Choosing the Best GSE Batteries: The Key to Efficient and Sustainable Airport Ground Support Equipment Electrification

The Significance of Electrification for Airport Ground Support Equipment (GSE)

The electrification of airport ground support equipment (GSE) plays a crucial role in advancing sustainability, reducing emissions, and enhancing operational efficiency at airports. One of the most significant benefits of electrication is zero emissions, leading to cleaner air around airports and contributing to global environmental goals. Additionally, electric GSE reduces noise pollution, which is particularly important in densely populated areas near airports. The safety of energy use is also greatly improved, with electric equipment offering enhanced security compared to traditional fuel-based counterparts.

In terms of operational efficiency, electrification boosts both energy conversion efficiency and overall airport productivity. By transitioning to electric ground support equipment, airports can achieve not only better performance from individual equipment but also streamline the entire airport operation. The reduced workload for ground crews, coupled with the ease of integrating intelligent systems, accelerates the automotion of airport processes.

Overall, electrifying airport ground support equipment ensures environmental benefits, enhances energy security, and improves the overall efficiency of airport operations while pushing forward the integration of smarter, more automated systems.

How to Choose the Best GSE Batteries

When selecting batteries for electric ground support equipment, it’s essential to understand the specific requirements for these devices. This selection process presents challenges, as airport operations prioritize safety, especially in civil aviation. The safety standards for airport GSE must exceed those required for road vehicles, given the critical nature of airport operations.

The reliability of these batteries is also vital – minimizing failure rates is essential to maintaining high fleet availability. Furthermore, airport GSE batteries must be durable, with long lifespans that can withstand the diverse environmental conditions in which these vehicles operate, from extreme temperatures to high humidity levels. The batteries should also be cost-effective, easy to deploy, and capable of fast delivery.

For these requirements, safety is paramount. The battery itself must ensure the safety of the equipment and, ultimately, the safety of airport personnel. With this in mnd, we design our battery systems based on four key dimensions of safety: mechanical, electrical, chemical, and functional. This comprehensive approach guarantees that every battery system provides full protection of both the equipment and operators.

In terms of improving reliability, we focus on enhancing the lifespan and durability of lithium-ion batteries, using advanced engineering methods to minimize the failure rates throughout the battery’s lifecycle. Innovations in materials, such as optimized cathodes and anodes, as well as the development of advanced manufacturing processes, significantly reduce the risk of mechanical and chemical degradation, thus extending battery life.

Additionally, batteries used in airport GSE are designed with features like IP67, IP68, and IP69K ratings, which provide effective moisture and dust protection. High-performance thermal management ensures the battery can operate within a broad temperature range, making it ideal for various environmental conditions found at airports worldwide.

One major challenge for airport GSE electrification is the relatively small scale of the equipment compared to road vehicles, leading to a greater variety of types and applications. To control costs and reduce development time, we have adopted a standardized solution approach. This includes the use of standardized battery modules and packs to meet the diverse needs of airport ground support equipment. Such a solution ensures that the system is both cost-effective and market-proven,while also offering the flexibility for small-batch, multi-type production. These standardized solutions will significantly support the sustainable development of airport GSE electrification.

Choosing the Right Chemical System for Airport GSE Batteries

When selecting the chemical system for electric GSE batteries, several factors must be considered. Unlike traditional batteries, lithium-ion batteries for GSE incorporate a complex integration of chemistry, electrical systems, mechanics, and thermal management, creating a highly sophisticated system. To evaluate the performance of these batteries, it’s necessary to assess all these aspects, rather than just focusing on individual material properties.

Among the different types of lithium-ion batteries, LiFePo4 (Lithium Iron Phosphate) batteries stand out as the safest and most reliable option for airport GSE. This is primarily due to their stable olivine structure, which ensures that the temperature rise during thermal runaway is slower than that of other battery types. For exmaple, in the event of thermal runaway, LiFePO4 batteries emit smoke but do not catch fire, unlike NCM (Nickel Cobalt Manganese) batteris, which can rapidly accelerate combustion when exposed to heat.

Additionally, LiFePO4 batteries offer superior cycle life, with some models reaching up to 4,000 charge cycles. This long lifespan significantly reduces the cost of ownership and increases the reliability of the battery over time. They are also capable of withstanding high temperatures – up to 65°C – and do not contain heavy metals or harmful pollutants, making them a highly eco-friendly choice for airport GSE.

In contrast, NCM batteries are more energy-dense but have lower thermal stability, making them less suitable for use in high-temperature environments, such as those encountered in airport ground operations. Moreover, LiFePO4 batteries are less expensive than NCM batteries and are more widely available, ensuring stable material supply and cost reductions over time.

Advantages of Lithium Iron Phosphate (LiFePO4) Batteries for Airport GSE

In summary, LiFePO4 batteries offer numerous advantages that make them the ideal choice for airport ground support equipment:

- Safety: LiFePO4 batteries are resistant to fire and explosion, providing higher level of safety in demanding environments.

- Long Cycle Life: With up to 4,000 charge cycles, these batteries have an exceptionally long lifespan, reducing long-term costs.

- High Capacity: LiFePO4 batteries have a high capacity, which simplifies system configurations and reduces the number of battery packs required.

- Energy Density: Despite their high safety and durability, LiFePO4 batteries maintain a competitive energy density.

- Thermal Stability: They can operate efficiently at temperatures up to 65°C, making them suitable for extreme environments.

- Environmental Friendliness: Free from toxic heavy metals, LiFePO4 batteries are a greener, more sustainable option.

- Stable Material Supply: Unlike NCM batteries, the raw materials for LiFePO4 are widely available, ensuring reliable supply and long-term cost reductions.

In conclusion, LiFePO4 batteries not only provide higher level of safety and efficiency for airport ground support equipment, but they also offer a cost-effective, sustainable solution for the growing demand for GSE fleet electrification at airports.

Brogen Lithium GSE Batteries Solutions

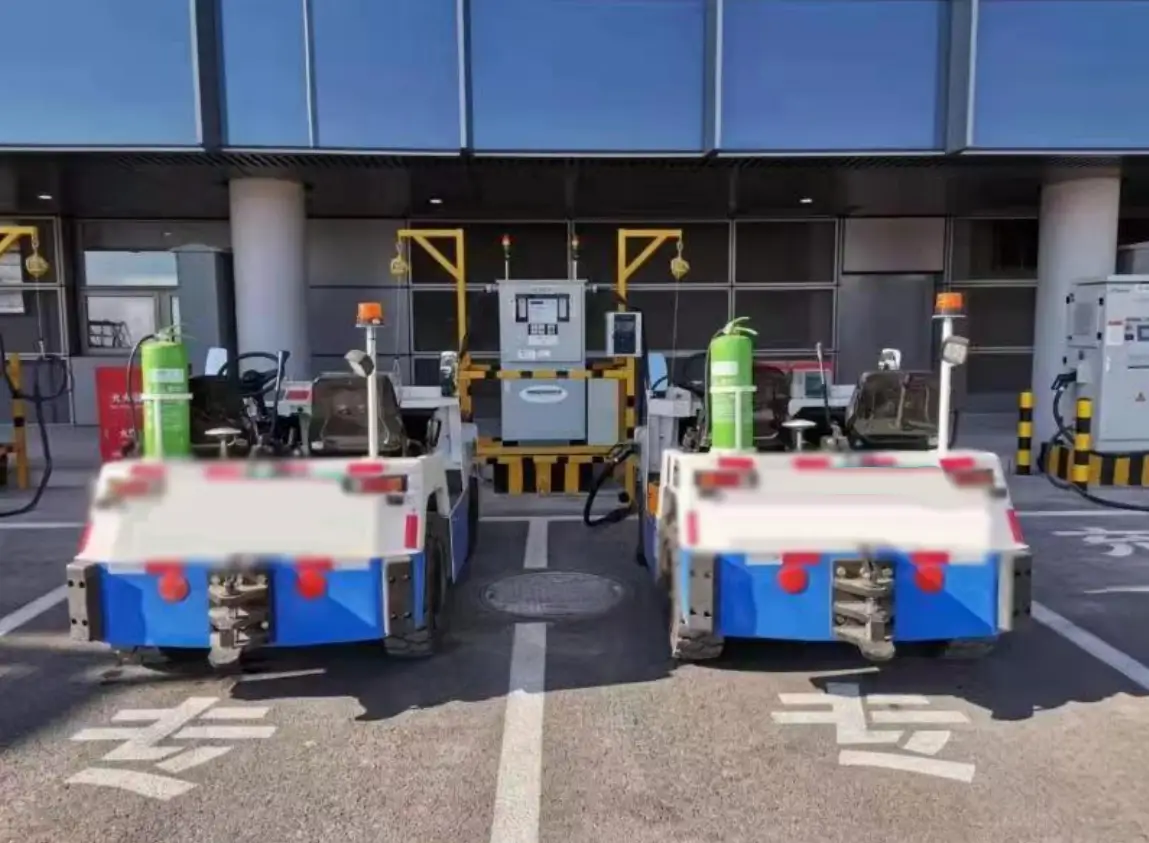

At Brogen, we use high-performance lithium batteries for airport GSE electrification. Our self-developed thermal management systme includes heating, cooling, and insulation components to ensure optimal performance in all conditions. The battery system is designed with a lightweight structure and high energy density. It supports wide voltage charging, compatible with both high and low voltage charging (80V to 750V). We have already provided solutions for leading domestic GSE manufacturers, supporting their electric tow tractor projects, which have successfully passed all required tests.

386.4 V 173 Ah Airport Tow Tractor

691.2 V 280 Ah Power Supply Vehicle

386.4 V 173 Ah Airport Tow Tractor

80 V 277 Ah Airport Tow Tractor

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >