Lithium Batteries for Airport Ground Support Equipment (GSE)

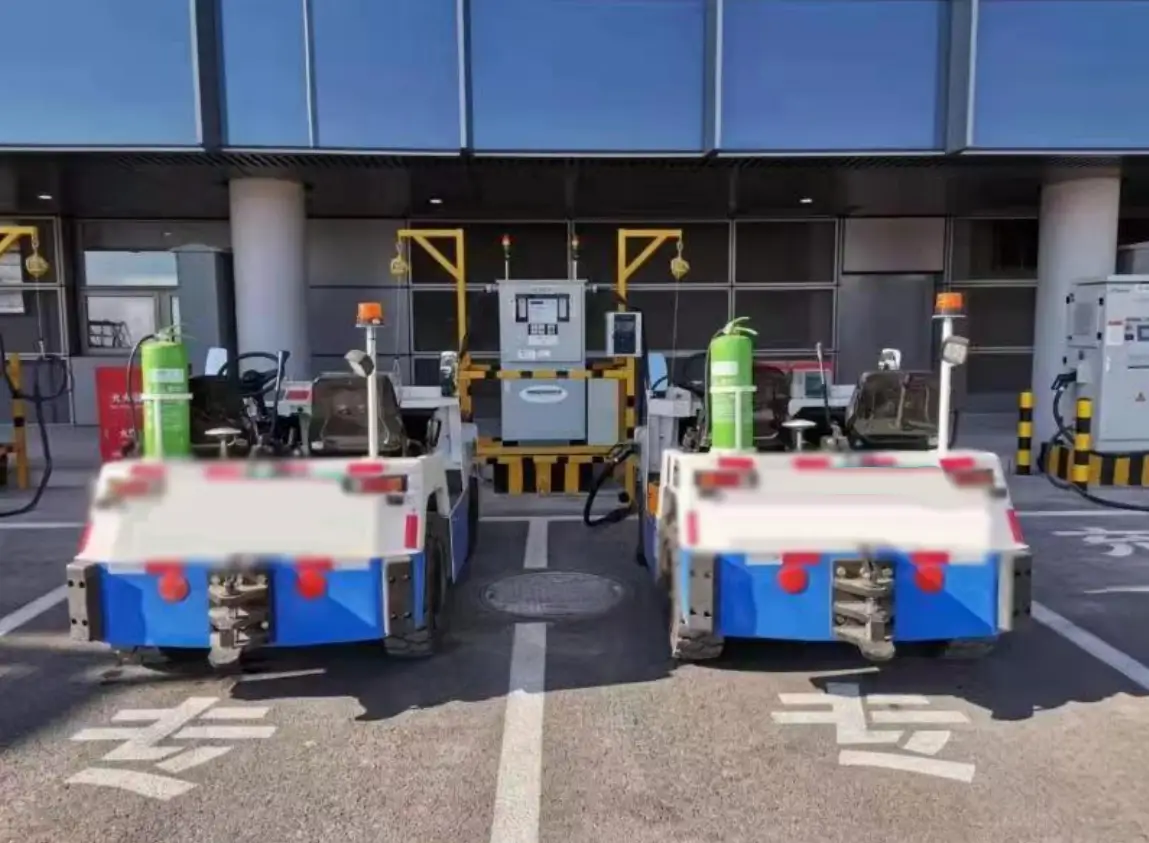

We bring extensive experience in providing advanced lithium batteries for airport ground support equipment (GSE) such as towing tractors, baggage handlers, shuttle buses, aircraft tugs, and more. Committed to sustainability, zero emissions, and reducing carbon footprints, we are at the forefront of driving the electrification of airport GSE, shaping a cleaner and greener future.

Email: contact@brogenevsolution.com

Lithium Batteries for Airport Ground Support Equipment (GSE) - Benefits

Premium Battery Cell

We use battery cells from top global lithium battery manufacturers, paired with a cushioning design in the battery cell and module space. This design quickly absorbs expansion due to battery "breathing" and provides added protection in collisions, enhancing overall battery safety.

Wide Voltage Charging

Utilizing core electronic control advantages and BDU control, our lithium GSE batteries are compatible with both high-voltage and low-voltage charging (80 V - 750 V), achieving "series charge, parallel discharge".

Intelligent Management

Our self-developed thermal management system includes heating, cooling, and insulation.

High Energy Density

The lithium batteries for airport ground support equipment feature a lightweight design for high energy density.

Highly Integrated Battery Solution for Enhanced Quality, Efficiency, Safety

High Integration for Maximum Energy Density

- Comprehensive active safety system with integrated wiring harnesses, aluminum busbars, temperature sensors, pressure monitoring, explosion-proof valves, electrolyte detection, and BMS sensor board.

- Saves 5%-10% of battery pack space.

Enhanced Insulation & Voltage Resistance for Safety

- Meets 2000 V insulation standard between adjacent aluminum busbars and between busbars and temperature sensors.

- Meets 6000 V insulation standard between aluminum busbars and PC module.

- Significantly lowers risks associated with insulation aging, fractures, and short circuits commonly seen in traditional wiring harnesses.

Brogen Lithium Batteries for Airport Ground Support Equipment (GSE)

*The battery system specifications below are based on our previous project applications and are provided for reference only. For your specific project, customization may be required depending on the application and vehicle platform. Please feel free to contact us for tailored solutions.

1. Lithium-Ion Batteries for Electric Aircraft Tugs (Reference Projects)

64.2 kWh, 831 Ah, 77.28 V LFP Battery System for Electric Aircraft Tugs

| Item | Parameters | Remark |

| Battery cell model | EC-AU277-CLH3L0 | LiFePO4 |

| Module configuration | 1P12S | |

| Battery box | Non-standard box, 1PCS | 1065*576*640 mm |

| System capacity | 831 Ah | System energy: 64.2 kWh |

| System rated voltage | 77.28 V | |

| System energy density | >110 wh/kg | |

| System configuration | 3P24S | |

| Cooling method | Natural cooling | |

| Heating method | PI heating film |

66.84 kWh, 831 Ah, 386.4 V LFP Battery System for Electric Aircraft Tugs

| Item | Parameters | Remark |

| Battery cell model | LF173Ah3.22V CLH3L0 | LiFePO4 |

| Module configuration | 1P12S | |

| Battery box | Non-standard box, 1PCS | 1115*645*645 mm |

| System capacity | 831 Ah | System energy: 66.84 kWh |

| System rated voltage | 386.4 V | |

| System configuration | 1P120S | |

| Cooling method | Natural cooling | |

| Heating method | PI heating film |

2. Lithium-Ion Batteries for Electric Airport Tow Tractors (Reference Projects)

64.91 kWh, 831 Ah, 77.28 V LFP Battery System for Electric Airport Tow Tractors

| Item | Parameters | Remark |

| Battery cell model | EC-AU 280 | Airport-specific 280 Ah LiFePO4 |

| Module configuration | 1P12S | |

| Battery box | Non-standard box, 1PCS | 1065*576*640 mm |

| System capacity | 831 Ah | System energy: 64.91 kWh |

| System rated voltage | 77.28 V | |

| System energy density | >125 wh/kg | |

| System configuration | 3P24S | Redundant design with three independent operating circuits |

| Cooling method | Natural cooling | |

| Heating method | PI heating film | |

| Fire suppression solution | S-type Aerosol | |

| Continuous charge/discharge current | 840 A | 25°C, 50% capacity |

63.68 kWh, 206 Ah, 309.12 V LFP Battery System for Electric Airport Tow Tractors

| Item | Parameters | Remark |

| Battery cell model | EC-AU 206 | Airport-specific 206 Ah LiFePO4 |

| Module configuration | 1P16S | |

| Battery box | Non-standard box, 1PCS | 1065*576*640 mm |

| System capacity | 206 Ah | System energy: 63.68 kWh |

| System rated voltage | 309.12 V | |

| System energy density | >125 wh/kg | |

| System configuration | 1P96S | |

| Cooling method | Natural cooling | |

| Heating method | PI heating film | |

| Fire suppression solution | S-type Aerosol | |

| Continuous charge/discharge current | 260 A | 25°C, 50% capacity |

47.46 kWh, 618 Ah, 76.8 V LFP Battery System for Electric Airport Tow Tractors

| Item | Parameters | Remark |

| Battery cell model | 206 Ah | LiFePO4 |

| Module configuration | 1P12S | |

| Battery box | Non-standard box, 1PCS | 1065*576*640 mm |

| System capacity | 618 Ah | System energy: 47.46 kWh |

| System rated voltage | 76.8 V | |

| System configuration | 3P24S | |

| Cooling method | Natural cooling | |

| Heating method | PI heating film | |

| Fire suppression solution | HFC-227ea | |

| Continuous charge/discharge current | 147 A | 25°C, 50% capacity |

43.28 kWh, 560 Ah, 77.28 V LFP Battery System for Electric Airport Belt Loaders

| Item | Parameters | Remark |

| Battery cell model | EC-AU 280 | Airport-specific 280 Ah LiFePO4 |

| Module configuration | 1P12S | |

| Battery box | Non-standard box, 1PCS | 1065*576*640 mm |

| System capacity | 560 Ah | System energy: 43.28 kWh |

| System rated voltage | 77.28 V | |

| System configuration | 2P24S | Redundant design with two independent operating circuits |

| Cooling method | Natural cooling | |

| Heating method | PI heating film | |

| Fire suppression solution | S-type Aerosol | |

| Continuous charge/discharge current | 560 A | 25°C, 50% capacity |

43.28 kWh, 560 Ah, 77.28 V LFP Battery System for Electric Airport Tow Tractors

| Item | Parameters | Remark |

| Battery cell model | EC-AU 280 | Airport-specific 280 Ah LiFePO4 |

| Module configuration | 1P8S | |

| Battery box | Non-standard box, 1PCS | 920*675*812 mm |

| System capacity | 560 Ah | System energy: 43.28 kWh |

| System rated voltage | 77.28 V | |

| System configuration | 2P24S | Redundant design with two independent operating circuits |

| Cooling method | Natural cooling | |

| Heating method | PI heating film | |

| Fire suppression solution | S-type Aerosol | |

| Continuous charge/discharge current | 560 A | 25°C, 50% capacity |

86.55 kWh, 280 Ah, 309 V LFP Battery System for Electric Airport Tow Tractors

| Item | Parameters | Remark |

| Battery cell model | EC-AU 280 | Airport-specific 280 Ah LiFePO4 |

| Module configuration | 1P16S | |

| Battery box | Non-standard box, 1PCS | 1200*576*635 mm |

| System capacity | 280 Ah | System energy: 86.55 kWh |

| System rated voltage | 309 V | |

| System configuration | 1P96S | |

| Cooling method | Natural cooling | |

| Heating method | PI heating film | |

| Fire suppression solution | S-type Aerosol | |

| Continuous charge/discharge current | 280 A | 25°C, 50% capacity |

11.52 kWh, 120 Ah, 96 V LFP Battery System for Electric Airport Tow Tractors

| Item | Parameters | Remark |

| Battery cell model | EC-AU 120 | 120 Ah LiFePO4 |

| Module configuration | 1P8S+1P6S | |

| Battery box | Non-standard box, 1PCS | 761*452*280 mm |

| System capacity | 120 Ah | System energy: 11.52 kWh |

| System rated voltage | 96 V | |

| System configuration | 1P30S | |

| Cooling method | Natural cooling | |

| Heating method | N.A. |

Why Choose Us

Exceptional R&D Expertise

BMS Design & Development

Independently develop BMS software; design control strategies and diagnostic analysis algorithms in-house; design the controller main board, control circuits, monitoring circuits, and communication circuits

Pack Structural & Electricial Design & Development

Independently design integrated battery pack structures to accommodate various battery cell types and capacity needs; independently design electrical circuits and select components, with electrical testing and verification environments to ensure compliance with standards

Battery System Integration Design & Development

Independently design electrical systems and structures; capable of integrating third-party systems, equipment, and components

Modern Manufacturing Plant

Our Airport Lithium Battery Projects

386.4 V 173 Ah Airport Tow Tractor

691.2 V 280 Ah Power Supply Vehicle

386.4 V 173 Ah Airport Tow Tractor

80 V 277 Ah Airport Tow Tractor

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >