Electric Truck Powertrain Solutions: Single-Motor + AMT Configuration

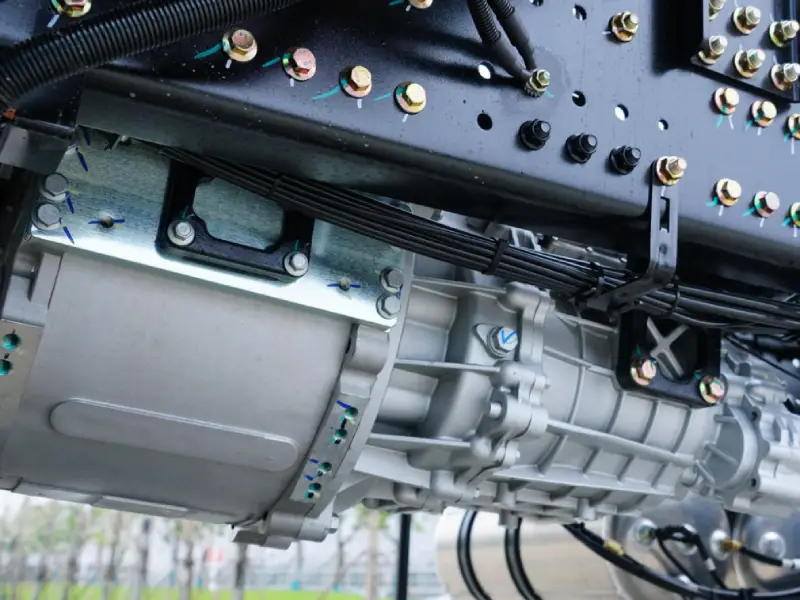

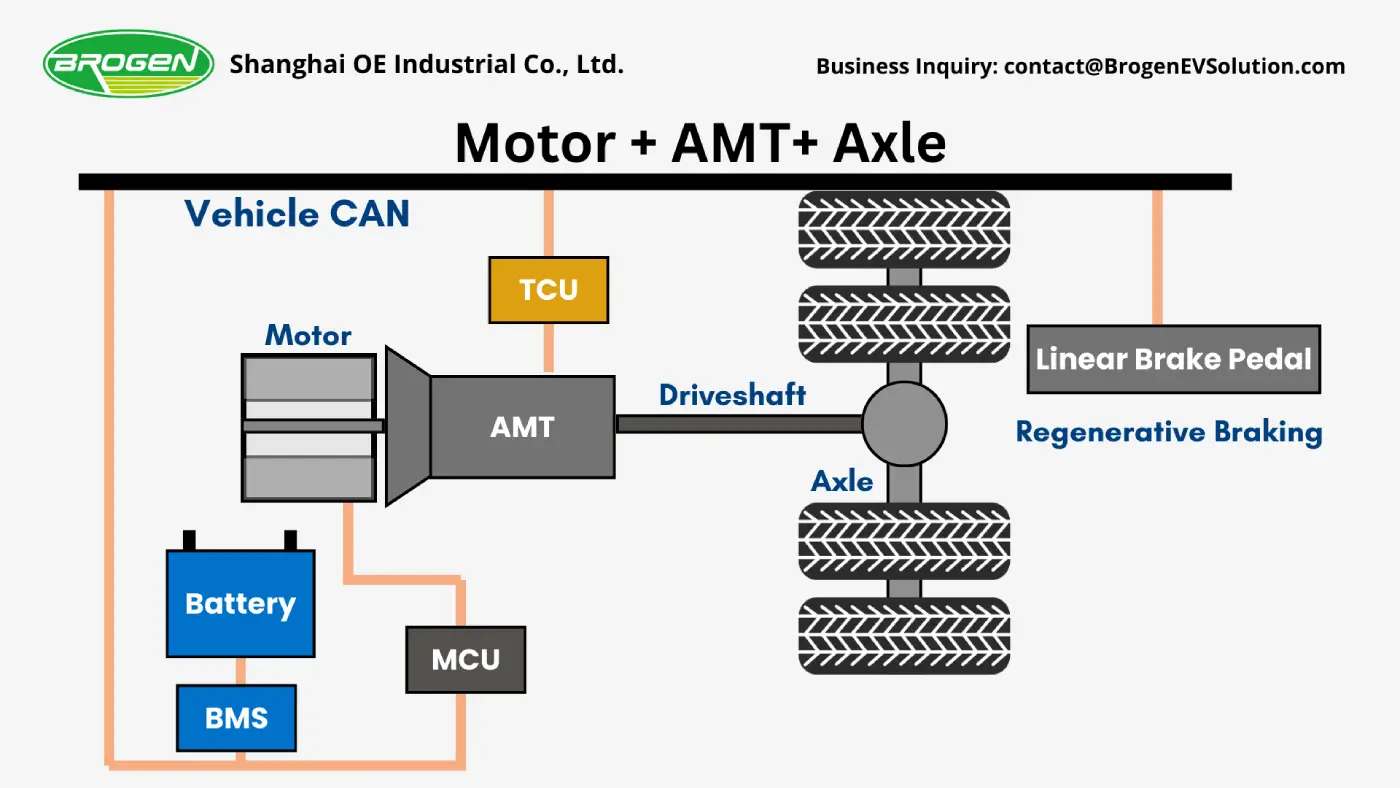

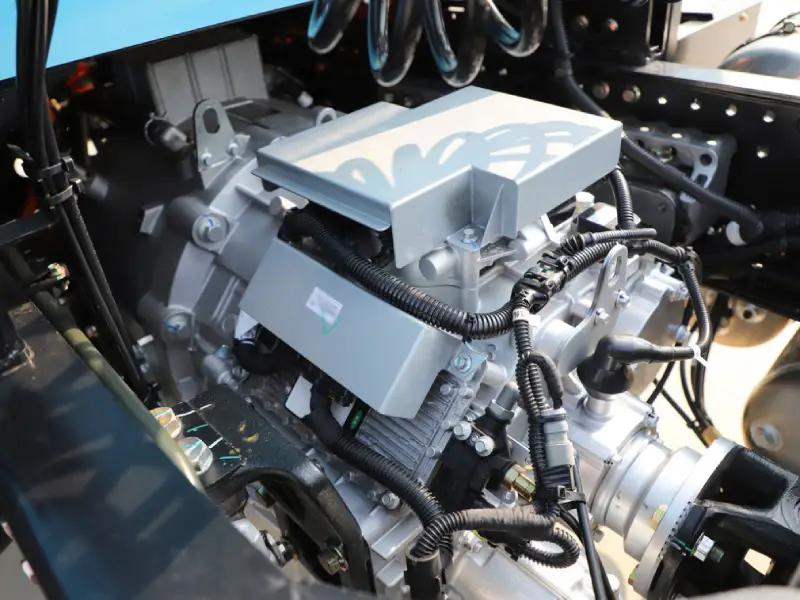

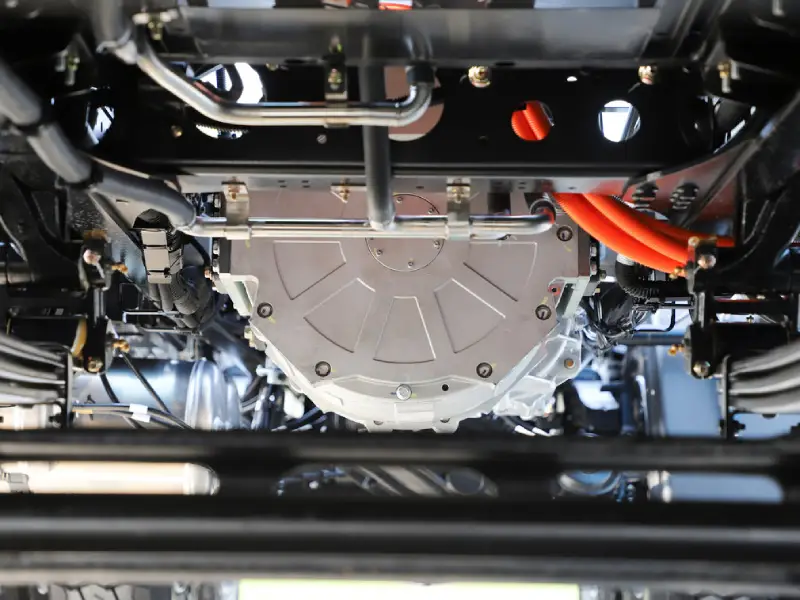

As the global demand for electric heavy trucks continues to grow, manufacturers are exploring efficient and cost-effective solutions for electrification. One of the most widely adopted configurations in the electric truck powertrain is the single motor + AMT (Automated Manual Transmission) solution, which combines a high-power PMSM with a multi-speed AMT while retaining the traditional driveshaft layout.

This article will explore how this solution works, its advantages and challenges, and why it is becoming a mainstream technology for electric truck powertrain in various heavy-duty applications.

1. What is the Single Motor + AMT Solution for Electric Trucks?

The single motor + AMT architecture is designed to provide strong power output and optimized efficiency across a wide speed range. By pairing a high-torque electric motor for trucks with a multi-speed AMT transmission, the system delivers excellent climbing capability, high-speed cruising, and smooth shifting performance.

1.1 Advantages of Single Motor + AMT Electric Truck Powertrain

- Simple Structure and Lower Cost: The single-motor + AMT architecture adopts a straightforward design, minimizing the number of components compared to multi-motor systems. This simplicity not only reduces manufacturing complexity but also lowers the overall system cost, making it an economical choice for OEMs and fleet operators.

- Easy Integration with Existing Chassis Platforms: One of the key benefits of this electric truck powertrain configuration is its compatibility with traditional heavy-duty truck chassis. OEMs can easily adopt this e-powertrain to their current platforms without major structural modifications, significantly reducing development time and cost.

- High Reliability for Demanding Applications: The system is designed for rigorous operating conditions such as long-haul transportation, construction vehicles, and high-load scenarios. With fewer components subject to wear, it provides excellent durability and reliability, ensuring stable performance over extended service life.

1.2 Challenges to Consider

- Mechanical Losses in the Transmission: Although the AMT provides efficient torque transmission across different speed ranges, mechanical losses can slightly reduce overall system efficiency compared to direct-drive configurations.

- Heat Management Under Continuous Climbing: In extended uphill operations, the motor operates under high load for prolonged periods, which can trigger overheating protection. This highlights the need for optimized thermal management and cooling strategies.

Despite these challenges, the single motor + AMT e-powertrain offers strong performance, high durability, and low energy consumption, making it the mainstream solution for electric heavy-duty trucks.

2. Key Application Scenarios for the Single Motor + AMT Electric Truck Powertrain

This electric truck powertrain configuration is widely applied in heavy-duty EV segments such as electric concrete mixer trucks, electric dump trucks, electric semi-trucks, and other specialized vehicles. Here are the major use cases:

2.1 Closed-Loop Transport Operations

- Ports & Terminals: Ideal for container handling and short-haul transfers with fixed routes and frequent stop-and-go conditions. The electric truck motor delivers high low-speed torque combined with regenerative braking for improved loading efficiency.

- Mining Operations: Handles rough terrain and heavy loads with optimized multi-gear power output, preventing power interruptions.

- Steel & Power Plants: Short-haul transfers with strict emission regulations benefit from zero-emission electric truck powertrain solutions.

2.2 Short-Haul Urban Logistics

- Electric Concrete Trucks & Municipal Vehicles: Frequent acceleration and hill climbing require efficient torque distribution, reducing energy consumption.

- Intermodal Coal Transport: Fixed routes, but long endurance requirements, making electric truck motors paired with AMT a practical choice.

2.3 Line-Haul Logistics

While battery-swap heavy-duty trucks currently dominate, the single motor + AMT solution is advancing with higher-density batteries and fast-charging technologies to penetrate this segment.

2.4 Special Operating Conditions

- Mounting Roads & Complex Terrain: Requires continuous high torque and power stability.

- Low-Temperature & High-Altitude Regions: Multi-gear adjustment optimizes motor operating range, ensuring reliable performance in harsh conditions.

2.5 Hybrid Transition Scenarios

For fuel-cost-sensitive markets, the single motor + AMT solution can work in hybrid configurations with internal combustion engines, bridging the gap toward full electrification.

Brogen Single Motor + AMT Solution for Electric Heavy Trucks

At Brogen, we deliver proven electric truck powertrain solutions tailored for heavy-duty commercial vehicles. Our single-motor + 4-speed AMT system has been successfully deployed in more than 20,000 vehicles worldwide, providing strong market validation and trusted performance.

For EV builders, this solution provides:

- Faster Time-to-Market with a validated platform

- Lower Risk through proven mass-production reliability

- Optimized Cost & Energy Efficiency with a scalable powertrain

- Compliance & Sustainability for zero-emission transportation

- Discover this solution here: https://brogenevsolution.com/250-kw-400-kw-electric-motor-for-heavy-duty-truck/

- Discover our other electric truck motors here: https://brogenevsolution.com/electric-motors-for-truck/

About Brogen

At Brogen, we provide advanced EV solutions for global commercial vehicle manufacturers, enabling them to streamline research and development while capitalizing on cutting-edge technology. Our offerings ensure superior efficiency, extended range, and seamless system integration with proven reliability—empowering our partners to lead in the rapidly evolving green mobility landscape.

Currently, our EV solutions for battery electric vehicles have been adopted by vehicle manufacturers in countries and regions such as Canada, Türkiye, Brazil, the Philippines, Indonesia, the Middle East, and more.

- Discover our HCV electrification solution here: https://brogenevsolution.com/heavy-duty-vehicle-electrification-solutions/

- Looking for an EV solution for your project? Reach out to us at contact@brogenevsolution.com

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >