The Role of the VCU in Electric Vehicles

In traditional internal combustion engine (ICE) vehicles, control systems are relatively segmented, with components like the ECU, TCU, ABS, BCM, PEPS, and IPC.

In electric vehicles (EVs), the engine and transmission are replaced by the electric motor and battery system. This shift introduces new key systems like the BMS and MCU. Beyond this fundamental shift, EVs also integrate a broad array of high- and low-voltage systems, such as DC/DC converters, onboard chargers (OBC), PTC heaters, and electronic braking systems (EBS), alongside intelligent controllers including the In-Vehicle Infotainment (IVI) system, Thermal Management System (TMS), Telematics Control Unit (T-Box), and Integrated Power Brake (IPB), etc.

Why is a VCU Essential for Electric Vehicles?

As vehicles evolve, so does the complexity of electronic controls. The number of controllers on board has significantly increased, especially in hybrid electric vehicles, where coordination between the traditional engine system and the electric drivetrain is critical.

For example, when the ECU and MCU issue conflicting commands, which system should take priority? This type of decision-making requires a central coordinator – the VCU – to act as the vehicle’s brain.

Beyond conflict resolution, EVs also have higher demands for drivability, energy efficiency, and real-time coordination across multiple subsystems. A VCU is necessary to optimize energy use, balance power delivery, improve safety, and ensure consistent performance across various scenarios.

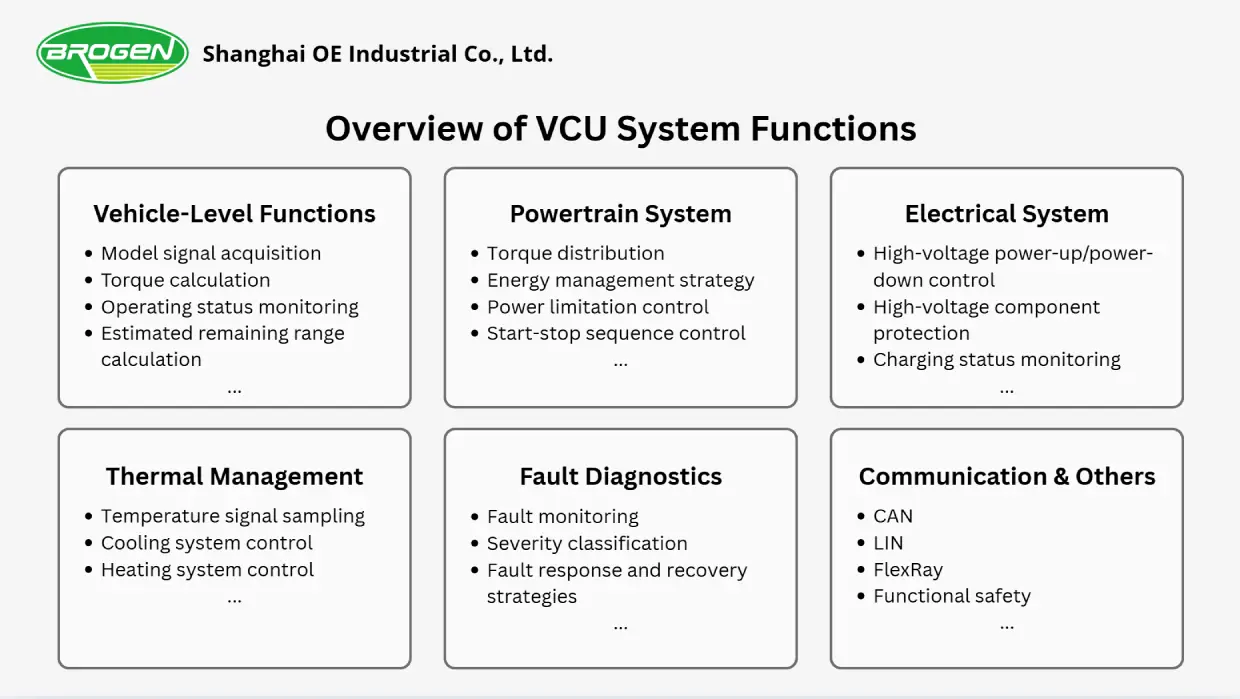

VCU Functional Overview

The functions of the VCU vary depending on the overall vehicle system architecture. They can be categorized into several functional domains, including vehicle system control, powertrain management, electric power systems, thermal management, diagnostics, communication, and safety monitoring.

Key functions include torque control and management, overall energy management, charging and thermal management, fault diagnosis and handling, as well as vehicle status monitoring.

1. Torque Management

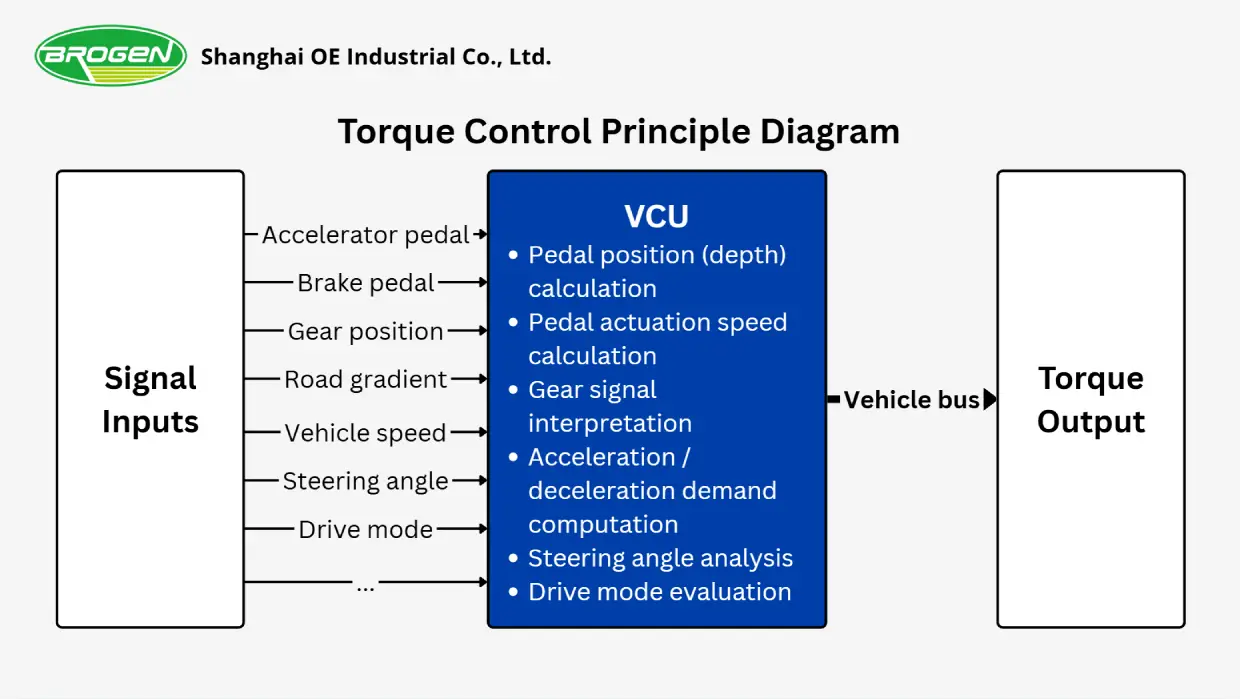

Torque management governs a vehicle’s acceleration and braking performance – both of which are determined by torque output from the electric motor or engine.

The VCU interprets signals from the accelerator and brake pedals (e.g., depth and speed of press), determines the required torque, and coordinates the engine, generator, and coordinates the engine, generator, front and rear drive motors to respond accordingly based on the vehicle’s current operating mode.

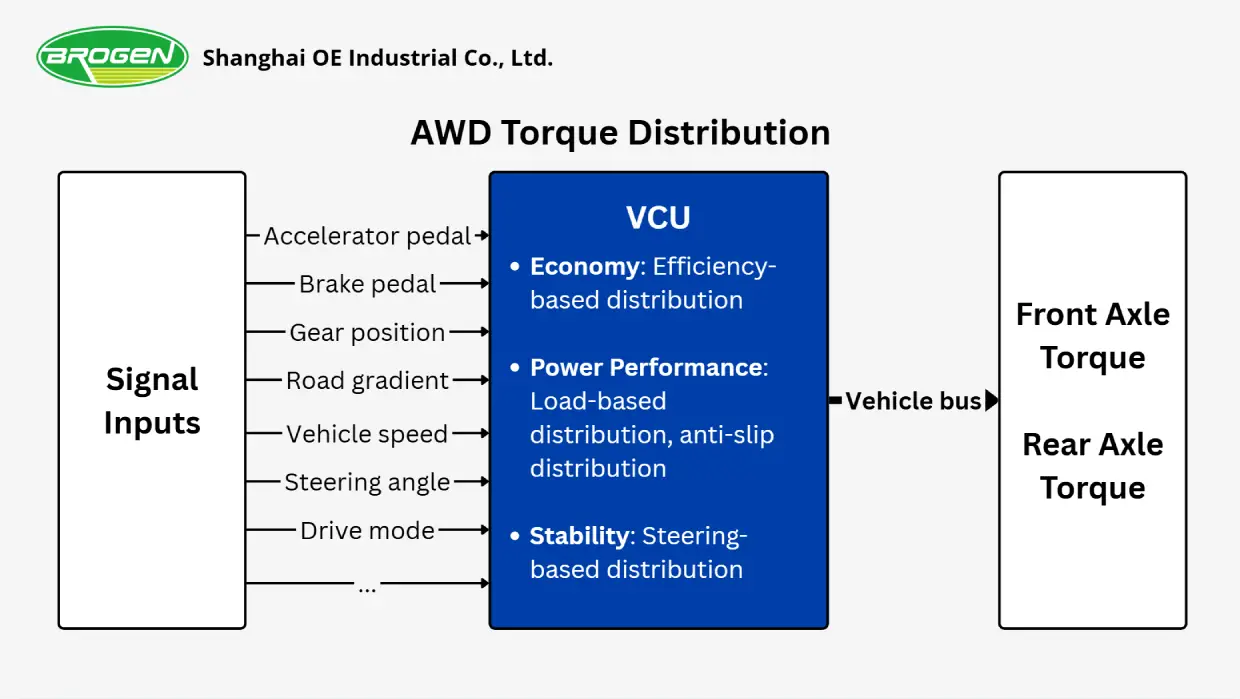

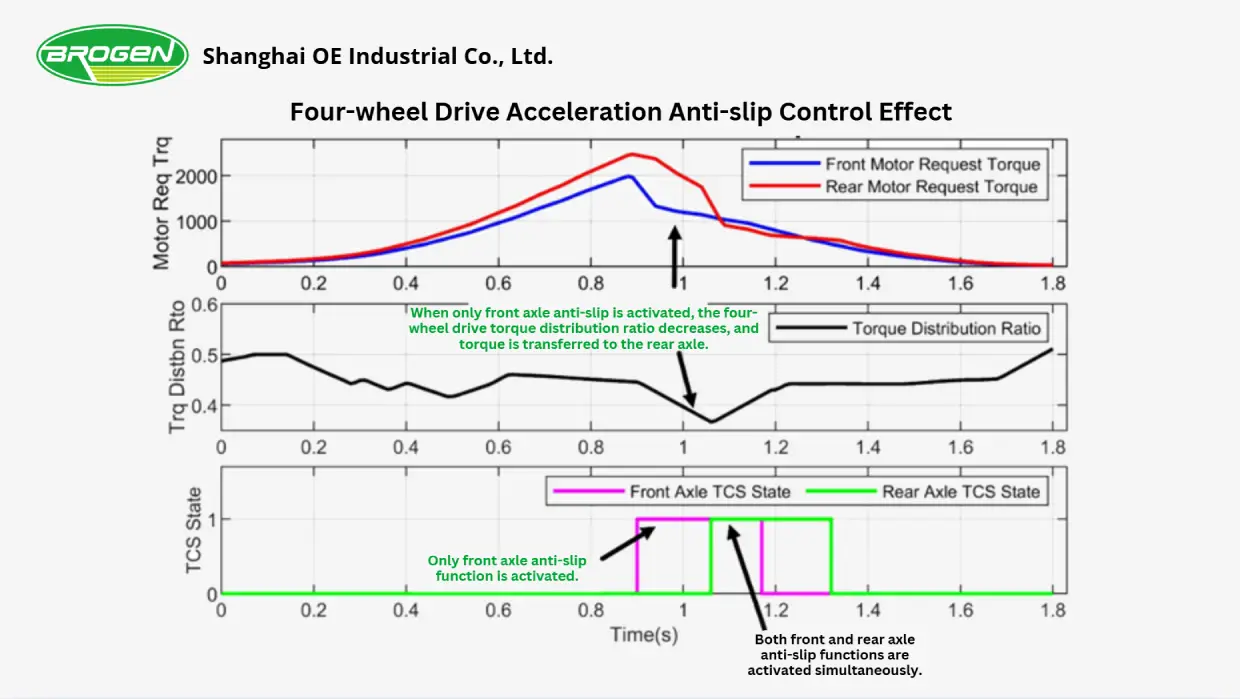

Case Example: Torque Distribution in AWD EVs

All-wheel-drive EVs (as opposed to two-wheel-drive models) feature both front and rear motors. The VCU is responsible for intelligently distributing torque between the two, depending on the efficiency (economy), performance, and stability.

The goal of economic torque distribution is to achieve optimal overall efficiency under the current torque demand. This involves intelligently coordinating dual-, triple, or quad-motor systems to ensure the most efficient power distribution, reducing energy consumption and extending battery range. This strategy is typically applied during steady-speed driving scenarios, such as cruising on highways.

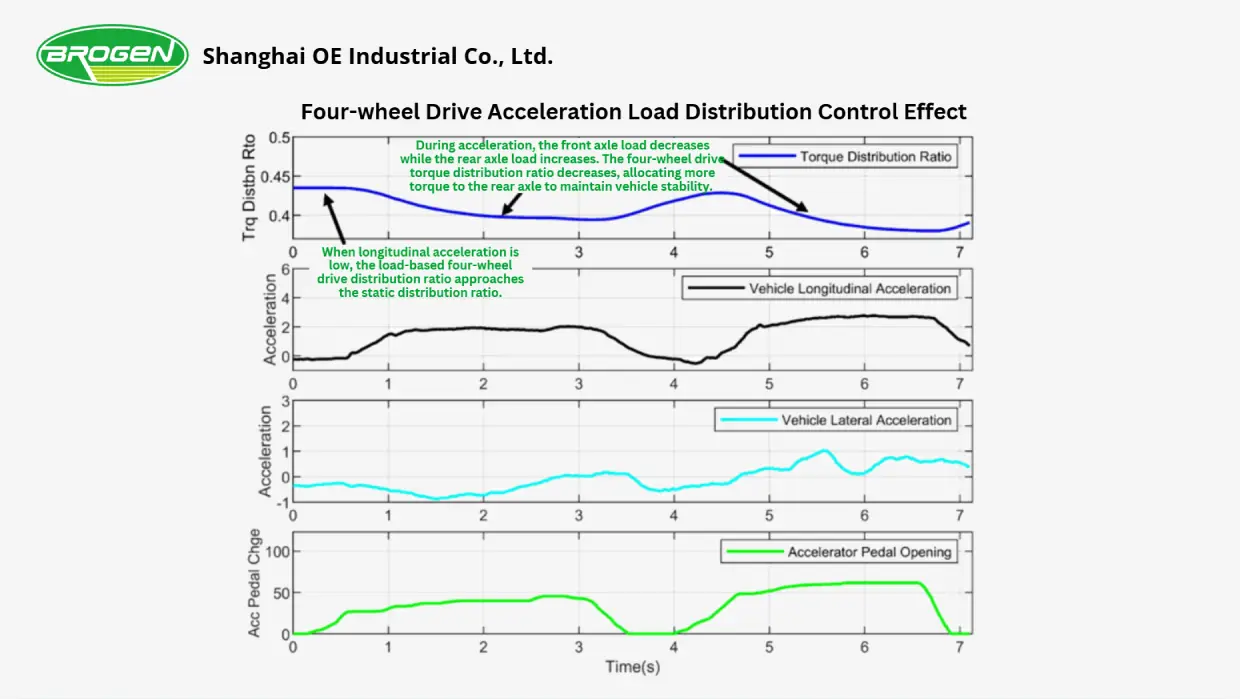

In the performance-oriented torque distribution, the load distribution function calculates the optimal torque ratio between the front and rear axles by recognizing current road gradients and the vehicle’s acceleration or deceleration status. By building a dynamic load model, the system automatically adjusts torque distribution during load transfers to make full use of the maximum available tire grip. This reduces wheel slip and enhances the vehicle’s acceleration performance.

Performance-oriented torque distribution must especially account for scenarios where a wheel becomes stuck and starts to slip, such as in mud or loose terrain. The basic principle is to actively adjust the torque distribution between the front and rear axles, transferring power to the axle that still has traction when one is slipping. This helps reduce power loss. When alternating slip between the front and rear axles is detected, the system dynamically adjusts torque distribution to maximize available grip, enhancing the vehicle’s ability to escape low-speed traction challenges.

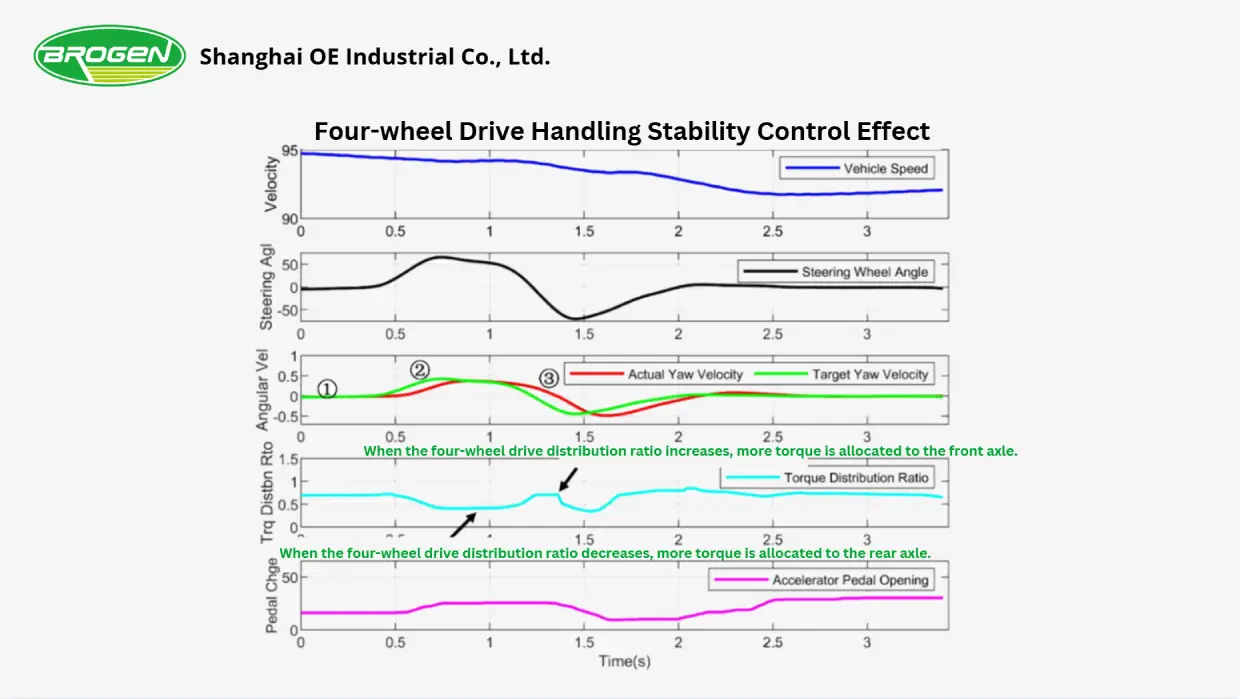

Stability-oriented torque distribution focuses on maintaining vehicle stability during steering maneuvers. While systems like ESP are designed to ensure body stability, frequent ESP interventions can lead to an uncomfortable driving experience. By monitoring steering behavior and controlling steering torque, the VCU can proactively adjust front and rear axle torque distribution in real time – before ESP activation – to correct vehicle dynamics. This helps suppress understeer (US) and oversteer (OS), reducing the need for ESP intervention during acceleration and cornering. As a result, it minimizes braking jolts and yaw disturbances, enhancing overall driving comfort and control.

When calculating the drive torque, it’s also necessary to consider the vehicle’s driving mode. Under different modes, the accelerator pedal position and vehicle speed are used to first determine the base drive torque. This base drive torque typically corresponds to the ECO mode. If the vehicle is in Normal mode, an additional compensation torque is applied. In Sport mode, a larger compensation value is added to enhance performance.

2. Mode & Energy Management

2.1 Operating Modes

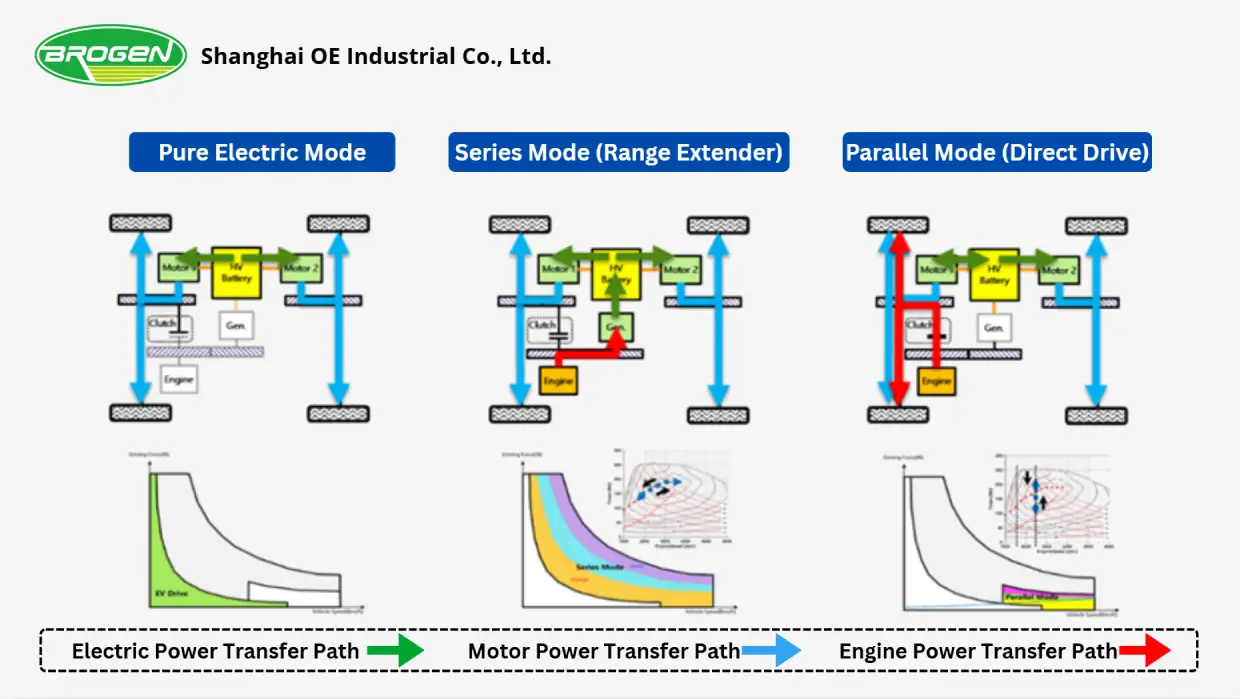

In addition to driving modes, vehicles – especially hybrid models – also operate under different operation modes. These include pure electric mode, series (range extender) mode, and parallel mode.

While both driving modes and operation modes aim to optimize energy efficiency and power distribution, they differ in how they are set:

- Driving modes (such as ECO, Normal, and Sport) are manually selected by the driver.

- Operation modes are automatically determined by the vehicle.

- In pure electric mode, the vehicle is powered solely by the electric motor using energy from the battery. The engine remains off.

- In series mode (range extender mode), the engine, generator, and battery are connected in series. When the battery’s state of charge is low, the engine activates the generator to produce electricity, which recharges the battery – effectively extending the vehicle’s range.

- In parallel mode (direct drive mode), both the engine and the battery provide propulsion simultaneously. Typically, the engine drives one axle while the electric motor powers the other. Since the engine directly contributes to wheel drive in this mode, it is also referred to as direct drive mode.

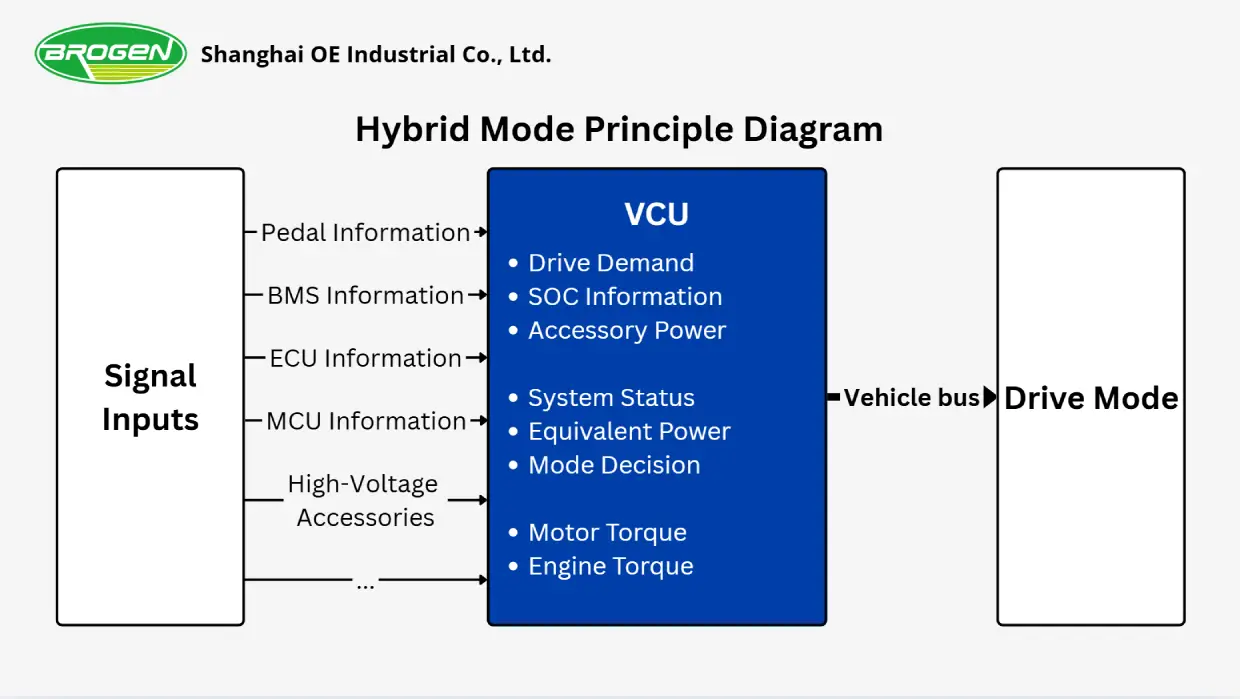

So how does the vehicle decide whether to use fuel or electricity?

The decision of whether to use fuel or electricity in different driving scenarios is made based on energy efficiency. The VCU calculates the equivalent consumption value of both fuel and electricity, then selects the operation mode that results in the lowest equivalent energy cost.

For example:

- At low to medium speeds, the VCU may activate the range extender to generate electricity using the engine, keeping the engine operating in its high-efficiency zone while supplying power to the drivetrain.

- At higher speeds, the engine and electric motor may work in parallel to drive the vehicle, balancing both performance and fuel economy.

When the vehicle’s operating conditions change and the operation mode needs to switch, the VCU ensures a smooth and rapid mode transition by coordinating engine speed, generator output, motor torque, and clutch engagement, all while maintaining the required driving torque for the driver. Internally, the VCU operates through a series of functional states, including initialization mode, high-voltage hold mode, charging mode, driving mode, battery replenishment mode, fault mode, etc. The VCU manages these states through a set of clear and logical transition conditions, enabling reliable and safe switching between them.

2.2 Energy Management

Mode management is essentially a form of energy management. When the total available energy of the vehicle is limited, the VCU imposes restrictions on power output to ensure system stability and efficiency. For example, when the battery SOC is low, the VCU will limit the output power of the drive motor. At the same time, it may also restrict high-power auxiliary loads, such as the air conditioning system.

Beyond energy control, the VCU also coordinates with other controllers and components to ensure holistic system optimization. This includes: air conditioning management, DC/DC power demand coordination, cooling water pump control, instrument cluster communication, vacuum pump operation, reverse light, and brake light control. By integrating vehicle-level requirements with component-level management, the VCU enables optimized energy calculation and dynamic distribution, ensuring safe, efficient, and intelligent operation of the entire vehicle system.

3. Thermal Management

The thermal management control function coordinates heating and cooling demands from multiple sources across the vehicle, including the battery, motor, engine, and cabin. It makes decisions and switches thermal control modes based on the overall vehicle operating mode, enabling a timely and efficient response to various thermal requirements.

For example:

- When the battery temperature is too low, the system can utilize engine waste heat to warm the battery.

- When the cabin temperature is low but the motor temperature is high, the system can redirect motor waste heat to heat the cabin.

This approach not only meets diverse thermal demands but also enhances energy efficiency by recycling available heat sources. By intelligently managing thermal energy flow, the system achieves optimal energy consumption, battery performance, and cabin comfort, balancing performance and efficiency in real time.

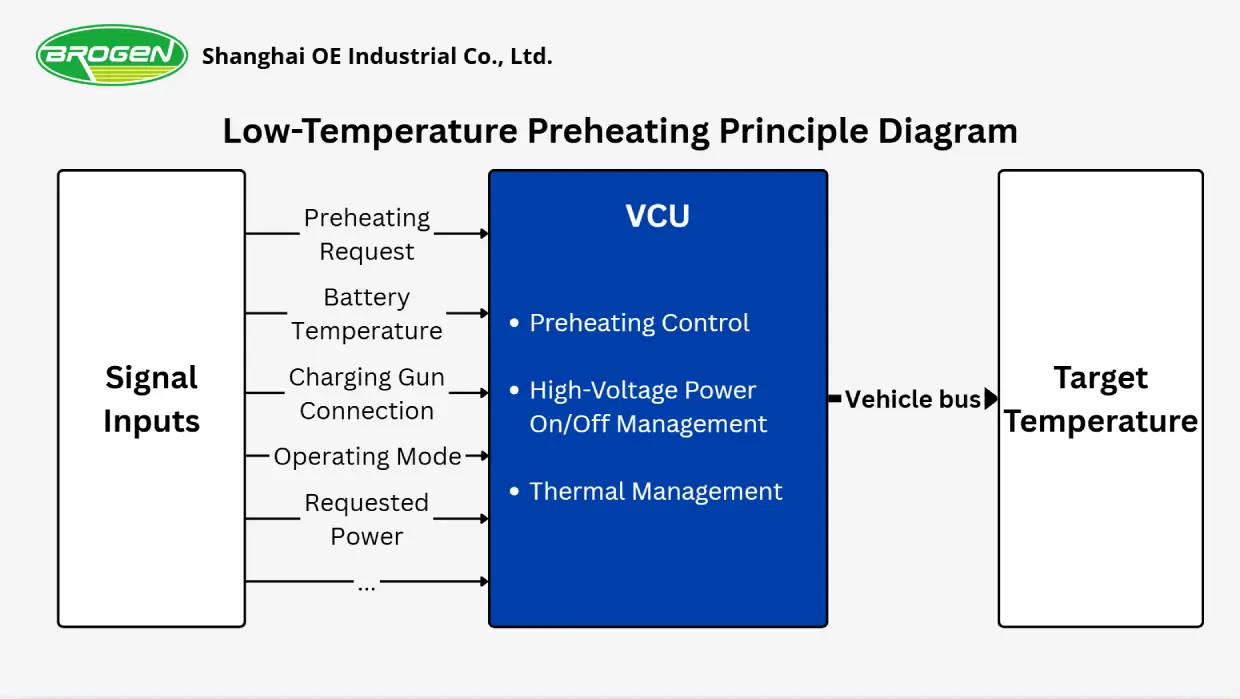

3.1 Battery Low Temperature Charging & Preheating Control

At low temperatures, the conductivity of the battery decreases, impairing the efficient transfer of electrical energy and resulting in reduced charging efficiency. Charging a battery in low-temperature conditions can lead to capacity loss and degradation of battery life. In extreme cases, low-temperature charging may cause deposition of internal battery materials, potentially leading to short circuits or even fire hazards.

To improve battery readiness quickly after vehicle power-on in cold environments, the VCU can perform battery preheating by considering factors such as the driver’s planned departure time, battery status, charging state, and the vehicle’s overall energy condition. This ensures the battery reaches optimal performance when the driver begins to use the vehicle.

During low-temperature plug-in charging, the VCU can activate battery preheating mode based on battery preheating requests. Within the charger’s output capability, power is supplied by the charger and directed to the battery heater (typically a PTC heater) to warm the battery.

In preheating mode, the battery’s main relay remains open, ensuring no current flows into or out of the battery, thus maintaining safety. Once the battery reaches the appropriate temperature, the VCU switches the battery out of preheating mode and transitions into normal charging mode.

When the battery temperature is very low, the battery’s charge and discharge power is limited. During driving, the battery often operates near its power limit, and when motor power is restricted, the motors can influence each other. Operating close to these power limits increases the risk of battery overcharge or over-discharge, which may cause vehicle vibrations.

At this point, the system needs to quickly adjust to bring the battery power back within safe limits. However, such adjustments can degrade driving performance. Therefore, balancing power limit protection and acceptable drivability in low-temperature conditions is a significant challenge.

One approach is to set different limits for long-term and short-term power demands. For example, use a long-term torque limit to restrict the driver’s continuous power demand, and use a short-term torque limit to handle transient torque needs, such as ESP interventions or engine start-up reserves. This strategy ensures that driving demands are met while preventing battery overcharge or over-discharge, maintaining both safety and drivability.

4. Fault Detection & Handling

Compared to traditional vehicles, electric vehicles are equipped with significantly more power and high-voltage components. This leads to a greater number and variety of potential faults, along with more complex handling strategies once a fault occurs.

The VCU not only manages high-voltage power-on and power-off sequences but also monitors potential faults across all drive-related components. Based on the severity of faults under different driving scenarios, the VCU defines a multi-level fault response strategy to ensure vehicle safety while maintaining the best possible driving experience.

- Level 1 Faults: These are non-critical issues. The vehicle notifies the driver through auditory and visual alerts, allowing driving to continue.

- Level 2 Faults: These require the system to limit power output to reduce risk while keeping essential functions operational.

- Level 3 Faults: These are critical. The system will immediately stop the vehicle to prevent further damage or safety hazards.

For example, in the event of motor over-temperature, if classified as a Level 2 fault, the system may reduce drive power to allow continued operation of basic vehicle functions. Then, based on the overall vehicle condition, the system can adopt adaptive strategies to manage the fault.

Possible system-level responses include: speed limitation; limp-home mode; power derating; shutting down high-voltage auxiliaries; emergency high-voltage shutdown.

Conclusion

The VCU serves as the brain of an electric vehicle, orchestrating coordination among various ECUs throughout the system. It handles key coupling functions and plays a central role in torque management, vehicle-level energy management, charging control and thermal management, fault diagnosis and handling, and real-time vehicle status monitoring.

As the automotive industry rapidly moves toward electrification and intelligent driving, the VCU is evolving toward a future of high integration, enhanced safety and reliability, while also improving comfort and energy efficiency.

About Brogen

At Brogen, we provide advanced EV solutions for global commercial vehicle manufacturers, enabling them to streamline research and development while capitalizing on cutting-edge technology. Our offerings ensure superior efficiency, extended range, and seamless system integration with proven reliability—empowering our partners to lead in the rapidly evolving green mobility landscape.

Currently, our EV solutions for battery electric heavy trucks have been adopted by vehicle manufacturers in countries and regions such as Canada, Türkiye, Brazil, the Philippines, Indonesia, the Middle East, and more.

- Discover our HCV electrification solution here: https://brogenevsolution.com/heavy-duty-vehicle-electrification-solutions/

- Looking for an EV solution for your project? Reach out to us at contact@brogenevsolution.com

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >