High Voltage Wire Harnesses in Electric Vehicles: Key Design Principles

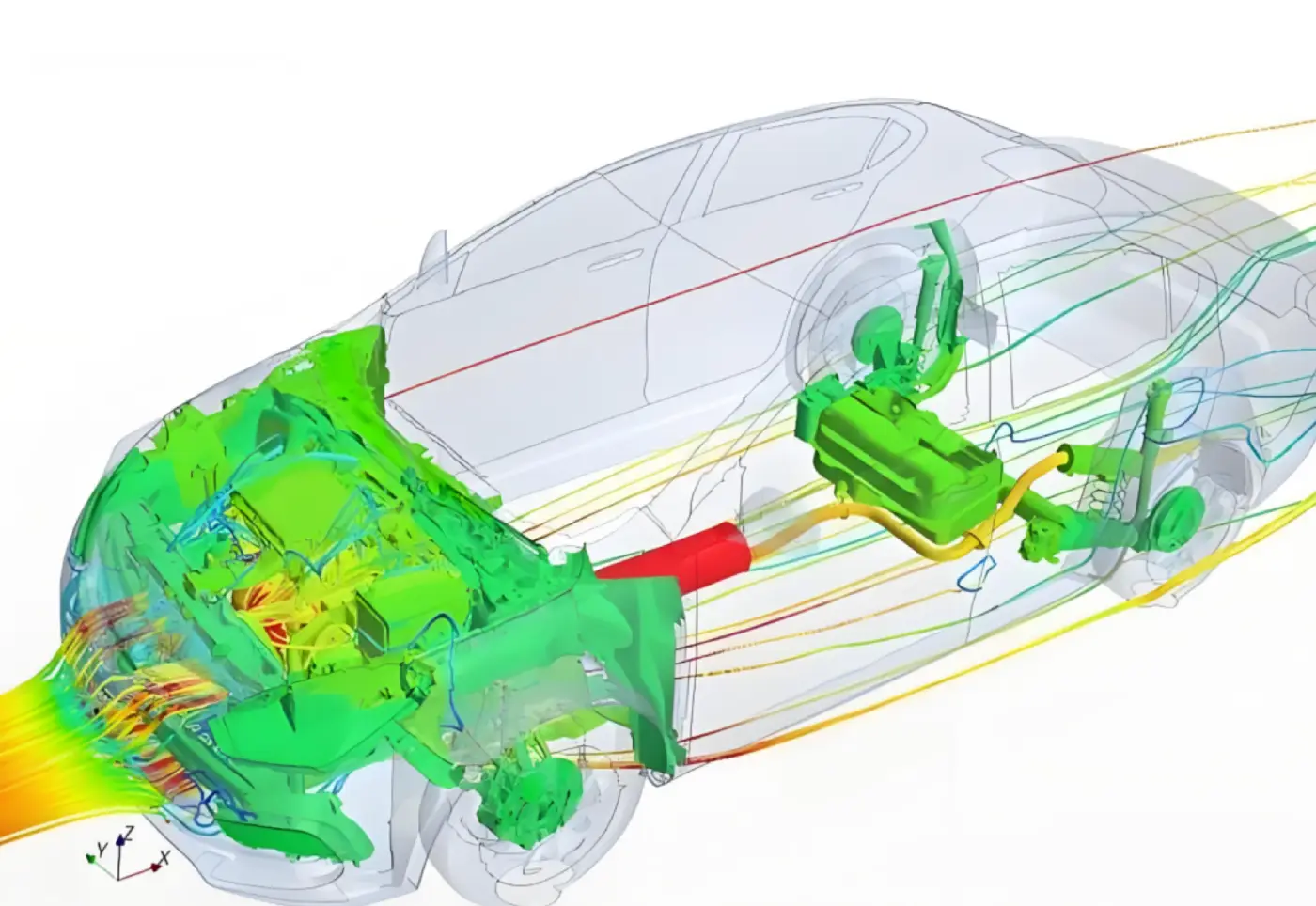

High voltage wire harnesses play a critical role in electric vehicles, transmitting high voltage and large currents between essential components like the battery pack, high-voltage PDU, inverter, and traction motor. These harnesses ensure efficient energy transfer, enabling EV systems to operate in perfect synchronization. Proper installation and secure mounting of high voltage wire harnesses is essential for safety, reliability, and performance..

1. Routing Principles for High Voltage Wire Harnesses

Before discussing installation and fixation, it’s crucial to understand routing principles.

1.1 Proximity Principle

The routing should follow the shortest feasible path to minimize voltage drop and weight, which supports efficiency and cost reduction.

1.2 Ease of Assembly

The overall design and fixation method of the EV wiring harness should prioritize ease of assembly to ensure simple and efficient installation.

- Connector Mounting and Fixation: Allow adequate length and installation space for connectors to facilitate smooth operations.

- Harness and Component Fixation: Ensure sufficient clearance for fastening tools, maintaining at least a 50 mm gap from the center of the nut for safe operation.

- Harness Clip Fixation: Position harness clips strategically to minimize quantity while ensuring secure attachment.

1.3 Maintainability

The principle of good maintainability in automotive wiring harness design means ensuring ease of maintenance and repair throughout the vehicle’s lifecycle. The layout should allow faults to be diagnosed and repaired in the shortest possible time while minimizing the impact on other components.

- Connector Placement and Fixation: Connectors should be positioned within easy reach. For connectors that require single-hand operation, the opposite end should be securely fixed.

- Avoiding Misconnection and Providing Extra Length: Connectors on the same component should be arranged to prevent incorrect mating. The end of the wiring harness should have a reserved length. For example, high-voltage wires near the connector tail must not be bent or stressed, must not be twisted, and should be secured within 120 mm.

- Fuse Box Harness Allowance: The wiring harness for the fuse box should have sufficient slack to provide adequate operating space during maintenance.

1.4 Safety and Reliability

Ensuring the safe and stable operation of the electrical system – and by extension, the proper functioning of all vehicle electrical equipment – is the ultimate goal of wiring harness design.

- Harness Fixation Location: Whenever possible, secure wiring along edges, channels, or areas that are less likely to be touched to prevent external forces from damaging the harness.

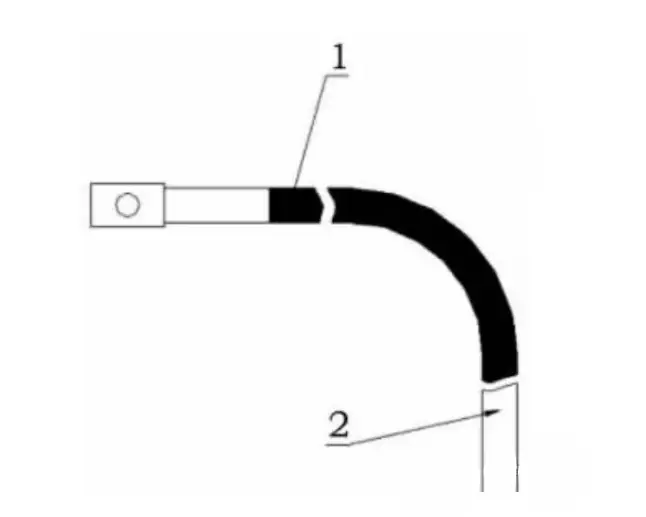

- Avoid Sharp Bends: When bends are unavoidable, allow adequate space and apply special fixation at the bend points. Ensure no kinks or excessive stress occur.

- Prevent Cable Damage: Harnesses passing through holes must be protected with sleeves, grommets, or protective tape to avoid abrasion. In the event of a collision, the harness should not be crushed, as this could lead to rupture and short circuits.

- Maintain Design Allowance: For main branches, ensure a sufficient bending radius to avoid tight routing that complicates assembly. Do not pull harnesses too tightly during installation, as vibrations during driving could shift fixation points.

- Avoid High-Vibration Zones: High-voltage harnesses should be routed away from major vibration sources such as air compressors or water pumps. If unavoidable, allow adequate slack based on vibration amplitude and the maximum motion envelope of moving parts to prevent tension on the harness.

- Avoid High-Temperature Zones: Keep harnesses away from high-temperature components such as compressors, brake lines, steering pumps, or oil pipes to prevent insulation melting or accelerated aging, which could lead to exposed conductors and short circuits.

- Maintain Bend Radius for High-Voltage Cables: Over-bending high voltage wire harnesses increases resistance, causing higher voltage drop and accelerating insulation aging or cracking. The minimum bend radius should be at least 4x the cable’s outer diameter. High-voltage cables exiting connectors must remain straight, without bending, twisting, or stress.

- Sealing and Waterproofing: To enhance mechanical protection and ensure dust and water resistance, use seals or gaskets at connector interfaces and cable entry points. This prevents moisture and debris ingress, ensuring insulation integrity and avoiding short circuits, arcing, or leakage.

1.5 Aesthetic and Organized Routing

- Hidden or Aligned: Harness routing should prioritize a neat and aesthetic layout, either by concealing the harness or arranging it in a horizontal and vertical orientation. The routing should follow the direction of the adjacent components and, in the projected view, maintain a straight, grid-like arrangement wherever possible. Diagonal paths and crossing layouts should be avoided. The harness should align with surrounding harnesses, water pipes, air pipes, and oil pipes to maintain visual uniformity and an overall clean appearance.

2. Installation and Fixation Design for High Voltage Wire Harnesses

2.1 Planning of Harness Fixation Points

The distribution of fixation points is the foundation for securing high-voltage harnesses and directly impacts their stability. Generally, the placement of these points should be determined based on factors such as harness length, routing, and bending positions. For longer harnesses, additional fixation points are necessary to prevent displacement caused by vibrations during vehicle operation.

At bends, fixation points should be placed at both the start and end of the curve to avoid excessive stress on the harness in these areas.

The spacing requirements for fixation points vary according to the cross-sectional area of the harness. Typically:

- For smaller harnesses (≤16 mm²), the spacing can be slightly larger but should not exceed 300 mm.

- For larger harnesses (>16 mm²), due to greater weight and mechanical stress, the spacing should be kept within 200 mm.

Additionally:

- The distance from the high-voltage connector outlet to the first fixation point should be ≤100 mm.

- The clearance between the high-voltage harness and heat sources should be >200 mm.

Through proper planning of fixation points, issues such as shaking or displacement during vehicle operation can be effectively avoided, ensuring stable and reliable power transmission.

2.2 Selection of Fixation Methods

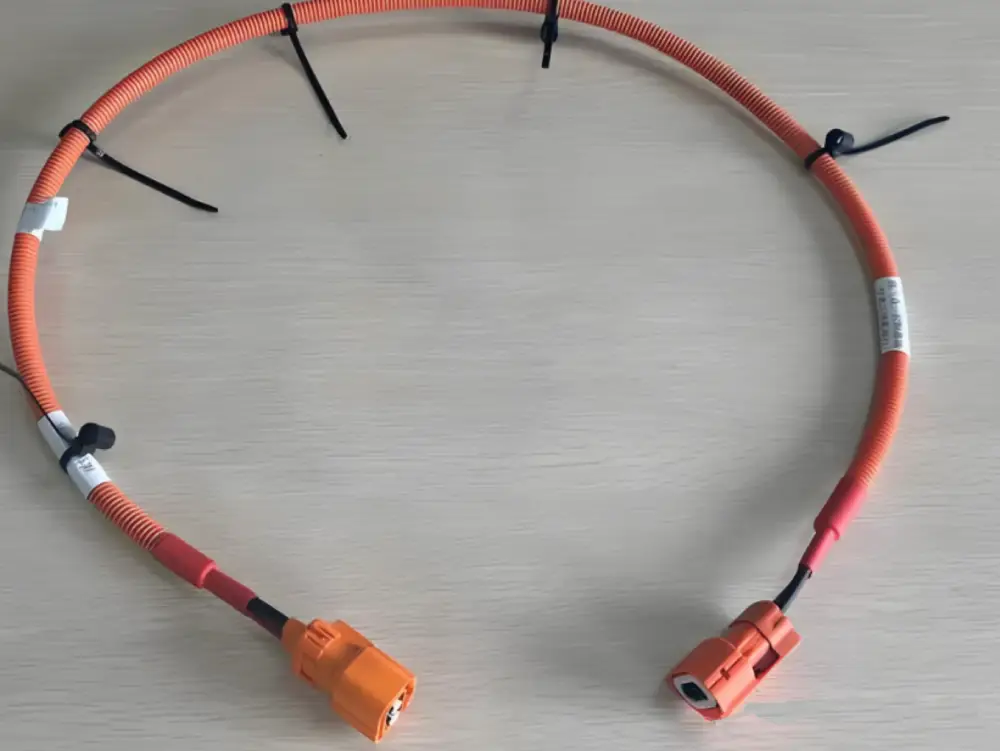

In the installation of high-voltage harnesses for electric vehicles, common fixation methods include cable ties, clips, and brackets. Each option has its advantages and limitations, making them suitable for different applications.

- Cable Ties: These are a cost-effective and easy-to-install solution, commonly used in areas where the harness layout is neat and subject to minimal mechanical stress. However, their strength is limited, and they may fail under prolonged vibration or high-load conditions.

- Clips: Clips are suitable for securing harnesses of various diameters by attaching them to the vehicle structure using plastic or metal clamps. They offer better stability and reliability than cable ties and can be adjusted to accommodate different harness sizes. The downside is that installation is relatively more complex and requires proper tools and skills.

- Brackets: Brackets are typically used for large or heavy harnesses, providing robust mechanical support. Usually made of metal, brackets are fixed to the vehicle body using bolts or welding, effectively withstanding both the weight of the harness and vibration loads. However, they are more expensive and require additional space for installation.

In practice, the choice of fixation method should be based on the harness characteristics and the vehicle’s structural layout. For example, in high-vibration areas such as the engine compartment, clips or brackets are recommended for better durability. In more stable areas, such as teh cabin, cable ties offer an economical and practical solution.

2.3 Clearance and Spacing from Surrounding Components

Maintaining proper clearance between high-voltage wire harnesses and surrounding components is critical for safe and reliable vehicle operation. During operation, high-voltage harnesses generate electric and magnetic fields, and if they are routed too close to other components, they may cause electromagnetic interference (EMI), affecting the normal function of those components.

Additionally, high-voltage harnesses generate heat while transmitting power. If positioned too close to heat sources, the temperature of the harness can rise, potentially degrading performance and shortening its lifespan.

To ensure safety and reliability:

- Maintain a minimum 10 mm clearance from stationary components.

- Maintain a minimum 25 mm clearance from moving components.

If these spacing requirements cannot be fully met, effective protective measures should be implemented. These may include adding shielding layers or using isolation sleeves to mitigate EMI and heat transfer. For example, when a high-voltage harness runs near electronic components such as the motor controller, a metal shielding sleeve can be used to wrap the harness and prevent interference with sensitive electronics.

2.4 Considerations for Bend Radius

The bend radius of high-voltage wire harnesses is a critical factor affecting performance and safety. Excessive bending can damage the internal conductor structure, increase resistance, reduce power transmission efficiency, and potentially create safety hazards.

Different harness cross-sections require specific minimum bend radii.

Wire Type / Minimum Bend Radius

- Shielded wires: Greater than 5× the outer diameter of the wire

- Unshielded wires (cross-section ≥ 5 mm²): Greater than 5× the outer diameter of the wire

- Unshielded wires (cross-section < 5 mm²): Greater than 3× the outer diameter of the wire

Note: The diameter refers to the outer insulation layer. Some manufacturers’ large-gauge high-voltage wires may allow smaller bend radii than standard guidelines; in such cases, the exact radius and testing requirements should be confirmed with the supplier.

During installation, it is essential to follow these bend radius requirements carefully. Avoid sharp bends or acute angles and maintain natural, smooth curves. When connectors or joints are installed along the harness, ensure the bend radius near these points meets the required specifications to prevent poor contact or damage.

Conclusion

Understanding and applying these high-voltage harness installation and fixation principles—proper fixation point planning, appropriate fixation methods, strict clearance control, and compliant bend radius—is crucial for ensuring safe, stable, and reliable operation of electric vehicles.

About Brogen

At Brogen, we provide advanced EV solutions for global commercial vehicle manufacturers, enabling them to streamline research and development while capitalizing on cutting-edge technology. Our offerings ensure superior efficiency, extended range, and seamless system integration with proven reliability—empowering our partners to lead in the rapidly evolving green mobility landscape.

Currently, our EV solutions for battery electric vehicles have been adopted by vehicle manufacturers in countries and regions such as Canada, Türkiye, Brazil, the Philippines, Indonesia, the Middle East, and more.

- Discover our HCV electrification solution here: https://brogenevsolution.com/heavy-duty-vehicle-electrification-solutions/

- Looking for an EV solution for your project? Reach out to us at contact@brogenevsolution.com

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >