Mining Electrification Solutions: Electric Dump Truck System Design

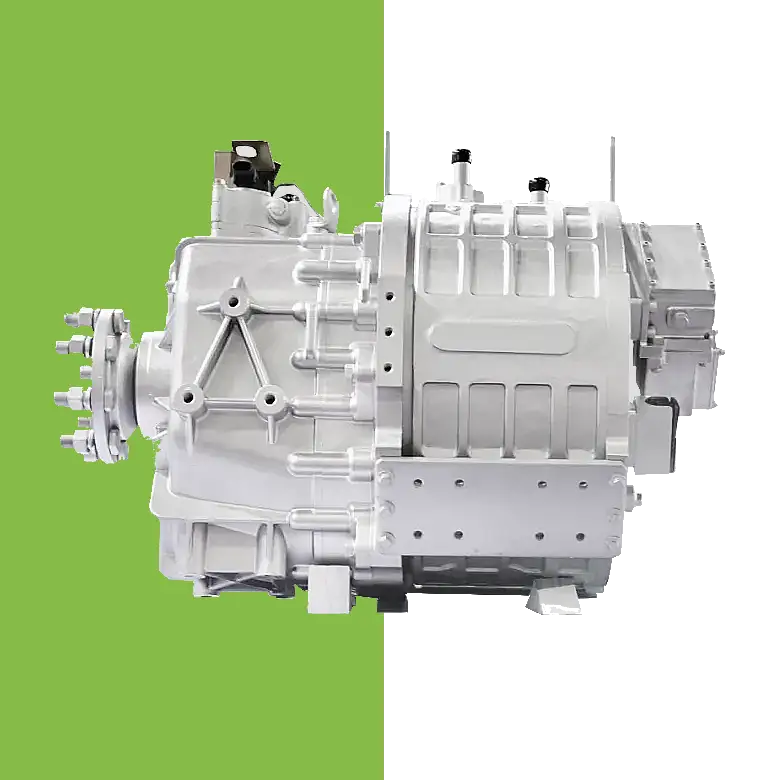

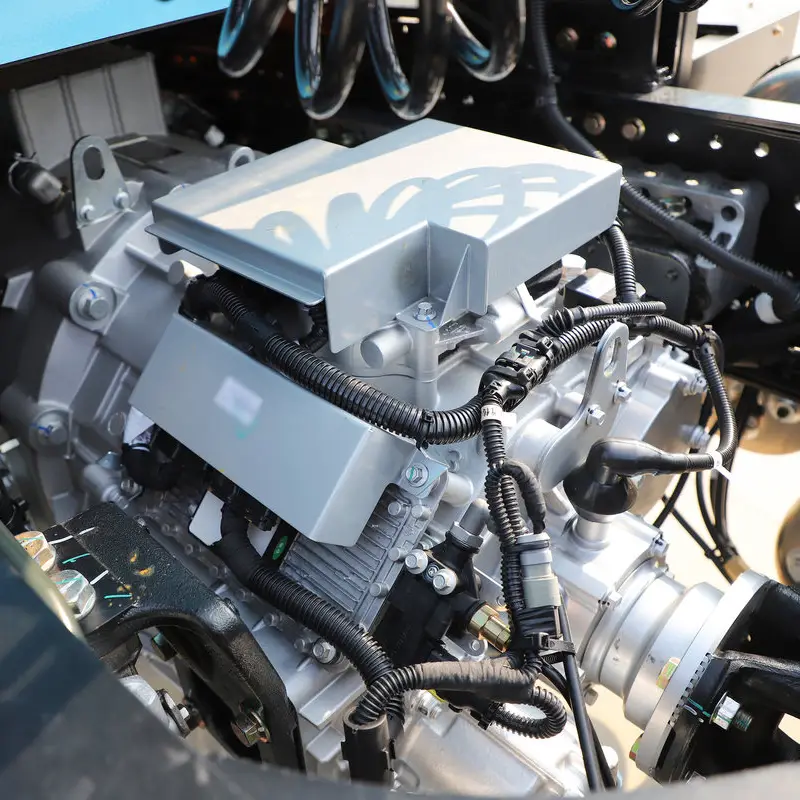

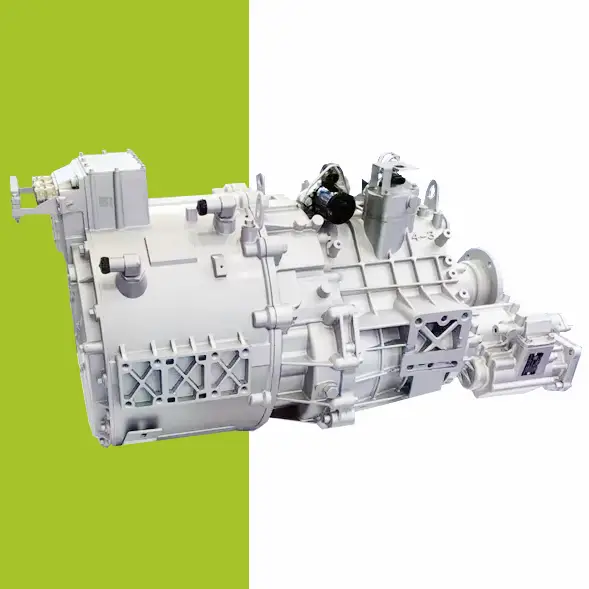

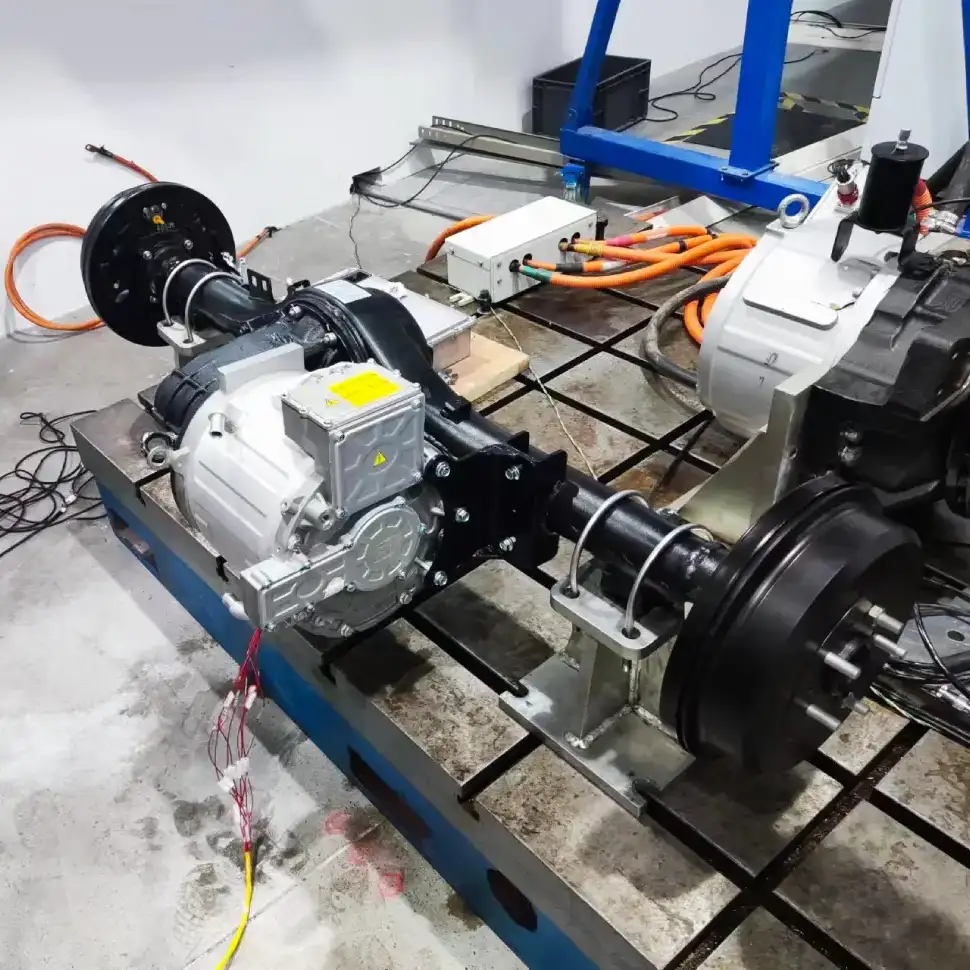

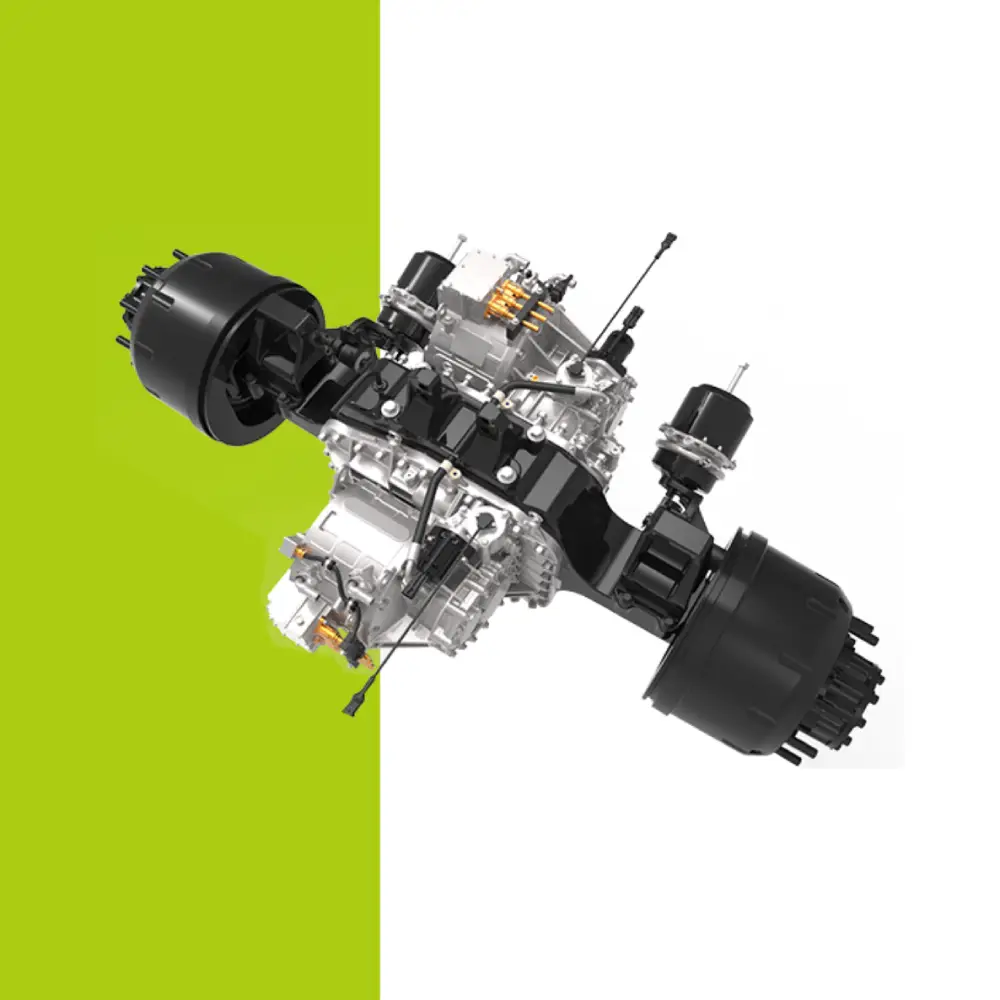

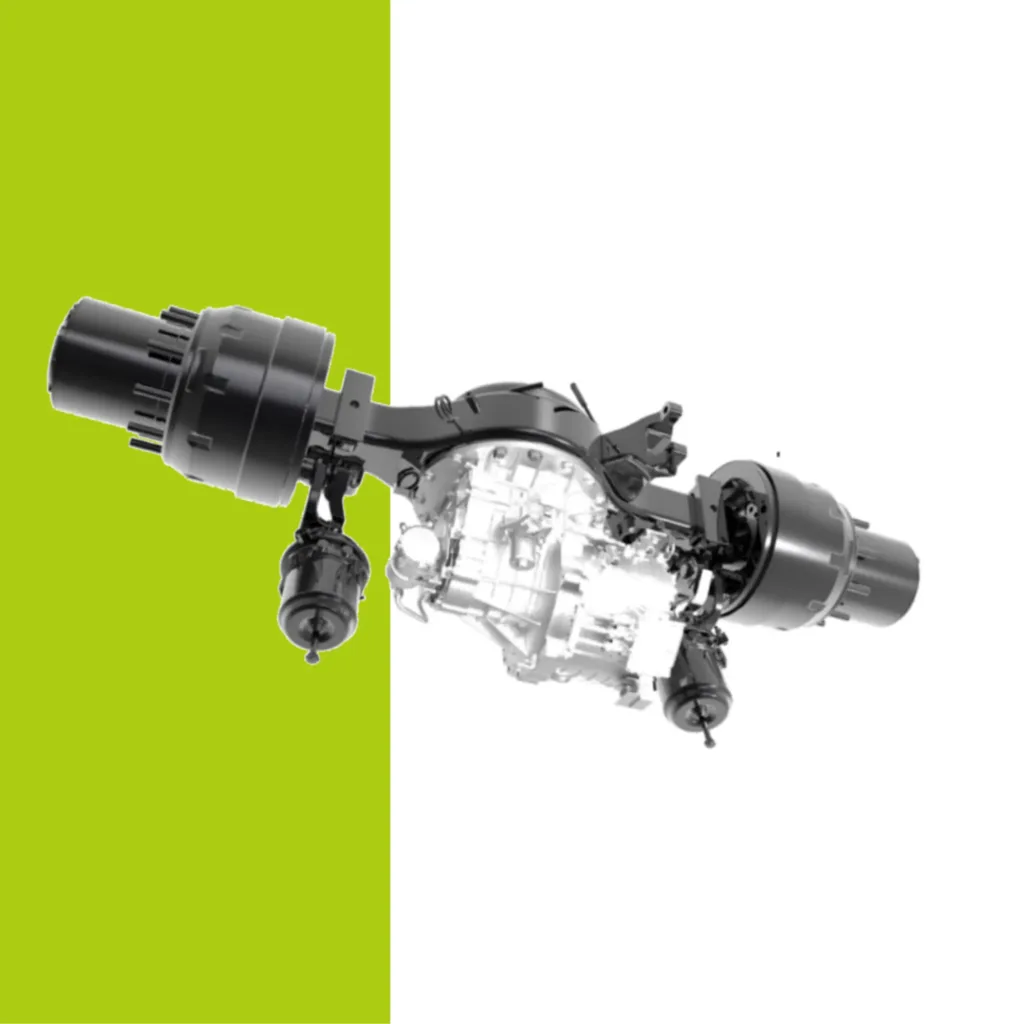

Mining Electrification Solutions: Electric Dump Truck System Design 1. Introduction The electric dump truck is a specialized off-highway vehicle designed for short-haul material transport in industries such as mining, metallurgy, cement, water conservancy, and construction. Its working conditions are characterized by steep slopes, short routes, large load variations, fixed transport lines, and complex operating environments. Traditional diesel-powered dump trucks face several challenges in these conditions: high fuel consumption, elevated maintenance costs, and shorter service life. By contrast, electric dump trucks replace diesel engines and manual transmissions with battery packs and electric drive motors. When traveling on flat roads or downhill, the motor operates in regenerative braking mode, converting braking energy into electricity to recharge the battery. This not only reduces wear on the mechanical brake system – improving safety and extending component life – but also increases vehicle range. With fewer maintenance needs, high protection levels, and superior adaptability to harsh mining environments, electric dump trucks are becoming the preferred choice for heavy-duty operations. 2. High-Voltage System Architecture of Electric Dump Truck High-voltage system architecture for the electric dump truck (for reference) Electric dump trucks replace the conventional powertrain with a high-voltage system. The main high-voltage components include: traction battery, PDU, DC fast charging port, integrated controller, thermal management system, and other auxiliary high-voltage systems. ● Traction Battery It’s the energy supply unit in an electric dump truck, providing electric power to all vehicle systems. When the battery is depleted, it also requires recharging. Therefore, the energy flow of the battery is bidirectional. ● High-Voltage Power Distribution Unit (PDU) The PDU is a distribution hub for high-voltage power, supplying electricity to all components within the high-voltage system. For example, battery heating, charging circuits, and power distribution to the integrated controller. Inside the PDU are fuses, relays, and a pre-charge circuit for each controllable high-voltage loop. Between the traction battery and the PDU, a Manual Service Disconnect (MSD) is installed. The MSD is a mandatory safety device that allows physical disconnection of the high-voltage circuit during battery servicing or vehicle maintenance. It ensures safe isolation of the high-voltage system and often incorporates fuse protection to enhance electrical safety and reliability. ● Thermal Management System The thermal management system integrates both heating and cooling functions, maintaining the traction battery within its optimal operating temperature range to ensure safety, efficiency, and extended service life. Brogen traction batteries for electric trucks Brogen PDU for electric trucks Brogen BTMS for electric trucks ● Motor Controller and Drive Motor The motor controller converts high-voltage DC from the integrated controller into three-phase AC to power the drive motor. It regulates motor torque and rotational direction, enabling smooth vehicle start, stop, forward, and reverse operations. Additionally, during braking or deceleration, the drive motor recovers kinetic energy, converts it into electrical energy, and feeds it back to the traction battery for extended range and efficiency. Brogen e-powertrain (motor+AMT) for heavy-duty trucks System schematic for Brogen’s electric motor + AMT e-powertrain ● DC Fast-Charging Port The DC fast-charging port delivers high-voltage direct current, which can be routed through the PDU directly to the power battery for rapid charging without additional processing. ● Integrated Controller The integrated controller receives commands from the VCU and coordinates both the main drive system and auxiliary subsystems. Key auxiliary loads include the cab air-conditioning compressor, PTC heater, electro-hydraulic power steering pump, air compressor, and DC/DC converter. The DC/DC converter steps down high-voltage DC from the traction battery to low-voltage DC to charge the auxiliary lead-acid battery. Compared with traditional distributed controllers, the integrated controller offers reduced size and footprint, optimizing vehicle layout. Minimizing high-voltage external wiring between discrete controllers reduces potential failure points, lowers costs, and enhances overall system reliability and safety. Brogen 4-in-1 integrated auxiliary inverter System schematic for Brogen’s integrated auxiliary inverter ● Auxiliary High-Voltage Systems The electric A/C compressor and PTC heater serve as the core components of the HVAC system, delivering cooling and heating functions. The electric air compressor supplies high-pressure compressed air for the braking system. The electro-hydraulic power steering pump provides hydraulic assistance to the steering system. 3. Traction Battery Selection and Design At present, mainstream electric vehicles generally adopt ternary lithium batteries or lithium iron phosphate (LFP) batteries. LFP batteries use lithium iron phosphate as the cathode material and graphite as the anode material. Compared with ternary batteries, LFP batteries offer the following advantages: High safety performance: The decomposition temperature of LFP is about 600°C. Even under high temperature or overcharge conditions, it does not undergo structural collapse, generate excessive heat, or form highly oxidative substances as ternary batteries do. In the event of a collision or short circuit, LFP batteries are also highly resistant to explosion. Long cycle life: The cell cycle life can reach up to 4,000 cycles, and around 3,000 cycles at the PACK level. Excellent high-temperature performance: Wide operating temperature range with strong thermal stability. Environmental friendliness: LFP batteries contain no heavy metals or rare metals, making them non-toxic and pollution-free. These features make LFP batteries particularly well-suited for mining applications, where operating conditions are harsh, ambient temperatures vary widely, and safety requirements are stringent. Battery packs for electric dump trucks Brogen traction battery factory Brogen traction battery pack details 4. High-Voltage Power Distribution Unit (PDU) Design The High-Voltage Power Distribution Unit (PDU) is responsible for distributing electrical power throughout the vehicle’s high-voltage system. Its function is similar to a fuse box in a low-voltage electrical system, primarily managing power distribution and providing overload and short-circuit protection for high-voltage circuits. High-voltage distribution schematic Brogen PDU system, typically integrated with the battery system The PDU distributes the energy supplied by the power battery to the integrated controller, as well as to the battery heating and cooling systems. During DC fast charging, the charging current also flows through the PDU to charge the power battery. Additionally, the Battery Management System (BMS) is integrated into the PDU. The BMS performs the following key functions: Monitoring the total battery voltage and charge/discharge current. Monitoring battery status, including individual cell