Blade Battery Solution for Heavy-Duty Trucks in Australia

Background

Our client is a leading provider of drilling services in Australia, operating across remote and challenging sites where reliability and efficiency are critical. Their fleet of heavy-duty trucks serves multiple functions – from transporting massive drilling rigs to carrying auxiliary equipment that keeps field operations running smoothly.

In line with Australia’s national push for decarbonization and their own corporate commitment to sustainability and green drilling practices, the client set a bold target: electrify their heavy-duty trucks. This would not only reduce carbon emissions but also cut operating costs, lower noise levels, and future-proof their business against tightening environmental regulations.

However, electrifying heavy trucks in such a demanding industry is no simple task. The client needed a solution that was proven, safe, and immediately deployable without incurring heavy R&D costs or long load times.

Challenge: High Energy Demand Meets Space Constraints

The first and most significant technical barrier was energy demand versus space availability.

- Energy requirement: Each truck requires around 500 kWh to operate effectively across long shifts without frequent charging interruptions.

- Space limitation: The trucks offered limited space for battery installation due to the chassis design and the drilling equipment they carried.

When evaluated against conventional LFP battery packs (in standard C-box format):

- Only 10 boxes could be installed, yielding ~350 kWh at most.

- To achieve 500 kWh, a new mold would need to be developed – raising development costs, introducing significant delays, and creating risks since the new product would not yet be proven in the market.

The client made it clear: they wanted a mature solution that was readily available, cost-effective, and reliable under real-world drilling conditions.

Brogen Blade Battery Solution for Heavy-Duty Trucks: Unlocking Efficiency with CTP Technology

- 100 kWh per pack: Each blade battery pack offers higher energy capacity than standard LFP packs.

- Only five packs required: To achieve the 500 kWh, only five packs were needed - fitting within the truck's limited installation space.

- Higher energy density: The CTP design eliminates the need for intermediate modules, improving efficiency and sapce utilization.

- Proven safety: Blade cells are known for their stability and strong thermal runaway resistance, suitable for demanding applications.

By adopting this solution, the client could avoid expensive mold development, minimize project risks, and directly deploy a system that was already market-proven and mature.

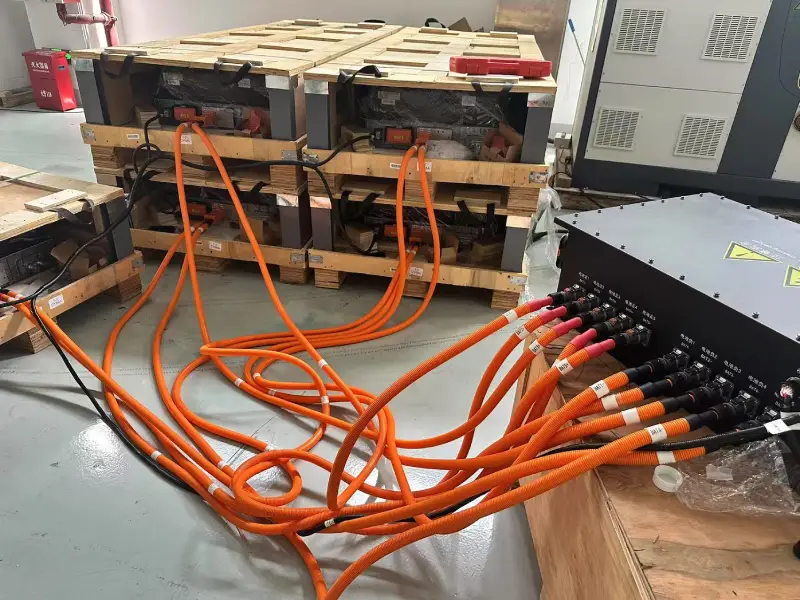

Our Offering: A Complete System, Not Just Batteries

We provided a fully integrated electrification solution, tailored specifically for the client’s drilling fleet.

System Components

- Five 100 kWh Blade Battery Packs (500 kWh total)

- PDU (Power Distribution Unit) for safe, efficient power control

- BMS (Battery Management System) with software customized from proven cases

- BTMS (Battery Thermal Management System) for cooling and heating

- E-Powertrain (Motor+Controller) for both trucks and retrofit equipment

Beyond Hardware - Our Services

- Pre-shipment debugging: We thoroughly tested and debugged the entire blade battery system before shipment, ensuring readiness on arrival.

- Remote technical assistance: Our engineers provided ongoing support to help the client integrate, operate, and maintain the system with confidence.

This holistic approach ensured that the client received not only components, but a complete balde battery solution for heavy-duty trucks.

Outcome: Reliable Blade Battery Solution for Heavy-Duty Trucks in Australia

By deploying our blade battery solution, the client can achieve their electrification goals without incurring unnecessary development risks.

- 500 kWh target capacity achieved within the limited installation space

- Significant cost savings by avoiding new mold development

- Higher system efficiency thanks to CTP technology

- Reliable performance across wide temperature ranges

- Reduced carbon emissions, supporting sustainability commitments

Currently, the project is still in progress, and we remain committed to helping our client drive fleet electrification while contributing to more sustainable drilling practices.

About Brogen

At Brogen, we provide advanced EV solutions for global commercial vehicle manufacturers, enabling them to streamline research and development while capitalizing on cutting-edge technology. Our offerings ensure superior efficiency, extended range, and seamless system integration with proven reliability—empowering our partners to lead in the rapidly evolving green mobility landscape.

Currently, our EV solutions for battery electric vehicles have been adopted by vehicle manufacturers in countries and regions such as Canada, Türkiye, Brazil, the Philippines, Indonesia, the Middle East, and more.

- Discover our blade battery solution here: https://brogenevsolution.com/blade-battery-technology-for-electric-commercial-vehicles/

- Discover our HCV electrification solution here: https://brogenevsolution.com/heavy-duty-vehicle-electrification-solutions/

- Looking for an EV solution for your project? Reach out to us at contact@brogenevsolution.com

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >