EV On Board Charger (OBC)

Experience peak performance and reliability with our integrated EV on board charger (OBC), DC/DC converter, and PDU combo tailored for electric vehicles. Engineered for top-tier power conversion efficiency and remarkable power density, our chargers cover a broad power spectrum, ranging from 3.3 kW to 40 kW. Whether you’re driving a passenger car, bus, van, or LCV, or require upfit power supply for specialized vehicles, our comprehensive solutions ensure seamless integration and optimal performance. Additionally, we provide OBC systems for 800V high-voltage platforms, ensuring versatility and reliability across the board.

Applicable models: passenger car, logistics vehicle, bus, sanitation truck, mini bus, pickup, street sweeper, etc.

Email: contact@brogenevsolution.com

Our On Board Charger Solution Features

Pickup Truck

Medium Truck

Heavy Truck

Passenger Car

Bus

- Applicable for both PHEV and BEV

- Wide input range, 1 phase and 3 phase

- Bidirectional options available (V2X)

- 400 V and 800 V versions for different output voltage ranges

- OBC power 3.3 kW / 4 kW / 6.6 kW / 11 kW / 20 kW / 40 kW

- Integrated system with DC/DC Converters & PDU

- Customizable OEM / ODM service

Brogen Offerings of On Board Chargers

1. Standalone On Board Charger

Solution Features

- Advanced Technology: utilizing advanced high-frequency digital control technology, our on board charger solution boasts exceptional power density, facilitating seamless integration into vehicle systems.

- Excellent Heat Dissipation: crafted through integral die-casting, the shell incorporates a patented 3D water channel design, ensuring excellent heat dissipation performance.

- Wide Voltage Output Range: with a wide output voltage range, our products are designed to accommodate diverse vehicle models’ requirements.

- Adaptable Configuration: designed with multiple low-voltage signal interfaces, allowing for adaptable configurations tailored to various vehicle systems.

- Enhanced Safety: ensuring electrical isolation for enhanced safety.

- Comprehensive Protection: comprehensive abnormal protection functionalities are embedded, guaranteeing a secure and reliable charging process.

- Electromagnetic Compatibility: meeting EMC standards, aligning with vehicle design specifications.

- Standard CAN 2.0B Interface: supporting UDS

- Flexible Customization: allowing for convenient online software upgrades and customized charging strategies, our solution offers flexible tuning and updating capabilities to meet evolving vehicle demands.

Technical Parameters

| Power | Rated input | Input voltage | Output voltage | Cooling | Weight |

| 3.3 kW | 220 VAC / 16 A | 90-265 VAC | 0-500 VDC | Air cooled | 7.5 kg |

| 4.0 kW | 220 VAC / 20 A | 90-265 VAC | 0-450 VDC | Air cooled | 8.0 kg |

| 6.0 kW (single phase) | 220 VAC / 30 A | 90-265 VAC | 0-450 VDC | Air cooled | 13.5 kg |

| 6.0 kW (three phase) | 380 VAC / 30 A | 152-456 VAC | 0-450 VDC | Air cooled | 13.5 kg |

| 6.6 kW (low voltage) | 220 VAC / 32 A | 90-265 VAC | 0-95 VDC | Air cooled | 13 kg |

| 6.6 kW (middle-high voltage) | 220 VAC / 32 A | 90-265 VAC | 0-850 VDC | Air cooled | 11 kg |

| 20 kW (single phase) | 220 VAC / 96 A | 90-265 VAC | 0-850 VDC | Liquid cooled | 25 kg |

| 20 kW (three phase) | 380 VAC / 96 A | 152-456 VAC | 0-850 VDC | Liquid cooled | 25 kg |

| 6.6 kW@1φ 40 kW@3φ | 154-265 VAC@1φ 267-456 VAC@3φ | 200-715 VDC | Liquid cooled | 55 kg |

*Parameters may differ depending on the configuration and vehicle model. Certain specifications can be customized. For more information, please contact us at contact@BrogenEVSolution.com

2. DC/DC Converter

Solution Features

- Utilizes advanced high-frequency digital control technology, ensuring high power density and easy integration with the vehicle’s installation.

- Features high-level electrical isolation for both input and output, providing enhanced safety.

- Meets stringent automotive electromagnetic compatibility standards.

- Equipped with overvoltage protection, overcurrent protection, over-temperature protection, and short circuit protection, ensuring reliable and safe operation.

- Comes with a built-in CAN 2.0B interface, supporting standard UDS diagnostic development.

- Can be customized according to vehicle requirements, with all software capable of online upgrades.

Technical Parameters

| Power | Input voltage range | Output voltage range | Cooling |

| 0.6 kW Voltage reduction | 40-200 VDC | 0-16 VDC | Natural cooled |

| 1.2 kW Voltage reduction | 40-700 VDC | 0-32 VDC | Natural cooled |

| 2.4 kW Voltage reduction | 40-700 VDC | 0-32 VDC | Air cooled |

| 3.6 kW Voltage reduction | 40-700 VDC | 0-32 VDC | Air cooled |

| 1.5 kW Voltage reduction | 80-700 VDC | 0-16 VDC | Air cooled |

| 2.0 kW Voltage reduction | 300-750 VDC | 0-450 VDC | Air cooled |

| 4.0 kW Voltage reduction | 300-750 VDC | 0-450 VDC | Air cooled |

| 6.0 kW Voltage reduction | 300-750 VDC | 0-450 VDC | Air cooled |

| 2.5 kW Voltage increase | 40-68 VDC | 35-400 VDC | Air cooled |

| 5.0 kW Voltage increase | 40-68 VDC | 35-400 VDC | Air cooled |

| 7.5 kW Voltage increase | 40-68 VDC | 35-400 VDC | Air cooled |

| 3.0 kW Voltage reduction | 200-900 VDC | 0-32 VDC | Air cooled |

| 6.0 kW Voltage reduction | 200-900 VDC | 0-32 VDC | Air cooled |

*Parameters may differ depending on the configuration and vehicle model. Certain specifications can be customized. For more information, please contact us at contact@BrogenEVSolution.com

3. On Board Charger & DC/DC Converter Combo

The integrated 2-in-1 OBC+DC/DC system consists of the on-board charger (OBC) and the DC-to-DC converter (DCDC). The OBC takes energy from the AC grid and converts it to high voltage DC to charge the vehicle’s power battery. The entire charging process of the vehicle can be monitored. At the same time, the OBC has the functions of inversion, achieving the transfer of energy from the power battery to the AC side. The on-board DC/DC converter converts the high-voltage DC to the required low-voltage DC, providing a low-voltage supply for the entire vehicle and charging the auxiliary battery. OBC and DC/DC report output voltage and current via the CAN bus, and achieve information exchange and operating status feedback with the BMS and VCU via CAN communication.

Solution Features

- Advanced Technology: utilizing advanced high-frequency digital control technology, our solution boasts exceptional power density, facilitating seamless integration into vehicle systems.

- Efficient Thermal Management: featuring a one-piece cast housing with a 3D water channel design, the system ensures efficient heat dissipation, enhancing overall performance.

- Adaptable Configuration: designed with multiple low-voltage signal interfaces, allowing for adaptable configurations tailored to various vehicle systems.

- Adjustable Power Allocation: in OBC mode, users have the flexibility to allocate power between high-voltage and low-voltage outputs according to specific needs.

- Streamlined Topology Design: the product employs a traditional full-bridge topology for the DCDC, effectively utilizing high-voltage power devices and EMI components shared with the OBC.

- Electromagnetic Compatibility: meeting EMC standards, aligning with vehicle design specifications.

- Standard CAN 2.0B Interface: supporting UDS

- Flexible Customization: allowing for convenient online software upgrades and customized charging strategies, our solution offers flexible tuning and updating capabilities to meet evolving vehicle demands.

Technical Parameters

| OBC | DC/DC | System | ||||

| Power | Output voltage range | Power | Input voltage range | Output voltage | Cooling | Weight |

| 3.3 kW | 50-450 VDC | 1 kW | 40-545 VDC | 14 V | Air cooled | 5.5 kg |

| 3.3 kW | 95-450 VDC | 1.5 kW | 88-454 VDC | 14 V | Liquid cooled | 5.8 kg |

| 6.6 kW | 95-450 VDC | 1.5 kW | 88-454 VDC | 14 V | Air cooled / Liquid cooled | 8.7 kg |

| 6.6 kW | 200-450 VDC | 2 kW | 206-454 VDC | 14 V | Air cooled / Liquid cooled | 8.7 kg |

| 6.6 kW | 360-785 VDC | 3 kW | 360-785 VDC | 14 V | Liquid cooled | 5.8 kg |

| 6.6 kW @1φ 9.9 kW @3φ | 350-800 VDC | 3 kW | 350-800 VDC | 14 V | Liquid cooled | 9.2 kg |

| 6.6 kW @1φ 9.9 kW @3φ | 200-450 VDC | 2.5 kW | 200-450 VDC | 14 V | Liquid cooled | 9.1 kg |

*Parameters may differ depending on the configuration and vehicle model. Certain specifications can be customized. For more information, please contact us at contact@BrogenEVSolution.com

4. On Board Charger &DC/DC Converter & PDU Combo

Solution Features

- Magnetic Integration Design: ultra-high power density integration of OBC, DCDC, PDU.

- Advanced Technology: utilizing advanced high-frequency digital control technology, our solution boasts exceptional power density, facilitating seamless integration into vehicle systems.

- Efficient Thermal Management: featuring a one-piece cast housing with a 3D water channel design, the system ensures efficient heat dissipation, enhancing overall performance.

- Adaptable Configuration: designed with multiple low-voltage signal interfaces, allowing for adaptable configurations tailored to various vehicle systems.

- Adjustable Power Allocation: in OBC mode, users have the flexibility to allocate power between high-voltage and low-voltage outputs according to specific needs.

- Streamlined Topology Design: the product employs a traditional full-bridge topology for the DCDC, effectively utilizing high-voltage power devices and EMI components shared with the OBC.

- Electromagnetic Compatibility: meeting EMC standards, aligning with vehicle design specifications.

- Standard CANFD Interface: supporting UDS

- Flexible Customization: allowing for convenient online software upgrades and customized charging strategies, our solution offers flexible tuning and updating capabilities to meet evolving vehicle demands.

Technical Parameters

| OBC | DC/DC | PDU | System | ||||

| Power | Output voltage range | Power | Input voltage range | Output voltage | PDU | Cooling | Weight |

| 6.6 kW | 250-460 VDC | 2 kW | 300-460 VDC | 14 V | Yes | Liquid cooled | 5.8 kg |

| 6.6 kW @1φ 9.9 kW @3φ | 230-500 VDC | 2.5 kW | 230-500 VDC | 14 V | Yes | Liquid cooled | 10.2 kg |

| 6.6 kW | 200-420 VDC | 2.5 kW | 200-450 VDC | 14 V | Yes | Liquid cooled | 20 kg |

*Parameters may differ depending on the configuration and vehicle model. Certain specifications can be customized. For more information, please contact us at contact@BrogenEVSolution.com

Brogen On Board Charger Example Applications

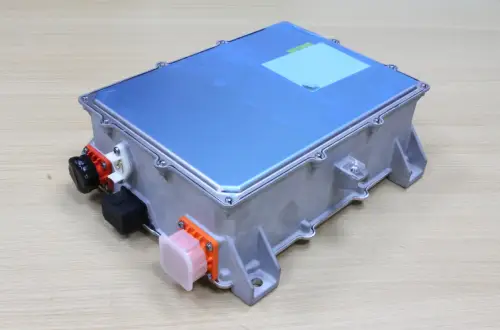

800V 10kW OBC+DC/DC

800V 10kW OBC+DC/DC

6.6kW OBC+DC/DC

20kW OBC

11kW OBC

20kW OBC

Brogen OBC Shipment

Brogen OBC Shipment

| OBC Model | TR1607 | TR1606 | TR1605 | TR1604 | TR1603 | TR1602 |

| Rated output power | 3.3 kW | |||||

| Rated output voltage | 24 V | 48 V | 72 V | 108 V | 144 V | 360 V |

| Cooling method | Air cooling | |||||

| Communication method | CAN | |||||

| Input voltage range | 90 VAC – 265 VAC | |||||

| Input frequency range | 46-65 Hz | |||||

| Input surge current | ≤16 A | |||||

| Output voltage range | 0-36 V | 0-70 V | 0-95 V | 0-136 V | 0-180 V | 0-440 V |

| Output current range | 0-100 A | 0-60 A | 0-45 A | 0-30 A | 0-22 A | 0-9A |

| Output response time | ≤5s | |||||

| Typical working efficiency | ≥94% | |||||

| System size | Weight | ≤6 kg | Dimension | 184*322*126 mm | ||

| Model | TR1615 | TR1614 | TR1613 | TR1612 |

| Rated output power | 3.3 kW | |||

| Rated output voltage | 80 | 144 | 360 | 540 |

| Cooling method | Air cooling | |||

| Communication method | CAN | |||

| Input voltage range | 90-265 VAC | |||

| Input frequency range | 46-65 Hz | |||

| Starting surge current | ≤32 A | |||

| Output voltage range | 0-102 V | 0-180 V | 0-440 V | 0-680 V |

| Output current range | 0-80 A | 0-44 A | 0-18 A | 0-12 A |

| Output response time | ≤5 s | |||

| Typical working efficiency | ≥94% | |||

| Model | TR3610 |

| Rated output voltage | 540 V |

| Charging mode | Response mode (CAN communicate) |

| AC input | 1-phase |

| Input voltage range | 90-265 V |

| Input frequency range | 47-63 Hz |

| AC current THD | <5% |

| Efficiency | >94% @ from 50% to Max. load |

| Max. input power | 22 kW |

| DC output | |

| Voltage programmable range | 400-700 VDC |

| Min. voltage constant power range | 540 VDC |

| Charging voltage accuracy | ≤1% |

| Charging current accuracy | ≤5% |

| Charging current ripple amplitude | ≤1% |

| Max. output power | 19.8 kW |

| Max. charging current | 36 A |

| Output response time | ≤5s |

| Pre-charging | Internal |

| Model | TR3201 | TR3202 | TR3203 | TR3204 | TR3223 | TR3224 | TR3225 | TR3226 |

| Rated output power | 6 kW | 20 kW | ||||||

| Peak output power | 8 kW (10s) | 24 kW (10s) | ||||||

| Communication method | CAN | |||||||

| Rated input voltage | 360 V | 540 V | 360 V | 540 V | ||||

| Input voltage range | 200-450 V | 400-700 V | 200-450 V | 400-700 V | ||||

| Rated input current | 25 A | 16 A | 64 A | 40 A | ||||

| Starting surge current | <25 A | <16 A | ≤64 A | ≤40A | ||||

| Rated output voltage | 48 V | 72 V | 48 V | 72 V | 80 V | 400 V | 80 V | 600 V |

| Rated output current | 125 A | 83 A | 125 A | 83 A | 250 A | 50 A | 250 A | 50 A |

| Output response time | ≤200 ms | |||||||

| Typical working efficiency | ≥92% | |||||||

| System weight | 7±0.3 kg | 15±1 kg | ||||||

| System size | 273*334*112 mm | 350*550*100 mm | ||||||

How We Work

Navigating Our Process

Demand Analysis & Project Evaluation

Once we receive your inquiry, our experts will connect with you within two business days to understand your specific requirements for the EV solution and conduct an initial feasibility evaluation of your project.

Project & Technical Coordination

If the project is deemed feasible, our engineering team will collaborate closely with your team on both hardware and software aspects to develop a viable solution. We will also provide a detailed quotation based on the technical requirements.

Development, Manufacturing & Testing

For customized or modified systems, we proceed with product development, including hardware and software adaptations. Our EV systems undergo rigorous testing to ensure quality, reliability, and full functionality before deployment.

In-Time Global Shipping & Delivery

We have established strong partnerships with international shipping providers, ensuring safe and timely delivery of products to your specified location. This guarantees a smooth and efficient deployment of your EV project.

Full-Stage Remote/Onsite Technical Support

We provide technical support throughout the entire project lifecycle, including consultancy, hardware and software development, calibration, and both onsite and remote debugging, ensuring optimal performance and long-term success.

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >