SbW System in Electric Vehicles: Detailed Explanation

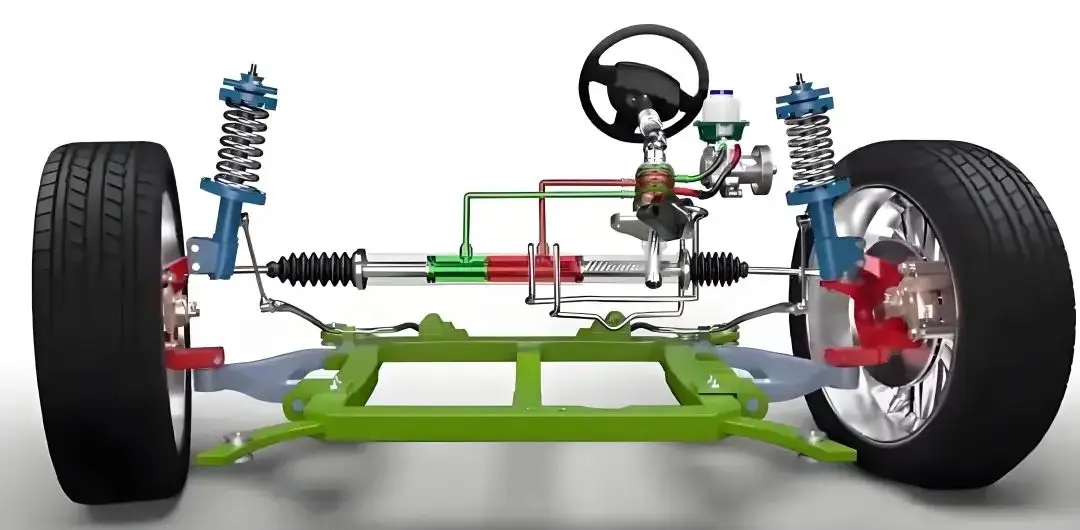

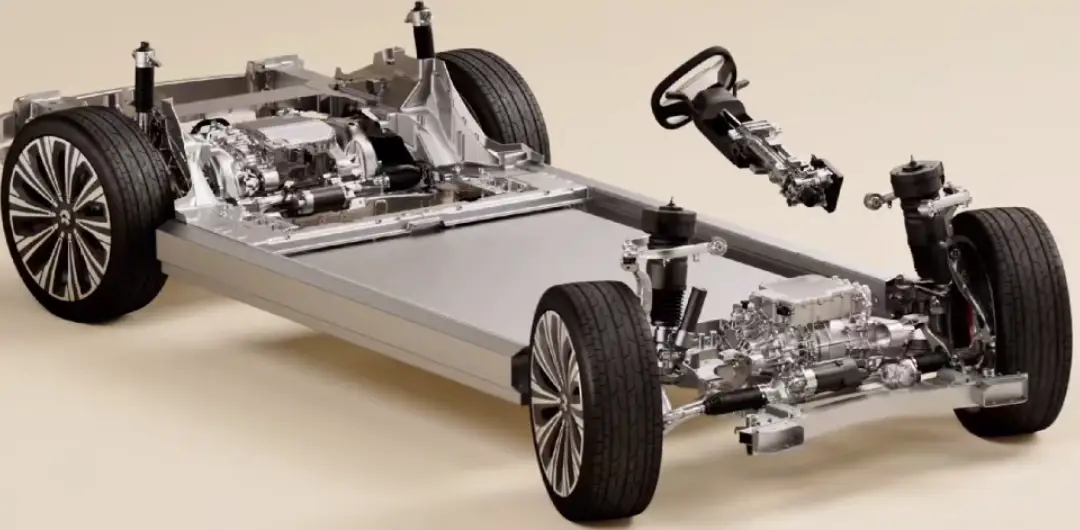

The Steer-by-Wire (SbW) system is a cutting-edge technology that significantly improves the steering mechanism in modern vehicles, particularly in the realm of electric vehicles. Traditional steering systems are mechanical, where the driver manipulates the steering wheel, transforming movement to the steering wheels via linkages and steering mechanisms. The SbW system, however, eliminates this mechanical connection, relying entirely on electrical signals to control the steering. This technological shift unlocks new possibilities for vehicle design and performance, enabling more precise, customizable steering characteristics and greater vehicle safety.

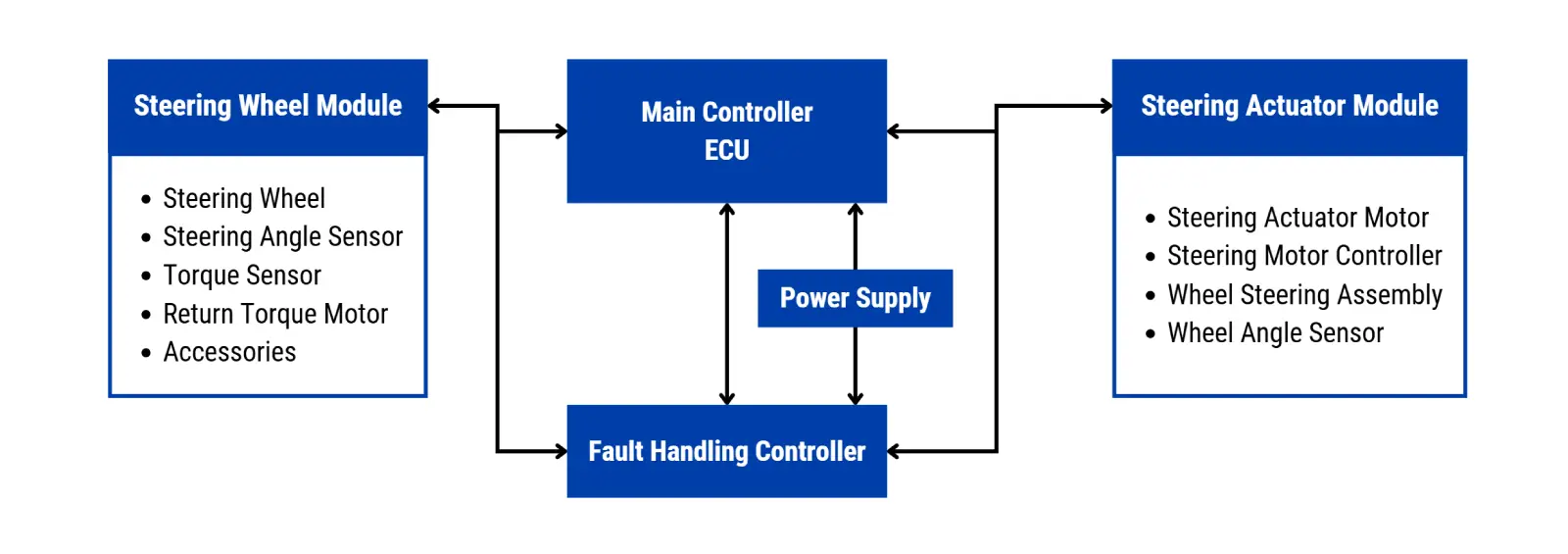

1. Overview of the SbW System

The SbW system consists of three core components: steering wheel assembly, steering actuator assembly, and main controller (ECU). Additional systems, such as fail-safe mechanisms and power supply systems, support the overall functionality and reliability of the system.

2. How the SbW System Works

The SbW system operates by detecting the driver’s steering intentions through sensors. These data points are then transmitted via a data bus to the vehicle’s ECU, which processes the information and sends feedback commands to the steering actuator system. This system controls the movement of the wheels, ensuring they reach the required angles. The steering angle and torque feedback are sent back to the system, completing the cycle of control.

3. Key Features of the SbW System

1. Enhanced Automotive Safety Performance

The SbW system removes mechanical components like the steering column, reducing the risk of injury during collisions. The intelligent ECU continuously monitors the driving conditions, adjusting the system to ensure optimal safety. In extreme conditions, the system can stabilize the vehicle automatically.

2. Improved Handling and Maneuverability

The SbW system dynamically adjusts the steering ratio based on driving parameters such as speed, traction, and road conditions. At low speeds, the steering ratio is reduced, requiring less wheel rotation for tight turns and parking. At higher speeds, the ratio increases for improved stability and handling during straight-line driving.

3. Enhanced Road Feel for Drivers

Without a mechanical connection between the steering wheel and the wheels, the SbW system uses simulated feedback to provide drivers with a realistic “road feel.” This feedback is derived from the vehicle’s actual driving and road conditions, ensuring that only useful information is relayed to the driver, resulting in a more natural driving experience.

4. Advantages of the SbW System

- Improved Handling Stability: The SbW system synchronizes the steering wheel and actuator, allowing for more responsive and precise control, which enhances driving stability.

- Enhanced Comfort: By eliminating vibrations caused by uneven surfaces or imbalances in the steering mechanism, the SbW system provides a smoother, more comfortable ride.

- Energy Efficiency: The SbW system only activates during steering input, optimizing energy consumption and contributing to improved fuel efficiency and eco-friendliness.

- Increased Passive Safety: In the event of a collision, the SbW system significantly reduces the impact force transmitted through the steering column, enhancing driver safety.

- Weight Reduction: By eliminating the mechanical linkages, the SbW system reduces vehicle weight by approximately 5 kg, contributing to vehicle light-weighting efforts.

5. Challenges for the SbW System

- Power Requirements: The SbW system requires high-power actuators and complex algorithms to ensure accurate force feedback and steering control.

- Reliability and Safety Concerns: As with any new technology, improving the safety and reliability of the SbW system remains a critical focus for automotive manufacturers.

- Increased Cost: The inclusion of redundant components and advanced sensors can increase the cost and weight of the system, which may present challenges in mass adoption.

6. Future Trends of the SbW System

The rise of intelligent driving technologies and the growing popularity of electric vehicles positions the SbW system as a key component in future vehicle designs. With advancements in autonomous driving and smart vehicle technologies, SbW is expected to become a mainstream solution, offering drivers a more accurate, safe, and comfortable driving experience. Ongoing research and development by automotive manufacturers will continue to drive innovations in SbW technology, unlocking new possibilities for the automotive industry.

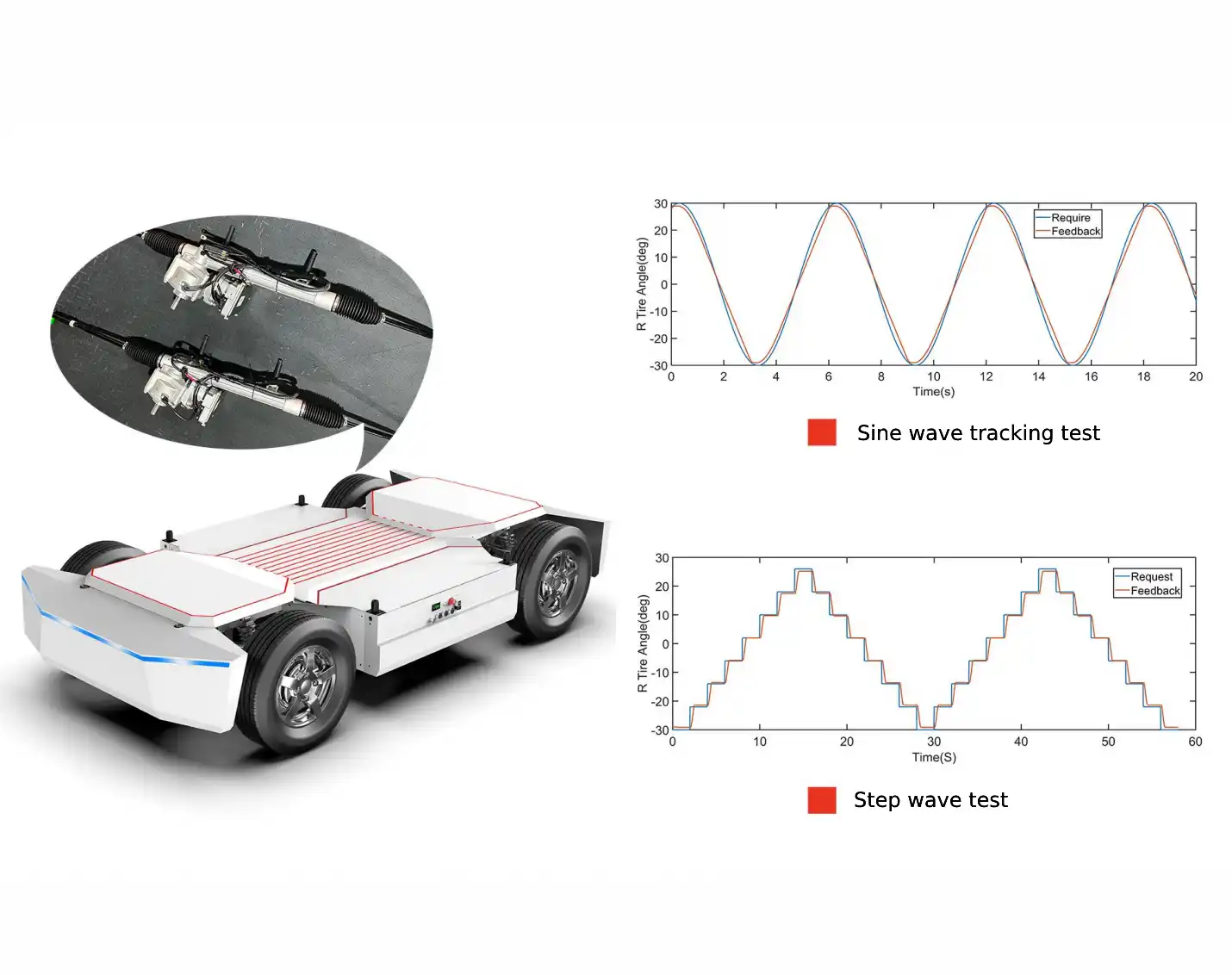

Brogen Steer-by-Wire Technology

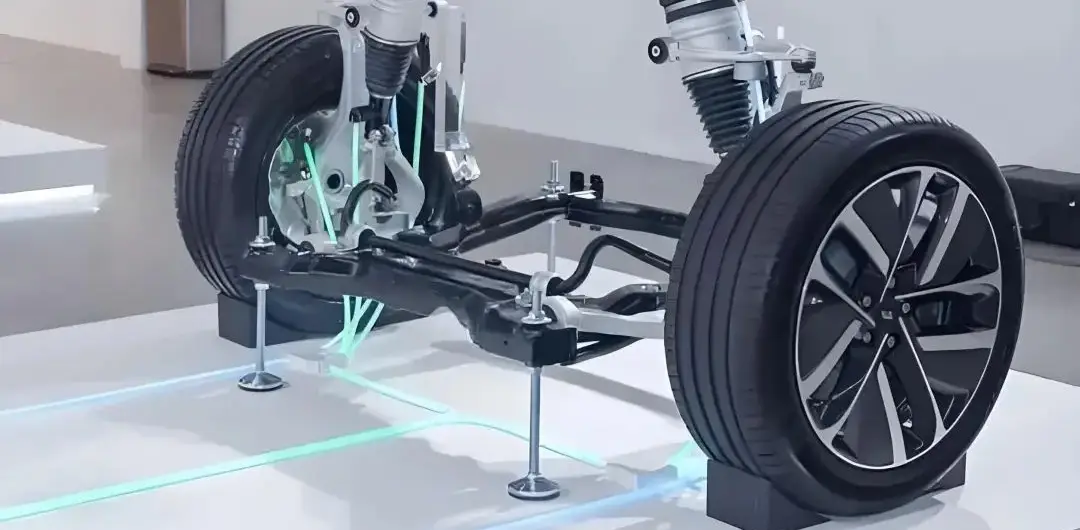

At Brogen, we offer a customized steer-by-wire system specifically developed for autonomous vehicles, adaptable to multiple operating modes (mechanical mode, power-assisted mode, and angle control mode). Our solutions are designed to meet the diverse needs of different customers, offering various design options such as electric power assistance and intelligent driving.

Our series of SbW products feature high intelligence and integration, making them ideal for applications in human-machine collaboration, autonomous driving scenarios, and various layout configurations.

Currently, our SbW products are being utilized in low-to-medium speed autonomous vehicle chassis, supporting commercial applications in driverless logistics and autonomous urban distribution.

- Support seamless transitions between human-machine collaboration modes in autonomous vehicles.

- Deliver rapid steering response with a latency of less than 50 ms.

- Manage steering angle overshoot effectively.

- Ensure precise steering control accuracy.

- Allow for steering angle and angular velocity control commands to be transmitted via bus communication, independent of manual electromechanical systems.

- Learn more here: https://brogenevsolution.com/steer-by-wire-sbw-system-oem-odm-manufacturer/

- Business inquiry: contact@brogenEVSolution.com

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >