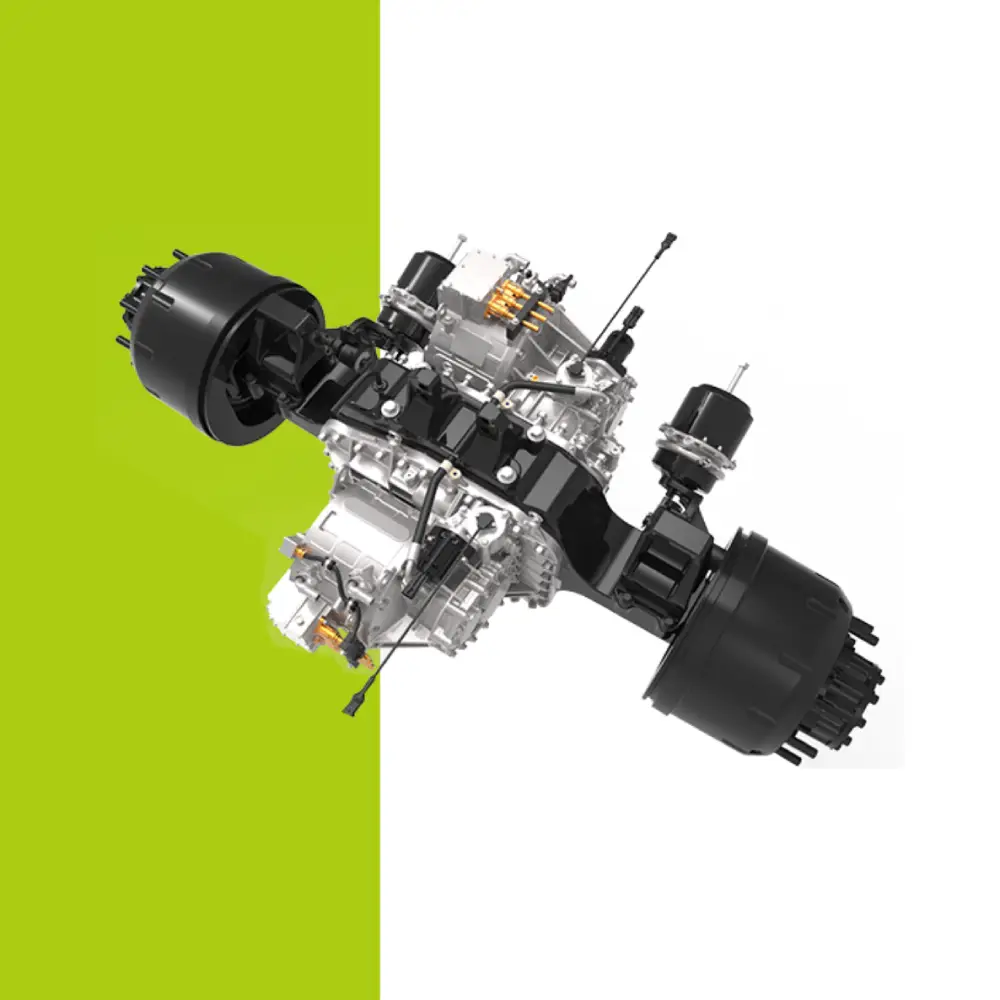

Heavy-Duty Electric Truck Axles (504 kW / 620 kW)

These heavy-duty electric truck axles feature a dual-motor integrated design and are engineered for high-performance applications. With a rated axle load of 13 tons and a maximum system power output of 504 kW or 620 kW, they are capable of meeting the demanding requirements of various heavy-duty commercial vehicles, including 4×2, 6×4, and 8×4 configurations such as municipal vehicles, semi-trucks, and dump trucks. By delivering strong performance and efficiency under heavy-load conditions, these e-axles help significantly reduce both carbon emissions and overall energy consumption.

Email: contact@brogenevsolution.com

Heavy-Duty Electric Truck Axles: Solution Details

1. Solution Features of Our Heavy-Duty Electric Truck Axles

- Dual Motor + 4-speed AMT Configuration: Adaptable to multiple use cases, from high-capacity long-haul electric semi-trucks to high-torque construction trucks operating under frequent load shifts.

- Modular Design for Easier Maintenance: High integration of motors and gearbox enables a compact layout and simplifies service and maintenance processes.

- Transverse Layout Without Hypoid Gear Set: Eliminates the hypoid gear set to reduce mechanical losses, enhancing transmission and regenerative braking efficiency.

- One-piece Axle Housing with Aluminum Alloy Casing: Integrated cast axle housing offers higher structural strength and sealing performance; aluminum casing helps reduce overall system weight.

2. Technical Parameters

| Model | OESTEA45000Z-1 | OESTEA45000Z-2 | |

| E-Powertrain | Rated Axle Load | 13 T (16 T Under Development) | |

| Wheel-End Output Torque | 45000 N.m | 45000 N.m | |

| Assembly Weight | 985 kg | 990 kg | |

| Reference Leaf Spring Distance | 1018-1050 mm (Adjustable) | ||

| Wheel Mounting Distance | 1837 mm | ||

| Compatible Suspension | Leaf Spring / Air Suspension | ||

| Motor Parameters | Motor Rated/Peak Power | 150/252 kW*2 | 190/310 kW*2 |

| Motor Rated/Peak Torque | 285/550 N.m | 280/590 N.m | |

| Motor Maximum Speed | 9000 rpm | ||

| Transmission Parameters | Speed Ratio | 4-speed 1st: main transmission 71.0+auxiliary transmission 46.8 2nd: main transmission 36.3+auxiliary transmission 46.8 3rd: main transmission 20.0+auxiliary transmission 13.2 4th: main transmission 10.2+auxiliary transmission 13.2 | |

| Brake | Brake Specifications | Drum brake φ410*220; disc brake 22.5″ | |

| Brake Torque | 2*18000 N.m (drum brake); 2*22000 N.m (disc brake) | ||

| Air Brake Chamber Specifications | 30/24 (recommended) | ||

| Other Options | Differential Lock | Optional | |

| PTO | Optional PTO for retrofit | ||

3. Advanced AMT Technology - Built for Smarter, Smoother Electric Trucks

This electric truck axle platform features a 4-speed AMT. It enables active speed synchronization between the motor and the transmission input shaft, allowing for rapid and smooth gear shifts. By combining gear profile modification with in-depth analysis of casing and shaft tooth deformation, the system achieves optimal meshing conditions, minimizing transmission error and reducing efficiency loss.

- Faster gear shifting: Reduced shift time improves drivability, especially under frequent stop-and-go scenarios.

- Higher drivetrain efficiency: Enhances energy use and supports longer driving range.

- Lower NVH: Quiet and smooth gear transitions improve driving comfort.

- Lower maintenance cost: Long-life gear oil with no initial oil chaange required; supports extended intervals of 50,000-200,000 km.

4. Key Performance Data

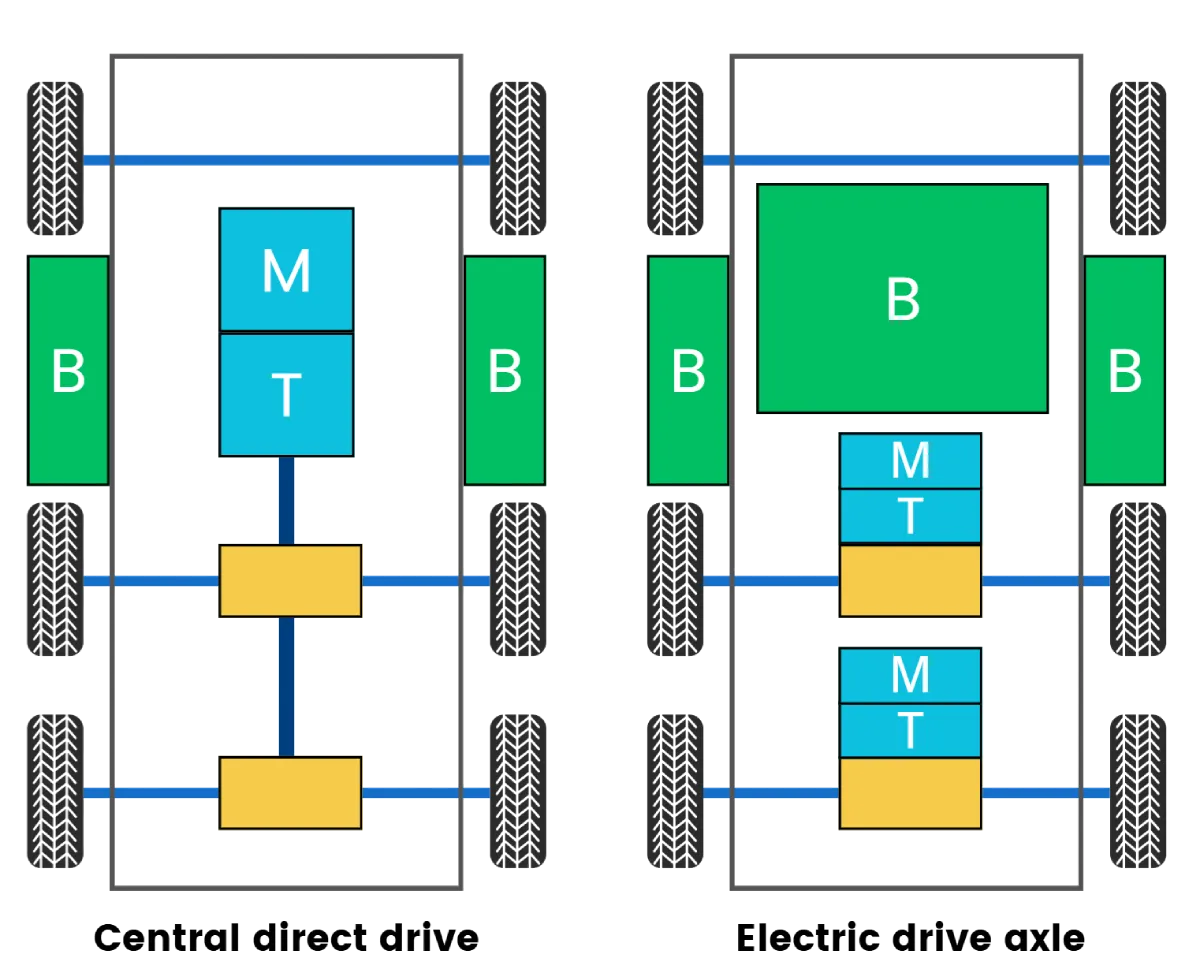

- Weight reduction vs. direct drive (dual axle): 22% per set

- Range improvement vs. direct drive: Up to 20%

- Energy use: 10% less per 100 km at 49t full load vs. industry average

- Axial space saving: 40%

- Deployed units (to date): ~13,000

- Projected annual production capacity (2025): Over 10,000 units

How We Ensure the Reliability of Our Electric Truck Axles

Our electric truck axles undergo a rigorous multi-level validation process to guarantee long-term performance, safety, and durability under real-world operating conditions.

Component-Level Testing

Over 50 tests are conducted on individual components to verify structural integrity, strength, and consistency. These include:

- Vibration

- Salt spray

- Tensile

- Torsion

- Hardness

- Full-dimension inspections

Subsystem-Level Testing

More than 90 tests are performed across all core subsystems – including the shifting mechanism, gearbox, motor, high/low voltage controllers, wiring harnesses, and software. These tests fall into six major categories:

- Module validation

- Functional testing

- Performance testing

- Durability testing

- Reliability testing

- Environmental resistance

System-Level Testing

Over 50 tests are carried out at the system level using specialized test benches and real-vehicle road trials, including:

- High and low temperature cycling

- Thermal shock testing

- Salt spray and corrosion resistance

- Waterproof and dustproof validation

- Vibration and noise testing

- System integration and special-condition simulation

R&D and Manufacturing Excellence

Comprehensive and Integrated R&D Capabilities

The R&D team is built on a robust, cross-functional framework encompassing structural engineering, electronic hardware, system architecture, software development, testing, and manufacturing processes. We maintain a full-spectrum development capability that spans from concept design to real-world validation. With in-house expertise in mechanical design, control unit development, computer-aided simulation, bench testing, and complete vehicle road testing, we are equipped to support rapid iteration and innovation across the entire product lifecycle.

- Hybrid and pure electric powertrains

- Transmission systems and controllers

- Electric motors and motor controllers

- Shift and clutch actuators

- Vehicle control units (VCUs)

Quality Management & Full Lifecycle Traceability

The factory strictly adheres to IATF 16949, ISO 14001, and other international standards, ensuring precise control over every production process and uncompromising quality in every product. The digital management system enables a full lifecycle traceability and control, ensuring that every component is trackable and accountable from production to delivery. In 2025, the e-axle for trucks production capacity is expected to exceed 10,000 units, further demonstrating our ability to scale with quality and consistency.

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >