Exploring the Benefits of Coaxial Electric Axle Technology for Light Commercial Vehicles

As the electric vehicle (EV) market expands, the demand for efficient, compact, and high-performance drivetrain systems has increased. Among the various innovations in electric drive systems, the coaxial electric axle has emerged. This article provides an in-depth look at the structural benefits, technical features, and promising applications of coaxial electric axles in light commercial vehicles.

Understanding the Coaxial Electric Axle Design

The coaxial electric axle is distinguished by its innovative design where both the motor shaft and output shaft are aligned along the same axis. This structure combines several components into a single, integrated system, which enhances efficiency and reduces the space required for drivetrain elements. The core components of the coaxial electric axle are as follows:

- Intermediate Powertrain Assembly:

- This includes the motor assembly and reduction gearbox.

- The semi-reduction gearbox housing is integrated with the motor housing, optimizing space and reducing mechanical complexity.

- The external casing is typically made from lightweight aluminum alloy, known for its strength and corrosion resistance.

- Wheel-Side Assembly:

- This consists of the left and right half-shafts, axle housings, and braking components, working together to ensure optimal power delivery to the wheels.

Key Advantages of Coaxial Electric Axle

1. Enhanced Efficiency

- Transmission Efficiency: The coaxial electric axle boasts a high total transmission efficiency of up to 93.17%, making it more efficient compared to conventional multi-in-one drive systems.

- Reduced Mechanical Losses: By eliminating the need for two sets of high-speed bearings, this system enhances mechanical efficiency by around 1%, contributing to better power conversion.

2. Space Optimization

- Compact Design: The coaxial design allows for better use of available space, freeing up room for larger battery packs or other critical components. This results in improved vehicle layout and greater design flexibility.

- Lightweight Construction: The integration of the motor and gearbox reduces overall system weight, which is crucial for improving vehicle range and efficiency.

3. Superior Performance

- High Load-Bearing Capacity: The coaxial electric axle is designed to handle heavy loads, making it suitable for a variety of vehicle types, including commercial and high-performance models.

- Improved NVH Performance: The alignment of the motor and output shafts minimizes vibrations, reducing noise and enhancing overall driving comfort.

- Direct Power Delivery: With its optimized power transmission system, the coaxial electric axle offers more direct and efficient power delivery to the wheels, improving vehicle responsiveness.

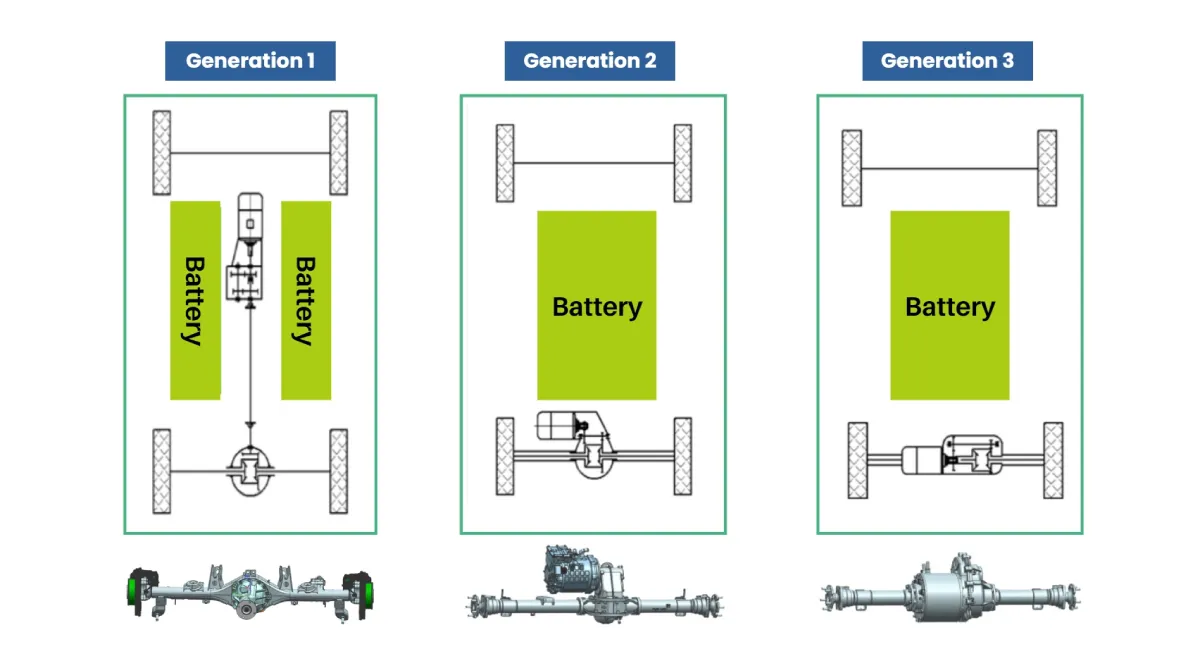

The Evoluion of Electric Powertrain Systems for Light Commercial Vehicles

1st Generation: Central Direct Drive

The 1st-generation electric powertrain system was based on minimal modifications to existing internal combustion engine (ICE) platforms. In this design, the electric motor replaced the engine, with power transmitted to the rear axle through a driveshaft.

- Pros: Low-cost integration and easy compatibility with existing vehicle architectures.

- Cons: The need for a driveshaft and traditional rear axle reduced chassis space and limited battery placement, decreasing overall range.

2nd Generation: Parallel-Axis Electric Drive Axle

The 2nd- generation electric powertrain system introduced a more compact parallel-axis electric axle design, where the motor was integrated directly into the axle, eliminating the driveshaft and creating additional space for battery placement.

- Pros: Simpler structure with fewer parts, improved space for batteries, and better range.

- Cons: The motor’s off-center weight distribution led to vibration issues, and NVH performance became a challenge due to the unique design.

3rd Generation: Coaxial Electric Axle

The 3rd-generation e-powertrain system is the coaxial electric axle. In this system, both the motor and output shaft are aligned along the same axis, allowing for a more compact, stable, and efficient design.

- Pros:

- Improved rotational stability, reducing vibrations and enhancing noise control;

- Weight reduction and space optimization with the motor housing serving as a load-bearing element;

- Increased system efficiency due to the elimination of high-speed bearings and a more direct power transfer;

- Superior NVH performance, with reduced center-of-gravity offset and less vibration.

- Cons: Higher initial costs and increased complexity in maintenance.

Applications of Coaxial Electric Axles

- Micro Electric Vehicles: Compact and energy-efficient for urban environments.

- Light Commercial Vehicles: Ideal for buses, vans, light trucks, and electric pickups due to its efficient power delivery.

- Hybrid SUVs and High-Performance EVs: Offers improved handling and performance in more demanding applications.

Our Coaxial Electric Axle Solution

Our coaxial electric axle for buses integrates the electric motor, drive shaft, and drive axle into a single unit. This highly integrated e-powertrain system effectively maximizes chassis space, reduces weight, and simplifies battery layout, enhancing e-powertrain system transmission efficiency, reducing energy consumption, and increasing driving range for the bus. Learn more here: https://brogenevsolution.com/coaxial-electric-axle-for-bus/

Business inquiry: contact@brogenevsolution.com

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >