60 kW / 130 kW Coaxial Electric Axle for Bus, Van

Our 60 kW / 130 kW coaxial electric axle is ideal for light trucks from 4.5-ton to 6-ton or electric vans and buses from 5 meters to 6 meters. With its lightweight design, low noise levels, and high transmission efficiency, it ensures a smooth and comfortable driving experience for drivers and a quiet, enjoyable ride for passengers. Compared to traditional direct-drive systems, this electric bus axle assembly reduces overall weight by more than 100 kg and largely decreases energy consumption. Electric buses with this e-axle have been exported to Japan, Australia, and Europe.

Email: contact@brogenevsolution.com

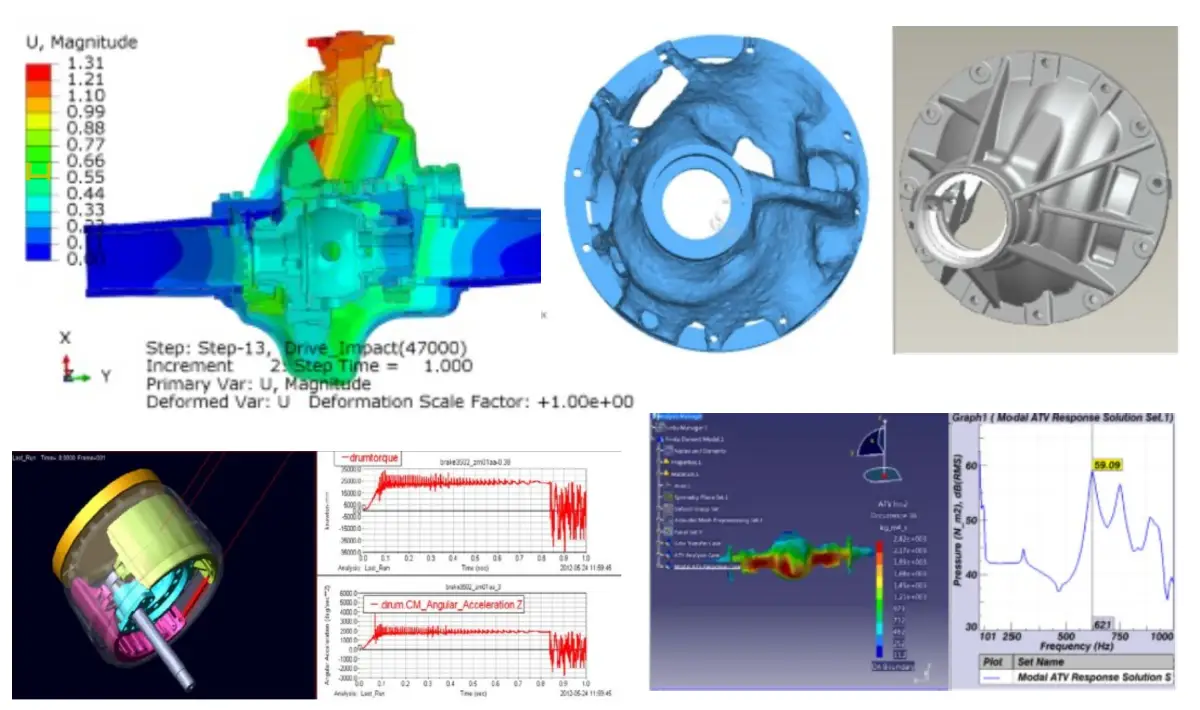

Technical Benefits of the Coaxial Electric Axle

Central Direct Drive Motor

Minimal modification to existing internal combustion engine (ICE) platforms. The electric motor replaces the engine, with power transmitted to the rear axle through a driveshaft.

- Low-cost integration and easy comprability with existing vehicle architectures.

- The need for a driveshaft and traditional rear axle reduces chassis space and limits battery placement, decreasing overall range.

Parallel-Axis E-Axle

A more compact electric powertrain design for commercial vehicles. The motor is integrated directly into the rear axle, eliminating the driveshaft and creating additional space for battery placement.

- Simpler structure with fewer parts, improved space for batteries, and better range.

- The motor's off-center weight distribution led to vibration issues, and NVH performance become a challenge due to the unique design.

Coaxial E-Axle

In this electric powertrain system, both the electric drive motor and output shaft are aligned along the same axis, allowing for a more compact, stable, and efficient design, helping improve overall layout.

- Improved rotational stability, reducing vibrations and enhancing noise control.

- Weight reduction and space optimization with the motor housing serving as a load-bearing element.

- Increased system efficiency due to the elimination of high-speed bearings and a more direct power transfer.

- Superior NVH performance, with reduced center-of-gravity offset and less vibration.

Technical Parameters

| Model | OEEP6 |

| Rated Axle Load Capacity | 3500 kg |

| Maximum Torque | 5700 N.m |

| Gear Ratio | 16.5 |

| Motor Voltage | 360 V / 540 V |

| Motor Rated / Peak Power | 60 kW / 130 kW |

| Motor Rated / Peak Torque | 145 N.m / 350 N.m |

| Motor Rated / Peak Speed | 4000 rpm / 12000 rpm |

- 100 kg reduce in weight compared to direct drive systems.

- 15% reduce in power consumption compared to direct drive systems.

- 30% increase in passenger capacity.

- 100% counter torque for increased cruising range.

- Lower than 70 dB noise for a more pleasant driving experience.

Applications

Relevant Solutions

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >