Battery Thermal Management System (BTMS)

Our Battery Thermal Management Systems (BTMS) are purpose-built for a wide range of commercial electric vehicles, including electric buses, trucks, semi-trucks, locomotives, and mining trucks.

Since launch, our BTMS solutions have tackled key industry challenges – such as all-DC variable frequency control, high-efficiency heat exchange, high-voltage DC protection, and EMC – ensuring safe, efficient, and stable operation under demanding conditions.

Today, our BTMS systems are mass-deployed by leading OEMs including Dongfent, XCMG, Sinotruk, SANY, Geely, Foton, and more, power electric commercial vehicles around the world.

Email: contact@brogenevsolution.com

What is a Battery Thermal Management System (BTMS)?

A Battery Thermal Management System (BTMS) is an integrated cooling and heating system designed to regulate the temperature of onboard batteries. It consists of key components such as a compressor, condenser, expansion valve, evaporator, water pump, expansion tank, PTC liquid heater, and essential control units.

The primary goal of BTMS is to keep the battery pack within an optimal temperature range, ensuring peak performance and longevity. By managing thermal energy across the vehicle, the system effectively reduces waste heat emissions, enhances energy efficiency, and minimizes environmental impact.

Functions of the Battery Thermal Management System (BTMS)

- Monitoring: Accurately measures and tracks battery temperature in real time.

- Cooling: Effectively dissipates heat when battery temperature is high, preventing thermal runaway.

- Preheating: Warms the battery in low temperatures to ensure safe and efficient charging and discharging.

- Temperature Balancing: Reduces temperature differences within the battery pack, preventing localized overheating and extending overall battery lifespan.

Proven Technology, Scalable Delivery

Our Battery Thermal Management Systems are built on more than 10 years of system-level development experience, incorporating industry-leading technologies and design practices. The solution is backed by a production capacity of over 100,000 units annually and is already in mass deployment with leading OEMs, including Dongfeng, XCMG, Hualing, Sinotruk, SANY, Geely, Foton, and more.

- All-DC variable frequency control

- High-efficiency heat exchanger design

- High-voltage DC safety protection

- Electromagnetic compatibility

How We Ensure Quality

We apply ISO 9001 and ISO/TS 16949 quality management standards across all core operations, from R&D and procurement to production and after-sales service.

Through systematic quality controls and digital tools, we ensure every product meets or exceeds customer expectations.

End-to-End Quality Control

The quality assurance is embedded throughout the entire product development cycle, ensuring that every stage meets rigorous standards.

Component Supplier Management Excellence

We implement strict supplier onboarding, evaluation, and elimination processes. Regular supplier audits are conducted to continuously enhance the quality and reliability of outsourced components.

Digital Quality Platform (QIS)

A comprehensive QIS (Quality Information System) is used to manage every aspect of product quality, including calibration tool management, raw material inspection, in-process quality control, non-confirming product handling, continuous quality improvement initiatives, etc.

Brogen Battery Thermal Management System Offerings

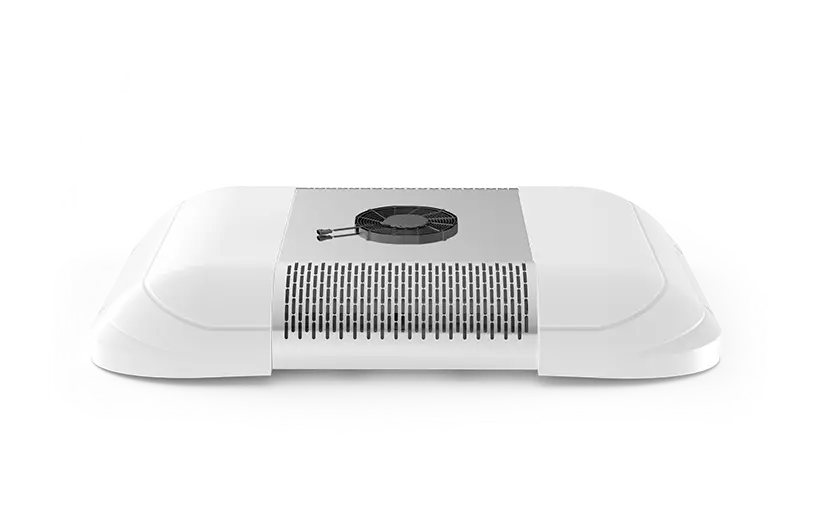

Roof Mounted Battery Thermal Management System (BTMS)

The roof-mounted Battery Thermal Management System (BTMS) is specially designed for battery electric and hybrid buses, offering a seamless fit with the vehicle’s roof curvature. It supports the thermal management requirements of battery systems in 6- to 18- meter buses as well as electric locomotives, ensuring reliable performance across a wide range of commercial vehicle platforms.

Our Roof Mounted BTMS Solution Features

- Lightweight aluminum alloy is used in the bottom shell. RTM material is used in the outer cover. The double waistline design is internally formed;

- Optional PTC liquid heater allows for selection of standby, with cooling, heating, and self-cycling working modes;

- The adoption of CAN bus communication enables it to have the function of fault self-diagnosis and real-time uploading of operating status and fault information;

- EMC can meet Level III requirements;

- Strong environmental adaptability to harsh operating conditions such as high and low temperatures, high corrosion, and high altitude.

Our Roof Mounted BTMS Offerings

| Model | OETLE105 | OETLE108 | OEEDDR-01 | OEEDDR-02 | OEEDDR-03 | OEEDDR-04 |

| Cooling capacity | 5 kW | 8 kW | 3 kW | 5 kW | 8 kW | 13 kW |

| Low voltage power consumption | 300 W | 500 W | 300 W | 300 W | 450 W | 700 W |

| High voltage input | DC 400-750 V | DC 400-750 V | DC 400-750 V | DC 400-750 V | DC 400-750 V | DC 400-750 V |

| Low voltage input | DC 24 V | DC 24 V | DC 24 V | DC 24 V | DC 24 V | DC 24 V |

| Control power | DC 24 V ON/OFF signal | DC 24 V ON/OFF signal | DC 24 V ON/OFF signal | DC 24 V ON/OFF signal | DC 24 V ON/OFF signal | DC 24 V ON/OFF signal |

| Low voltage power supply | Vehicle provided | Vehicle provided | DC-DC (standard configuration) / Vehicle provided | DC-DC (standard configuration) / Vehicle provided | DC-DC (standard configuration) / Vehicle provided | DC-DC (standard configuration) / Vehicle provided |

| Size | L1029*W1369*H280 mm | L1029*W1369*H280 mm | L1300*W1920*H256 mm | L1300*W1920*H256 mm | L1300*W1920*H256 mm | L1300*W1920*H256 mm |

| Refrigerant | R134a | R134a | R134a | R134a | R407c/R134a | R407c |

| Water pump | External | External | For selection | For selection | For selection | For selection |

| Pipe diameter | 25 mm | 25 mm | 25 mm | 25 mm | 25 mm | 25 mm |

| PTC heater | Can be integrated, <14 kW | Can be integrated, <14 kW | Reserve 5 kW / 10 kW / 14 kW / 24 kW for selection | Reserve 5 kW / 10 kW / 14 kW / 24 kW for selection | Reserve 5 kW / 10 kW / 14 kW / 24 kW for selection | Reserve 5 kW / 10 kW / 14 kW / 24 kW for selection |

Bottom / Skirt Mounted Battery Thermal Management System (BTMS)

The bottom-mounted (skirt-mounted) Battery Thermal Management System (BTMS) is designed to be installed on the vehicle frame or chassis, aligning with the height of most mainstream battery systems. It is suitable for a wide range of applications, including battery-swapping or fast-charging heavy-duty trucks, pure electric municipal vehicles, mining trucks, and other forms of heavy construction machinery, providing efficient and reliable thermal management in demanding environments.

Our Bottom Mounted BTMS Solution Features

- The unit adopts an aluminum alloy fame structure, which can meet the needs of weight reduction and efficiency improvement.

- Optional PTC liquid heater allows for selection of standby, with cooling, heating, and self-cycling working modes.

- The adoption of CAN bus communication enables it to have the function of fault self-diagnosis and real-time uploading of operating status and fault information.

- EMC can meet Level III requirements.

- Optional configuration: tube-fin condenser, DC-DC, expansion tank.

Our Bottom Mounted BTMS Offerings

| Model | OETLE205 | OETLE207 | OETLE208 | OEEFDR-01 | OEEFDR-02 | OEEFDR-03 | OEEFDR-04 |

| Cooling capacity | 5 kW | 7 kW | 8 kW | 3 kW | 5 kW | 8 kW | 10 kW |

| Low voltage power consumption | 500 W | 700 W | 700 W | 450 W | 800 W | 800 W | 1000 W |

| High voltage input | DC 400-750 V | DC 400-750 V | DC 400-750 V | DC 400-750 V | DC 400-750 V | DC 400-750 V | DC 400-750 V |

| Low voltage input | DC 24 V | DC 24 V | DC 24 V | DC 24 V | DC 24 V | DC 24 V | DC 24 V |

| Low voltage power supply | Vehicle provided | DC conversion | Vehicle provided | DC-DC (standard configuration) / Vehicle provided | DC-DC (standard configuration) / Vehicle provided | DC-DC (standard configuration) / Vehicle provided | DC-DC (standard configuration) / Vehicle provided |

| Control power | DC 24 V ON/OFF signal | DC 24 V ON/OFF signal | DC 24 V ON/OFF signal | DC 24 V ON/OFF signal | DC 24 V ON/OFF signal | DC 24 V ON/OFF signal | DC 24 V ON/OFF signal |

| Size | L643*W599*H3863 mm | L835*W560*H310 mm | L669*W621*H461 mm | L685*W600*H280 mm | L685*W600*H280 mm | L818*W600*H280 mm | L1005*W557*H280 mm |

| Refrigerant | R134a | R410a | R134a | R134a | R134a | R407C/ R134a | R407C |

| Water pump | Q=1200L/h, H>10m | Q=2400L/h, H>13m | Q=2800L/h, H>16m | 100 W | 180 W | 240 W | 240 W |

| Pipe diameter | 25 mm | 25 mm | 25 mm | 25 mm | 25 mm | 25 mm | 25 mm |

| Expansion tank | No | No | No | Can be integrated | |||

| PTC heater | No | No | No | Reserve 5 kW / 10 kW / 14 kW / 24 kW for selection | |||

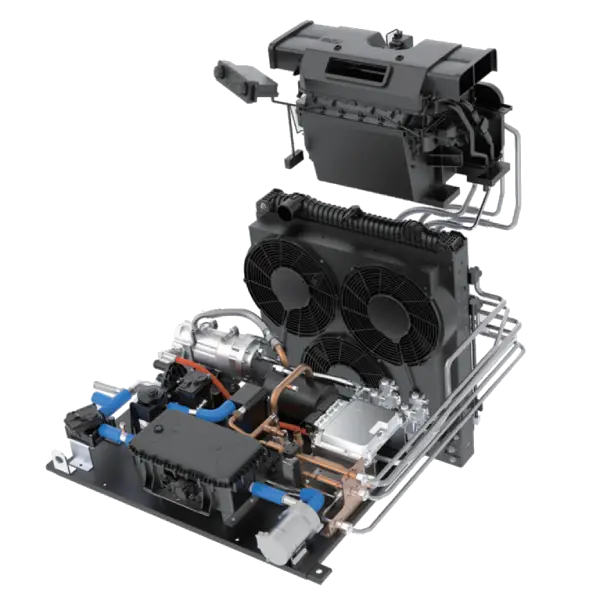

Integrated Thermal Management Solution for Commercial Vehicles

As a representative solution of the second stage of thermal management evolution in commercial vehicles, our integrated thermal management solution has been in pilot deployment since 2022. It has now completed platform integration for heavy-duty trucks, light-duty trucks, and construction machinery, with over 21,000 units deployed to date.

This solution demonstrates significant advantages in platform modularity, centralized control, and intelligent connectivity, while delivering proven results in system integration, smart decision-making, predictive maintenance, and energy efficiency.

- Cooling capacity range: 5-20 kW

Our Integrated TMS Solution Features

- Designed for use in battery-electric and fuel cell heavy-duty and light-duty commercial vehicles.

- HVAC-based cabin climate control: supports cooling, heating, dehumidification, defogging, and defrosting, with adjustable airflow modes to meet diverse operational needs.

- Liquid cooling for battery systems: utilizes a liquid-cooled architecture, now the mainstream approach for battery thermal management in commercial EVs.

- Highly integrated architecture: core components such as the compressor and condenser are shared between the cabin and battery systems, enabling high integration while allowing both to operate independently, reducing system footprint and operational cost.

- Self-diagnostic capability: integrated fault detection functions enhance system reliability and ensure a safe and stable driving experience in demanding operating conditions.

16 Working Modes

| Cab cooling | Cab heating (e-drive heat recovery) | Defrosting | Defogging (cold+hot) |

| Traction battery cooling (compressor cooling) | Traction battery cooling (radiator cooling) | Battery heating (PTC) | Battery heating (motor heat recovery) |

| Motor cooling | Cab cooling and traction battery cooling | Cab cooling + e-drive cooling | Cab cooling + traction battery cooling + e-drive cooling |

| Cab heating (PTC + e-drive heat recovery) | Cab heating + traction battery cooling | Cab heating + traction battery cooling + e-drive cooling | Traction battery cooling + e-drive cooling |

Relevant Topics & Applications

- All Posts

- EV Industry

Contact Us

Get in touch with us by sending us an email, using the Whatsapp number below, or filling in the form below. We usually reply within 2 business days.

Email: contact@brogenevsolution.com

Respond within 1 business day

Whatsapp: +8619352173376

Business hours: 9 am to 6 pm, GMT+8, Mon. to Fri.

LinkedIn channel

Follow us for regular updates >

YouTube channel

Ev systems introduction & industry insights >