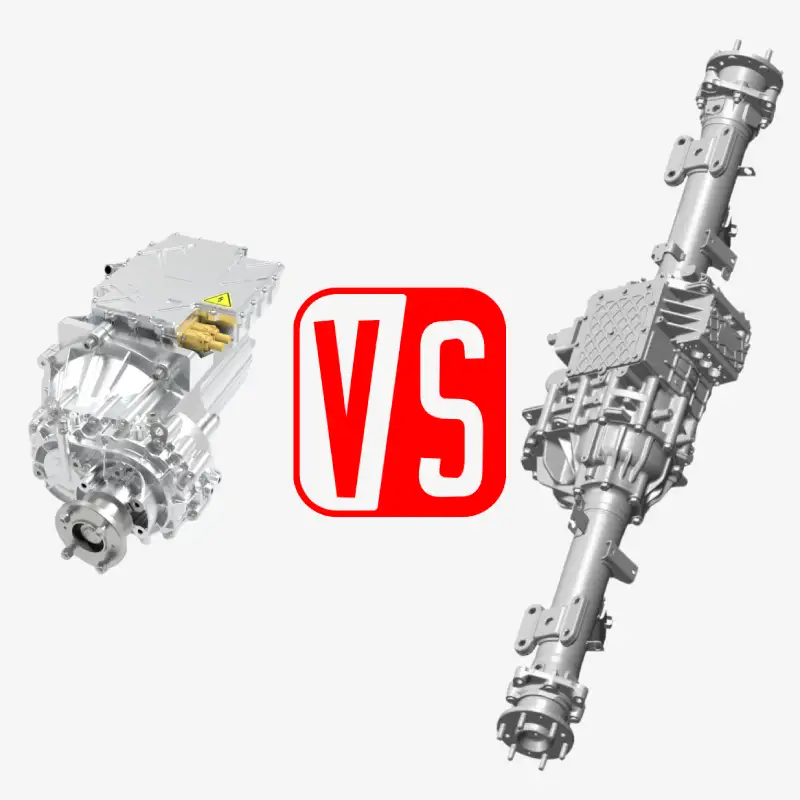

Electric Drive Unit vs.E-Beam Axle: Which Powertrain Solution Wins for Electric LCVs

As global commitments to carbon neutrality intensify, the electrification of commercial vehicles has shifted from a long-term ambition to an immediate necessity. Europe, in particular, is moving rapidly toward zero-emission mobility, with regulations requiring all light commercial vehicles to be either fully electric or powered by carbon-neutral fuels by 2035.

Yet despite strong policy momentum, the transition to battery-electric LCVs continues to face three persistent barriers: limited driving range, reduced payload capacity, and high manufacturing cost.

The e-Beam electric rigid axle offers a fundamentally different engineering approach that directly addresses these industry-wide challenges. This article breaks down the technology and explains how it enhances efficiency, payload, and cost structure for next-generation electric LCVs.

Europe's LCV Market: Pressure and Opportunity in the Electrification Era

Understanding the value of e-Beam technology starts with the context of Europe – one of the world’s most demanding arenas for emissions compliance, cost competitiveness, and technological innovation.

1. Market Size and Structure

- Global annual vehicle production is roughly 90 million units, including around 15 million LCVs. Europe produces approximately 3 million LCVs per year, representing 16% of the EU’s total light vehicle output – making it one of the world’s core LCV markets.

- The global LCV market is dominated by vans, SUVs, and pickups. Manufacturing is concentrated in segments such as Class B/C/D/E vehicles, mini-sized vans, and full-size body-on-frame models.

- In Europe, most LCVs are front-wheel-drive (FWD) or rear-wheel-drive (RWD). AWD and 4WD applications remain smaller but are growing with increasing EV adoption.

2. Regulatory Landscape Driving Electrification

Europe enforces some of the world’s strictest CO₂ regulations, pushing LCV electrification into high gear:

2025–2029: LCV CO₂ limit at 153.9 g/km

2030–2034: Reduced to 90.6 g/km

2035 onward: Zero-emission or carbon-neutral fuels required

As a result, BEV penetration across Europe is expected to reach 50% by 2030. The LCV segment will follow a similar trajectory, approaching full electrification around 2035.

3. OEM Strategies: Alliances and New Platforms for Electric LCVs

OEMs are accelerating development or forming alliances to reduce cost and boost competitiveness:

Volkswagen & Ford Joint Agreement(platform sharing for urban vans, midsize vans, and pick-ups; Ford EVs built on VW’s MEB platform)

BYD e-VALI: 700 kg payload, 300 km range, FWD, 100 kW motor

Iveco eMoovy Modular LCV: 1500 kg payload, 265–320 km range, FWD, 160 kW motor

Hyundai & Iveco EV Models: 3.5–4.25 t GVW, 1500 kg payload, RWD/AWD, 150–250 kW

SAIC Maxus eTerron 9: 620 kg payload, 3500 kg towing, 430 km range, AWD, 325 kW power

4. Core Challenges in Electric LCVs

A comparison between diesel and electric Mercedes Sprinter models highlights the problem:

| Parameter | Diesel Sprinter | eSprinter (400 V) |

| Drive Layout | RWD (rigid axle) | RWD (independent suspension) |

| GVW | 3.5 t / 3.9 t | 3.5 t / 4.25 t |

| Energy Storage | 93 L diesel | 81 / 113 kWh battery |

| WLTP Range | 989 / 1081 km | 259 / 433 km |

| Power | 112 / 125 kW | 100 / 150 kW |

| Payload | 1013 / 1392 kg | 497 / 1003 kg |

| Price (excl. VAT) | £49,340 / £52,635 | £58,740 / £74,230 |

EVs offer zero emissions and lower maintenance costs, but also suffer from the same issues across the industry: shorter range, reduced payload, and significantly higher price. The e-Beam axle solution is specifically designed to address these three structural challenges.

The Engineering Benefits of Using an e-Beam Axle in Electric LCVs

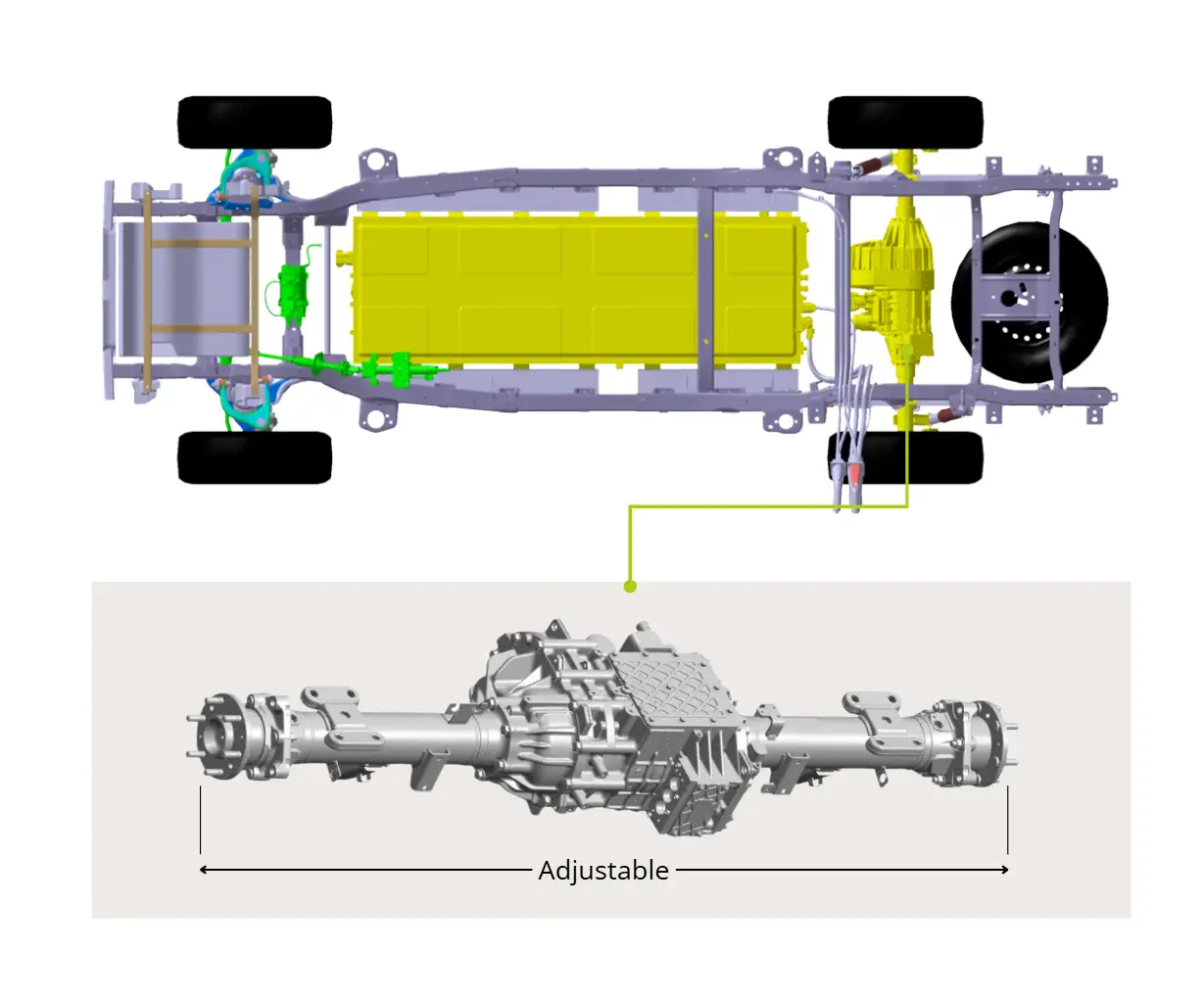

The e-Beam axle is an electric rigid axle that replaces traditional independent electric drive units (EDUs). Its architecture – simpler, stronger, and more vertically integrated – directly improves weight, efficiency, and cost.

1. Architecture Optimization

Independent Electric Drive Unit (EDU)

- Uses independent suspension (multi-link, trailing-arm, MacPherson, etc.)

- Requires knuckles, hubs, driveshafts, and multiple joints

- Low unsprung mass but high system complexity

- A longer power transfer path means more mechanical losses

e-Beam Electric Rigid Axle

- Integrated axle housing with motor and driveline

- Compatible with leaf-spring and multi-link suspensions

- Fewer mechanical components

- Shorter power transfer path

This structural simplicity is the foundation for e-Beam’s performance advantages.

2. Weight Optimization: Over 25 kg Reduction and Higher Payload

Benchmark testing demonstrates that when both systems are designed to their minimum feasible mass (EDU with trailing-arm independent suspension vs. eBeam with leaf-spring rigid suspension), the eBeam achieves a 5–10% weight reduction, cutting over 25 kg from the vehicle.

Key contributors:

- Fewer mechanical parts

- No standalone half-shafts or complex knuckles

- Simplified housing and integrated functions

For commercial fleets, a 25 kg weight reduction can translate into:

- Higher usable payload

- Lower energy consumption

- Longer real-world driving range

3. Efficiency Optimization: Up to 1.7% Longer Range

WLTP cycle tests were performed to assess and compare the energy loss characteristics of both solutions.

Root cause of the efficiency gap:

The EDU relies on a relatively long and load-sensitive power transmission path – gearbox output seal → inner CV joint → outer CV joint → wheel bearing → wheel. As vehicle load increases, the suspension compresses, causing the CV joint angles to rise. Larger CV angles lead to higher friction and mechanical losses, which directly reduce drivetrain efficiency.

The e-Beam, however, adopts a much more direct transmission layout- gearbox output seal → bearing → wheel. With fewer components and no CV joints, the system is far less affected by changes in vehicle load. The shorter, straighter path inherently minimizes parasitic losses.

Backed by real-world test data:

- At curb vehicle weight (CVW, 4000 lb / 1814 kg), the e-Beam reduced energy consumption by 0.36 kWh per 100 miles versus the EDU, improving overall vehicle efficiency by 0.5%-0.9%.

- At gross vehicle weight (GVW, 5000 lb / 2268 kg), the advantage becomes even more pronounced – 0.67 kWh saved per 100 miles, delivering an efficiency gain of 1.0%-1.7%.

A 1.7% efficiency improvement may seem small on paper, but for electric LCVs with 300-400 km of typical range, it translates to an extra 5-7 km of real-world driving range. For urban logistics, last-mile delivery, and frequent stop-and-go usage, this added buffer meaningfully reduces range anxiety.

Even more importantly, this improvement comes without increasing battery capacity or adding system cost. It is a pure engineering optimization – a genuine “free” range extension achieved through a more efficient mechanical architecture.

4. Cost Optimization: 10%-20% BOM Reduction, Up to $500 Savings

Cost is one of the core factors OEMs consider when selecting a technology path, and the e-Beam architecture offers a clear advantage in this area as well. According to the cost comparison data, under equivalent system configurations, the e-Beam can reduce BOM costs by 10-20%, translating into up to $500 in total vehicle cost savings.

The cost advantage comes primarily from two sources:

- Fewer components: The e-Beam integrates more functions into a single housing, eliminating components such as knuckles and certain suspension parts. This directly reduces both parts procurement and assembly-related expenses.

- Higher manufacturing efficiency: Its simplified mechanical layout shortens the assembly process, lowers labor hours, and reduces equipment investment, which further drives down manufacturing cost.

What’s even more compelling is the potential for secondary cost optimization. Thanks to the e-Beam’s lighter weight and higher efficiency, OEMs can reduce battery capacity while maintaining the same driving range. For example, a 1.7% improvement in drivetrain efficiency could allow the removal of 1-2 kWh of battery capacity. Considering that the battery is the single most expensive component in an EV, this secondary reduction amplifies the e-Beam’s overall cost advantage.

5. Additional Advantages: Balancing Performance and Practicality

Beyond the “trinity” of mass reduction, efficiency gains, and cost optimization, the e-Beam architecture also delivers several practical benefits:

- Higher payload and towing capability: Its lightweight construction increases the vehicle’s usable payload, while the rigid-axle suspension design provides greater structural strength – making it well-suited for heavy-load and towing applications.

- Improved cabin space utilization: The simplified underbody layout frees up chassis space, enabling more flexible packaging. This can indirectly increase cabin room and enhance overall driver comfort.

- Enhanced traction performance: By integrating the rigid suspension with the axle, the e-Beam achieves a more direct power delivery path. This improves mechanical grip and traction, especially valuable in challenging road conditions.

Of course, the e-Beam also has its practical boundaries. For example, its track-width adjustability is more limited, and it is not ideal for vehicles requiring extremely low floor heights. However, for D/E-segment LCVs – such as the Mercedes-Benz Sprinter, Ford Transit, and Volkswagen Crafter – the e-Beam’s strengths can be fully leveraged.

Conclusion: Industry Value and Market Outlook of e-Beam Technology

At this pivotal stage of LCV electrification in Europe, the e-Beam electric drive axle offers a precise and pragmatic solution. Rather than chasing optimization in a single dimension, it delivers a balanced, innovation-driven breakthrough across three pillars – lower mass, higher efficiency, and reduced cost – perfectly aligned with the core priorities of commercial-vehicle OEMs.

For OEMs, the value of the e-Beam can be understood on three levels:

- Regulatory compliance: It enables electric LCVs to better meet Europe’s increasingly stringent carbon-emission and energy-efficiency regulations, supporting a smoother transition toward full electrification.

- Product competitiveness: The e-Beam improves payload capability and extends real-world driving range, addressing two of the most critical user pain points in the LCV segment. This translates into stronger market competitiveness and a more compelling product offering.

- Business performance: By lowering manufacturing costs and reducing battery investment, it enhances vehicle profitability and accelerates the economic viability of large-scale electric LCV adoption.

From a market perspective, the e-Beam is strategically positioned for D/E-segment LCVs – a core category that includes mid- to large-size cargo vans, pickups, and other mainstream commercial modes. With an estimated European market size of around 2 million vehicles, the application potential is substantial. As more OEMs expand their electric LCV lineups, the e-Beam is well-placed to become one of the dominant drivetrain architectures in the segment.

Beyond its immediate market impact, the e-Beam also offers a broader lesson for the industry: electrification does not always require a “clean-sheet” reinvention. By re-engineering and integrating proven mechanical structures, manufacturers can still achieve an optimal balance of performance, cost, and manufacturability. This form of practical innovation may open up new pathways for commercial-vehicle electrification – ones that emphasize efficiency, feasibility, and scalability.

Brogen e-Beam Axle Solution for Electric LCVs

At Brogen, we provide modular and flexible e-Beam axle solutions for electric LCVs, including pickup trucks, light vans, SUVs, MPVs, and light logistics vehicles.

- Learn more here: https://brogenevsolution.com/e-beam-axle/

- Business inquiry: contact@BrogenEVSolution.com

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >