Axial Flux Motors - Frequently Asked Questions (FAQ)

1. What are Axial Flux Motors?

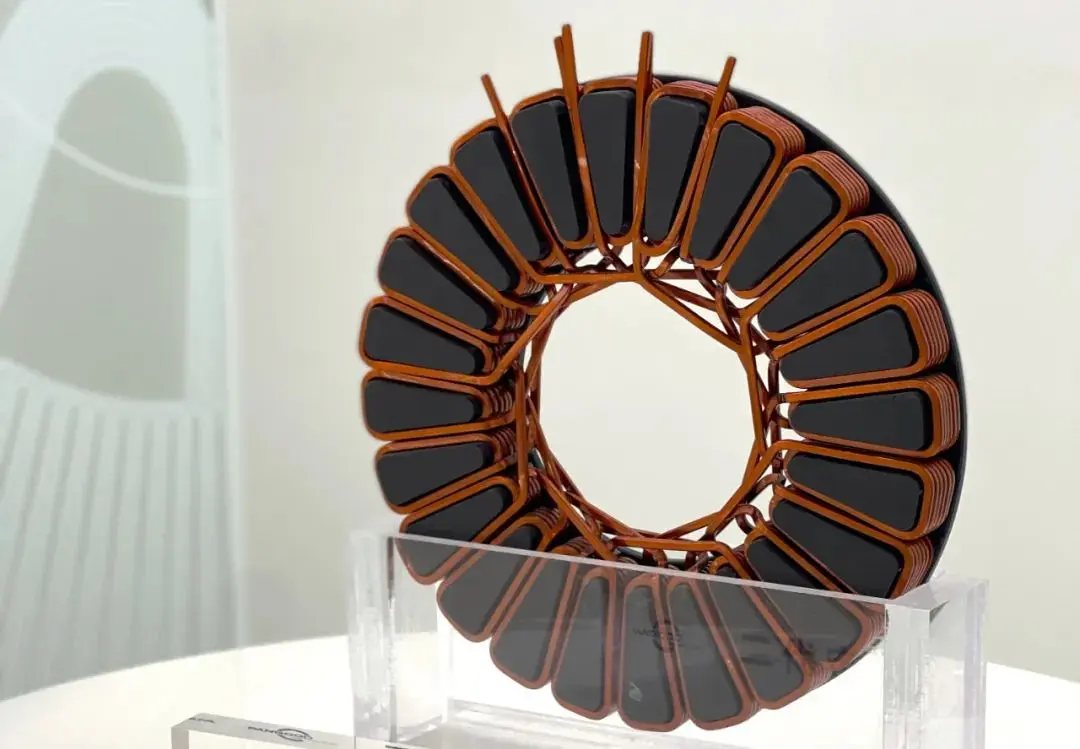

Axial flux motors differ from radial flux motors in that their magnetic flux direction is axial, with current-carrying conductors arranged in a radial pattern. Both the stator and rotor cores have a disc-like structure.

2. What are the advantages and benefits of Axial Flux Motors?

In situations where they have the same power, they have a smaller volume and lighter weight. For instance, our axial flux motor weighs and occupies approximately half the space of a traditional radial flux motor, resulting in higher power and torque density.

3. Why aren't Axial Flux Motors popular?

While radial flux motors are well understood, and manufacturing methods are well-established, axial flux motors face significant challenges in design and production. The gap between the stator and rotor, known as the air gap, is crucial in the motor’s magnetic circuit. Axial flux rotor lying flat on the stator significantly increases the air gap area, demanding high precision in surface smoothness and gap uniformity. This translates to stringent requirements for manufacturing and assembly precision, leading to high production costs and low production flexibility.

The manufacturing difficulty also hinders the scalability of axial flux motors, resulting in a smaller market capacity with insufficient component matching. However, our axial flux motor has overcome these challenges, achieving mass production and undergoing 15,000 km of safety testing in vehicles like buses and heavy trucks, ensuring stability and safety.

4. What are the applications of Axial Flux Motors?

They find application in various scenarios:

- Low-Power Applications: Compact, lightweight, and stable, suitable for power requirements below 5 kW. Widely used in automotive cooling systems, as well as in areas like garden machinery and drones.

- High-Power Commercial & Industrial Use: High-power axial flux motors, especially those with a single rotor core, are suitable for commercial vehicle propulsion, heating, cooling, hydraulics, fans, and other industrial applications.

- Compact Systems: Axial flux motors with dual rotor cores are ideal for compact vehicle structures, making them suitable for car drives and other systems with limited space.

5. What electric vehicles are they suitable for?

They can be applied in various electric vehicles, including:

- Cooling systems in passenger cars.

- Drive systems in mid-size and large SUVs.

- Electric drive axles in heavy-duty trucks, mining trucks, and tractors.

- Electrification of mixing tank and electric drive axles in mixer trucks.

- Electric drive axles in buses.

Business Inquiry: contact@brogenevsolution.com