Oil-Free Air Brake Compressor for Commercial EVs: The Next Step in Clean Mobility

With the rapid growth of electric vehicles worldwide, the electrification of commercial vehicles has entered a stage of fast expansion. Among their key subsystems, the electric air brake compressor plays a critical role in the pneumatic braking system, air suspension, and other auxiliary air systems. It’s a core component that directly impacts vehicle safety, reliability, and efficiency – and is now entering a rapid phase of technological evolution.

This article explores the current market landscape and development trends of EV air brake compressors, particularly for commercial vehicles.

1. What is An Electric Air Brake Compressor in Commercial Vehicles

In traditional commercial vehicles, the air compressor is typically driven by the engine. However, in electric vehicles, which no longer rely on internal combustion, an electric air compressor replaces this function. It provides compressed air for the vehicle’s brake system, air suspension, and auxiliary actuators, making it an essential element of EV safety and performance. With strong government policies promoting EVs globally, the market demand for electric air brake compressors has grown significantly.

2. Current Status of Electric Air Brake Compressor Technology

The shift toward electrification in commercial vehicles has given rise to multiple types of electric air brake compressors, such as screw, vane, and scroll compressors. However, over nearly a decade of market validation, these designs have shown limitations such as oil-gas emulsification, low discharge pressure, and poor reliability – leading to their gradual replacement.

Today, piston-type air compressors have become the mainstream solution for electric commercial vehicles, offering better efficiency, reliability, and adaptability to high-pressure systems.

| Item | Oil-lubricated piston type | Screw type | Vane type | Scroll type |

| Lubricating oil type | Traditional diesel engine oil | Special screw compressor oil | Special vane compressor oil | – |

| Driving safety | Safe | If maintenance is not timely, it will contaminate the air system, causing rubber parts to expand and age, easily leading to brake system failure | – | |

| Lubricant consumption | Small | Large | Large | – |

| Lubricant emulsification and deterioration | None | Easy | Easy | – |

| Environmental adaptability (air contact) | Less contact with external air | Easily affected by external air contamination | – | |

| Oil-gas separator | Not required | Required | Required | – |

| Oil separator filter element lifespan | – | Short | Short | – |

| Lubricant temperature control | Not required | Required | Required | – |

| Impact of ambient humidity | Small | Large | Large | – |

| Discharge pressure | Can withstand short-term overload | General | General | Low |

| Special maintenance experience requirements | None | High | High | Very high |

| Environmental adaptability | Good | Poor | Poor | Poor |

| Service life | Good | Poor | Poor | Poor |

3. The Rise of Oil-Free Piston Electric Air Brake Compressor

Most piston-type electric air compressors in use today are still oil-lubricated, which requires regular oil changes and maintenance. Problems such as oil leakage or contamination can lead to secondary pollution and increased maintenance costs.

In constrast, oil-free air brake compressors eliminate the need for lubrication oil, reduce system complexity, and ensure clean, oil-free compressed air – protecting pneumatic components and improving environmental sustainability.

Based on years of market application and customer feedback, the trend is clear: oil-free piston compressors are becoming the future direction of EV air brake compressor technology.

4. Oil-Free Air Brake Compressor Technology Overview

Among current oil-free air compressor designs, scroll compressors have seen early adoption in electric vehicles. They offer compact structure, smooth operation, and high efficiency. However, due to their tight sealing gaps, scroll compressors require extremely clean intake air, making them vulnerable to dust and humidity, especially since compressors in commercial EVs are often mounted on the chassis.

Additionally, scroll compressors tend to have high discharge temperatures and struggle to meet the >1 MPa high-pressure requirements of commercial brake systems. Maintenance is also costly, as damaged scroll plates must be replaced entirely. As a result, oil-free piston compressors have emerged as the mainstream solution due to their superior pressure performance, environmental adaptability, and long service life.

| Comparison of Oil-Free Air Compressor Types | ||

| Item | Oil-free piston air compressor | Oil-free scroll air compressor |

| Discharge pressure | Strong high-pressure capability; easily meets the standard requirement of ≥ 1 Mpa. | Limited by the scroll sealing structure, poor high-pressure sealing performance leads to low discharge pressure. High-pressure performance decays significantly over time, making it difficult to maintain 1 MPa for long periods. |

| Structural sealing | Use a direct-drive motor design with a simple and reliable transmission structure; minimal high-pressure attenuation. | Requires a precise clearance between moving components to achieve sealing, resulting in high requirements for sealing materials. The complex sealing structure is prone to thermal deformation and leakage. |

| Environmental adaptability | Excellent adaptability; IP67 or higher protection level allows operation in harsh environments (high temperature, low temperature, high altitude). | Both the orbiting and fixed scroll plates feature curved surfaces requiring high machining accuracy. The strict sealing demands on upper and lower end faces make it sensitive to environmental conditions. |

| Cooling performance | The compressor head uses air or water cooling with an additional cooler, providing excellent heat dissipation. | The internal working chamber cannot be externally cooled, making heat removal difficult. Localized overheating occurs easily, resulting in high discharge temperatures. |

| Maintenance | Requires no special maintenance – only periodic air filter cleaning. | High sealing precision requirements lead to faster seal wear. Maintenance involves disassembling the entire unit to replace seals, making servicing difficult and costly. If scroll plates are damaged, the entire assembly must be replaced. |

| Service life | High reliability and long service life. | Due to its unique sealing structure, service life is highly dependent on working conditions. Components operate under high temperature, humidity, and pressure, significantly shortening lifespan and overall reliability. |

5. Advantages of the Two-Stage Oil-Free Piston Air Brake Compressor

In response to the GB 7258 national standard requiring brake air pressure above 1 MPa, and OEMs demanding even higher efficiency and emission reduction, two-stage oil-free piston compressors have become the latest evolution trend. They are designed for high discharge pressure, low exhaust temperature, high efficiency, and long service life.

| Item | Two-stage oil-free electric air compressor | Single-stage oil-free electric air compressor |

| Discharge pressure | Two-stage compression with intercooling enables maximum discharge pressure above 1.2 MPa, with almost no performance decay. | Single-stage compression has low efficiency; output significantly decreases as pressure rises, making it difficult to reach 1 MPa. |

| Bearing load | Two-stage compression reduces gas forces, resulting in lower bearing load. Equipped with imported bearings for extended service life. | Single-stage compression causes higher bearing loads and shorter bearing life. |

| Piston ring & guide ring | Uses self-lubricating piston and guide rings. Two-stage compression lowers the compression ratio and air pulsation. Equipped with imported piston rings proven in railway applications, ensuring over 8,000 hours of lifespan. Both piston and guide rings are replaceable. | High single-stage compression ratio causes strong air pulsation and shorter lifespan. Adhesively bonded guide rings are prone to detachment, with poor reliability and non-replaceable design. |

| Cylinder Bore Technology | Advanced surface treatment and mirror-grade finishing (Ra < 0.2) minimize wear and extend service life. | Poor surface finish (Ra > 0.8) results in greater wear and reduced durability. |

| Transmission Structure | Double-crank internal support design ensures high reliability. | Single cantilever structure with lower reliability. |

6. Conclusion

The electric air brake compressor industry is in a stage of rapid technological iteration. As performance standards and environmental requirements continue to rise, manufacturers must focus on efficiency, reliability, compactness, and sustainability.

The future belongs to oil-free, high-pressure two-stage piston air brake compressors – systems designed not just for compliance, but for the next era of clean and intelligent transportation.

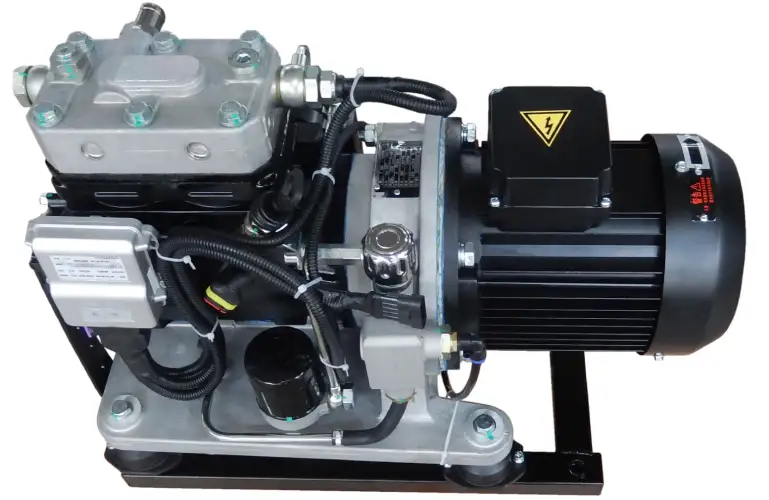

At Brogen, we provide advanced two-stage oil-free piston electric air brake compressors for commercial vehicles—including trucks, buses, vans, and other PHEV, HEV, and BEV applications. Our two-stage oil-free compressors deliver clean, oil- and moisture-free air, eliminating risks of oil emulsification, leakage, and fire hazards. Featuring an innovative structural design, they significantly reduce energy loss during compression and enhance overall system efficiency. Learn more here: https://brogenevsolution.com/air-compressors-for-commercial-vehicles/

- Business inquiry: contact@BrogenEVSolution.com

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >