Electric Axle for Truck Platforms: Why Multi-Speed, Single-Motor Architectures Still Matter?

As electrification continues to move into medium- and heavy-duty truck segments, the electric axle for truck platforms is increasingly evaluated not only by motor output, but by system-level considerations such as packaging constraints, functional integration, and duty cycle adaptability.

For OEMs and truck manufacturers, selecting an electric axle for truck applications is no longer a purely component-level decision. It is a drivetrain architecture choice that directly affects vehicle layout, efficiency, and application coverage.

Among the available solutions, the single-motor, multi-speed electric axle for trucks remains a highly relevant option — particularly for platforms that require both performance flexibility and compact integration.

Engineering Challenges in Electric Axle Design for Trucks

Designing an electric axle for truck applications presents unique challenges that differ significantly from those of passenger vehicles.

In electric heavy-duty trucks, integrating the electric motor and transmission into the drive axle inevitably increases axial packaging length outside the axle housing. If not carefully managed, this can lead to interference with chassis structures, suspension components, or auxiliary systems — limiting platform flexibility.

One common response is to reduce the number of gear ratios in the electric axle. While this simplifies packaging, it often introduces trade-offs between:

- Low-speed launch torque and gradeability

- High-speed cruising efficiency

- Energy consumption across mixed truck duty cycles

At the same time, many truck applications require additional functional interfaces within the electric axle, including:

- Power take-off (PTO)

- Hydraulic pump output

- Mechanical differential locking

For many electric axle for truck designs, limited installation space restricts the integration of these functions, ultimately narrowing the vehicle’s usable operating scenarios.

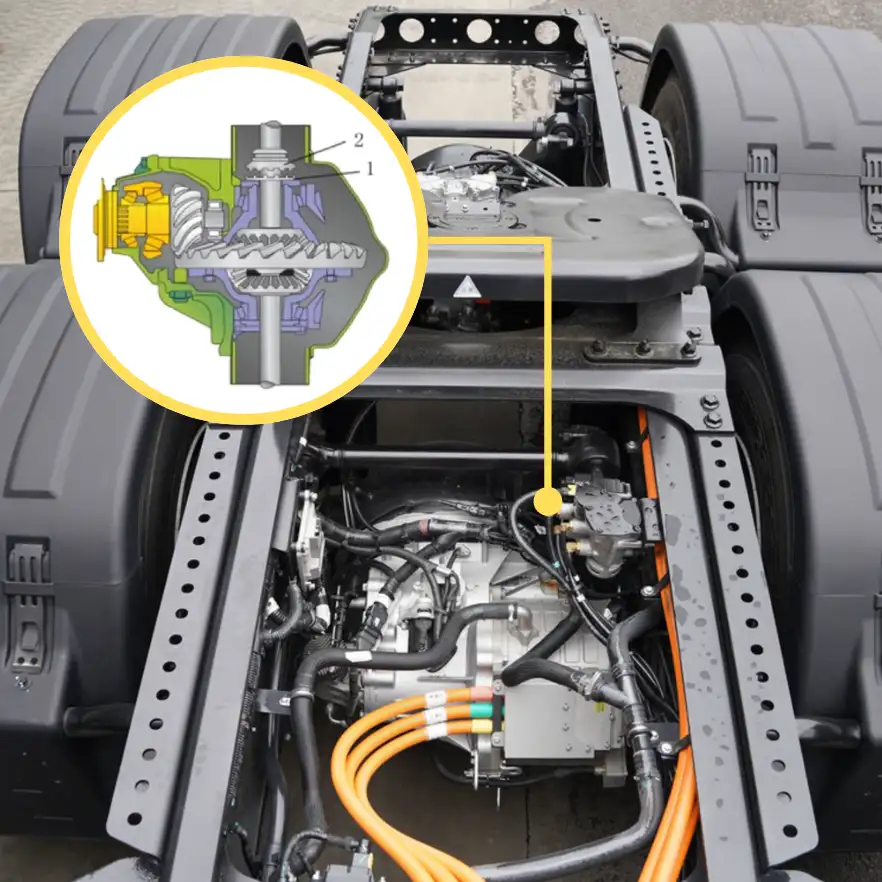

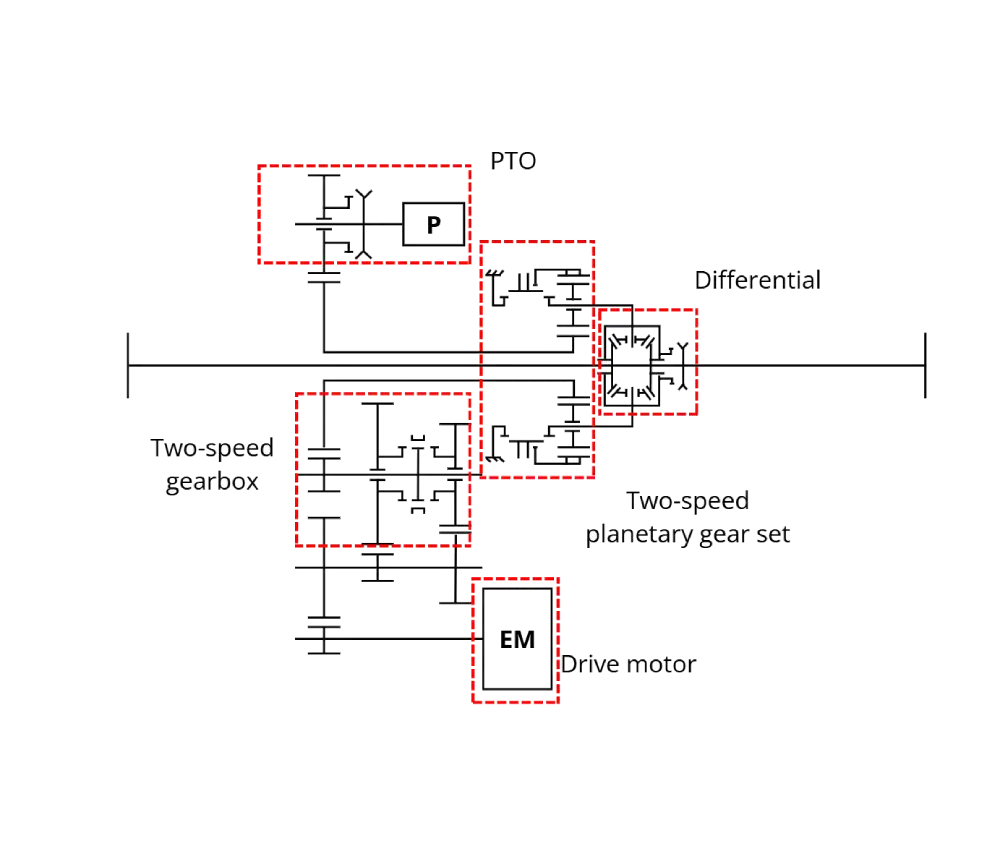

Our Multi-Speed Electric Axle for Truck Applications

Our multi-speed, single-motor electric axle platform is designed to address these constraints, specifically optimized for heavy-duty use cases. The architecture combines:

- A compact parallel-shaft two-speed gearbox

- A planetary gear-based high/low range mechanism

This configuration enables a four-speed transmission layout within a reduced axial envelope, improving compatibility with medium- and heavy-duty truck chassis designs. More importantly, the compact layout preserves sufficient space for functional expansion, allowing the electric axle to integrate PTO interfaces, hydraulic pump output, and differential locking mechanisms.

This makes the electric axle suitable not only for highway trucks, but also for vocational and mixed-duty applications where auxiliary functions are required.

System-Level Advantages of Truck OEMs and EV Builders

From a vehicle integration perspective, this electric axle for truck platforms delivers several key system-level benefits:

- Improved drivetrain efficiency across both low-speed, high-load, and cruising conditions

- Reduced reliance on oversized motors, improving overall system efficiency

- Greater adaptability to diverse truck duty cycles, from line-haul to vocational use

- Expanded application coverage, without compromising chassis layout

By balancing performance, efficiency, and functional integration, the multi-speed electric axle provides OEMs with greater freedom in truck platform design.

Conclusion: Choosing the Right Electric Axle for Truck Platforms

There is no universally optimal electric axle for truck applications. For OEMs and EV builders, the right solution depends on duty cycle severity, vehicle layout constraints, auxiliary function requirements, and cost-performance targets.

Our multi-speed, single-motor electric axle for truck platforms remains a highly practical choice where packaging efficiency, energy optimization, and functional flexibility must be achieved simultaneously.

In truck electrification, architecture-driven decisions consistently outperform feature-driven design —and the electric axle is no exception.

- Explore our electric axle for truck solutions here: https://brogenevsolution.com/centralized-electric-drive-axle-solution-for-trucks/

- Business inquiry: contact@BrogenEVSolution.com

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >