190 kW / 320 kW Electric Portal Axle for Bus, Distributed Drive

This 190 kW / 320 kW electric portal axle for bus is characterized by its highly compact design, incorporating dual motors that deliver substantial power. Specifically engineered to support fully flat low-floor configurations and one-step entry, this e-axle has undergone comprehensive testing and integrates advanced EDS (Electronic Differential System) technology.

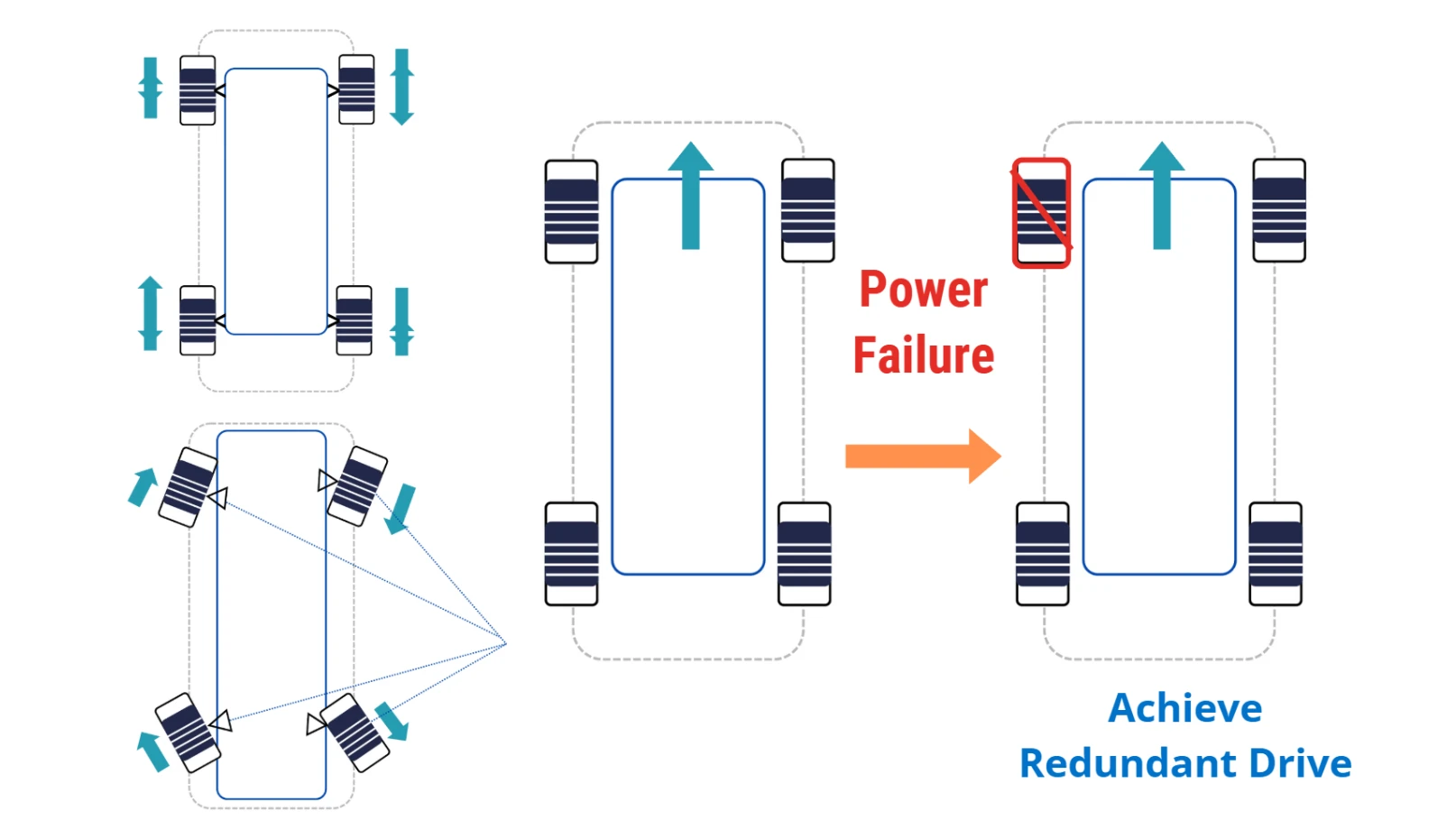

Adopting the distributed drive approach, it provides enhanced safety redundancy. The system is well-suited for electric buses, including double-decker buses and articulated buses, with lengths ranging from 10.5 meters to 18 meters.

Whatsapp: +8619352173376

Email: contact@brogenevsolution.com

Key Features of Brogen Electric Portal Axle for Bus

Distributed Drive

It employs distributed drive technology, enabling precise independent control of torque and speed for each wheel. This enhances safety redundancy, ensuring the vehicle remains operational even if one motor fails.

Compact & Lightweight

The compact design integrates two motors, the reduction assembly, braking systems, and the drive axle, effectively minimizing the need for complex components and the space required by traditional drivetrains.

Advanced Core Technologies

Our electric portal axles can be integrated with advanced safety configurations and strategies, such as EDS, EASR, and IESS, to enhance vehicle safety and stability, especially during critical maneuvers like steering or acceleration.

Technical Parameters

| Motor Type | PMSM |

| Motor Power (Rated / Peak) | 2×160 kW / 2×95 kW |

| Maximum Motor Speed | 8000 rpm |

| Motor Output Torque (Rated / Peak) | 2×220 N.m / 2×580 N.m |

| Rated Voltage | 540 VDC |

| IP Rate | IP67 |

| Axle Weight | 1080 kg |

| Rated Axle Load | 13000 kg |

| Maximum Wheel Speed | 430 rpm |

| Gear Ratio | 18.58 |

| Rim Size | 22.5 inch |

| Tire Size | 275/70R22.5 |

| Brake | Air disc brake |

Basic Structure

- With high torque and power density, the two PMSM wheel-side drive motors provide a strong and reliable output.

- The wheel-side reducers reduce the motor output speed while amplifying the torque delivered to the wheels.

- The 2-in-1 motor controller controls the left and right motors to operate at the desired speed, angle, direction, and response time.

- Other electronic components and sensors

Working Principle

- The VCU calculates the total torque demand based on the driver’s acceleration or deceleration intent.

- The electric drive control unit (DCU) allocates the total torque between the left and right drive motors based on the steering angle, vehicle posture sensors, and road surface traction coefficients.

- The left and right motor controllers (or the integrated 2-in-1 controller), upon receiving the instructions, convert the energy from the battery to the necessary power for the drive motors, ensuring the vehicle’s stability and handling.

Solution Benefits

Low-Floor Design

Adapts to the fully flat low-floor design and allows for easy one-step entry, providing a spacious aisle and reducing the risk of passenger falls.

IP67 Protection

An IP67 protection rating effectively prevents the intrusion of dust and water, providing enhanced performance in challenging conditions.

Lower Maintenance Costs

Utilizes maintenance-free wheel hub units, lowering maintenance costs. The advanced EDS ensures tire replacement intervals exceed 100,000 kilometers.

Core Technology - Distributed Drive Electric Powertrain

Traditional Electric Powertrain Solution

- Centralized Drive → Poor driving maneuverability

- Centralized Brake → Long braking distance

- Centralized Steering → Large turning radius

- Long Mechanical Transmission Chain

- Significant energy transmission losses;

- Poor applicability across vehicle models;

- Insufficient passenger space

Distributed Drive Electric Powertrain Solution

- Drive / Brake Decoupling

- Distributed Drive → Enhanced control on complex surfaces

- Distributed Brake → Reduced braking distance on complex surfaces

- Distributed Steering

- Four-wheel Independent Steering → Reduces turning radius; enables lateral movement and zero-radius turns; significantly enhancing maneuverability

- Eliminates Mechanical Transmission → Increases user space; reduces energy transmission losses

Our Projects

Our distributed electric drive axle systems have been successfully implemented in city buses across Europe, the Middle East, Asia, and other regions. Incorporating advanced design concepts and control strategies, we prioritize the safety and reliability of our systems, delivering profitability for public transport vehicle manufacturers.

Hydrogen buses with 320 kW eaxles

Buses with the low-floor design

Airport shuttle bus with 14T eaxles

Pur electric buses with our eaxles

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >