E-Powertrain Solutions for Light Trucks, Vans, and Pickups: Overview, Analysis, and Key Insights

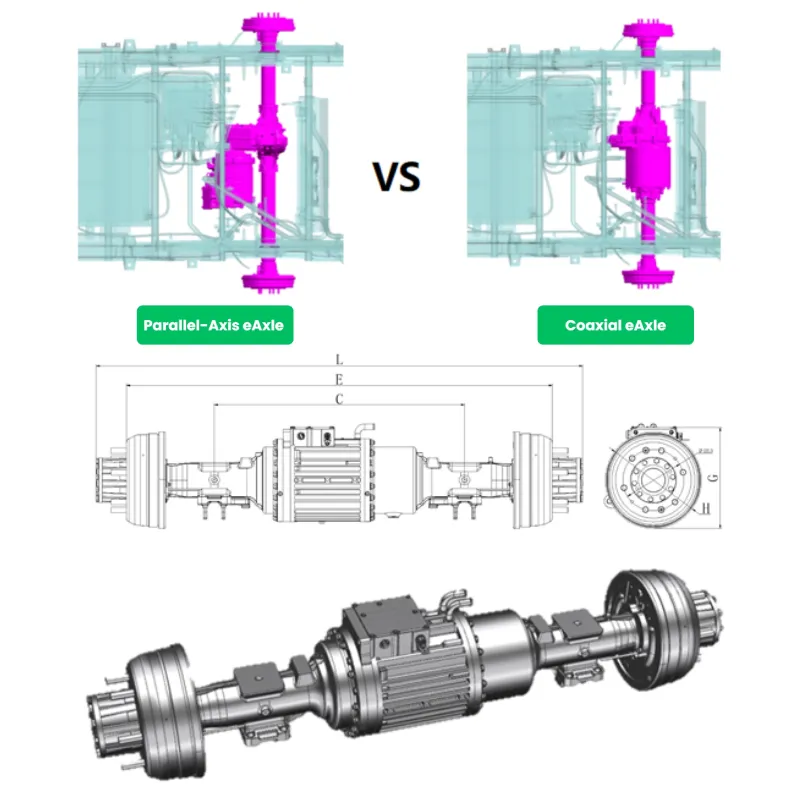

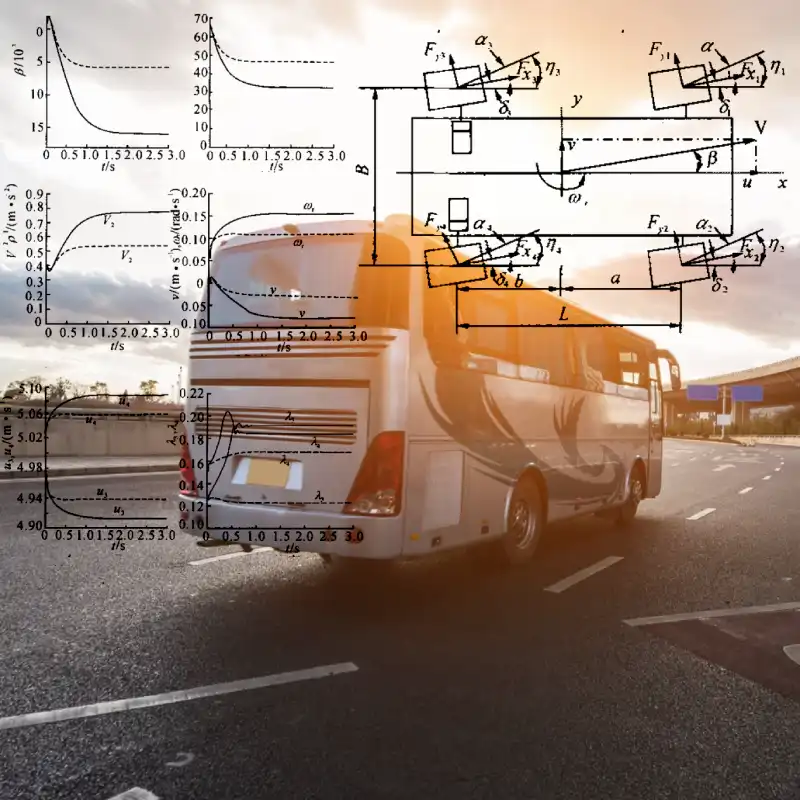

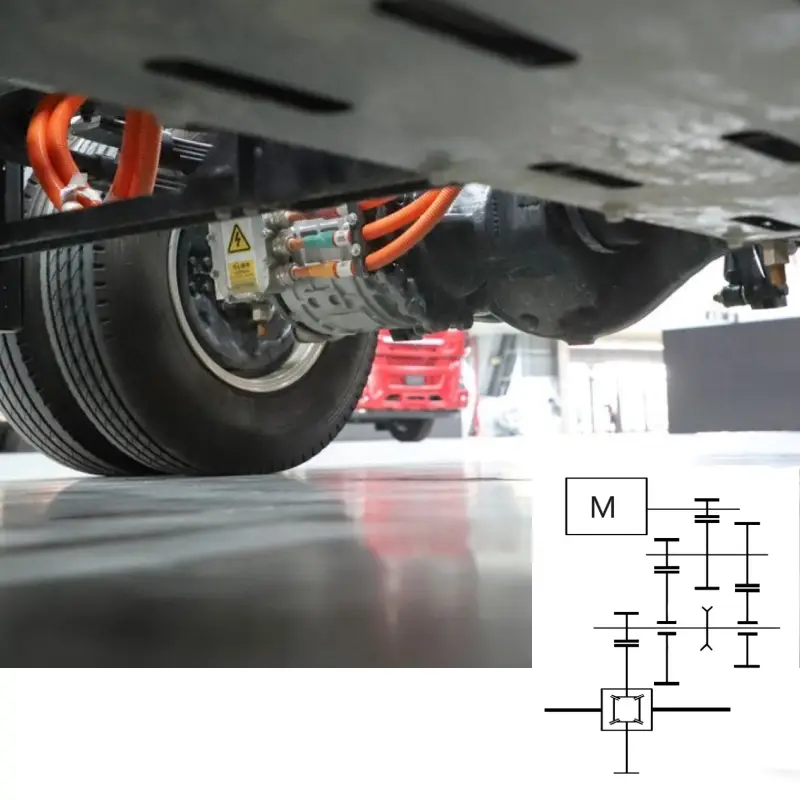

E-Powertrain Solutions for Light Trucks, Vans, Pickups: Overiview The transition to electric powertrains is revolutionizing the light commercial vehicle (LCV) market, driven by increasing demand for sustainability, regulatory compliance, and operational efficiency. OEMs face critical decisions in selecting the right e-powertrain architecture to balance performance, cost, and integration complexity. This article explores the three primary e-powertrain solutions for LCVs: Central Drive, Centralized Electric Drive Axle, and Distributed Electric Drive, highlighting their advantages, challenges, and applications. 1. Central Drive: The Most Established Conversion Approach The central drive system remains a widely adopted method for converting conventional internal combustion engine (ICE) vehicles to electric power. This architecture retains key drivetrain components, such as the driveshaft, rear axle, and suspension, making it a cost-effective transition option. There are two main configurations: Direct Drive: The electric motor directly transmits power to the rear axle via the driveshaft. This solution is widely adopted due to its simplicity and ease of integration. Motor + Transmission/Reducer: The motor’s power is first adjusted by a transmission or reducer before reaching the rear axle, optimizing torque and efficiency. Central Direct Drive Configuration Brogen Direct Drive Motor Solution Integrated Motor+Reducer Configuration Brogen Motor+Reducer+MCU Solution Integrated Motor+Transmission Configuration Brogen Motor+2-Speed AMT Solution While the central direct drive system offers a straightforward path to electrification, it presents certain limitations in terms of efficiency, weight, and cost. Key challenges include: Efficiency Constraints: Although modern electric motors achieve efficiency levels of up to 95%, the mechanical complexity of the central direct drive system introduces additional losses. Weight Considerations: Direct drive configurations require high-torque motors, which are typically larger and heavier, resulting in increased energy consumption. Cost Implications: The need for high-torque motors leads to higher production costs, making it challenging to achieve significant cost reductions. An alternative approach involves integrating the motor with a reducer or multi-speed transmission. This configuration enhances torque multiplication and motor efficiency while reducing overall system weight and cost. Multi-speed transmissions are particularly beneficial for larger commercial vehicles that require a broader torque range. 2. Centralized Electric Drive Axle: An Integrated Powertrain Solution The centralized electric drive axle incorporates the motor directly into the axle assembly, eliminating the driveshaft and enabling improved packaging for the battery system. This architecture is available in three configurations: Parallel-Axis Electric Drive Axle: Utilizes a high-speed cylindrical gear transmission to enhance power density and efficiency while maintaining the structural integrity of conventional axles. Coaxial Electric Drive Axle: Aligns the motor and drive axle to simplify installation and reduce weight, making it an optimal solution for LCVs with a gross vehicle weight of up to 4.5 tons. Independent Suspension Electric Drive Axle: Integrates the motor and reducer within the vehicle frame, optimizing space utilization and improving ride comfort. However, this configuration is typically limited to LCVs under 4.5 tons due to cost and engineering constraints. Parallel-Axis eAxle Configuration Brogen Parallel-Axis eAxle Co-Axial eAxle Configuration Brogen Co-Axial eAxle Independent Suspension eAxle Configuration Brogen Independent Suspension eAxle The centralized electric drive axle offers several advantages, including: Enhanced Efficiency: The elimination of a driveshaft reduces energy losses and increases overall powertrain efficiency. Optimized Chassis Space: The available space allows for a centrally mounted battery pack, improving vehicle weight distribution and safety. Improved Handling: Reduced unsprung mass contributes to better ride comfort and vehicle stability. 3. Distributed Drive: A Next-Generation Powertrain Architecture Distributed drive technology encompasses wheel-end electric drive axles and in-hub motor drive axles, offering greater flexibility in vehicle design and operational efficiency. Wheel-End Electric Drive Axle: Integrates the motor, reducer, and axle into a single unit, eliminating differentials and reducing drivetrain length. This configuration improves efficiency and creates additional underfloor space for battery placement. In-Hub Motor Drive: Embeds the motor directly within the wheel hub, eliminating traditional drivetrain components and maximizing efficiency. However, current technological constraints restrict its application to specific vehicle types such as large buses and low-speed commercial vehicles. Wheel-Side eAxle Configuration In-Hub Motor Configuration Although distributed drive systems offer numerous benefits, they require advanced electronic differential control to ensure precise torque distribution between wheels. When effectively implemented, these systems enhance vehicle performance in high-speed and high-load conditions. Key Trends Influencing the Future of LCV E-Powertrain Development Several industry trends are shaping the advancement of next-generation e-powertrain solutions for LCVs: Greater Adoption of Multi-Speed Transmissions: Improving energy efficiency and torque adaptability across various driving conditions. Increased System Integration: Combining motors, transmissions, and controllers into compact, high-efficiency units to reduce weight and manufacturing costs. Dedicated Electric Chassis Platforms: Purpose-built vehicle architectures designed exclusively for electrification. Lightweight Design Innovations: Implementing advanced materials and structural optimizations to reduce vehicle weight and extend driving range. Brogen specializes in advanced e-powertrain solutions tailored to the evolving requirements of commercial electric vehicle manufacturers. Our integrated three-in-one system, which combines a motor, gearbox, and controller, enhances efficiency while reducing system complexity. Additionally, our centralized and distributed electric axle solutions provide OEMs with optimized powertrain architectures that enhance vehicle performance and reliability. For OEMs navigating the rapidly evolving commercial EV market, selecting the appropriate e-powertrain solution is critical. Brogen’s expertise and cutting-edge technologies empower manufacturers to achieve superior efficiency, durability, and cost-effectiveness in their electrification initiatives. Discover our LCV electrification solutions here: https://brogenevsolution.com/light-commercial-vehicle-electrification-solutions/ EV Motors for LCVs: https://brogenevsolution.com/electric-motors-for-lcvs/ eAxle for LCVs: https://brogenevsolution.com/electric-axle-for-light-truck/ EV Battery Solutions for LCVs: https://brogenevsolution.com/ev-battery-solutions-for-lcv/ Business inquiry: contact@BrogenEVSolution.com Contact Us Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days. Email: contact@brogenevsolution.com Respond within 1 business day Whatsapp: +8619352173376 Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri. LinkedIn channel Follow us for regular updates > YouTube channel Ev systems introduction & industry insights > ContactFill in the form and we will get in touch with you within 2 business days.Please enable JavaScript in your browser to complete this form.Please enable JavaScript in your browser to complete this form. Name * FirstLast Work Email *Company Name *Your Project Type *– Please select –Car, SUV, MPVBus, coach, trainLCV (pickup truck, light-duty truck,