Do Electric Heavy-Duty Trucks With E-Axles Still Need Differential Locks?

Mechanical differential locks were originally developed to address a specific and well-defined engineering problem: traction loss caused by asymmetric wheel grip.

In conventional heavy-duty trucks, this condition occurs relatively infrequently, but when it does—particularly in off-road or mixed-terrain operations—it can lead to vehicle immobilization, operational disruption, or safety risks.

With the increasing adoption of e-axles in electric heavy-duty trucks, the relevance of this traditional solution deserves re-examination. Changes in drivetrain architecture, control capability, and operating duty cycles raise a fundamental engineering question:

Does traction imbalance still occur frequently enough—and with sufficient impact—to justify the continued use of a mechanical differential lock in e-axle-based electric heavy-duty trucks?

This article approaches the question from a system-level perspective, analyzing how traction loss manifests in modern electric truck architectures and how different technical solutions address the issue under defined operating conditions.

1. Differential Locks: Function and Mechanical Struccture

Why Differential Locks Exist

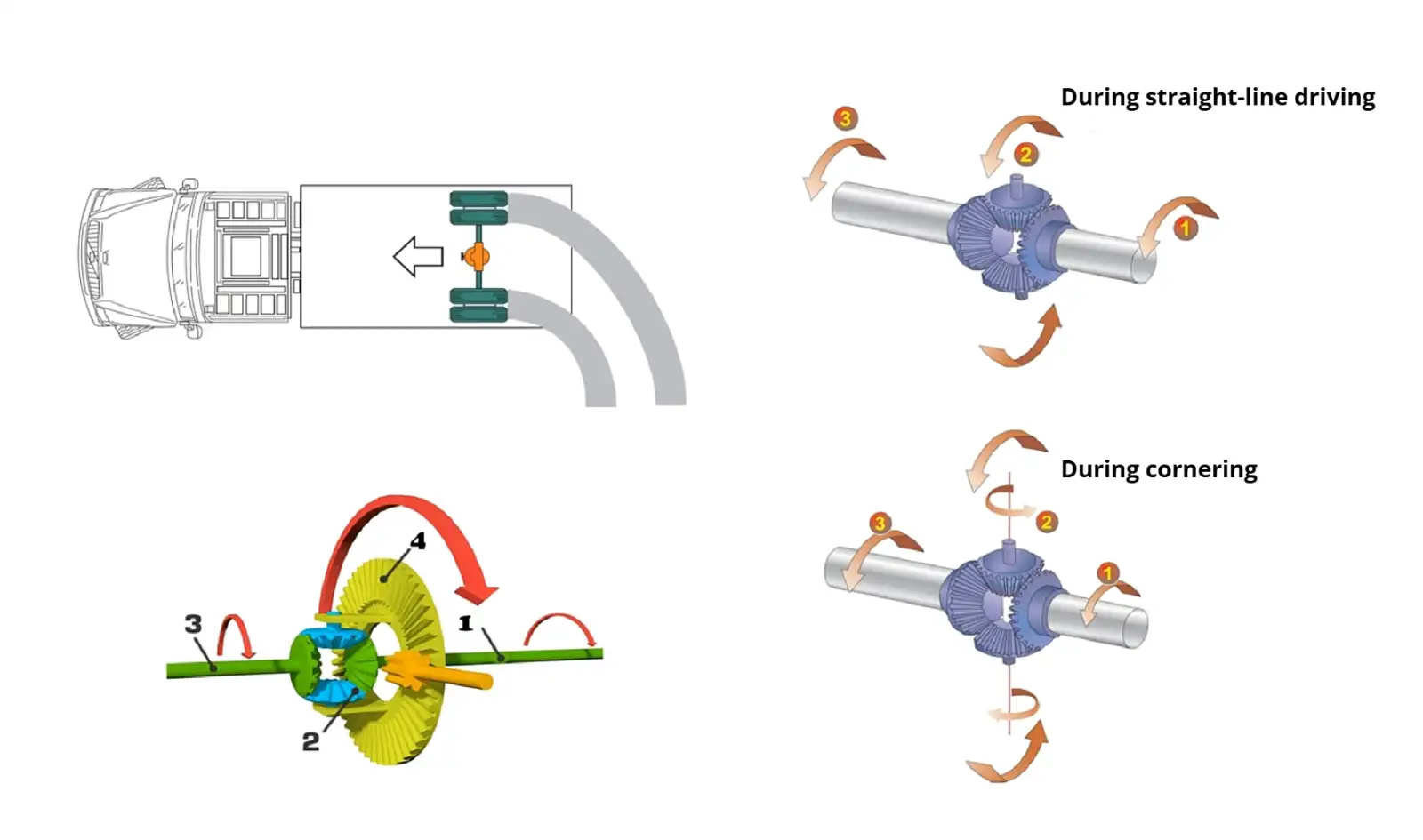

During straight-line driving, the left and right wheels rotate at the same speed. During cornering, however, the outer wheel must rotate faster than the inner wheel due to the longer travel path.

To accommodate this requirement, the automotive differential was developed. It allows torque transmission while permitting wheel speed differences during turns.

However, on low-adhesion surfaces — such as mud, snow, or wet roads — this mechanism introduces a limitation. If one wheel loses traction and begins to spin at high speed, the differential routes most of the drive torque to the wheel with the least resistance. As a result, the wheel with available grip on the opposite side receives insufficient torque, and the vehicle may become immobilized.

In such situations, a differential lock becomes necessary. By mechanically locking the differential, torque can be delivered to the wheel with traction, enabling the vehicle to move forward and recover from the stuck condition.

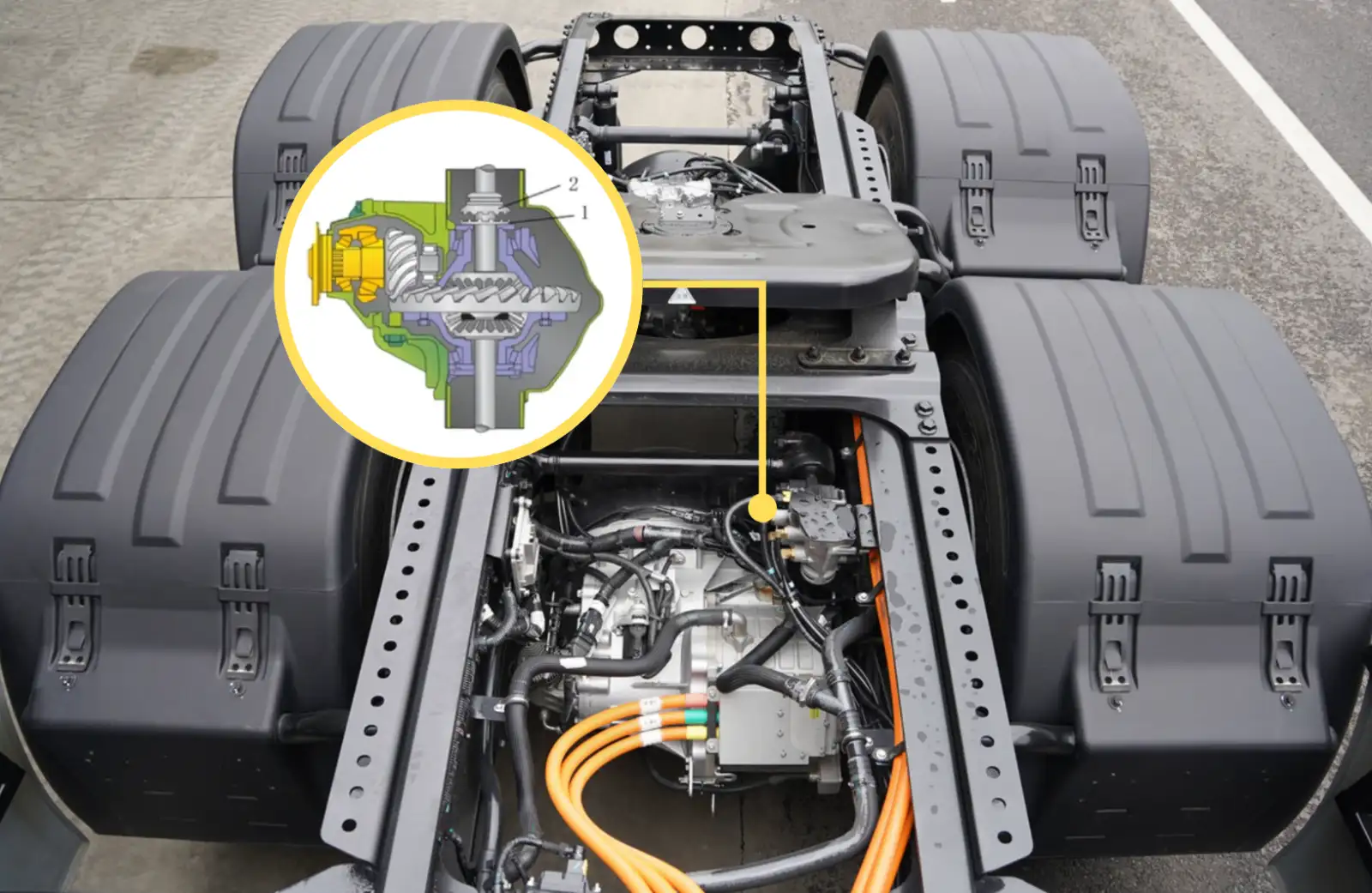

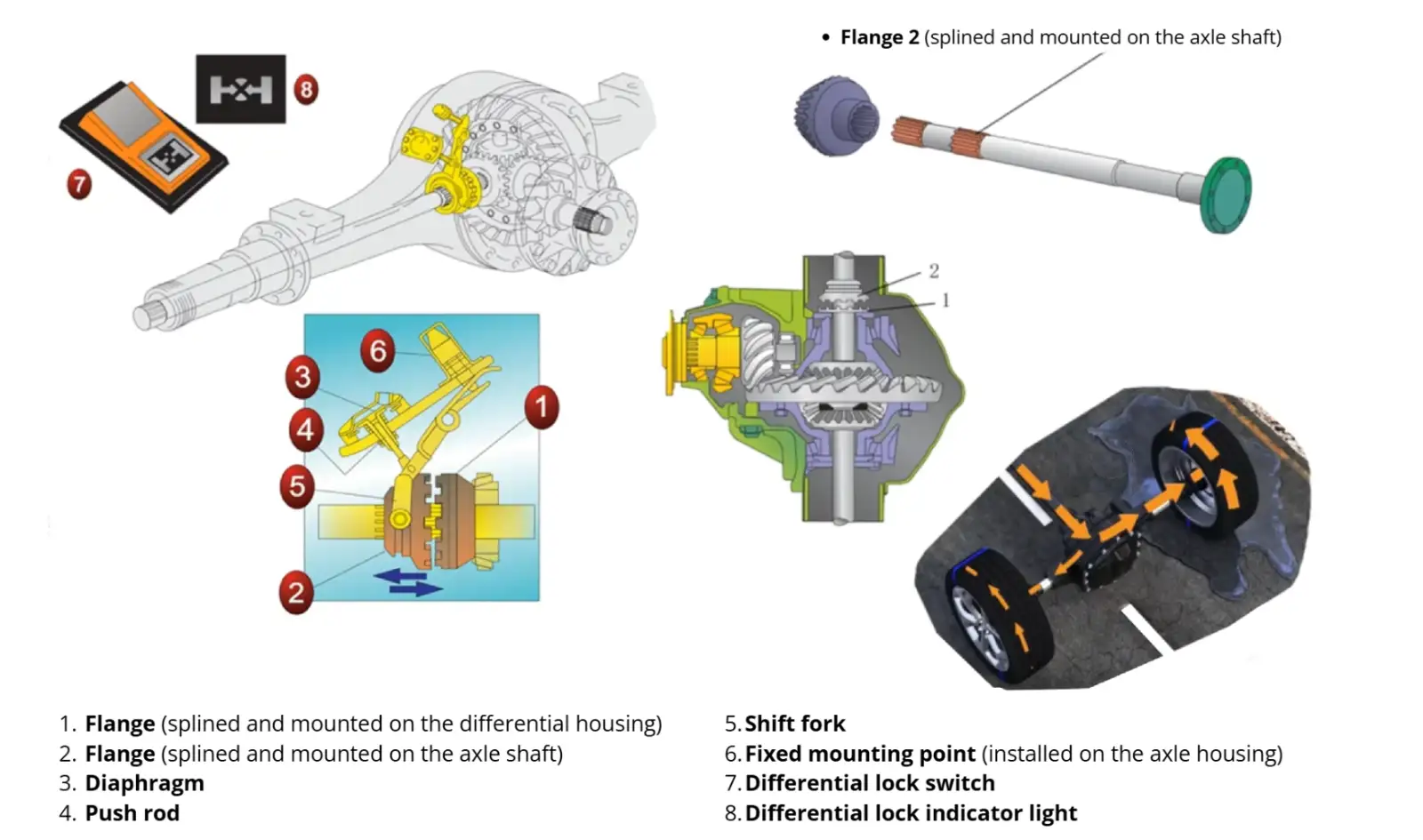

Mechanical Structure of a Differential Lock

A mechanical differential lock is typically installed on one side of the differential. It is actuated — commonly by a pneumatic cylinder — that drives a sliding sleeve engaged with the spline of one axle shaft. Once engaged, the axle shaft is locked to the differential case.

In this locked state, the left and right axle shafts rotate together as a rigid assembly, delivering identical rotational speed to both drive wheels.

2. Cost, Packaging, and Platform Considerations

From a component cost perspective, the incremental cost of a differential lock is relatively modest. However, the more significant implications lie in axle housing design, tooling investment, and material cost.

As a result, many axle platforms are developed with built-in provisions for differential locks, regardless of whether the end application truly requires them.

3. Relevance of Traction Loss in E-Axle Duty Cycles

In previous articles — Electric Axle for Truck: Top Use Cases and Benefits and Electric Truck Axle Guide: How to Choose the Right E-Axle for Heavy-Duty Trucks? — We discussed the operating conditions under which e-axles are most commonly applied.

Electric heavy-duty trucks equipped with e-axles are typically deployed in environments characterized by:

- Predominantly paved roads

- Predictable duty cycles

- Limited exposure to extremely low-traction surfaces

From a vehicle-level perspective, factors such as reduced ground clearance and increased unsprung mass naturally constrain e-axle deployment in highly uneven or off-road environments.

Consequently, current e-axle adoption is concentrated in applications such as parcel and express logistics, cold-chain transportation, and dedicated line-haul operations. These vehicles operate mainly on highways and regional roads with relatively stable surface conditions.

4. Software-Based Traction Control as an Alternative

Some electric heavy-duty truck platforms—particularly on-road tractor applications—have already moved away from mechanical differential locks in favor of software-based traction recovery strategies.

Most modern electric trucks are equipped with Electronic Stability Control (ESC) systems. ESC monitors vehicle dynamics through sensors near the vehicle’s center of gravity. When instability is detected, the control unit calculates the appropriate intervention and applies differential braking forces to individual wheels, generating stabilizing moments to prevent loss of control.

Because ESC can apply braking force independently to each wheel, it can also support traction recovery. When one wheel spins due to low traction, braking force is applied to the slipping wheel, allowing drive torque to be transferred to the wheel with available grip on the opposite side.

Similarly, when operating on ice, snow, mud, or uneven surfaces, the system continuously monitors left and right wheel speeds. If a significant speed difference is detected, the faster-spinning wheel is identified as slipping and is immediately braked, ensuring more stable and controlled torque delivery.

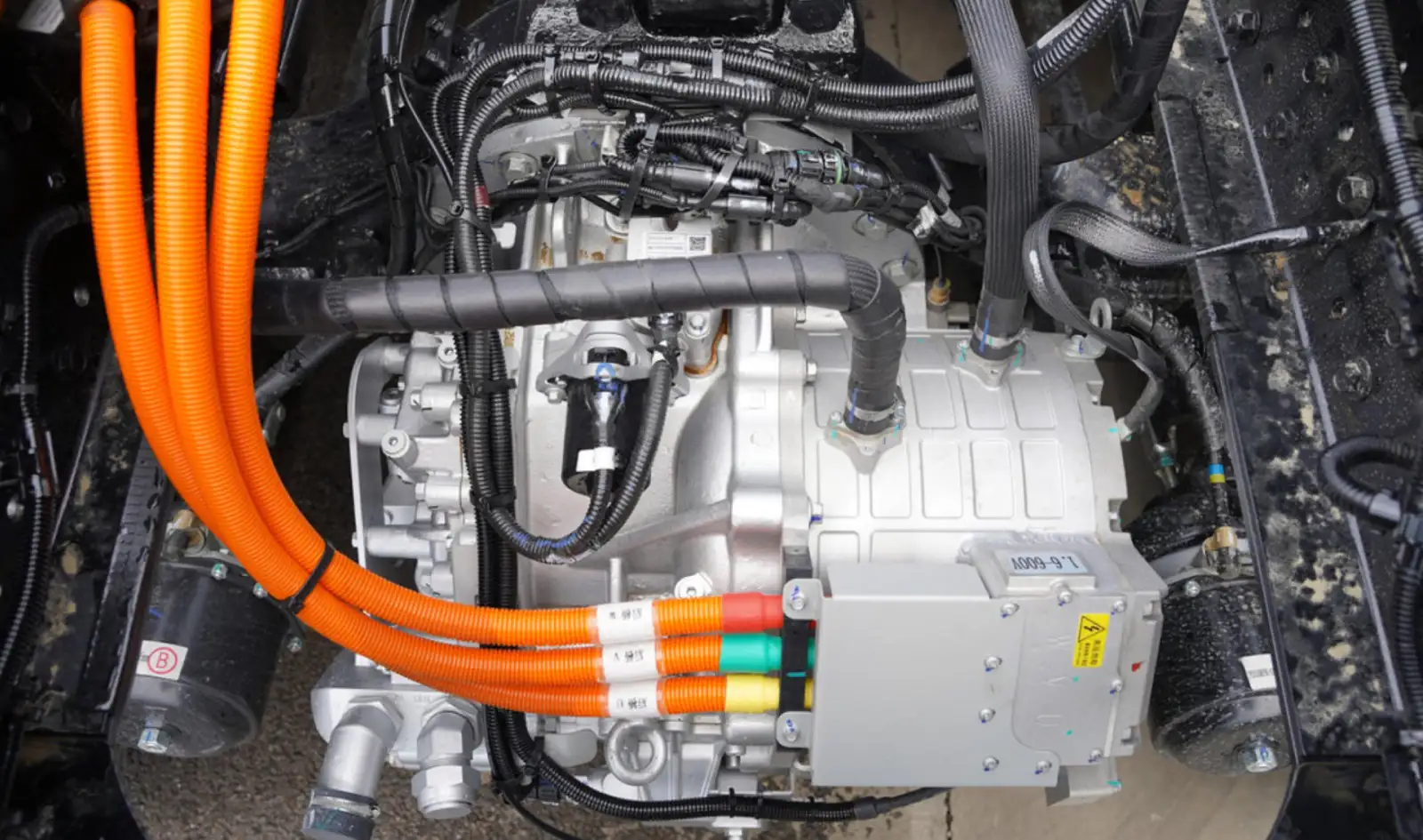

5. Distributed Drive Architectures: Eliminating the Mechanical Differential

A more fundamental shift occurs with distributed electric drive architectures, where each wheel—or each side of the axle—is driven by an independent motor.

In such systems:

- Mechanical differentials are no longer required

- Differential locks become structurally irrelevant

- Wheel speed differences during cornering are managed through electronic differential control

By precisely controlling motor torque and speed based on steering input, vehicle speed, and traction feedback, distributed drive e-axles enable:

- Accurate torque vectoring

- Improved vehicle stability

- Enhanced energy efficiency

As this technology matures, distributed drive architectures provide OEMs with greater freedom in drivetrain design, particularly for applications prioritizing efficiency, controllability, and software-defined performance.

6. Technical Conclusion: Selecting the Right Solution

From an OEM and EV integration perspective, there is no universally “best” traction solution for electric heavy-duty trucks.

Instead, traction strategies should be selected based on duty cycle, platform architecture, operating environment, and cost-performance targets:

Mechanical differential locks remain valid for severe off-road or highly variable terrain

Software-based traction control can replace mechanical locks in many on-road applications

Distributed drive architectures redefine the problem entirely by removing the mechanical differential

As electric vehicle architectures continue to evolve, traction solutions should be chosen through system-level analysis rather than legacy assumptions.

Our E-Axle Solutions for Heavy-Duty Applications

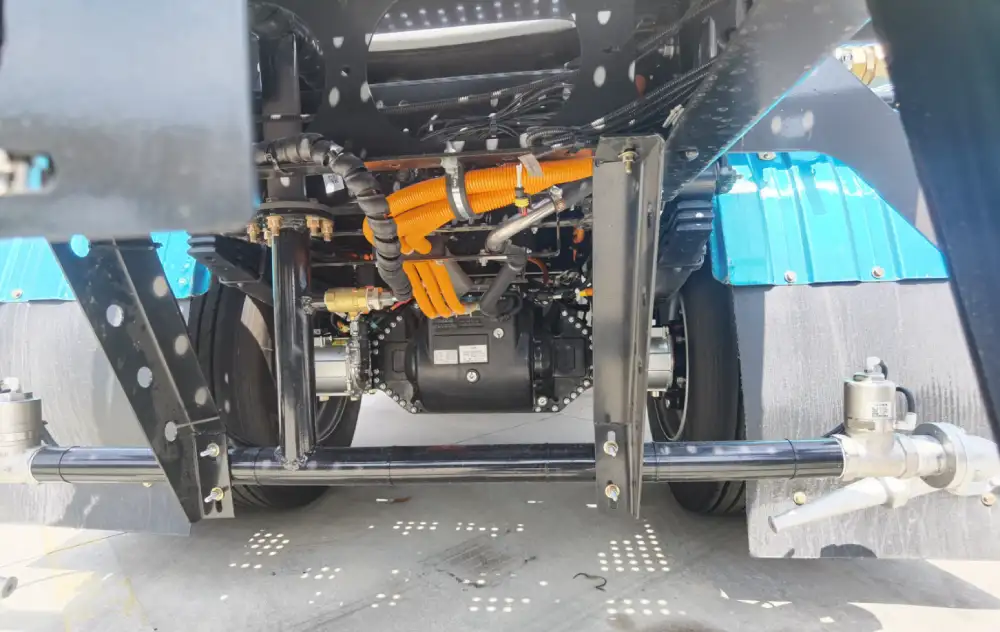

To support diverse traction strategies and application requirements, our electric truck axle portfolio includes both centralized and distributed drive architectures.

For centralized electric drive axles used in 4×2 and 6×4 configurations, an optional mechanical differential lock is available to address asymmetric traction conditions caused by uneven road surfaces or high torque demand.

For distributed drive e-axle architectures, traction management is achieved through electronic differential control enabled by independent motor actuation. These systems are equipped with EASR and IESS safety functions, allowing coordinated wheel-level torque control without mechanical locking components.

- Explore our centralized e-axle solutions here: https://brogenevsolution.com/centralized-electric-drive-axle-solution-for-trucks/

- Explore our distributed drive e-axle solutions here: https://brogenevsolution.com/electric-axle-for-heavy-duty-truck/

- Business inquiry: contact@BrogenEVSolution.com

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >