-72-1200

- Model: OE250-80-1000

- For 3.6m and 4.8m large cutters

- The comprehensive power-saving rate is 20%.

- Adapt to the harsh working environment of mines with dust, water mist, and unstable voltage. The motor runs stably, the saw table moves faster and the stone cut surface is smoother.

Spinning machine

- Model: OE132-18.5-1500

- Model: OE132-22-1500

- The comprehensive power-saving rate is 10%.

- The motor runs more stably, and the yarn production is increased by 10%.

Extruder machine

- Model: OE355-400-1000

- Model: OE315-280-1000

- Application of high-power motors in rubber, mixing, and extrusion industries.

- The machine size is 3 frame sizes smaller than asynchronous machines and 1-2 frame sizes smaller than competing products.

- The comprehensive power-saving rate is 25%.

Gantry saw

- Model: OE250-132-1000

- Model: OE250-110-1000

- The motor has strong power, high power density, and easy installation.

- Stable operation, constant cutting depth, smooth cutting surface, and reduced waste of rough materials.

- The comprehensive power-saving rate is 25%.

Why Choose Us

Exceptional R&D Expertise

We prioritize customer requirements, utilizing a V-model positive development process aligned with automotive industry standards. Additionally, we have established rigorous verification systems encompassing functional, performance, environmental, EMC, NVH, vibration, and reliability assessments for both component-level and assembly-level evaluations across magnetic field, structural hardware, and software domains.

Comprehensive Electric Powertrain Solutions

Our electric powertrain solutions include motors, controllers, and other systems, all of which can be customzied to meet specific customer requirements.

Extensive Global Project Experience

With a multilingual team, we serve clients worldwide and have successfully completed electric powertrain projects overseas, earning appreciation letters from satisfied customers.

Experienced R&D Team

We specialize in the development of high-power-density, high-safety, and long-lifespan electric motors, driven by a dedicated and highly skilled research and development team.

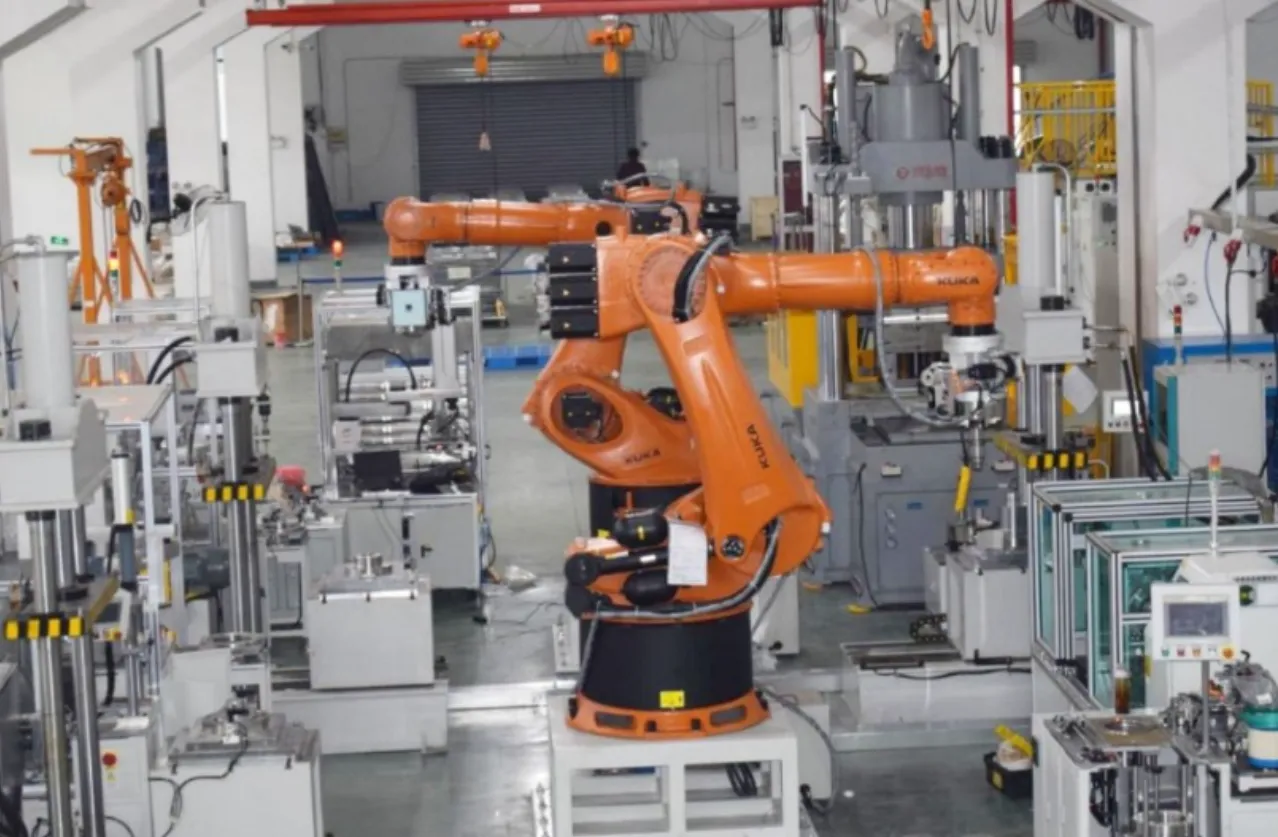

Strong Manufacturing Capabilities

Our electric motor factory has achieved full in-house design and production capabilities for key components such as motors and transmissions. Equipped with internationally advanced production line equipment, we ensure consistency and quality in mass production, meeting customers’ high standards for product performance.

Motor Stator Automatic Production Line

Capable of automated processes such as wire embedding, shaping, wire tiring, and terminal pressing, with a high level of automation.

Motor Rotor Automatic Production Line

Features automated material handling, magnet insertion with full position recognition, press-fitting with pressure and stroke monitoring, and automatic dynamic balancing.

Transmission Housing and Gear Shaft Automatic Production Line

Supports automated marking, scanning, machining, cleaning, pressure testing, and on-line measurement. Pre-heating shaft and gear machining lines employ robots for material handling, replacing manual operations. The entire production process is transparent, efficient, controlled, and traceable in real-time.

Comprehensive Gear Grinding With Modifications

Transmissions for (hybrid) electric vehicles require higher speeds, greater efficiency, improved NVH performance, and the ability to withstand greater reverse torque. Our advanced gear modification and full grinding processes meet these demanding requirements.

Connected Equipment

CNC equipment is interconnected, enabling real-time monitoring of equipment status, production orders, and operator information. This enhances product traceability, supports automated statistical analysis, and provides production anomaly alerts, improving both quality and efficiency.

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >