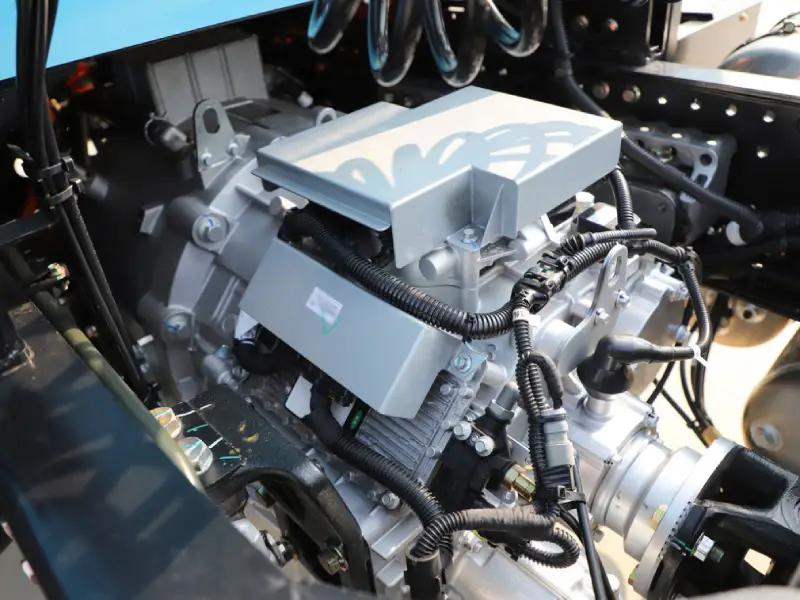

250 kW / 400 kW Electric Motor for Heavy-Duty Trucks

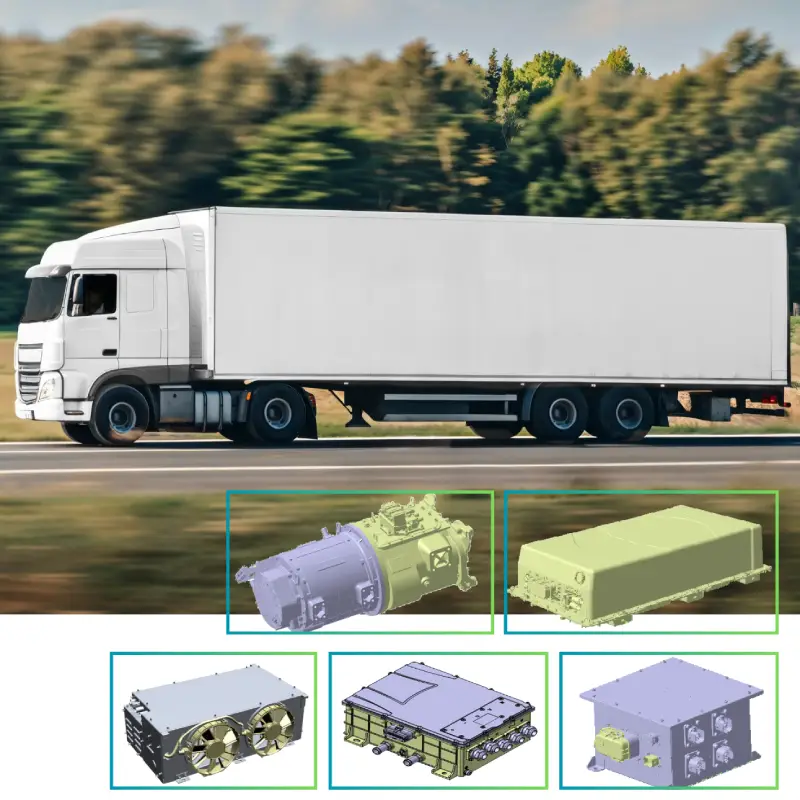

This 250 kW / 400 kW electric motor paired with a 4-speed AMT is a highly mature and proven e-powertrain solution for heavy-duty commercial vehicles such as electric dump trucks, electric semi-trucks, and other construction machinery weighing between 31 and 55 tons.

The system employs a single high-power motor integrated with a 4-speed AMT, leveraging the gear ratio variation and torque multiplication capabilities of the transmission. This approach enables the use of a smaller, high-efficiency motor while still achieving the high-torque output required for heavy-duty operations.

Key technical advantages include optimized torque delivery, smooth gear shifts, high reliability, and a wide operational range.

Email: contact@brogenevsolution.com

250 kW / 400 kW Electric Motor for Heavy-Duty Trucks: Solution Details

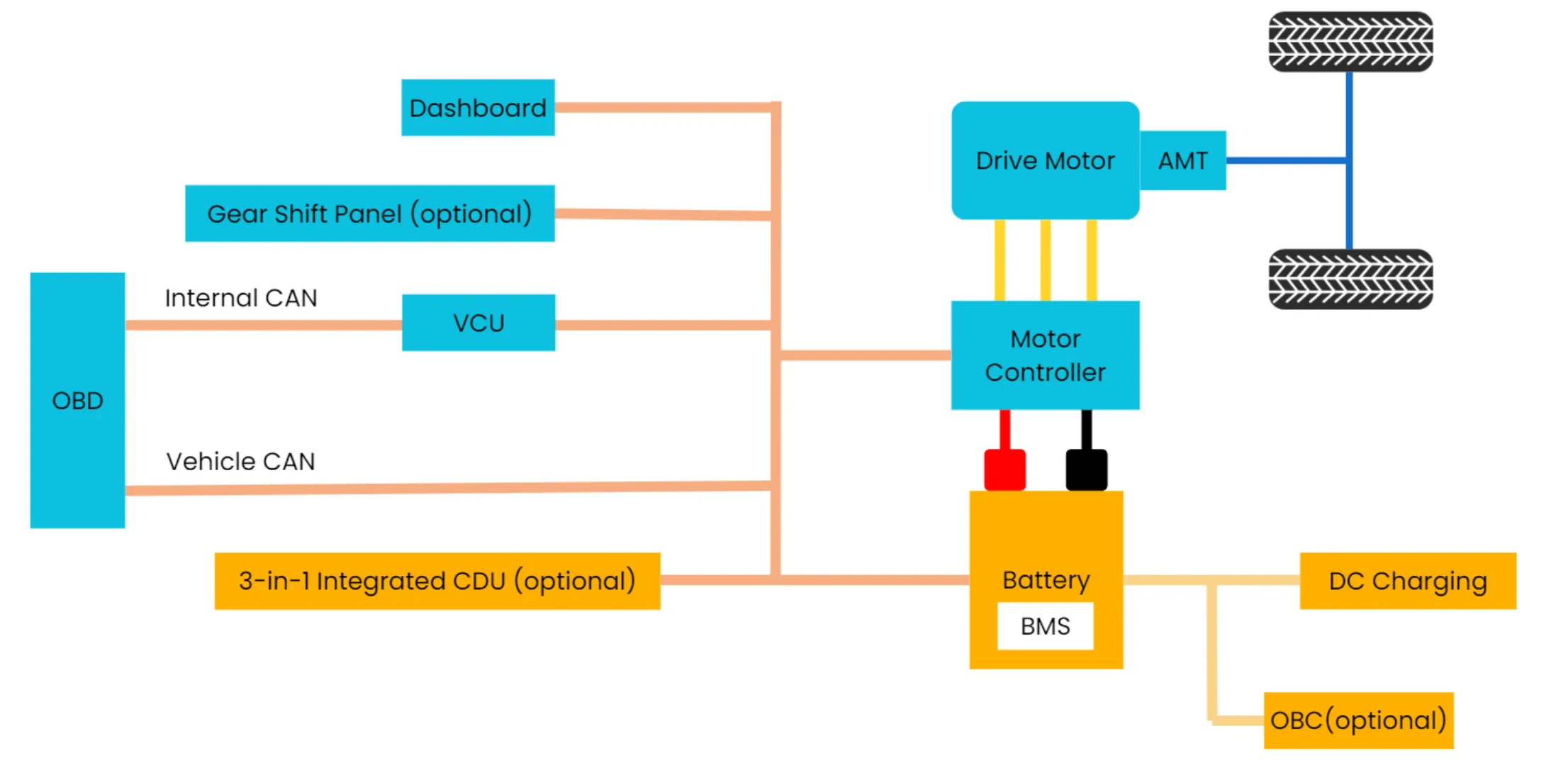

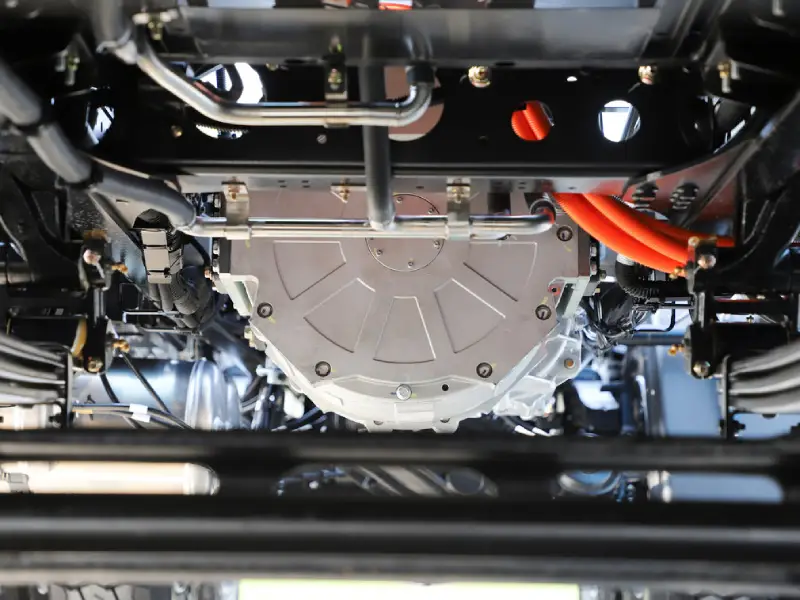

1. System Architecture Diagram

2. Technical Parameters

*Parameters may differ depending on the configuration and vehicle model. Certain specifications can be customized. For more information, please contact us at contact@BrogenEVSolution.com

| System Parameters | |||

| Model | OEHTED16000 | OEHTED20000L2 | OEHTED22000 |

| Applications | Electric concrete mixer truck, heavy truck, semi truck | ||

| System Maximum Output Torque | 16360 N.m | 20136 N.m | 21814 N.m |

| Total Weight | 400 kg | 425 kg | 445 kg |

| Dimension | 1145x612x615 mm | ||

| Motor Parameters | |||

| Rated/Peak Power | 200 kW / 300 kW | 250 kW / 400 kW | 280 kW / 420 kW |

| Rated/Peak Torque | 850 N.m / 1950 N.m | 1200 N.m / 2400 N.m | 1500 N.m / 2600 N.m |

| Peak Speed | 3500 rpm | 3500 rpm | 3500 rpm |

| Transmission Parameters | |||

| Gear Numbers | 4 | ||

| Maximum Input Torque | 2600 N.m | ||

| Speed Ratio | 8.39, 3.54, 1.74, 1 | ||

| PTO Parameters | |||

| Total Speed Ratio | 1.643 | ||

| Peak Output Torque | 700 N.m | ||

3. Solution Features

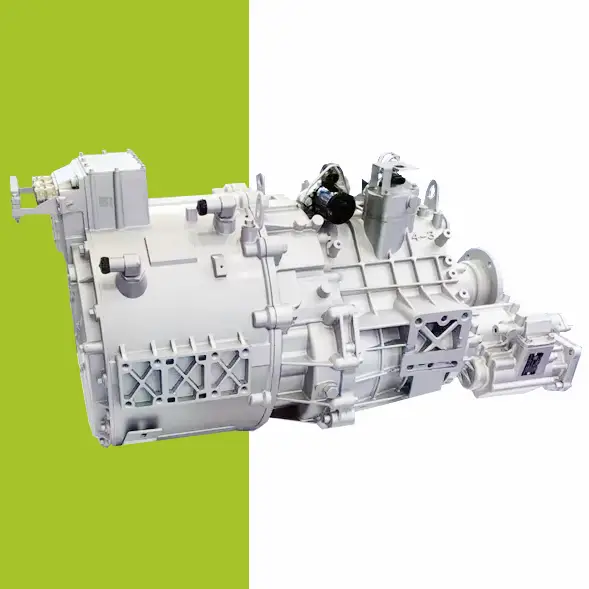

- Proven AMT Architecture: Utilizes a 4-speed Automated Manual Transmission (AMT), the industry-standard solution for heavy-duty commercial EVs. This transmission delivers excellent low-gear gradeability, high-speed capability, and optimized efficiency across the entire operating range, ensuring performance in diverse operating conditions.

- Single Motor + AMT ePowertrain Design: The system adopts a PMSM integrated with an AMT in a clutchless coaxial layout, enabling smooth and synchronized shifting through motor speed control. This design eliminates the need for a mechanical clutch, improving reliability and reducing complexity.

- High Power Density & Torque Multiplication: Rated at 250 kW (continuous) / 400 kW (peak) and delivering 1200 N.m (continuous) / 2400 N.m (peak) torque, the solution leverages AMT’s gear ratio flexibility to provide high torque for heavy-load starts and steep gradients while maintaining high efficiency at cruising speeds.

- Operational Efficiency & Energy Savings: Compared with direct-drive systems, this solution offers lighter weight for the same torque capability and superior efficiency at high speeds, reducing energy consumption and enhancing vehicle range.

- Enhanced Driving Comfort & Reliability: Features smooth gear shifts, robust system reliability, and a quiet powertrain operation, improving driving comfort and reducing NVH levels during operations.

- Full-Scope Application Adaptability: Designed for heavy-duty applications such as construction material transport, resource hauling, and urban infrastructure projects, delivering high transport efficiency, strong performance, and optimized total cost of ownership (TCO).

- Proven in the Market: With over 20,000 units in operation, this solution platform has demonstrated stable performance and long-term durability in real-world conditions. It is widely deployed in dump trucks, concrete mixers, semi-trucks, and even electric cranes.

4. Benefits for EV Builders

- Accelerated Time-to-Market: The mature solution minimizes development cycles, helping OEMs achieve faster commercialization.

- Proven Reliability: With large-scale deployment and robust performance, we reduce technical and operational risks for new projects.

- Customization Support: We provide platform adaptability and engineering support to meet specific operational needs and vehicle designs.

- Sustainability Advantage: Our system supports green mobility, helping OEMs meet regulatory and ESG goals.

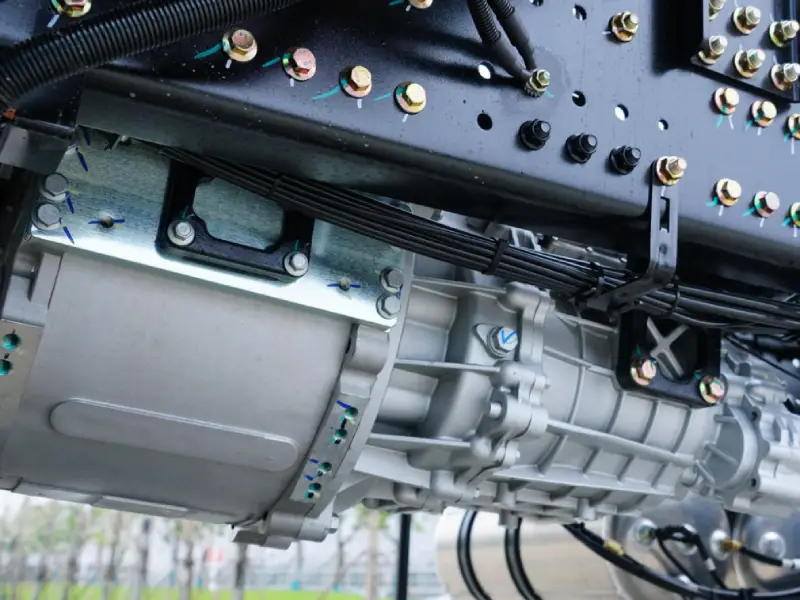

5. Real-World Applications

The 250 kW / 400 kW electric motor + 4-speed AMT solution has already entered mass production and represents a mature and proven solution. The platform’s products have been deployed in over 20,000 vehicles, demonstrating strong market validation. It’s ideally suited for sectors such as construction waste removal, concrete transport, building materials delivery, and resource logistics.

Vehicles equipped with this e-powertrain deliver high transport efficiency, excellent cost-effectiveness, and reduced noise, creating a much quieter and cleaner working environment at depots and job sites.

Business inquiry: contact@BrogenEVSolution.com

Relevant Solutions

- All Posts

- EV Industry

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >