Development Trends in Battery Electric Heavy-Duty Trucks (e-HDTs)

1. Transition Toward Purpose-Built Development of Electric Heavy Duty Trucks

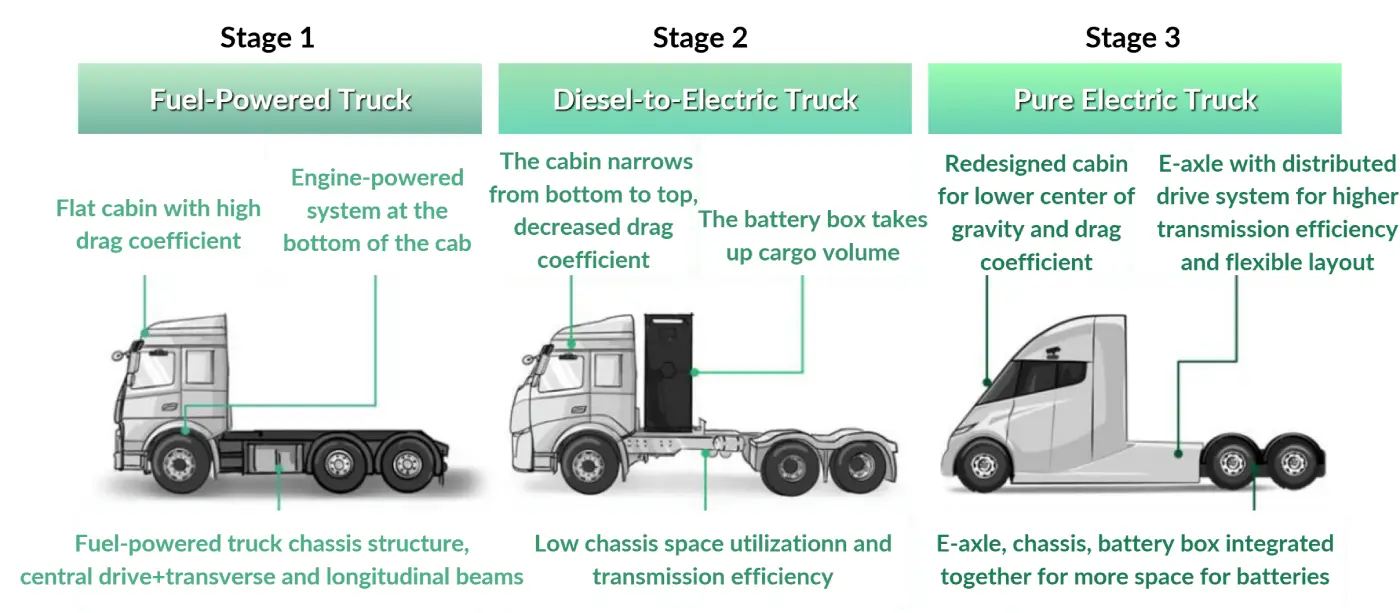

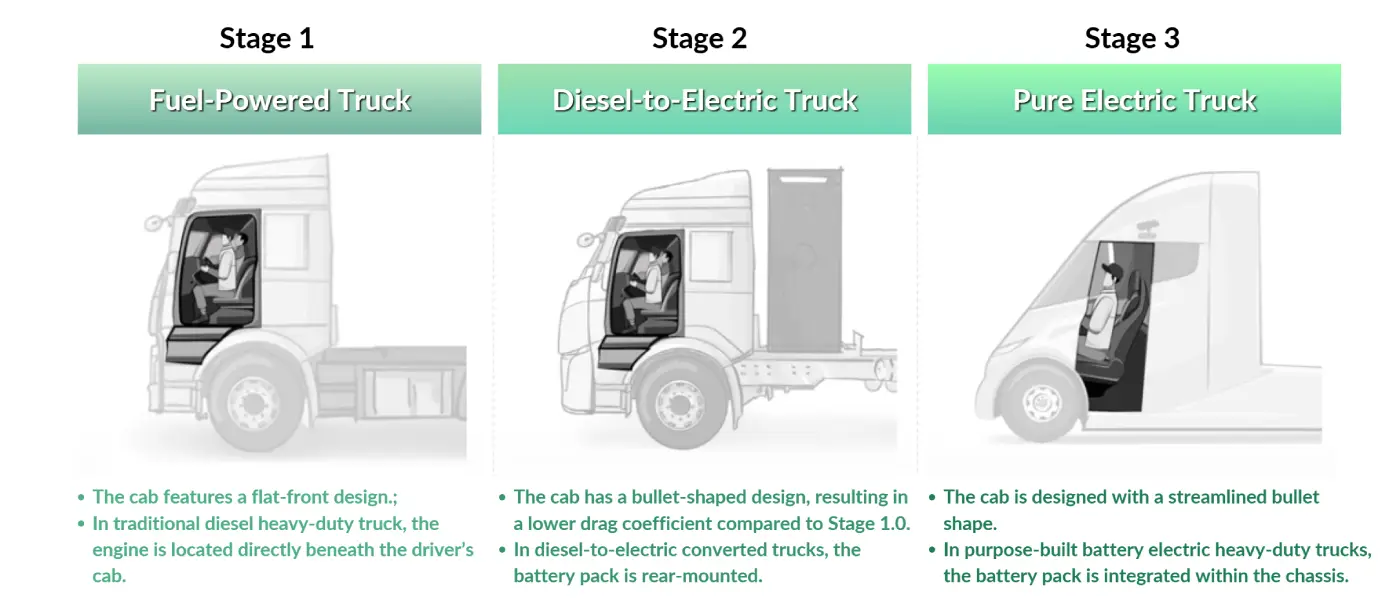

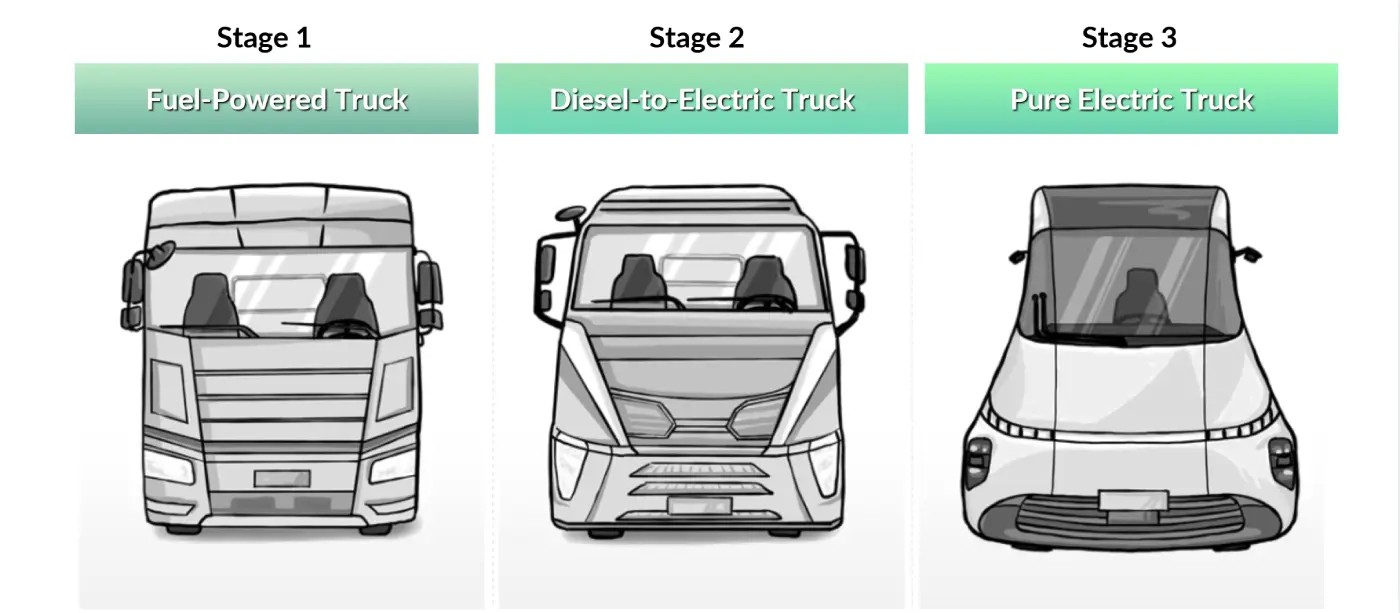

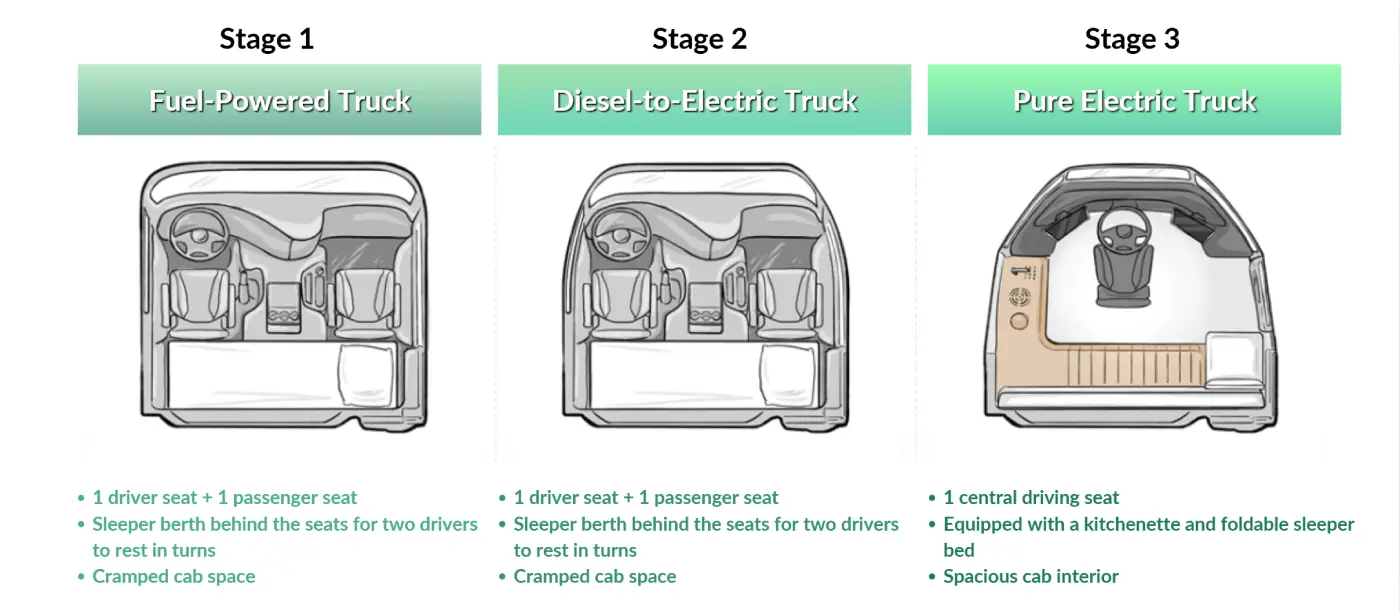

In the current stage of the development of electric heavy-duty trucks (e-HDTs), most models still follow a “diesel-to-electric conversion” approach due to immature technologies and limited production scale. However, in the long run, purpose-built development of dedicated e-HDT platforms will be essential for performance enhancement and is the strategic direction adopted by leading OEMs.

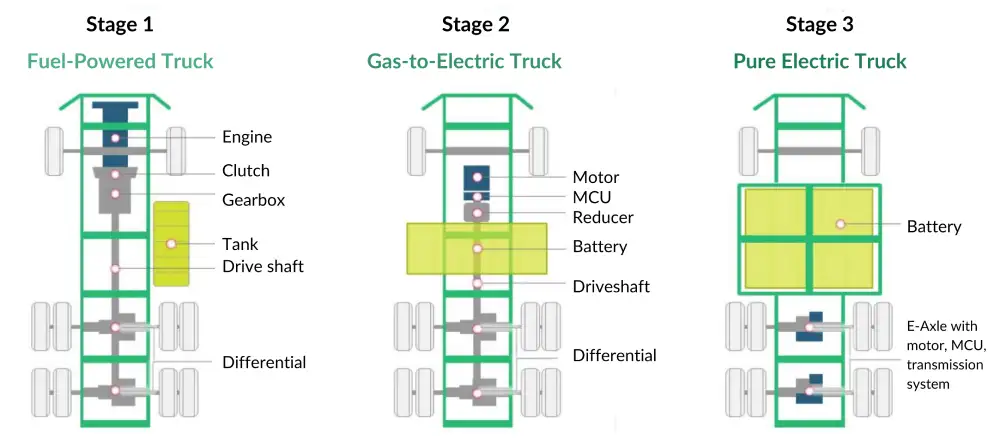

Today’s diesel-converted e-HDTs retain the basic layout of their diesel counterparts. The internal combustion engine is replaced with an electric motor, and battery packs are typically mounted behind the cab or on both sides of the chassis. While this transitional approach allows for faster product rollout at controlled costs, it comes with performance compromises, such as inefficient chassis space usage, lower drivetrain efficiency, and limited battery space, reducing cargo capacity and driving range, thus affecting operational effectiveness and cost-efficiency.

To achieve large-scale commercialization, industry leaders are moving toward ground-up development of e-HDT platforms, optimizing the e-powertrain, chassis architecture, and vehicle aerodynamics to fully unlock the advantages of electrification.

2. Electric Drive Systems

Limitations of Central Drive Architecture

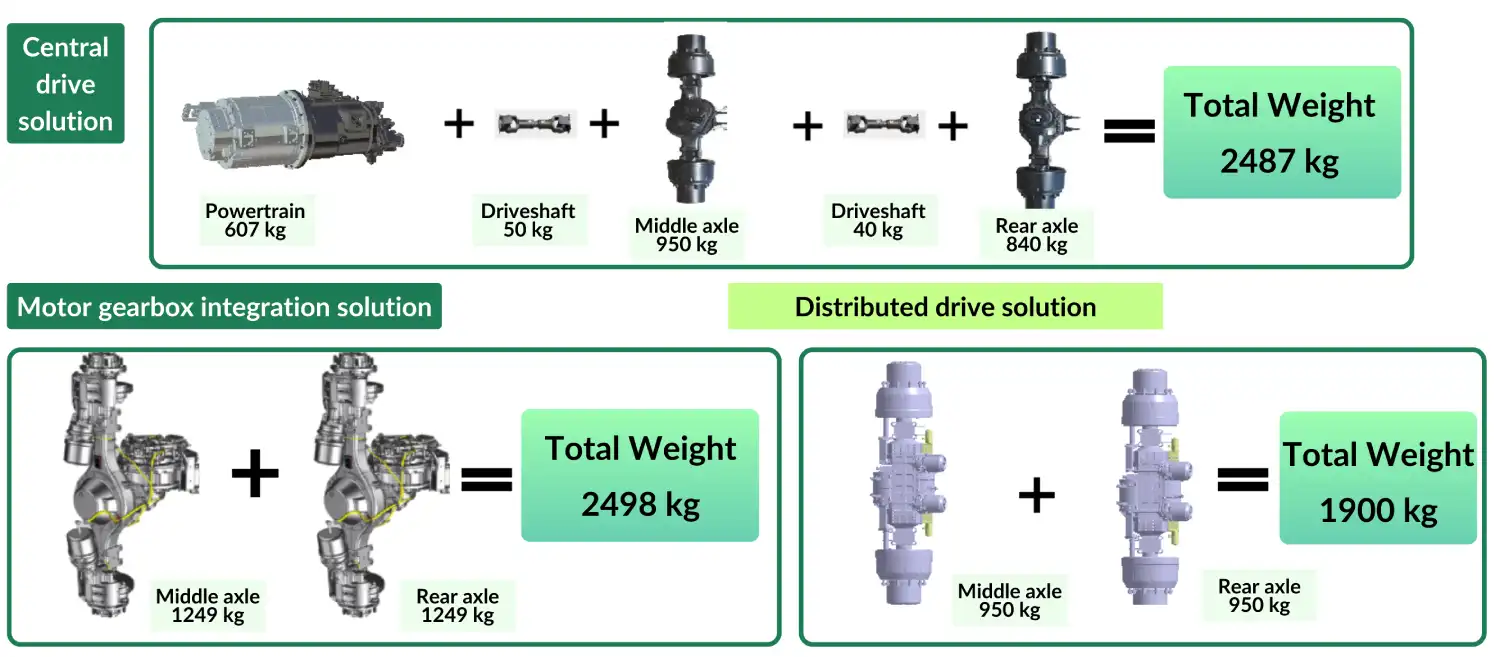

Most converted e-HDTs continue to use the central drive architecture typical of diesel trucks – simply replacing the engine with an electric motor. This results in systems that are bulky, heavy, and less efficient.

Integrated E-Axles & Distributed Drive

Purpose-built e-HDTs allow for deep optimization of the electric drivetrain. As commercial EV powertrains become more integrated, both integrated e-axles and distributed drive solutions are emerging. Although distributed drive systems using hub motors are still in early development, integrated e-axles are currently the mainstream choice.

Compared to the central drive, integrated e-axles combine the motor, gearbox, and drive shaft into a compact, highly integrated system. Advantages include:

- Smaller spatial footprint

- Higher integration and system efficiency

- Fewer transmission components

- Lower vehicle weight and increased usable space

These benefits translate into improved performance, energy efficiency, and packaging flexibility.

High-Voltage Platforms: The Next Step

The trend is shifting from 400V systems (common in passenger EVs) and 600V systems (used in commercial vehicles) toward 800V-1000V high-voltage platforms. Key advantages include:

- Ultra-fast Charging: Higher voltage enables significantly faster charging, especially critical for commercial vehicles with large battery capacities and tight operational schedules.

- Enhanced Driving Efficiency: Lower current at higher voltage reduces power losses, increasing overall system efficiency and extending driving range.

Porsche first adopted the 800V platform in 2019 with the Taycan. Now, commercial vehicle manufacturers are starting to follow suit. The realization of ultra-first charging requires not only vehicle-side high-voltage systems but also widespread deployment of high-powered charging stations.

3. Fast Charging Technology Evolution

The realization of ultra-fast charging requires not only vehicle-side high-voltage systems but also widespread deployment of high-powered charging stations. To support the rising demand for ultra-fast charging:

- Charging Module Power is steadily increasing – from 7.5 kW (1st gen) to 15-20 kW (2nd gen), and now 30-40 kW (3rd gen) in mainstream systems.

- Liquid-Cooled Systems are becoming standard for improved heat dissipation, reduced noise, and easier maintenance.

Tesla’s V2 Supercharger (2019) and GAC Aion’s A480 (2021) are early adopters of liquid-cooled fast-charging technologies. These trends are expected to transition from passenger to commercial EVs in the near future.

4. Chassis Layout Optimization for Electric Heavy Duty Trucks

Diesel truck chassis are traditionally designed with a ladder frame to accommodate a front-engine, rear-drive layout. Retaining this setup in e-HDTs creates challenges, especially in battery packaging, leading to inefficient space use and reduced cargo volume.

With a clean-sheet design, purpose-built eHDTs can eliminate the driveshaft and re-engineer the frame to accommodate skateboard-style battery layouts. Benefits include:

- Higher Energy Density: More battery space improves range without compromising cargo space.

- Structural Integration: Box-section frames housing the battery enhance structural integrity and load-bearing performance.

- Lower Center of Gravity: Improves handling, cornering stability, and safety.

- Sleeker Exterior: Optimized space usage allows for better design flexibility.

5. Aerodynamic and Lightweight Body Design for Electric Heavy Duty Trucks

With purpose-built platforms, e-HDTs are no longer limited to the traditional “cab-over” shape. Redesigning the cab structure enables the use of lightweight materials and aerodynamic profiles to reduce drag and improve efficiency.

For example, most cab-over trucks in China have a drag coefficient (Cd) between 0.55 and 0.65. In contrast, Tesla’s Semi, which features a bullet-nose design and a single-seat cab, claims a Cd as low as 0.36.

Conclusion

The electrification of heavy-duty trucks is transitioning from retrofitted solutions to fully purpose-built platforms. From integrated drivetrains and high-voltage architectures to optimized chassis and aerodynamic designs, leading OEMs are paving the way for the next generation of e-HDTs designed for higher efficiency, better performance, and large-scale commercial viability.

About Brogen

At Brogen, we provide advanced EV solutions for global commercial vehicle manufacturers, enabling them to streamline research and development while capitalizing on cutting-edge technology. Our offerings ensure superior efficiency, extended range, and seamless system integration with proven reliability—empowering our partners to lead in the rapidly evolving green mobility landscape.

Currently, our EV solutions for battery electric heavy trucks have been adopted by vehicle manufacturers in countries and regions such as Canada, Türkiye, Brazil, the Philippines, Indonesia, the Middle East, and more.

- Discover our HCV electrification solution here: https://brogenevsolution.com/heavy-duty-vehicle-electrification-solutions/

- Looking for an EV solution for your project? Reach out to us at contact@brogenevsolution.com

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >