How Electric Truck Axles Enhance Semi-Truck Performance: A Technical Look at the J6L BEV

Developing battery-electric semi-trucks involves managing energy efficiency, thermal performance, system mass, and packaging constraints while keeping operating requirements in mind. At the 2025 China Commercial Vehicles Show (CCVS), FAW Jiefang presented a 400 kWh J6L 6×4 battery-electric semi-truck that uses dual electric truck axles. Its drivetrain configuration provides an example of how e-axle-based layouts can influence the performance and operation of a BEV semi-truck intended for demanding duty cycles.

1. Energy Consumption Characteristics

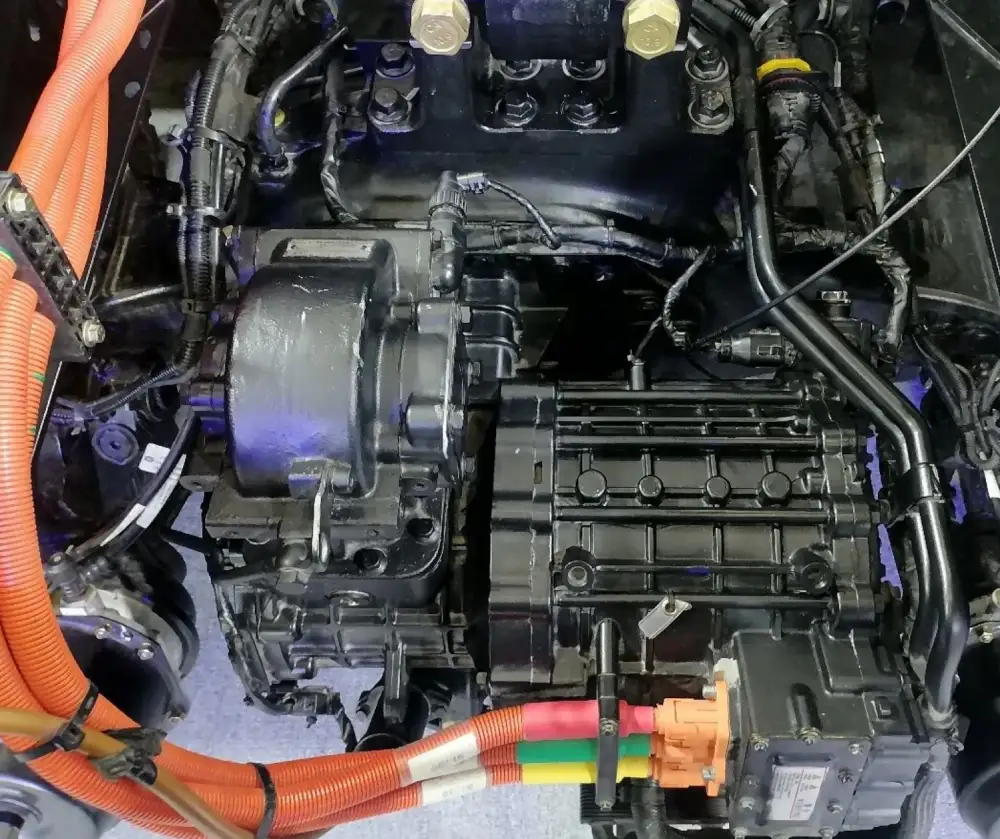

The J6L is equipped with two 240 kW two-speed electric drive axles, replacing the more common centralized motor and prop-shaft system.

1.1 Mechanical Layout Effects

Switching to electric truck axles removes the prop-shaft and several intermediate driveline components, reducing system mass by roughly 140 kg. A shorter transmission path also decreases mechanical losses, improving efficiency by about 5% during steady-state operation.

1.2 Operating Modes

Each electric truck axle is equipped with a 2-speed transmission, allowing the vehicle to operate in five useful combinations:

- Both e-axles in low gear – for high-load launch, grades, or rapid acceleration.

- One low / one high – for low-speed, full-load stop-and-go conditions.

- Both in high gear – for loaded high-speed cruising (up to 89 km/h).

- One low / one neutral – single-axle drive at low speeds when empty to reduce energy use.

- One high / one neutral – single-axle drive at higher speeds when empty.

This gear-state flexibility helps match torque and speed to varying load conditions, improving overall efficiency compared with a fixed-path contralized drivetrain.

1.3 Motor Cooling & Efficiency

Both electric truck axles utilize oil-cooled flat-wire motors, which simultaneously support rotor and stator cooling. This reduces torque derating on long climbs and offers a modest efficiency improvement – around 2% – compared with water-cooled designs.

1.4 Estimated Energy Use

Typical 49-ton BEV trucks transporting sand and gravel operate at:

- ~1.6 kWh/km loaded

- ~0.8 kWh/km empty

With its dual-axle configuration and reduced mechanical losses, the J6L’s estimated energy use is:

- ~1.4 kWh/km loaded

- ~0.7 kWh/km empty

2. Packaging and Cost Considerations

Current BEV heavy-truck layouts generally fall into three categories:

- Rear-mounted battery + centralized drive

- Under-frame transverse batteries + e-axle

- Side-mounted batteries + centralized drive

The J6L uses rear-mounted batteries combined with dual electric truck axles, a layout that simplifies packaging on the existing J6L platform.

Battery System Configuration

Under-frame solutions frequently use three 171 kWh battery packs (513 kWh). While this increases range, it also raises cost. The J6L’s 400 kWh arrangement provides a balance for sand-and-gravel transport, where:

- A 342 kWh dual-pack layout is typically insufficient for the daily operating range

- A full 513 kWh system increases the cost significantly

The chosen configuration reduces battery system cost while still meeting expected range requirements.

Conclusion

The J6L BEV reflects how electric drive axles can influence key aspects of BEV semi-truck development:

- reduced mechanical losses and lower mass,

- improved torque and speed matching under various load conditions,

- better energy consumption in mixed duty cycles,

- and straightforward integration on an existing platform.

For OEMs evaluating next-generation BEV platforms, this example illustrates how e-axle configurations can support efficiency and packaging goals in heavy-duty commercial applications.

Brogen EV Solutions for Electric Semi-Truck

- For electric semi-trucks, we offer proven electric truck axles that have entered SOP and are now deployed at scale in BEV heavy-duty trucks. Learn more here: https://brogenevsolution.com/electric-axle-for-truck/

- We also provide custom EV battery systems for heavy-duty trucks, including LFP battery packs, BMS, PDU, BTMS, and other key subsystems. Learn more here: https://brogenevsolution.com/electric-truck-battery-solution/

- Business inquiry: contact@BrogenEVSolution.com

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >