Lessons from a Real-World Overseas Electric Bus E-Axle Application

In commercial vehicle electrification, performance gaps often emerge not from hardware capability, but from mismatches between assumed and actual operating duty cycles.

During an overseas customer deployment of an electric bus with an e-axle, the system was exposed to operating conditions that significantly exceeded the original calibration assumptions. These differences introduced system-level behaviors that could not be identified through specification review alone.

This experience reinforces the importance of duty cycle definition as a foundational engineering input—particularly for overseas projects with unfamiliar road and operating environments.

Project Background and Initial Design Assumptions

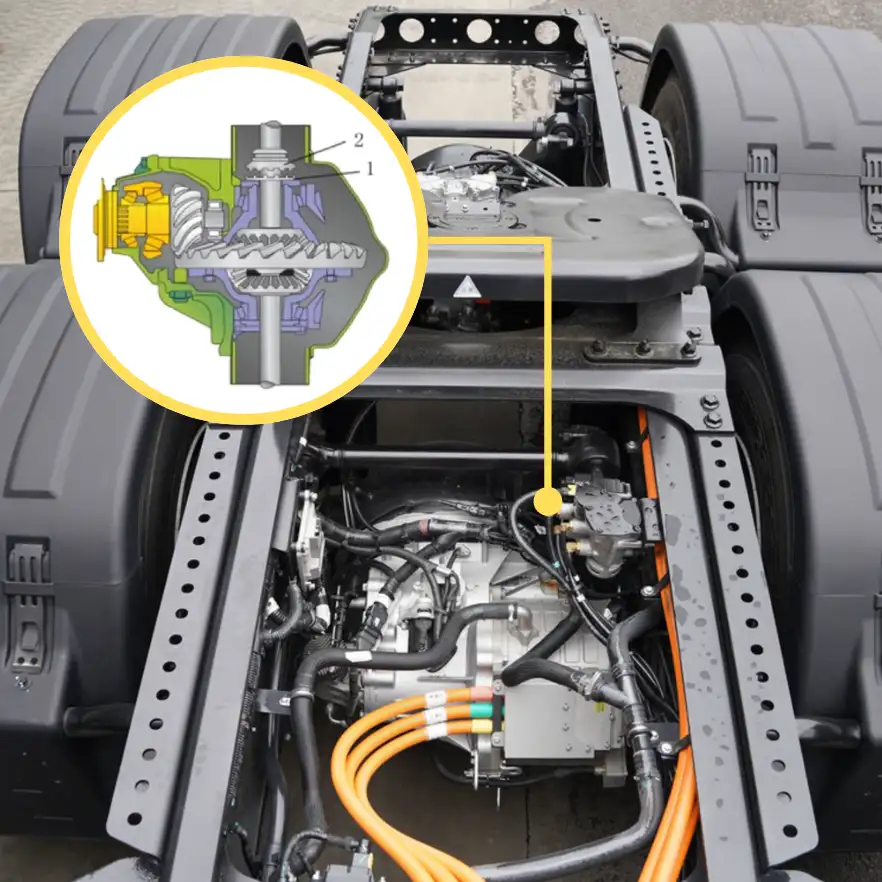

The project involved an electric bus equipped with an electric axle platform originally developed for heavy-duty vehicle applications. From a hardware perspective, the axle was fully capable of supporting the application, having been designed to withstand the higher axle loads and sustained torque levels typically associated with heavy-duty trucks.

The decision to apply this e-axle platform to a bus application was not based on vehicle mass considerations. Instead, it was driven by a common engineering assumption: that typical city bus duty cycles are less dynamically demanding than heavy-duty truck applications.

In conventional system assessments, bus operation is often associated with smoother torque profiles, more predictable load transitions, and less aggressive drivetrain dynamics than long-haul or vocational heavy-duty trucks.

Based on this understanding, the control software and calibration strategy were originally optimized for operating environments characterized by:

- Relatively smooth road surfaces

- Stable longitudinal load profiles

- Low shift frequency

- Highway-oriented or intercity duty cycles

Under these assumptions, the electric axle demonstrated stable shifting behavior and predictable system response during development and validation.

Unexpected Behavior in Real-World Operation

After deployment, the vehicle exhibited operational issues that were not predicted during the development phase.

The vehicle was operating under conditions that differed substantially from the original engineering assumptions:

- Poor and uneven road surfaces

- Frequent stop-and-go operation

- High shift frequency

- Rapid and repeated load transitions

At first glance, this behavior appeared counterintuitive. City bus applications are commonly perceived as operating under more benign duty cycles than heavy-duty trucks, particularly in terms of drivetrain dynamics and transient loading.

Based on this assumption, the observed system behavior could not be readily explained during early analysis.

Root Cause: Duty Cycle Severity Is Not Defined by Vehicle Category

Clarity emerged only after the engineering team conducted on-site testing and collected real road spectrum data.

The data revealed a critical insight: Although the vehicle operated under lower average loads, the actual duty cycle was significantly more aggressive from a dynamic perspective.

High-frequency shifting, continuous torque reversals, and persistent suspension excitation imposed substantially higher demands on:

- Shift control logic

- Motor torque response

- System pressure stability

This case reinforced a fundamental system-level principle:

Duty cycle severity is defined by dynamic behavior, not by application category or static load assumptions.

In regions with poor road infrastructure, urban bus operation can introduce harsher transient conditions and control challenges than many highway-based heavy-duty truck applications.

Software Calibration and Control Logic Optimization

Once the real operating conditions were clearly quantified, the corrective path became well-defined.

Based on measured road spectrum data and operational feedback, multiple iterations of control software tuning and logic optimization were conducted. Following these software updates, the previously observed operational issues were effectively resolved.

This outcome confirmed that the hardware platform itself was not the limiting factor. The root cause lay in the mismatch between assumed and actual duty cycle characteristics during early system definition.

System-Level Finding: Pressure Boundary Misalignment

Beyond control calibration, on-site analysis also revealed a broader system-level issue.

The vehicle was not equipped with a pressure-limiting valve. In typical domestic applications, system pressure is controlled below 8 bar. In this overseas deployment, however, operating pressure was measured at 11–13 bar.

This elevated pressure level increased mechanical and thermal stress across the system, further amplifying the observed issues. Importantly, this condition had not been explicitly discussed during early integration stages, highlighting how regional practices and local configurations can silently exceed original design boundaries.

Engineering Takeaways for OEMs and EV Integrators

This project offers several transferable lessons for overseas electrification programs:

Duty cycle definition must extend beyond load assumptions

Dynamic factors such as road quality, shift frequency, and transient behavior are equally critical.Control software is not universally transferable

Calibration strategies must be explicitly aligned with the intended operating environment.System boundaries must be clarified early

Parameters such as pressure limits, thermal margins, and auxiliary components can materially affect system performance.On-site data remains indispensable

Simulation and bench validation cannot fully substitute real-world road spectrum measurements.

Conclusion

Electrifying commercial vehicles is not merely a matter of selecting capable hardware. It is a system integration challenge that demands early and precise understanding of how a vehicle will actually operate—particularly in overseas markets where infrastructure quality, usage patterns, and local practices may differ substantially from initial assumptions.

For OEMs and EV integrators, duty cycle definition is not a procedural step.

It is a foundational engineering decision that ultimately determines whether an electric drivetrain performs reliably throughout its service life.

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >