Maritime Battery Solution

We provide tailored maritime battery solutions designed to power the electrification of vessels with safety, reliability, and sustainability. Our product range includes lithium-ion marine traction battery systems, featuring high-performance battery cells, modules, packs, and advanced Battery Management Systems (BMS). Each solution is tailored to meet the specific requirements of a diverse range of vessel types. These systems have been successfully deployed in ships, yachts, boats, ferries, tugboats, and more, delivering outstanding performance across diverse water conditions and operational demands.

Email: contact@brogenevsolution.com

Our Maritime Battery Solution

For maritime applications, our lithium-ion battery offerings cover a wide range of configurations, including standard battery packs, integrated battery packs, long-life battery packs, standard and high-rate battery clusters, battery management units (cluster high-voltage boxes and pack-level busbar cabinets), as well as containerized marine traction battery systems. For customized lithium-ion battery solutions, please contact us at contact@BrogenEVSolution.com

Disclaimer: As our products are continuously being improved and upgraded, the product information shown on this page is for reference only. Actual specifications are subject to the final physical product. We reserve the right to update or modify data and related information at any time. Some data are obtained under laboratory conditions and may vary depending on the specific product or application. For detailed specifications, please contact us.

| Typical Battery System Offerings | |

| Battery pack | Configured based on actual project requirements, including BMU and BTU. |

| High-voltage box (cluster) | Includes BCU, emergency stop switch, and reset switch. |

| Junction box | Integrated with local display, alarms, and emergency stop functions. |

| Battery rack | Configured based on actual project requirements. |

| Internal battery system harness | Includes power and communication lines for connections such as battery pack to high-voltage box and high-voltage box to busbar cabinet; environmental temperature monitoring harness for battery compartment. |

| External battery system harness | Includes power and communication lines such as high-voltage box to busbar and busbar cabinet to DC/AC. |

1. Lithium-Ion Marine Traction Battery Pack

- Lightweight product design

- High-efficiency liquid-cooling system

- Independent safety pre-conditioning system

- Cell thermal runaway protection

- Full-series IP67 protection rating

- User-friendly panel design with neat, integrated installation

- Compliant with multiple classification society standards

| Nominal Voltage | Nominal Capacity | Nominal Energy | Dimension (mm) | Maximum Continuous Charging/Discharging Rate | Cooling Method | Weight |

| 57.6 VDC | 210 Ah | 12.1 kWh | 649*517*221 | 0.66C | Forced-air cooling | 100±5 kg |

| 38.4 VDC | 315 Ah | 12.1 kWh | 649*517*221 | 0.66C | Forced-air cooling | 100±5 kg |

| 38.4 VDC | 280 Ah | 10.8 kWh | 630*440*240 | 0.66C | Forced-air cooling | 83±5 kg |

| 57.6 VDC | 280 Ah | 16.1 kWh | 897*426*240 | 1C | Forced-air cooling/liquid cooling | 118±5 kg |

| 57.6 VDC | 310 Ah | 17.9 kWh | 897*426*240 | 1C | Forced-air cooling/liquid cooling | 125±5 kg |

| 154.6 VDC | 125 Ah | 19.3 kWh | 674*900*196 | 3C | Dual-sided liquid cooling | 150±5 kg |

| 77.2 VDC | 250 Ah | 19.3 kWh | 674*900*196 | 1.5C | Dual-sided liquid cooling | 150±5 kg |

- Structural safety: All-steel housing with IP67 protection rating; designed to operate reliably under all harsh environmental conditions

- Electrical safety: Equipped with comprehensive protection functions, including overcharge, over-discharge, short-circuit, overcurrent, and overtemperature protection

- Thermal safety: Single cells and battery modules pass nail penetration tests without fire, explosion, or thermal propagation; no oxygen release during thermal runaway; battery pack equipped with a safety relief valve for timely venting of combustible gases

- Integrated display screen

- Supports GPS positioning and standard charge/discharge interfaces

- Built-in buzzer alarm for safety alerts

- Supports stackable installation, secure fixation, and portable operation

| Item | Parameters |

| Grouping | 1P15S |

| Dimension | 480*610*320 mm |

| Battery Pack Nominal Capacity | 230 Ah |

| Battery Pack Max. Charging/Discharging Current | 230 A / 230 A |

| Battery Pack Nonimal Energy | 11.040 kWh |

| Battery Pack Weight | 85±5 kg |

| Communication Protocol | CAN/RS485 |

| Operating Mode | Support multi-pack parallel expansion |

| Explosion-Proof Design | Explosion-proof vent valve |

| Enclosure Material | Sheet metal fabrication |

| Protection Level | IP67 |

| Thermal Management | Natural cooling |

| BMS | Master-slave integrated BMS |

| Start Method | Local+optional remote start |

| Positioning | 4G & GPS positioning |

| Alarm | Buzzer |

- Battery cell zero capacity fade in the first year

- Long cycle life; total service life up to 15 years

- Thermal management solution: liquid cooling/liquid heating

- Equipped with explosion-proof valve, fire prevention devices, and leakage detection to ensure safety

- C5 corrosion resistance, suitable for inland and marine environments

- IP67 high protection rating, ensuring full-scenario operation

| Item | 1 | 2 |

| Grouping | 1P18S | 1P18S |

| Nominal Voltage | 52.2 VDC – 63 VDC | 52.2 VDC – 63 VDC |

| Voltage Range | 1C | 1C |

| Max. Continuous Charging/Discharging Rate | 280 Ah | 310 Ah |

| Capacity | 16.128 kWh | 17.856 kWh |

| Energy Density | ≥134 Wh/kg | ≥140 Wh/kg |

| Thermal Management | Liquid cooling/heating | Liquid cooling/heating |

| Life Cycle | ≥6000 | ≥10000 |

| Operating Temperature | -20~45°C | -20~45°C |

| Corrosion Resistance Rating | C5 | C5 |

| Maximum Operating Altitude | 2000 m | 2000 m |

| Dimension | 426*897*240 mm | 426*897*240 mm |

| Protection Level | IP67 | IP67 |

- Maximum charge/discharge rate: 3C

- Equipped with explosion-proof valves, fire prevention devices, and leakage detection

- Temperature control and cell balancing: efficient liquid cooling+active thermal equalization

- C5-level corrosion resistance, suitable for inland and marine environments

- IP67 high-protection rating, ensuring full-scenario battery operation

- Compliant with mainstream classification society design requirements

| Item | 1 | 2 |

| Grouping | 1P48S | 2P24S |

| Nominal Voltage | 154.56 VDC | 77.28 VDC |

| Voltage Range | 139.2 VDC – 168 VDC | 69.6 VDC – 84 VDC |

| Max. Continuous Charging/Discharging Rate | Maximum 3C | Maximum 1.5C |

| Capacity | 125 Ah | 250 Ah |

| Energy Density | 19.32 kWh | 19.32 kWh |

| Thermal Management | Dual-sided liquid cooling | Dual-sided liquid cooling |

| Life Cycle | ≥6000, 70%EOL | ≥6000, 70%EOL |

| Operating Temperature | -20~45°C | -20~45°C |

| Corrosion Resistance Rating | C5 | C5 |

| Maximum Operating Altitude | 2000 m | 2000 m |

| Dimension | 900*674*196 mm | 900*674*196 mm |

| Protection Level | IP67 | IP67 |

2. Lithium-Ion Marine Traction Battery Cluster

- CCS type approval

- Integrated exhaust duct, reduces the risk of fire or explosion in the battery compartment

- Battery cluster-level thermal management solution: options for air cooling or liquid cooling

- C5 enclosure corrosion resistance: suitable for inland and offshore use

| Item | 1 | 2 |

| Grouping | 1P270S | 1P270S |

| Energy | 241.92 kWh | 267.84 kWh |

| Battery Cluster Dimension | 1110*1054*3169 (liquid cooling) / 1110*1054*2700 (air cooling) | 1110*1054*3169 (liquid cooling) / 1110*1054*2700 (air cooling) |

| Nominal Capacity | 280 Ah | 310 Ah |

| Max. Continuous Charging/Discharging Current | 280 A / 280 A | 310 A / 310 A |

| Rated Voltage | 864 VDC | 864 VDC |

| Voltage Range | 841 VDC – 945 VDC | 783 VDC – 945 VDC |

| Weight | 2000±50 kg | 2100±50 kg |

| Communication | CAN/RS485 | CAN/RS485 |

| Explosion-Proof Design | Explosion-proof vent valve | Explosion-proof vent valve |

| Enclosure Material | Square steel welding | Square steel welding |

| Start Mode | Local+remote start | Local+remote start |

| Alarm | Buzzer | Buzzer |

- DNV and BV Type Approvals

- Thermal management: liquid cooling, liquid heating

- Leakage detection + fire prevention to ensure safety

- C5 enclosure corrosion resistance suitable for inland and offshore use

- IP44 system protection level to ensure safe operation

| Item | 1 | 2 |

| Grouping | 1P270S | 8P270S |

| Energy | 241.92 kWh | 1935.36 kWh |

| Battery Cluster Dimension | 3308*1654*2233 | 13232*1085*2233 |

| Nominal Capacity | 280 Ah | 2240 Ah |

| Max. Continuous Charging/Discharging Current | 280 A / 280 A | 2240 A / 2240 A |

| Rated Voltage | 864 VDC | 864 VDC |

| Voltage Range | 841 VDC – 945 VDC | 783 VDC – 945 VDC |

| Weight | 2000±50 kg | 16000±50 kg |

| Communication | CAN/RS485 | CAN/RS485 |

| Explosion-Proof Design | Explosion-proof vent valve | Explosion-proof vent valve |

| Enclosure Material | Square steel welding | Square steel welding |

| IP Rate | IP44 | IP44 |

| Thermal Management | Liquid cooling/liquid heating | Liquid cooling/liquid heating |

| BMS | Integrated BMS | Integrated BMS |

| Start Mode | Local+remote start | Local+remote start |

| Alarm | Buzzer | Buzzer |

- High rate: can reach 3C

- Compliant with mainstream classification society design requirements

- Battery cluster-level thermal management: efficient liquid cooling solution

- C5 enclosure corrosion resistance suitable for inland and offshore use

| Item | Parameters |

| Grouping | 1P288S |

| Energy | 115.92 kWh |

| Battery Cluster Dimension | 1000*1000*2500 |

| Nominal Capacity | 125 Ah |

| Max. Continuous Charging/Discharging Current | ≤375 A |

| Rated Voltage | 927.36 VDC |

| Voltage Range | 835.2 VDC – 1008 VDC |

| Weight | 1240±50 kg |

| Communication | CAN/RS485 |

| Explosion-Proof Design | Explosion-proof vent valve |

| Enclosure Material | Square steel welding |

| Enclosure Corrosion Level | C5 |

| Thermal Management | Dual-sided liquid cooling |

| Protection Level | IP44 |

| Start Mode | Local+remote start |

| Alarm | Buzzer |

3. Containerized Marine Traction Battery System

- High safety: A60 fire protection/flexible system configuration

- Supports parallel connection between multiple containers

- Supports battery swapping and maintenance operations

- Equipped with liquid cooling for temperature equalization

- Standard interface output

- Large-capacity configuration

- Compatible with port shore power systems

| Item | Battery Cell Capacity | Nominal Voltage | Voltage Range | Nominal Capacity | Nominal Energy | Weight | Dimension |

| 1 | 280 Ah | 864.0 V | 783.0-945.0 V | 2240 Ah | 1935.36 kWh | 27.0±0.2 t | 6058*2438*2591 mm |

| 2 | 310 Ah | 806.4 V | 730.8-882.0 V | 2480 Ah | 1999.87 kWh | 26.0±0.2 t | 6058*2438*2591 mm |

How We Work

Our Key Workflow Process

Customer Requirements Confirmation

Gather customer needs and project details, including operating environment, vessel information, and equipment conditions, etc.

Technical Solution Development

Define the technical details and establish a clear, specific technical plan.

Technical Agreement Finalization

Confirm the product design, key component specifications, and complete internal reviews before reaching an agreement with the customer.

Signing the Commercial Contract

Negotiate and finalize delivery terms, pricing, payment, and services, followed by signing the supply contract.

Develop a detailed project schedule, manage the project's progress, and ensure tasks are completed on time.

Define technical requirements for the BMS, complete internal reviews, and secure customer approval.

Deliver structural and wiring harness designs and drawings for customer approval.

Organize, monitor, and inspect the production process to ensure quality and adherence to specifications.

Execute delivery and shipping according to customer requirements.

Case Study

Tailored Maritime Battery Solution for Electric Boat Project in Spain

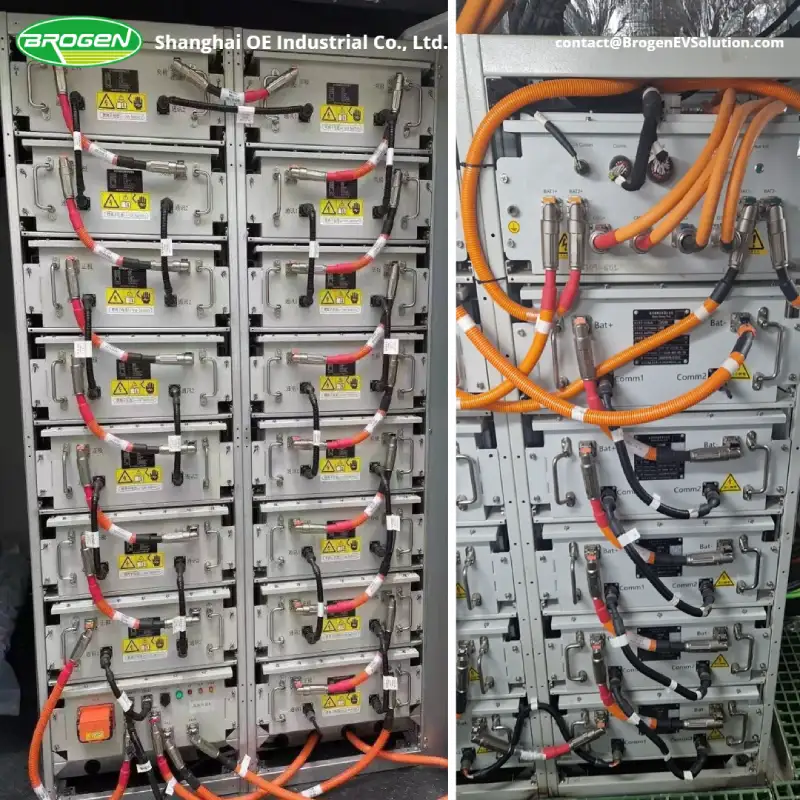

For our client’s electric boat project in Spain, we delivered a custom electric propulsion and battery solution, including maritime-grade battery packs, BMS, PDU, wiring harnesses, and battery racks.

In compliance with strict maritime redundancy regulations, the battery system required multiple fully independent packs (or battery groups), with complete isolation across mechanical structure, electrical architecture, thermal management, and control units.

Based on these requirements, we proposed an optimized configuration consisting of two independent battery groups, each comprising two clusters, with 10 battery modules per cluster.

The BMS adopts a three-level architecture (slave, master, and supervisory controllers) to effectively minimize cell imbalance and prevent associated risks of overcharging and over-discharging.

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >