High-Voltage Connectors: An Overview

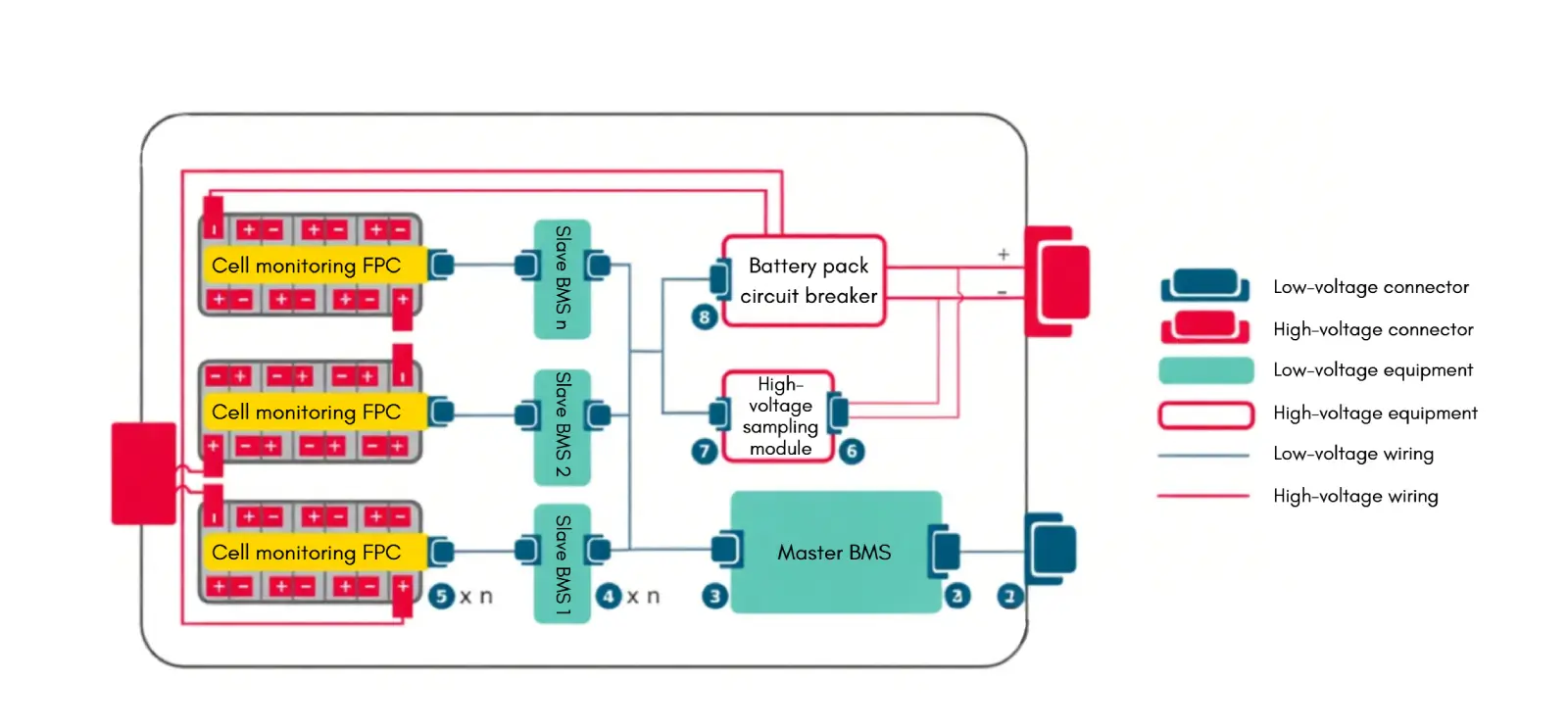

In electric vehicle systems, high-voltage connectors serve as the “bridge” for power transmission and are a critical components in ensuring electrical safety.

Although small in size, these connectors integrate multiple precision structures and safety features. Let’s break down their key components and see how they ensure safe and reliable performance in high-voltage, high-current environments.

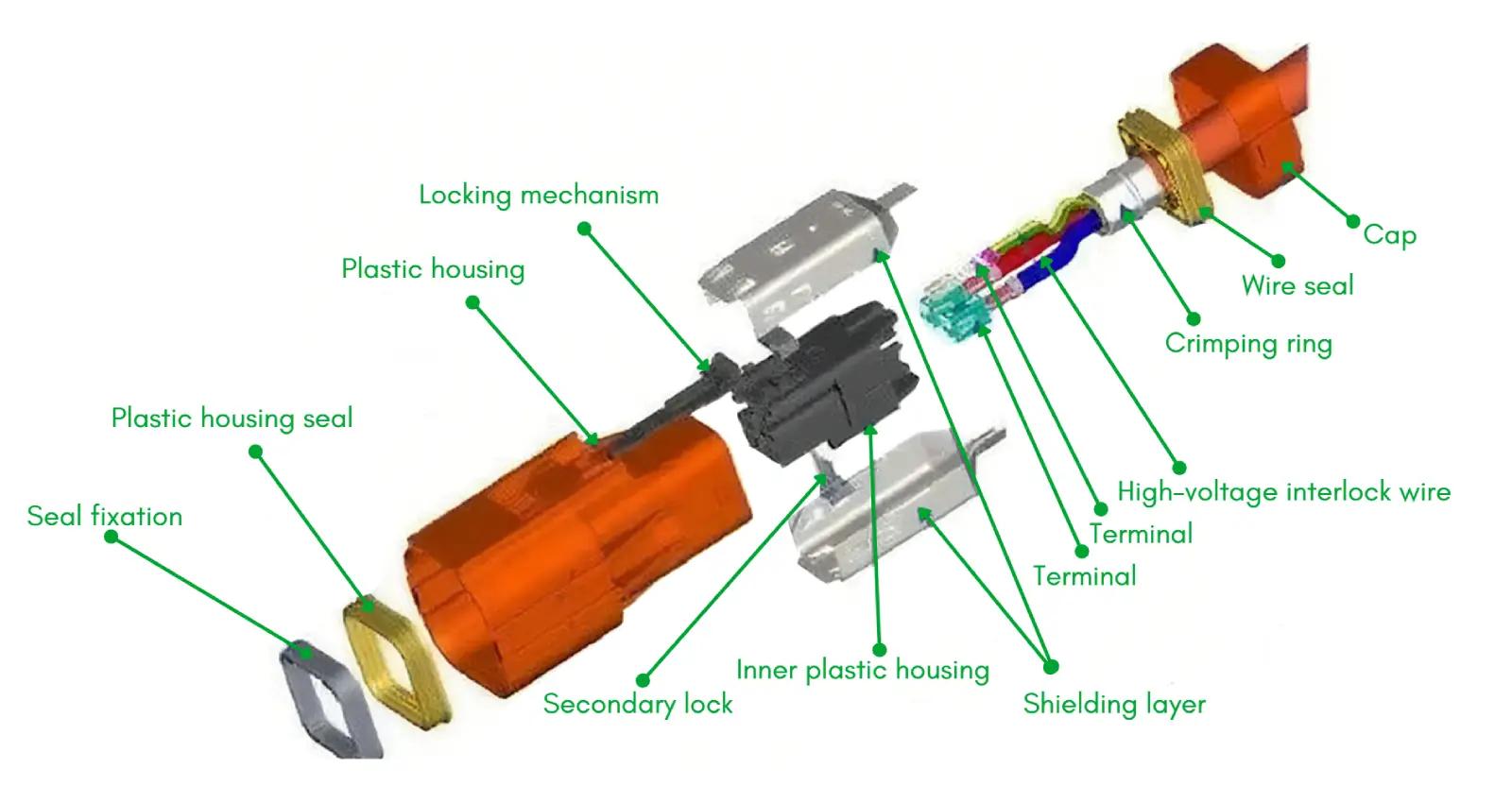

1. Components of High-Voltage Connectors

High-voltage connectors are generally composed of the following structures: housing (male and female ends), terminals (male and female terminals), shielding shell, seals (rear, half-end, wire-end, and contact seals), rear protective cover, high-voltage interlock system, and CPA (Connector Position Assurance device).

1.1 Housing

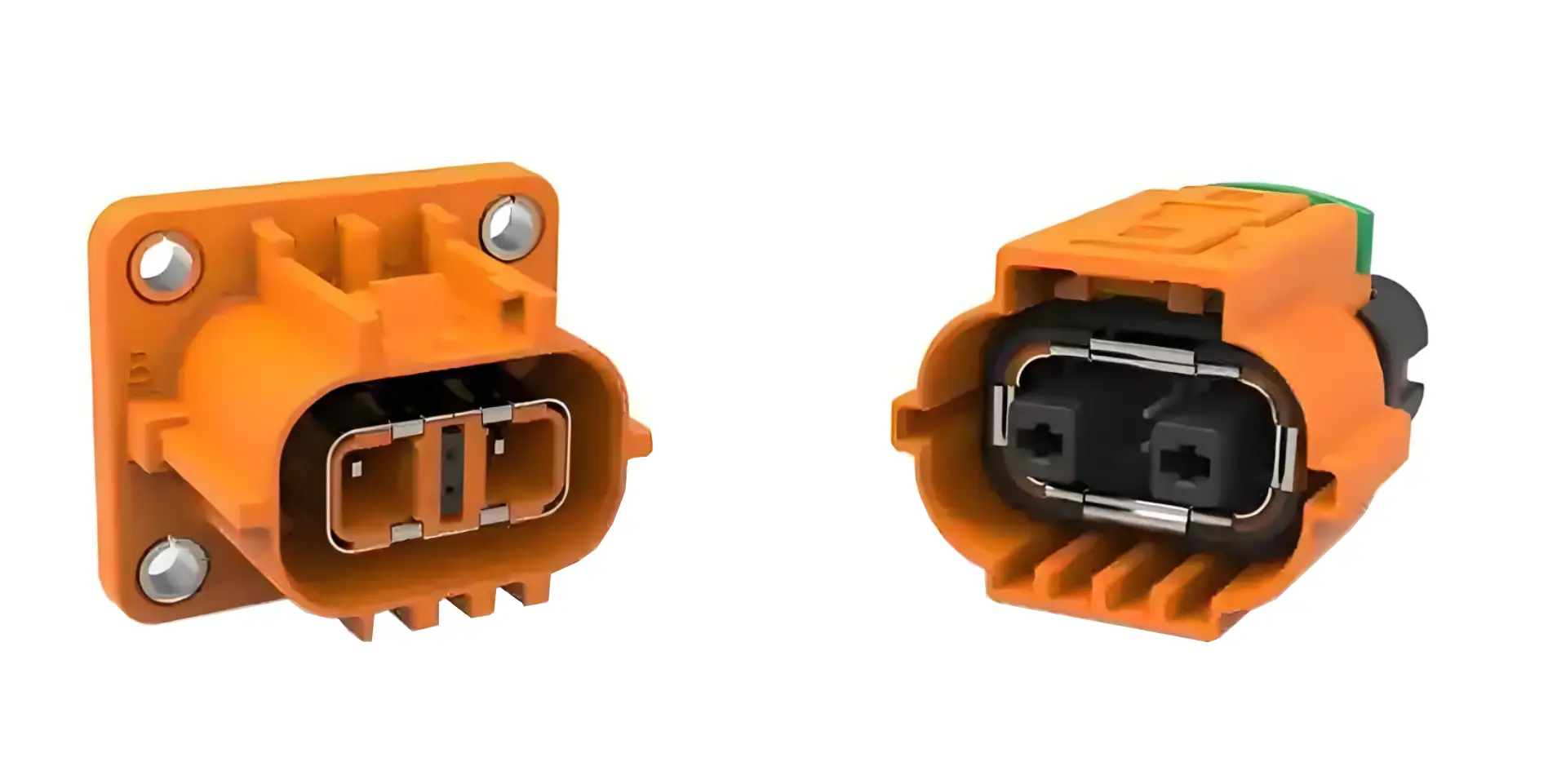

The housing acts as the “armor” of the connector, providing both mechanical protection and structural support. It consists of male and female shells that fit together seamlessly.

- Material strength: Typically made of PA66+GF (glass fiber-reinforced nylon) or PBT, designed to withstand ≥ 125°C (up to 150°C in some applications) and certified to UL94 V-0 for flame resistance. Anti-static surface treatments prevent arcing in high-voltage environments.

- Thoughtful design: Male and female housings lock together via snap-fit mechanisms, with mating forces carefully controlled between 80-150 N to ensure both secure connection and ease of operation.

1.2 Therminals

If the housing is the armor, the terminals are the heart, responsible for current transmission.

- Materials: High-purity T2 copper or CuCrZr (copper-chrominum-zirconium alloy) with silver or nickel plating, ensuring contact resistance below 5 mΩ。

- Design: Male terminals are typically pin-type, while female terminals use spring or crown structures that apply ≥20 N contact pressure. Even after 500+ mating cycles, resistance variation remains under 10%, ensuring durability.

1.3 Shielding

High-voltage transmission can generate EMI (electromagnetic interference) that disrupts vehicle electronics. The shielding enclosure acts as an “invisble barrier”.

- Performance indicators: Made of copper alloy or aluminum alloy, the shielding efficiency reaches ≥60 dB within the 100 MHz-1 GHz frequency range, equivalent to putting electromagnetic signals into “silent mode”. At the same time, it works with the housing and terminals to form a complete grounding loop, with grounding resistance ≤50 mΩ, effectively eliminating interference risks.

- Installation details: Fixed to the housing by clips or welding, it achieves a fully enclosed shielding structure, leacing no “escape gap” for electromagnetic signals.

1.4 Sealing System

EV batteries are often exposed to harsh environments such as rain and dust. The sealing system acts as a “waterproof shield” for the connectors, building multiple layers of protection:

- Rear seal: Silicone rubber sealing rings wrap around the cables, achieving IP67 (no water ingress after 30 minutes of immersion at 1m depth) or IP6K9K (resistant to high-pressure water spray). Even when the vehicle drives through water, safety is ensured.

- Half-end/Wire-end Seal: At the connector interface and cable entry point, O-rings or lip structures fit into housing grooves to form dual protection – like adding a “double safeguard” to every gap.

1.5 Rear Protective Cover

The cable interface at the rear of the connector is relatively fragile and prone to damage. The rear protective cover functions like a “safety helmet,” secured to the rear end by threads or clips. It can withstand an axial tensile force of ≥50 N, preventing cable loosening due to pulling, while also enhancing the sealing performance. Some models are further equipped with integrated harness clamps, ensuring a more organized cable layout.

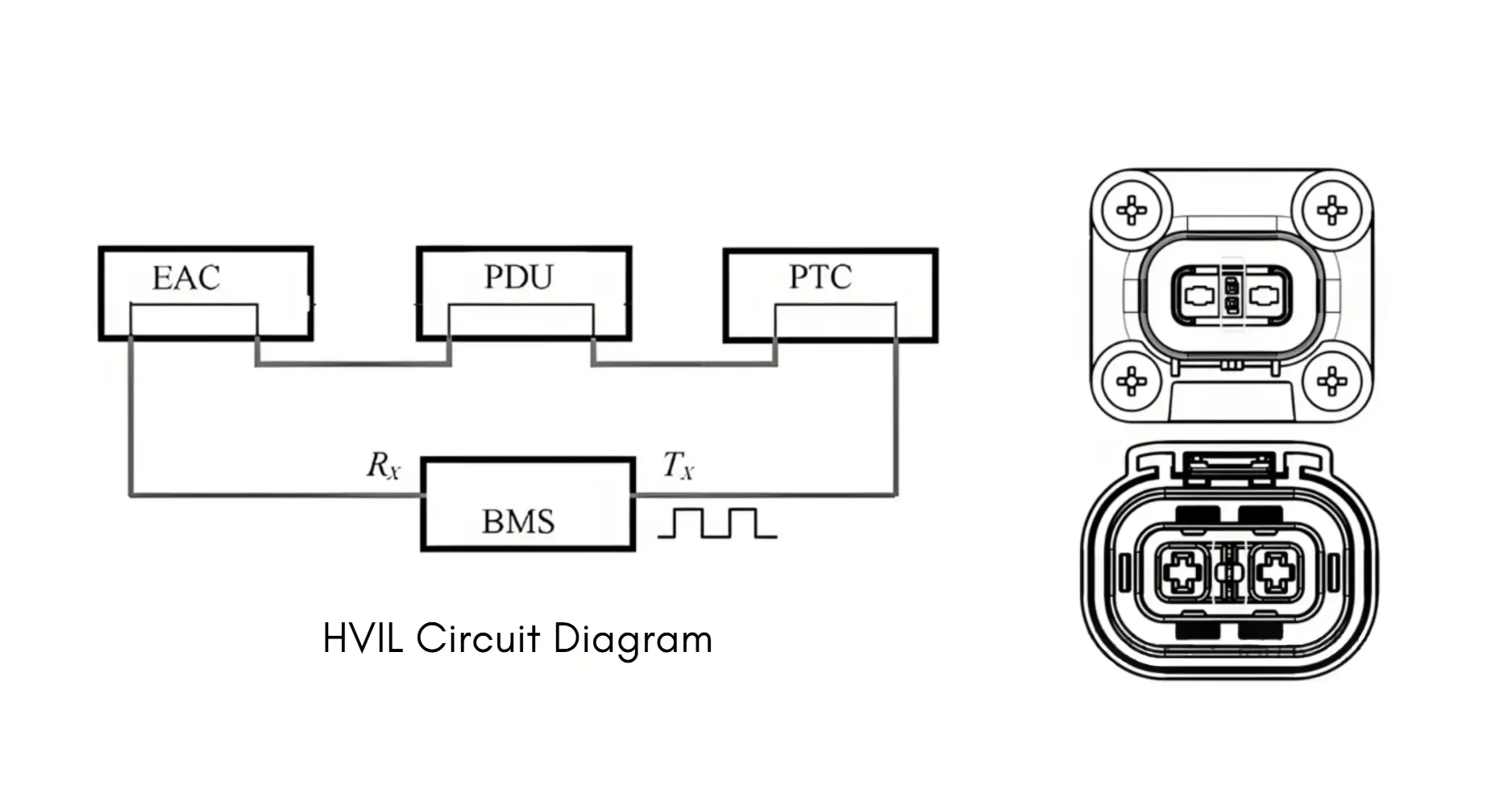

1.6 High-Voltage Interlock System (HVIL)

This is an intelligent system that continuously monitors the connection status – serving as the “safety guardian” of the connector.

- Working principle: A 5V closed-loop circuit is established via micro-switches or Hall sensors. If the connector loosens or disconnects, the circuit is immediately interrupted. The BMS triggers power cut-off protection within 100 ms, cutting the high-voltage supply like an “emergency brake,” fundamentally eliminating the risk of electric shock.

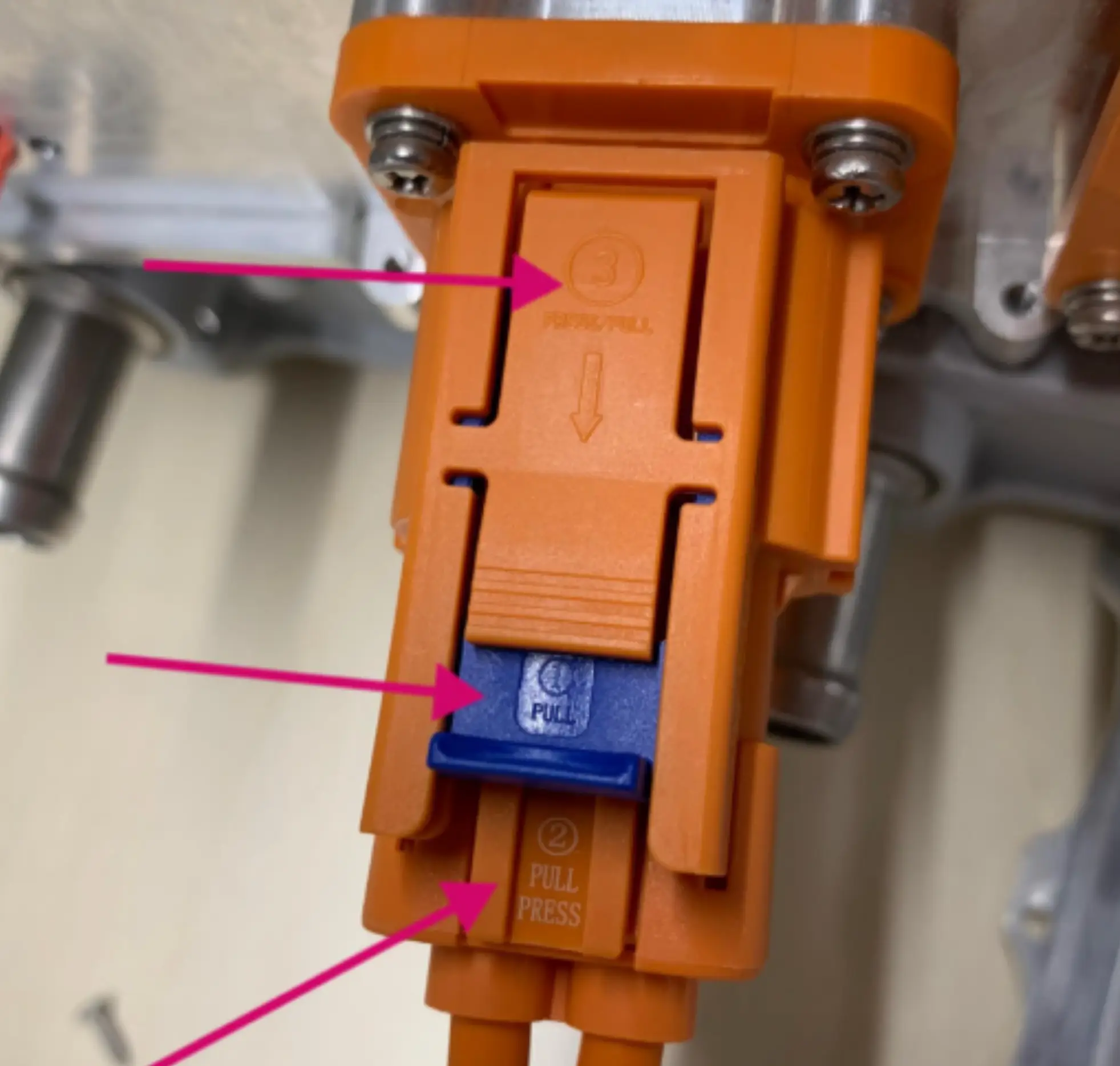

1.7 CPA

To prevent issues such as poor contact or overheating caused by incompletely inserted connectors, the CPA (Connector Position Assurance device) was developed.

- Design details: It typically uses mechanical structures such as plastic clips. When the male and female terminals are fully mated, the CPA provides a clear confirmation – either an audible “click” or a visual color indicator, allowing operators to easily verify the connection status and eliminate the risk of “false mating”.

1.8 Auxiliary Structures

In addition to the core components, these auxiliary designs are equally essential:

- Mis-insertion prevention: The male and female housings feature asymmetric keys, grooves, or other positioning structures – like uniquely shaped keys – preventing connectors of different specifications from being mismated.

- Thermal management structure: For high-power platforms such as 800 V systems, the connector may include built-in heat sinks or thermally conductive silicone. This controls the temperature rise during high-current transmission to within 50 K, preventing overheating and ensuring stable performance.

2. Key Considerations in High-Voltage Connectors Selection

When selecting a high-voltage connector, critical parameters include:

- Operating temperature: -40°C to 125°C (or higher depending on vehicle requirements).

- Current capacity: Rated and peak current must meet system requirements.

- Voltage capacity: Must exceed the maximum battery system voltage.

- Locking system: Secondary locking (hook+latch) to prevent loosening under vibration.

- Waterproofing: IP67 / Ip6K9K compliance.

- Insertion/withdrawal force: Controlled within specified ranges.

- HVIL support: Determined by system requirements.

Conclusion

From the housing and terminals to the sealing and interlock systems, every aspect of a high-voltage connector is engineered with safety and reliability in mind. It is this advanced, compact technology that ensures EV batteries can transmit energy efficiently and stably under high-voltage conditions, safeguarding the safe operation of electric vehicles.

About Brogen

At Brogen, we provide advanced EV solutions for global commercial vehicle manufacturers, enabling them to streamline research and development while capitalizing on cutting-edge technology. Our offerings ensure superior efficiency, extended range, and seamless system integration with proven reliability—empowering our partners to lead in the rapidly evolving green mobility landscape.

Currently, our EV solutions for battery electric vehicles have been adopted by vehicle manufacturers in countries and regions such as Canada, Türkiye, Brazil, the Philippines, Indonesia, the Middle East, and more.

- Discover our HCV electrification solution here: https://brogenevsolution.com/heavy-duty-vehicle-electrification-solutions/

- Looking for an EV solution for your project? Reach out to us at contact@brogenevsolution.com

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >